Purification method and preparation method of high-purity chlorine trifluoride

A technology of chlorine trifluoride and purification method, which is applied in the field of purification method and preparation of high-purity chlorine trifluoride, and can solve the problems of low purity of chlorine trifluoride gas, failure to meet technical indicators, and high impurity of ClF

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

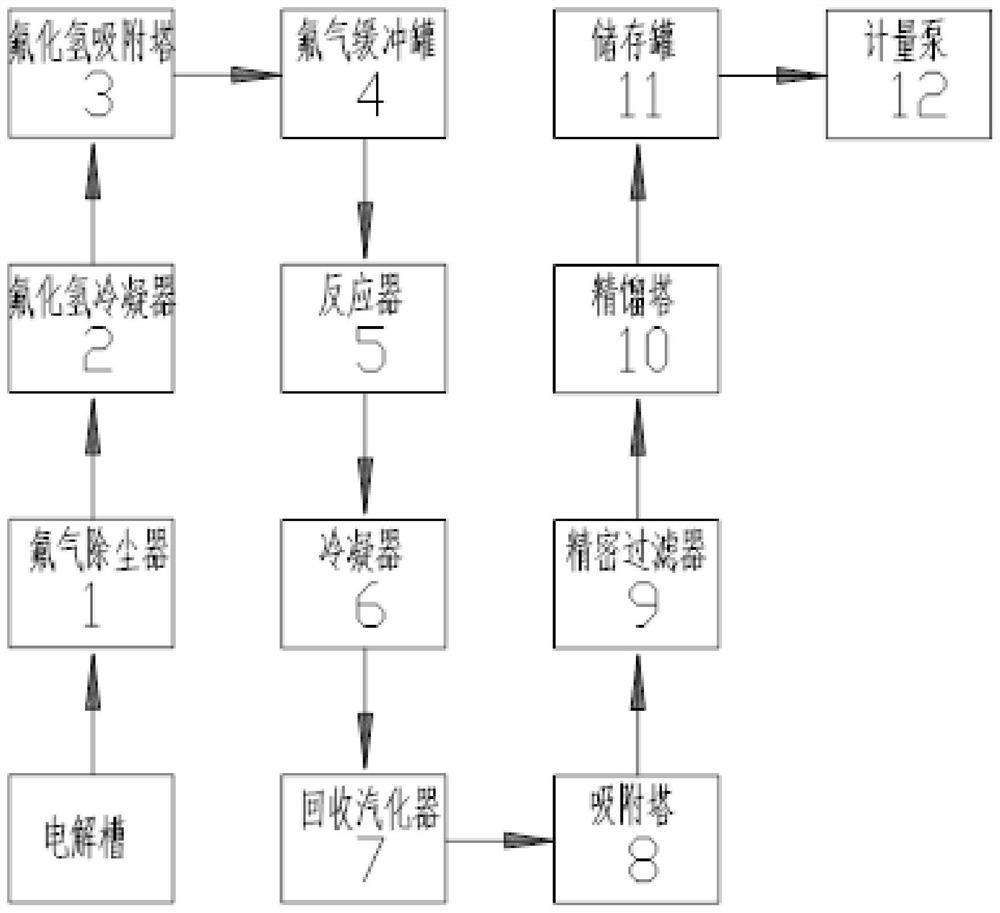

Method used

Image

Examples

Embodiment 1

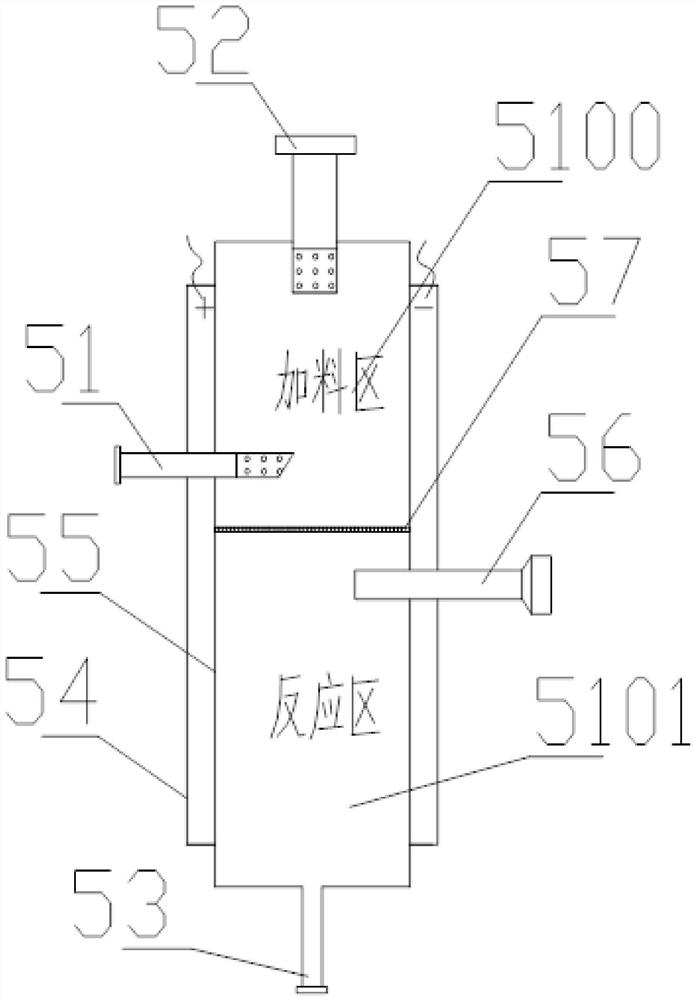

[0075] The purpose of this embodiment is to provide a kind of reactor 5 of high-purity grade chlorine trifluoride, comprise following structure:

[0076] The reactor 5 of this high-purity chlorine trifluoride comprises a housing 55, and a partition 57 is arranged in the housing 55, and the partition 57 is specifically arranged on the middle and upper part of the reactor 5 horizontally, and the housing The environment in 55 is divided into upper and lower areas. The upper part is the feeding chamber 5100, and the lower part is the reaction chamber 5101. The height of the upper feeding chamber 5100 is better than that of the lower reaction chamber 5101. The feeding chamber 5100 is used for automatic mixing of fluorine gas and chlorine gas. storage area; the feeding chamber 5100 and the reaction chamber 5101 communicate with each other through the through holes on the partition plate 57 .

[0077] The outer wall of the reactor 5 is covered with an electric heating blanket 54 for ...

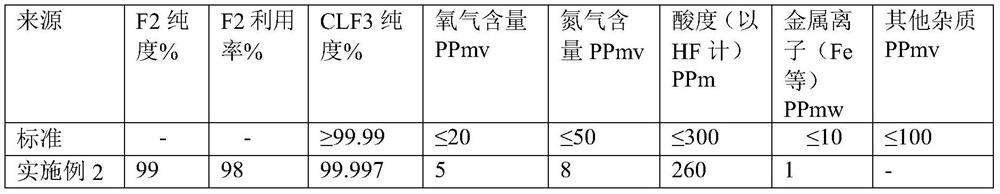

Embodiment 2

[0082] The purpose of this embodiment is to provide a kind of purification method of high-purity grade chlorine trifluoride, comprises the steps:

