Plate-type wood multifunctional processing machine tool and using method thereof

A processing machine tool and multi-functional technology, applied in wood processing appliances, multi-purpose machinery, woodworking safety devices, etc., can solve the problems of low degree of automation, low work efficiency, high labor intensity, etc., and achieve low labor intensity and high processing accuracy. , the effect of avoiding safety accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with accompanying drawing.

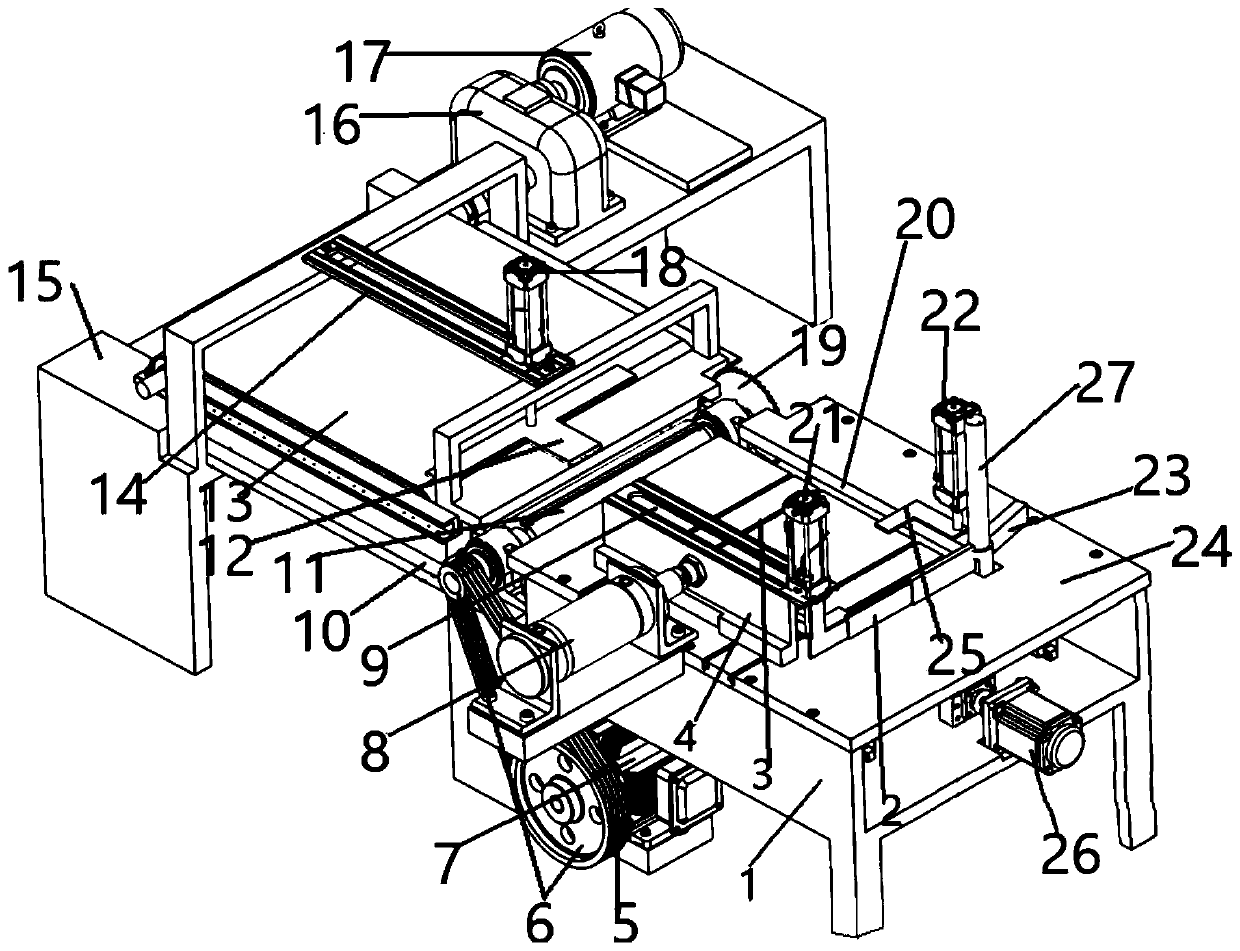

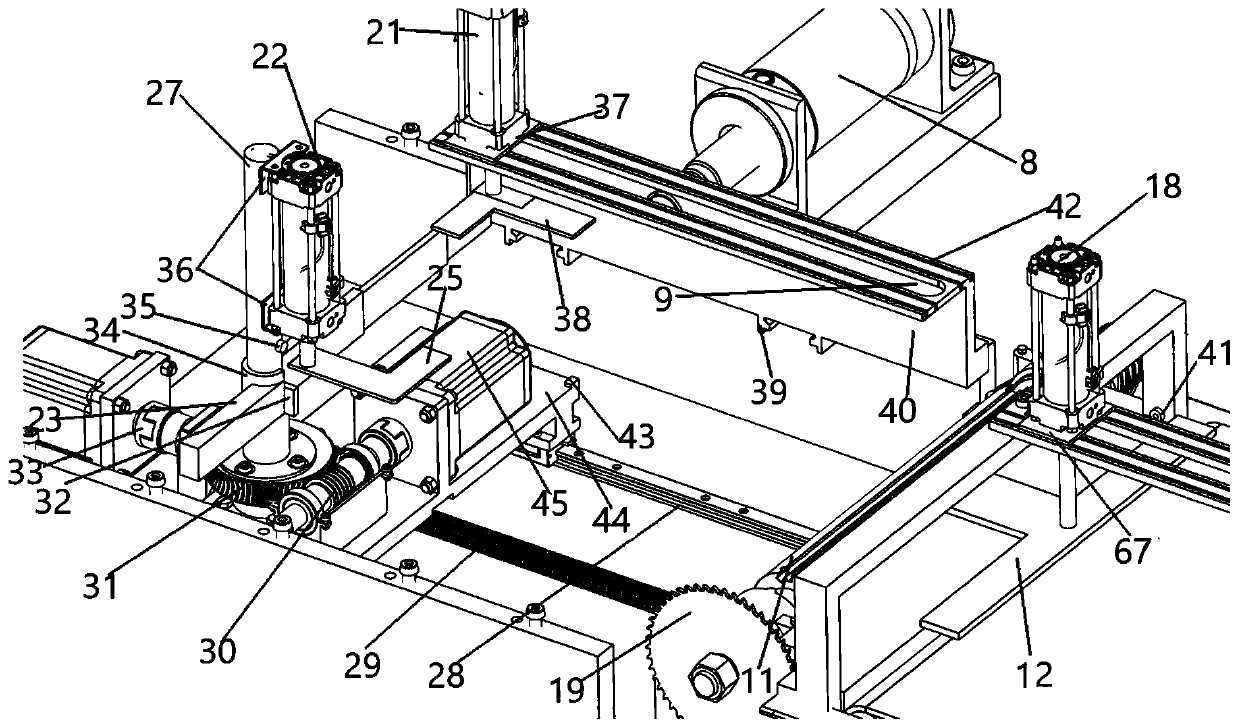

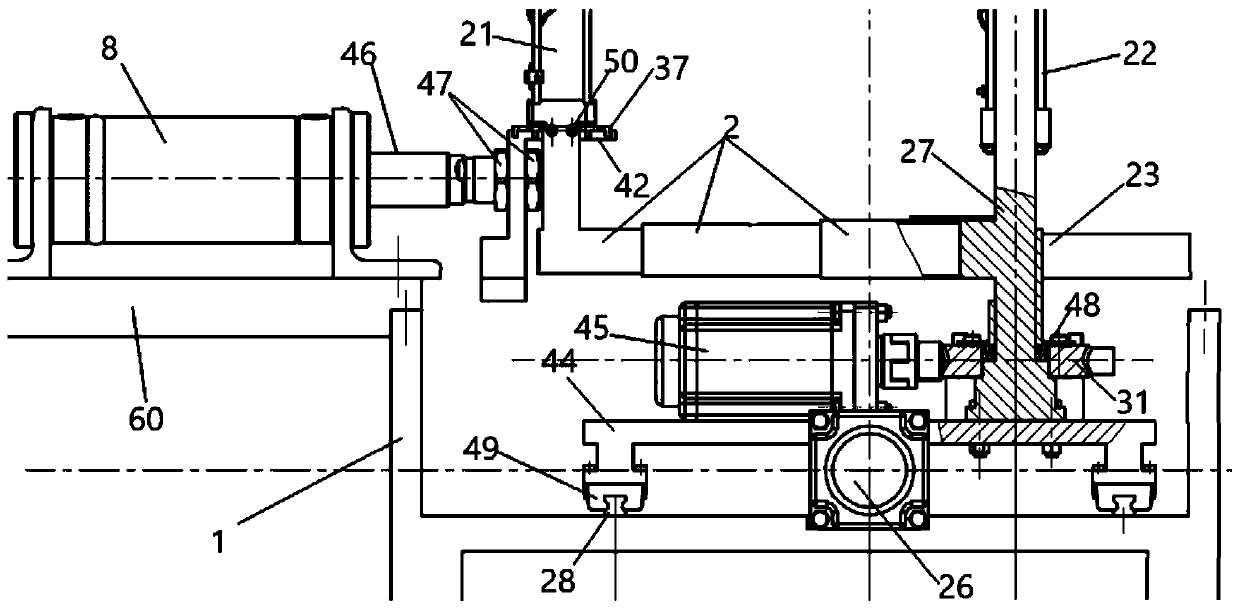

[0041] combine figure 1 , the board type wood multifunctional processing machine tool of the present invention comprises a support 1, a workbench installed on the support, a discharge conveyor belt 13, a cutter device, a plank longitudinal (advancing direction in plank processing) positioning device, and a plank angle positioning device , plank pressing device, plank propulsion device, laser sensor and PLC controller.

[0042] combine figure 1 , Figure 6 and Figure 12 , described workbench comprises front workbench 24 and back workbench 10, and transverse guide rail 3 and longitudinal sliding hole 20 are arranged on front workbench, and the front portion of rear workbench has front door type beam 63.

[0043] combine figure 1 and Figure 13 , the discharge conveyor belt (13) is connected to the rear side (discharge side) of the rear workbench, and is driven by a mot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com