Simplified grinding head movable type horizontal shaft circular truncated cone plane grinding machine

A surface grinder, mobile technology, applied in the direction of machine tools, grinding machines, and grinding beds suitable for grinding workpiece planes, it can solve the problems of complex structure of grinding machines, lack of protective equipment, low processing accuracy, etc., and reduce the weight of machine tools , The protective area can be adjusted to improve the effect of safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below with reference to the drawings and specific embodiments.

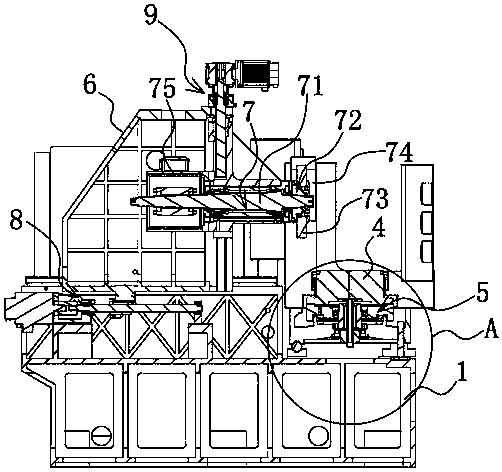

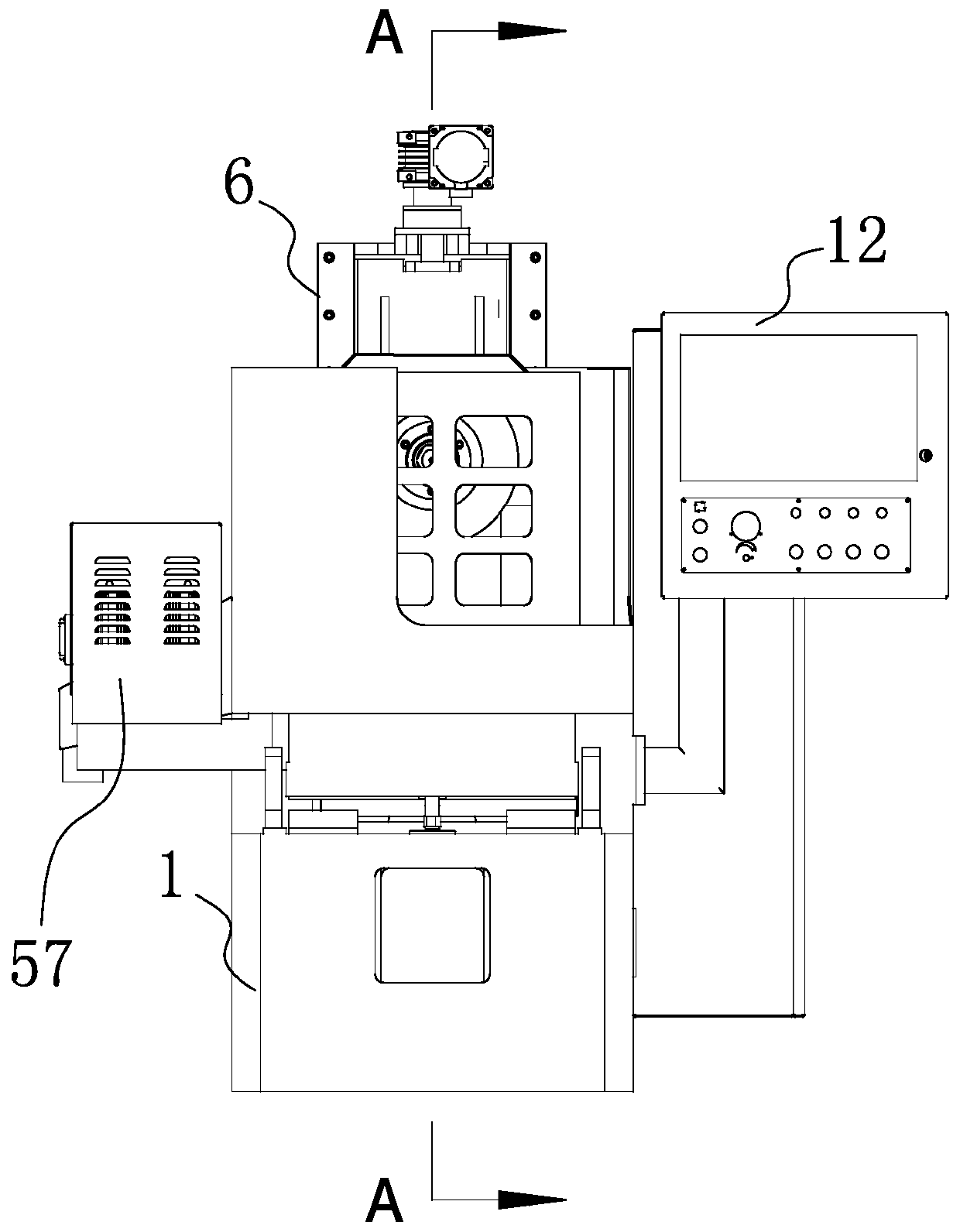

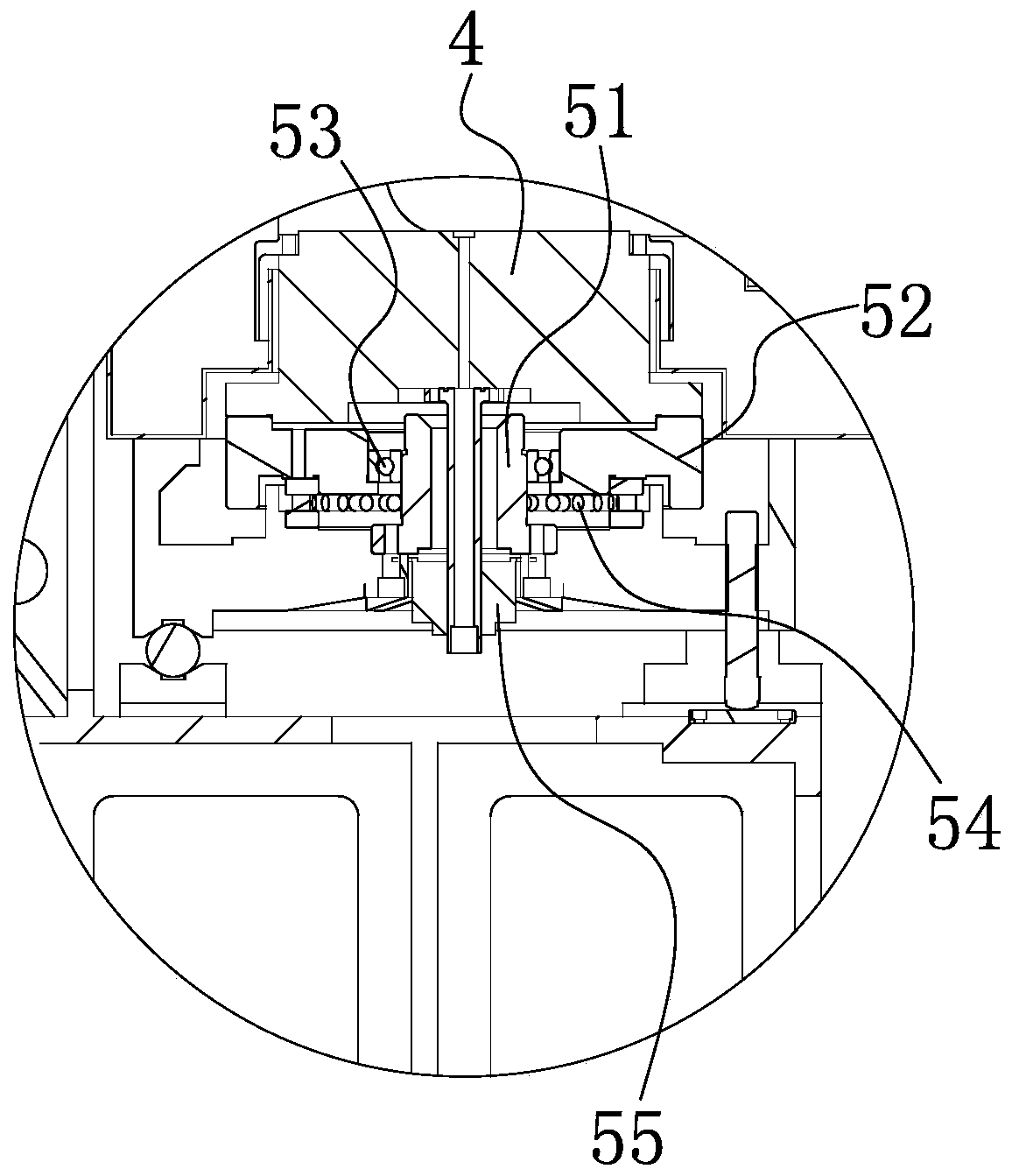

[0027] Such as Figure 1-6 As shown, the simplified grinding head mobile horizontal axis round table surface grinder includes a bed 1, the front side of the bed 1 is provided with a workbench body 3 through an adjustable installation structure 2, and a workbench is provided on the workbench body 3 4. The worktable 4 is connected with a rotating drive mechanism 5 that can drive its circumferential rotation. A moving column 6 is respectively movably arranged on the rear side of the bed 1, and the moving column 6 is provided with a grinding machine assembly 7 corresponding to the worktable 4. A horizontal driving structure 8 is provided between the column 6 and the bed 1 which can drive the movable column 6 to approach or move away from the worktable 4 in the horizontal direction. Between the movable column 6 and the grinder assembly 7 is provided a colum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com