Patents

Literature

50 results about "Chlorine trifluoride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Chlorine trifluoride is an interhalogen compound with the formula ClF₃. This colorless, poisonous, corrosive, and extremely reactive gas condenses to a pale-greenish yellow liquid, the form in which it is most often sold (pressurized at room temperature). The compound is primarily of interest as a component in rocket fuels, in plasmaless cleaning and etching operations in the semiconductor industry, in nuclear reactor fuel processing, and other industrial operations.

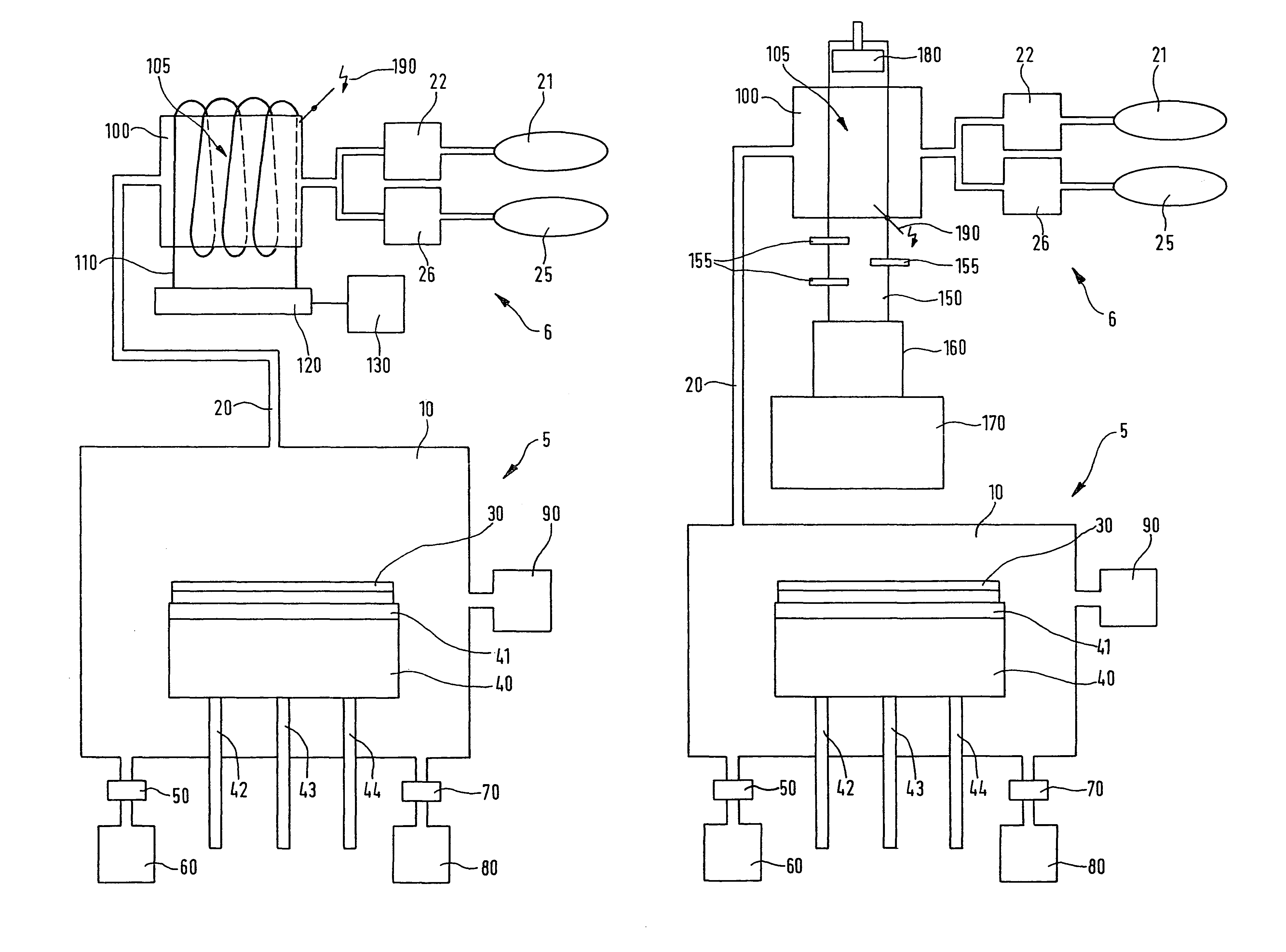

