Glass placement rack

A technology for placing racks and glass, which is applied in the direction of transportation, packaging, and load hanging components, etc. It can solve the problems of safety hazards, falling, easy shaking, etc., and achieve the effect of safe use and avoiding glass falling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

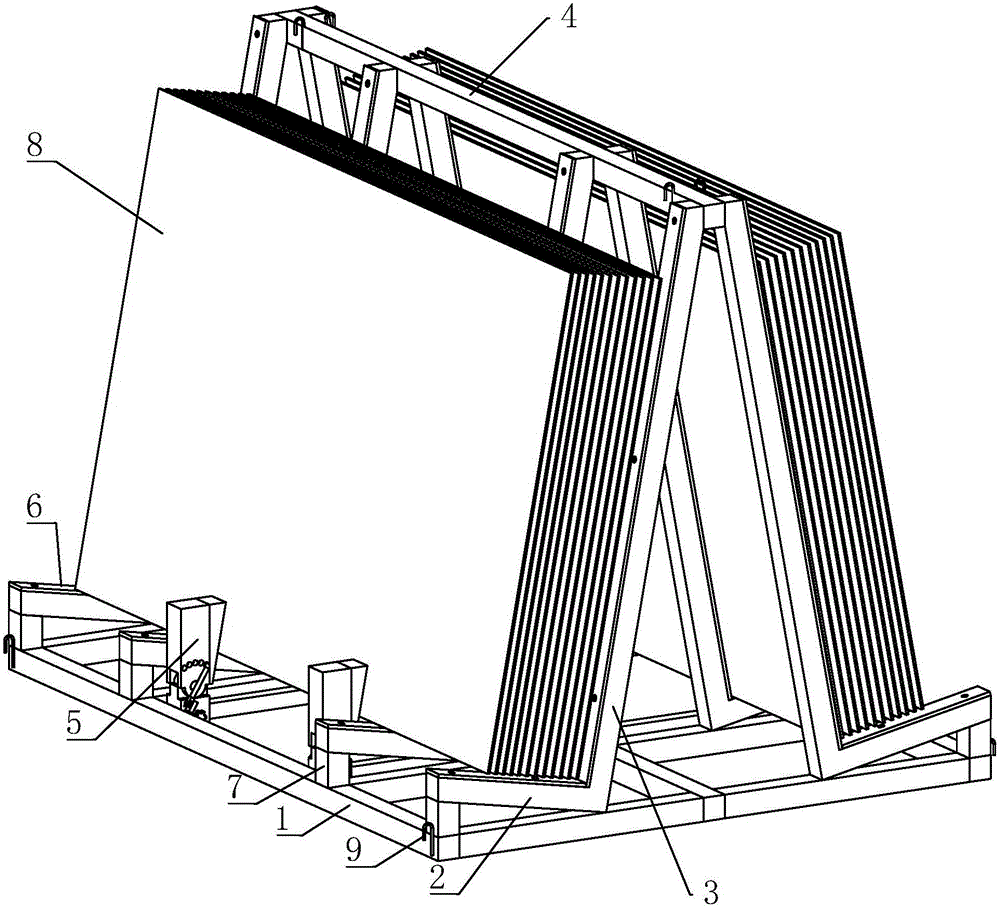

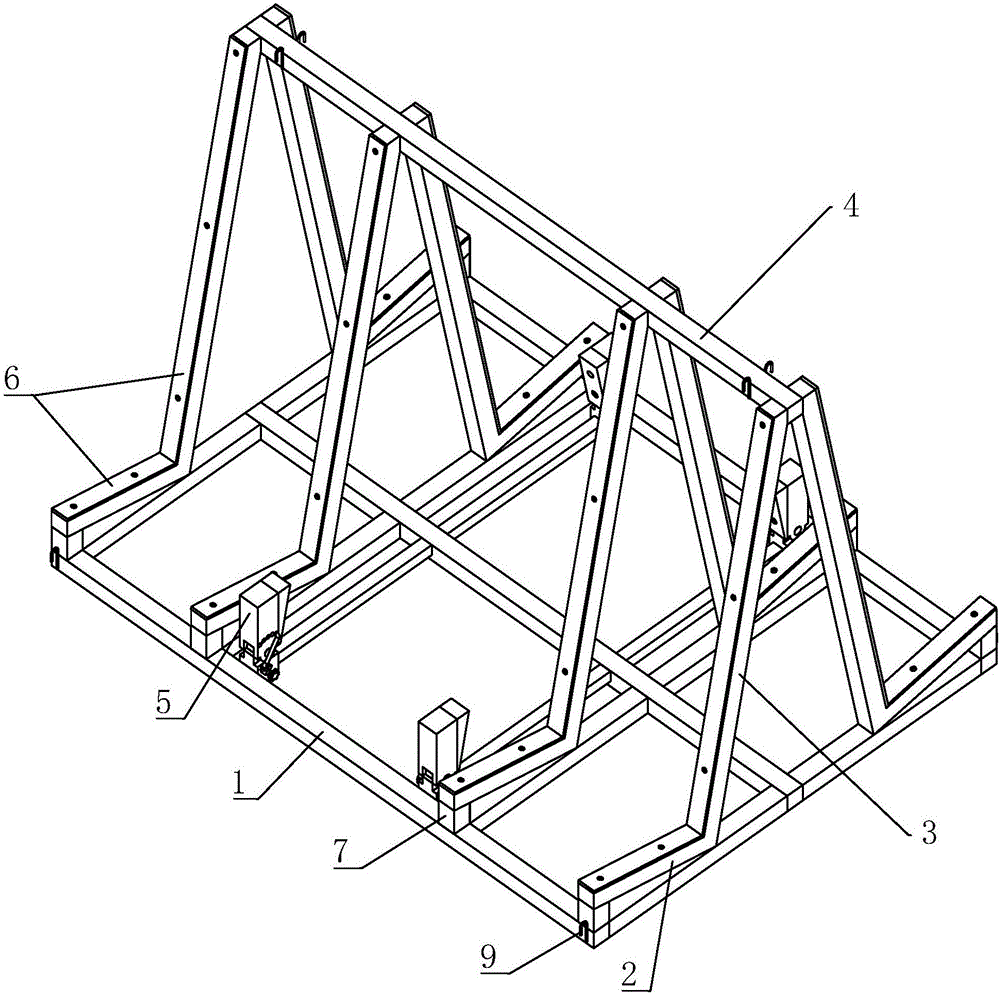

[0032] Embodiment 1: A kind of glass placement rack, refer to figure 1 , figure 2 , comprising a rectangular underframe 1 set on the ground, which is welded using square steel pipes. Four corners of the underframe 1 are respectively provided with a suspension hook 9 for lifting. On one side of the chassis 1 along its