[0083] S1. Condensation: Lead the produced chlorine trifluoride mixed gas into condenser 6 for condensation, the temperature of the condenser is controlled at -25°C, the pressure is -0.03Mpa, the liquid obtained by condensation is crude chlorine trifluoride, non-condensable gas and The unreacted fluorine gas is vented after being treated by the exhaust gas purification system;

[0084] S2. Recovery and vaporization: the chlorine trifluoride gas purified in step S3 passes through the recovery vaporizer 7, the temperature of the recovery vaporizer is controlled at 35°C, and the pressure is -0.02Mpa to further remove trace amounts of unreacted fluorine gas and non-condensable gas, trifluorine The concentration of chlorine chloride is controlled at 96-99%, and then the recovery vaporizer is heated and vaporized to provide pressure for ...

Embodiment 3

[0091] The purpose of this embodiment is to provide a kind of purification method of high-purity grade chlorine trifluoride, comprises the steps:

[0092] S1. Condensation: The produced chlorine trifluoride mixed gas is introduced into the condenser 6 for condensation. The temperature of the condenser is controlled at -40°C and the pressure is 0Mpa. The liquid obtained by condensation is crude chlorine trifluoride, non-condensable gas and unreacted The fluorine gas is vented after being treated by the exhaust gas purification system;

[0093] S2. Recovery and vaporization: the chlorine trifluoride gas purified in step S3 passes through the recovery vaporizer 7, the temperature of the recovery vaporizer is controlled at 43°C, and the pressure is 0.3Mpa, and traces of unreacted fluorine and non-condensable gases are further removed. The chlorine concentration is controlled at 96-99%, and then the recovery vaporizer is heated and vaporized to provide pressure for the low-pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com