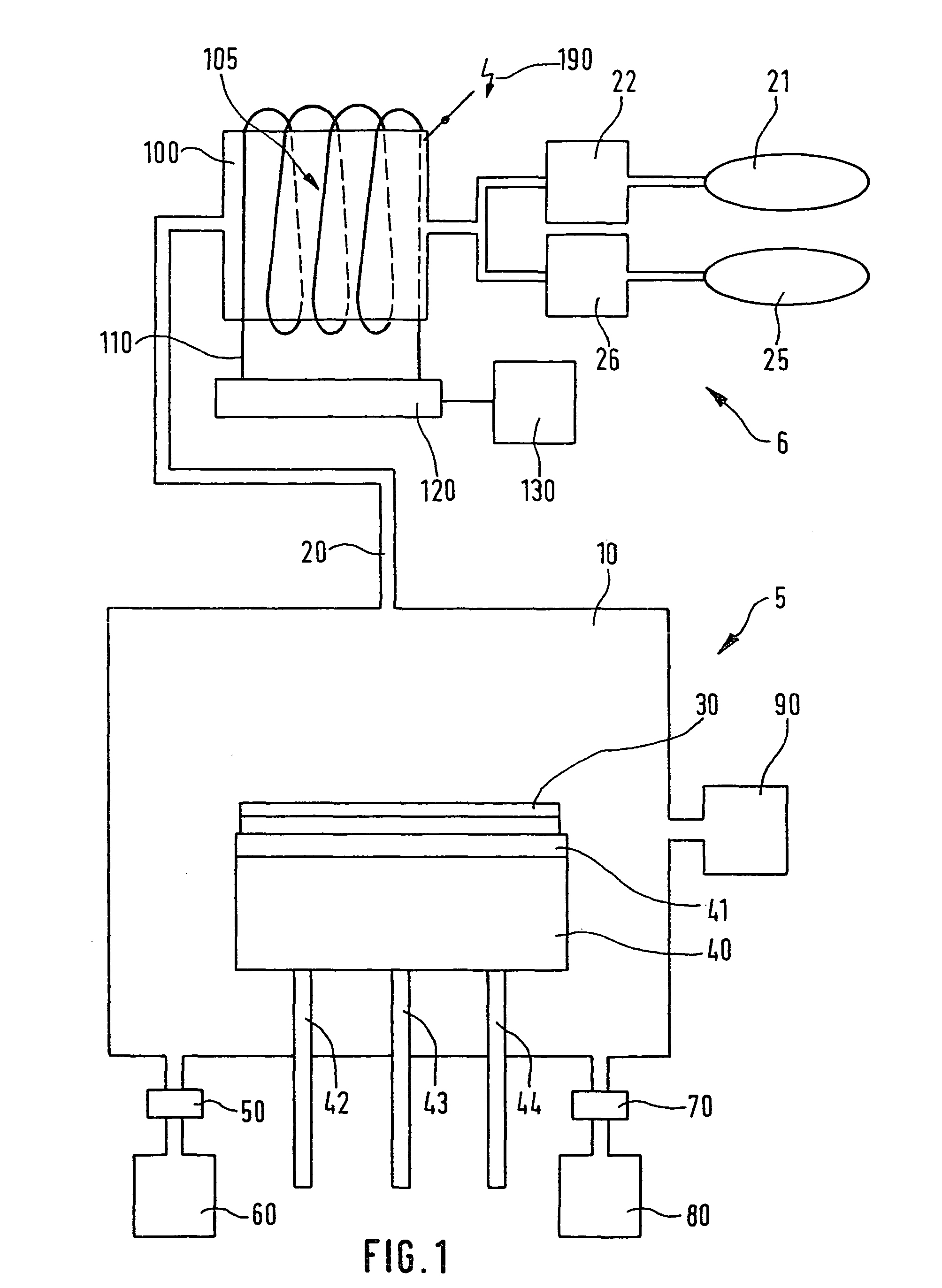

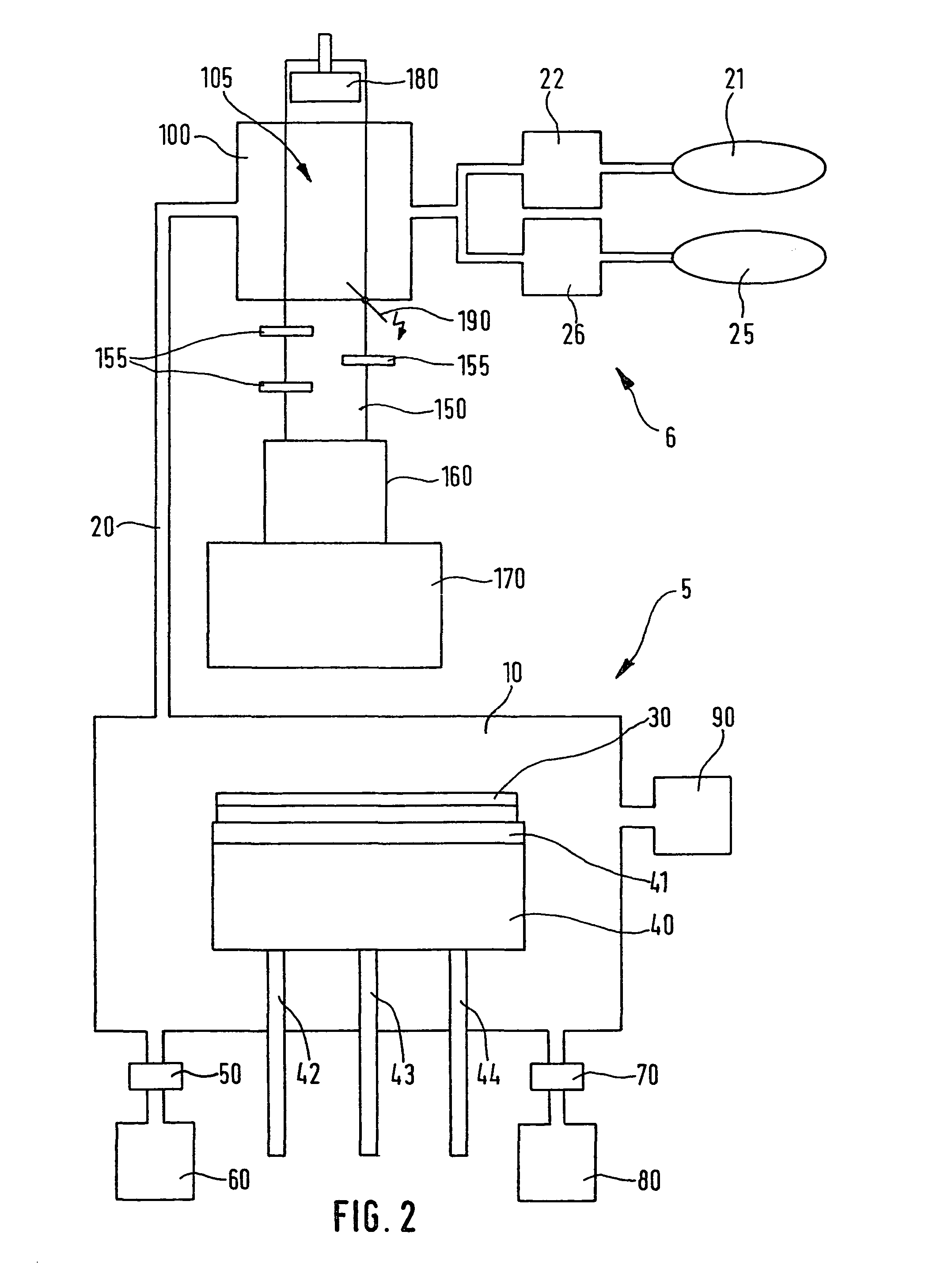

Device and method for the production of chlorotriflouride and system for etching semiconductor substrates using said device

InactiveUS20060006057A1Avoid hoardingElectric discharge tubesDecorative surface effectsChemistryChlorine trifluoride