length direction, there are four support rods 2 with one end upturned at intervals. One end is directly welded to the chassis 1. On the lower end of the support rod 2, a relying rod 3 is also connected, and the relying rod 3 is inclined to the side away from the supporting rod 2 and has an angle of 90°-100° with the supporting rod 2. Rely on the upper end of the bar 3 to be connected by a crosspiece 4, and the crosspiece 4 is made of a square steel pipe and welded with the rely on the bar 3. If want to further improve the intensity of glass placement rack, also can set several crosspieces 4 more.

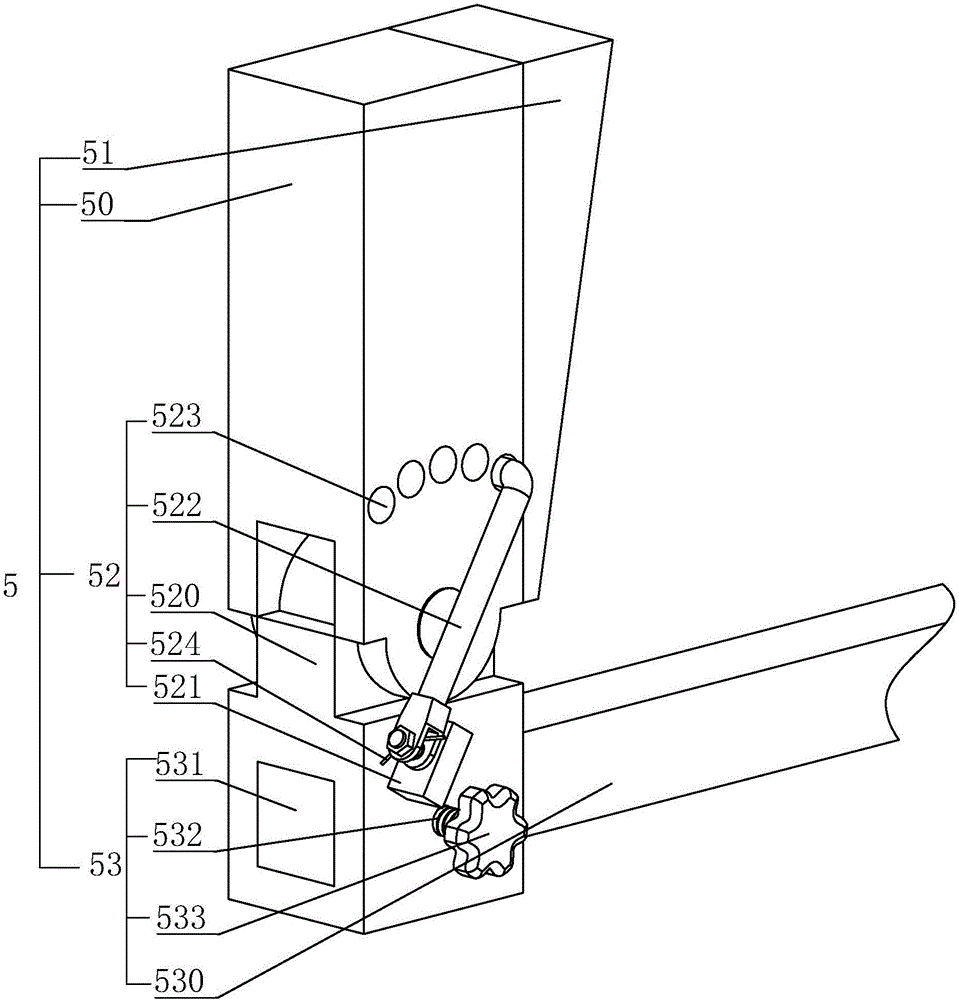

[0033] refer to figure 1 , figure 2 , in order to increas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com