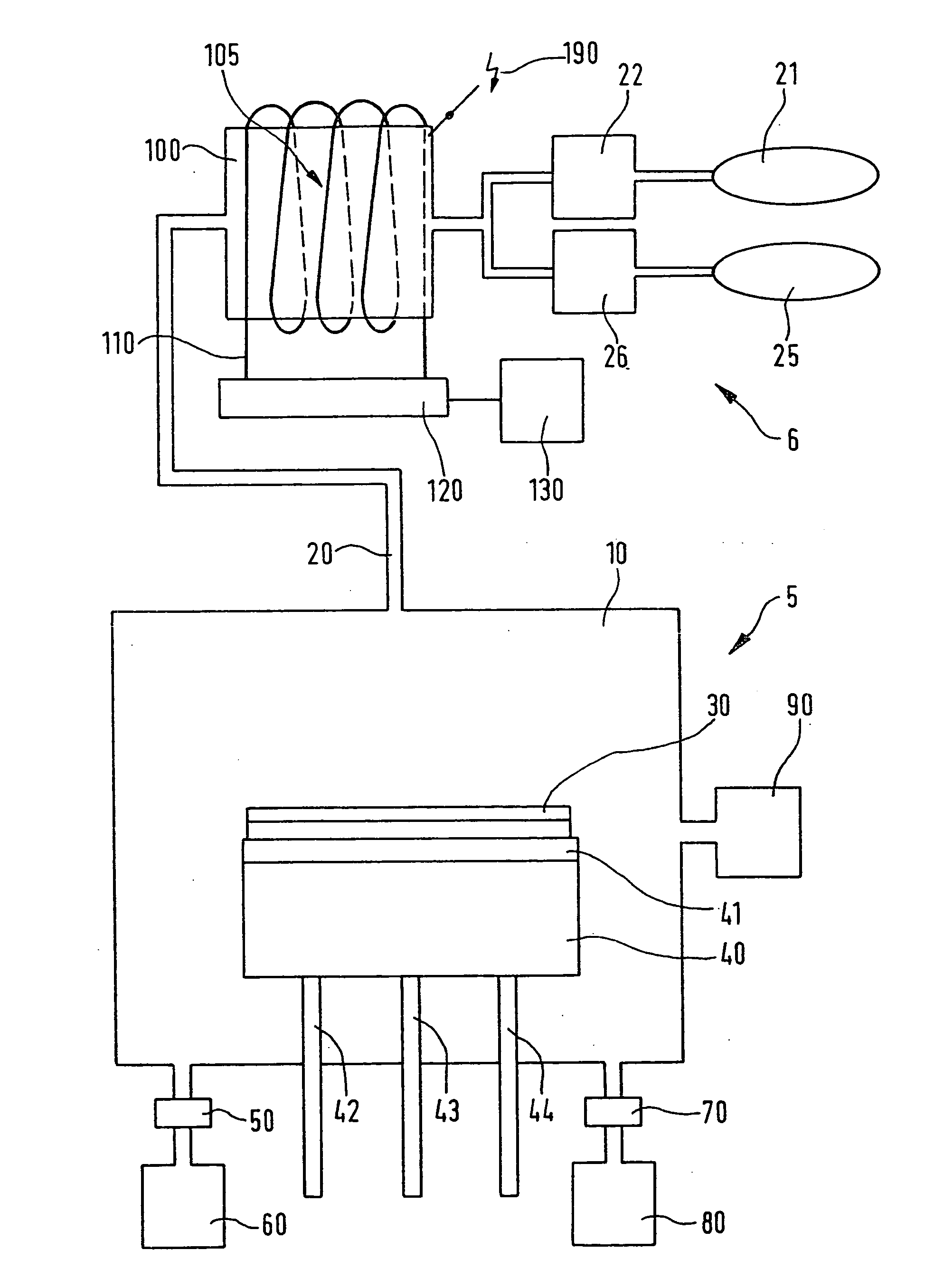

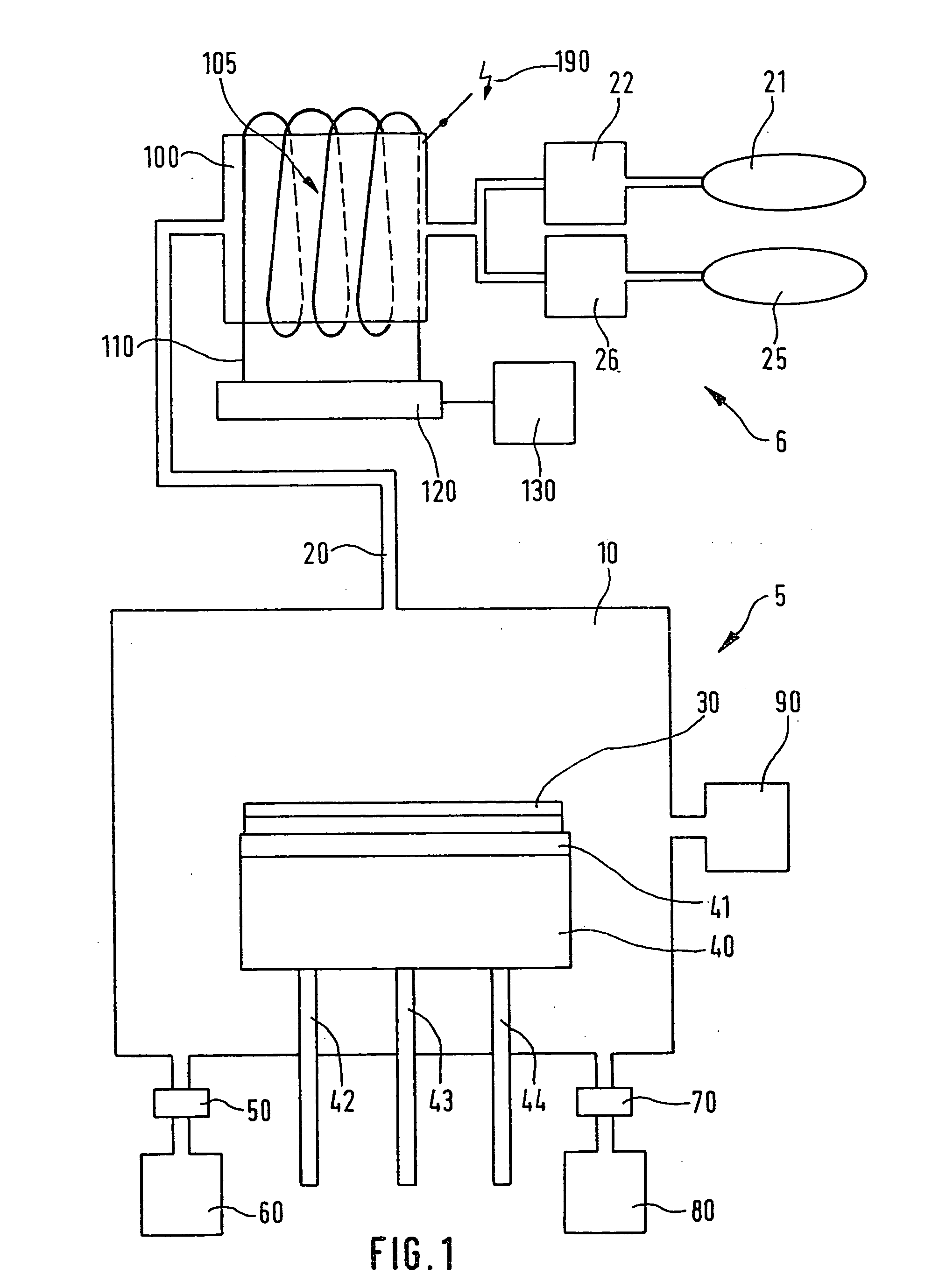

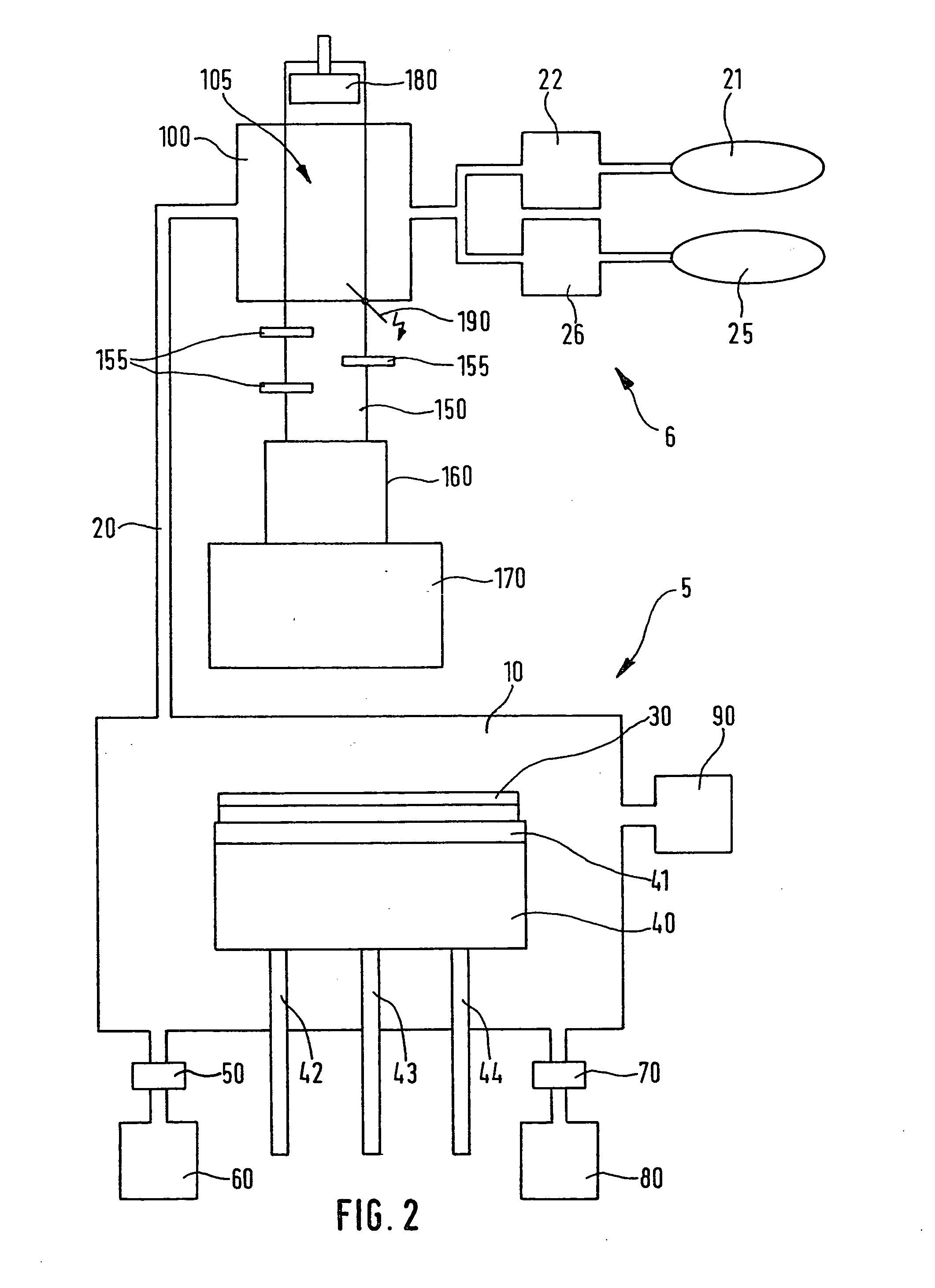

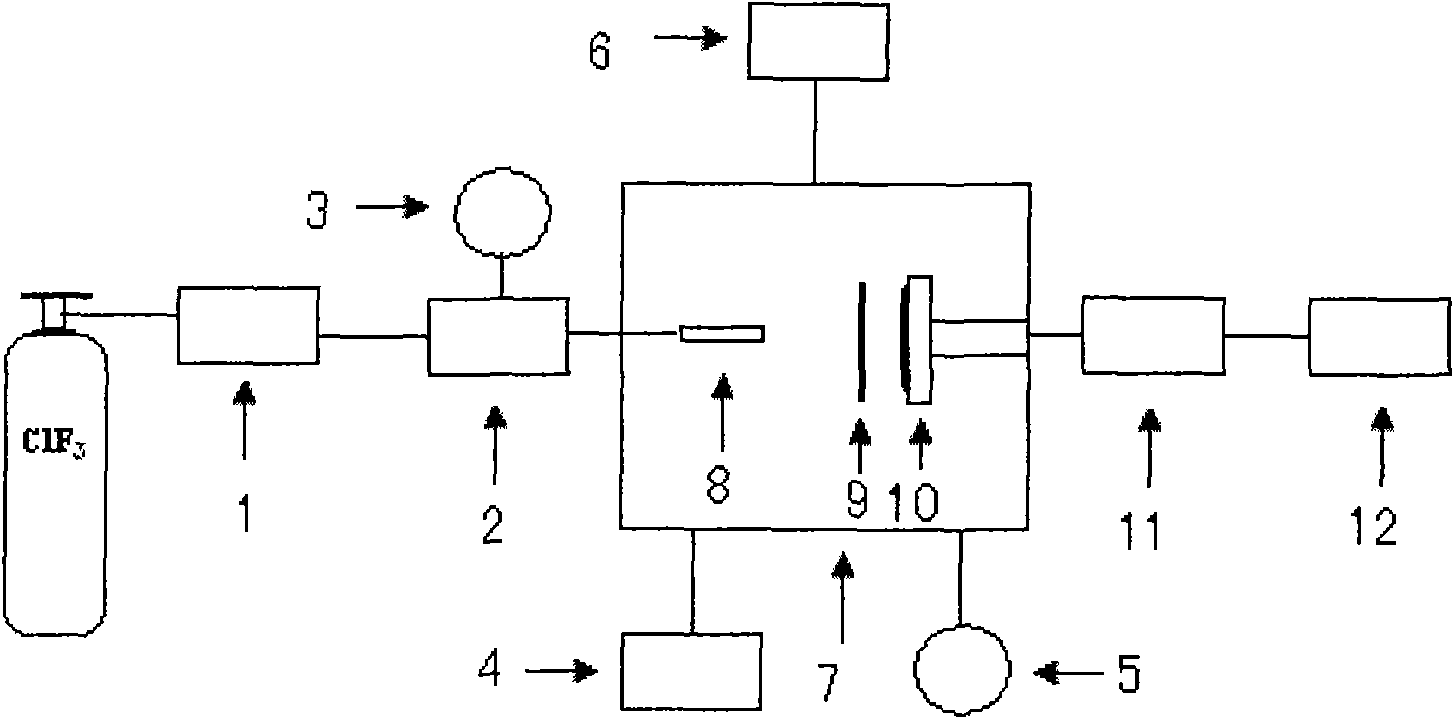

A device (6) and a method for generating chlorine trifluoride is described, a high-density plasma (105) being generated in the interior of a plasma reactor (100) using plasma generating means (110, 120, 130, 150, 155, 160, 170, 180), and a first gas and a second gas, which react with one another under the influence of the high-density plasma (105) in the plasma reactor (100) under the formation of chlorine trifluoride, being supplied to the plasma reactor (100) via gas supply means (21, 22, 25, 26). In addition, a gas outlet (20) is provided, via which the generated chlorine trifluoride can be removed from the plasma reactor (100). Finally, a system (5) for etching semiconductor substrates (30), silicon wafers in particular, is described including such an upstream device (6), the system (5) having a process chamber (10) which is connected to the plasma reactor (100) via the gas outlet (20), and the semiconductor substrate (30) being situated in the process chamber (10) and exposed to the gaseous chlorine trifluoride generated by the device (6).

Owner:ROBERT BOSCH GMBH

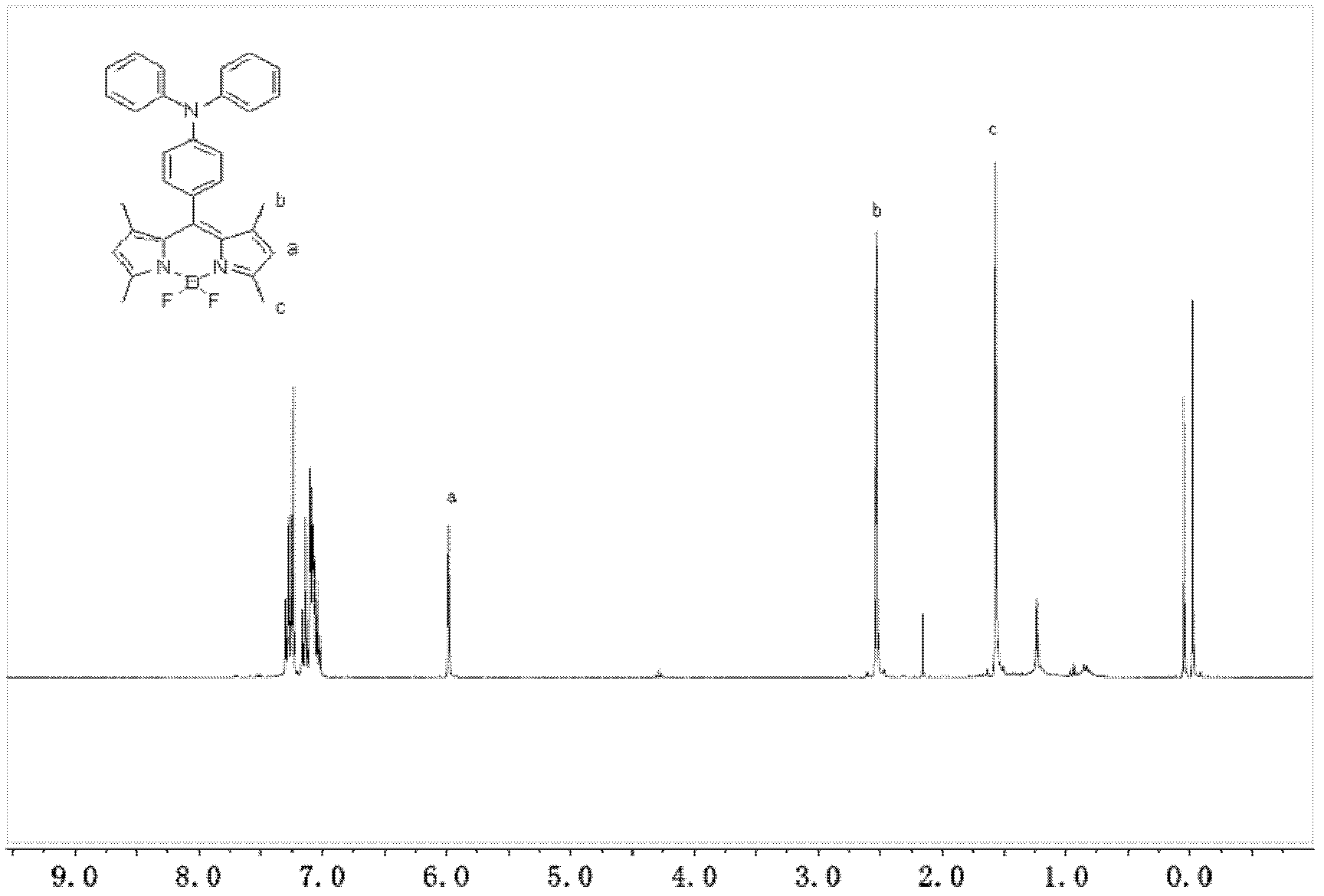

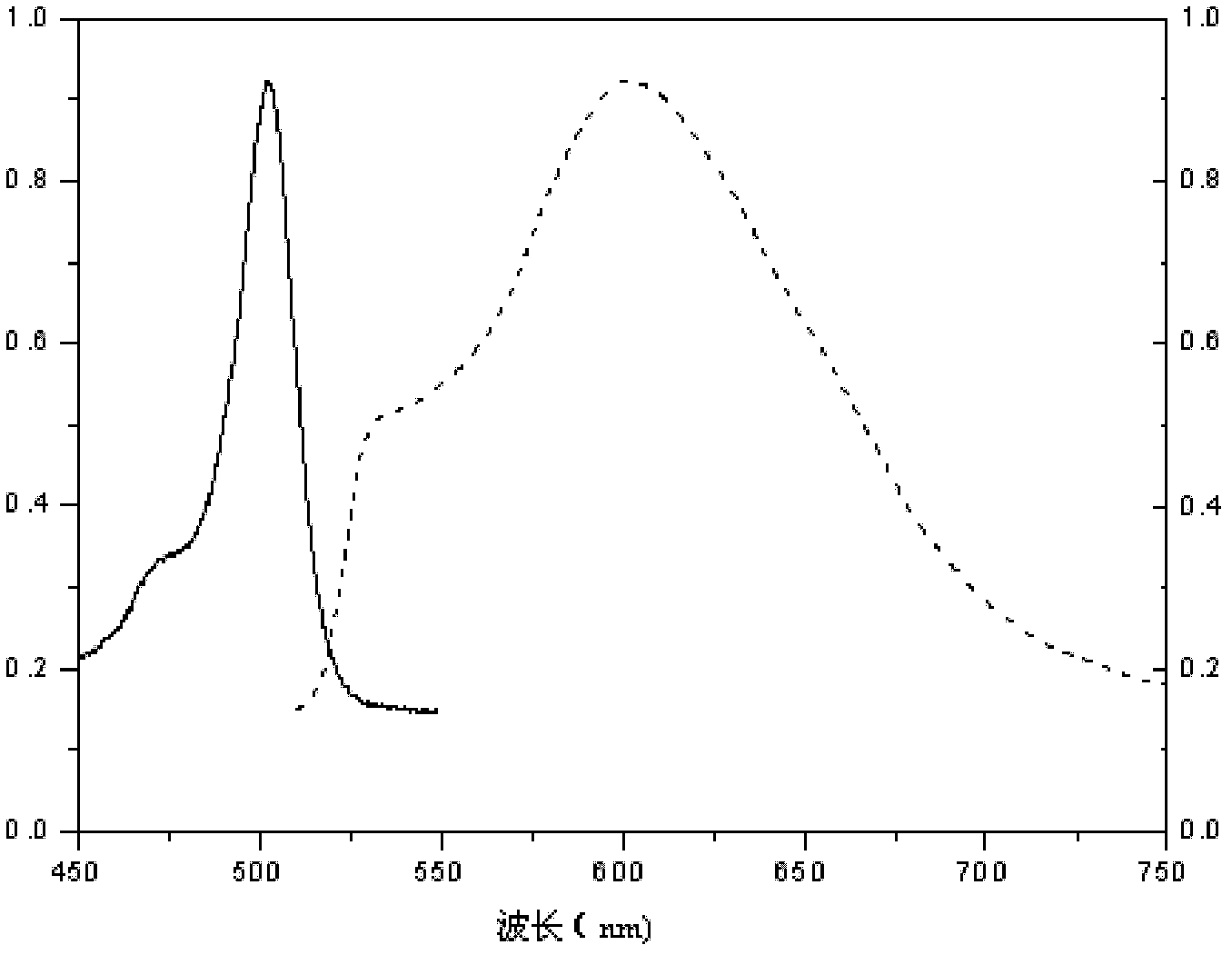

1,3,5,7-tetramethyl-8-triphenylamine base pyrrole methane-boron difluoride complex compound and preparation method thereof

InactiveCN102321109AOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsMethylene DichlorideOrganic synthesis

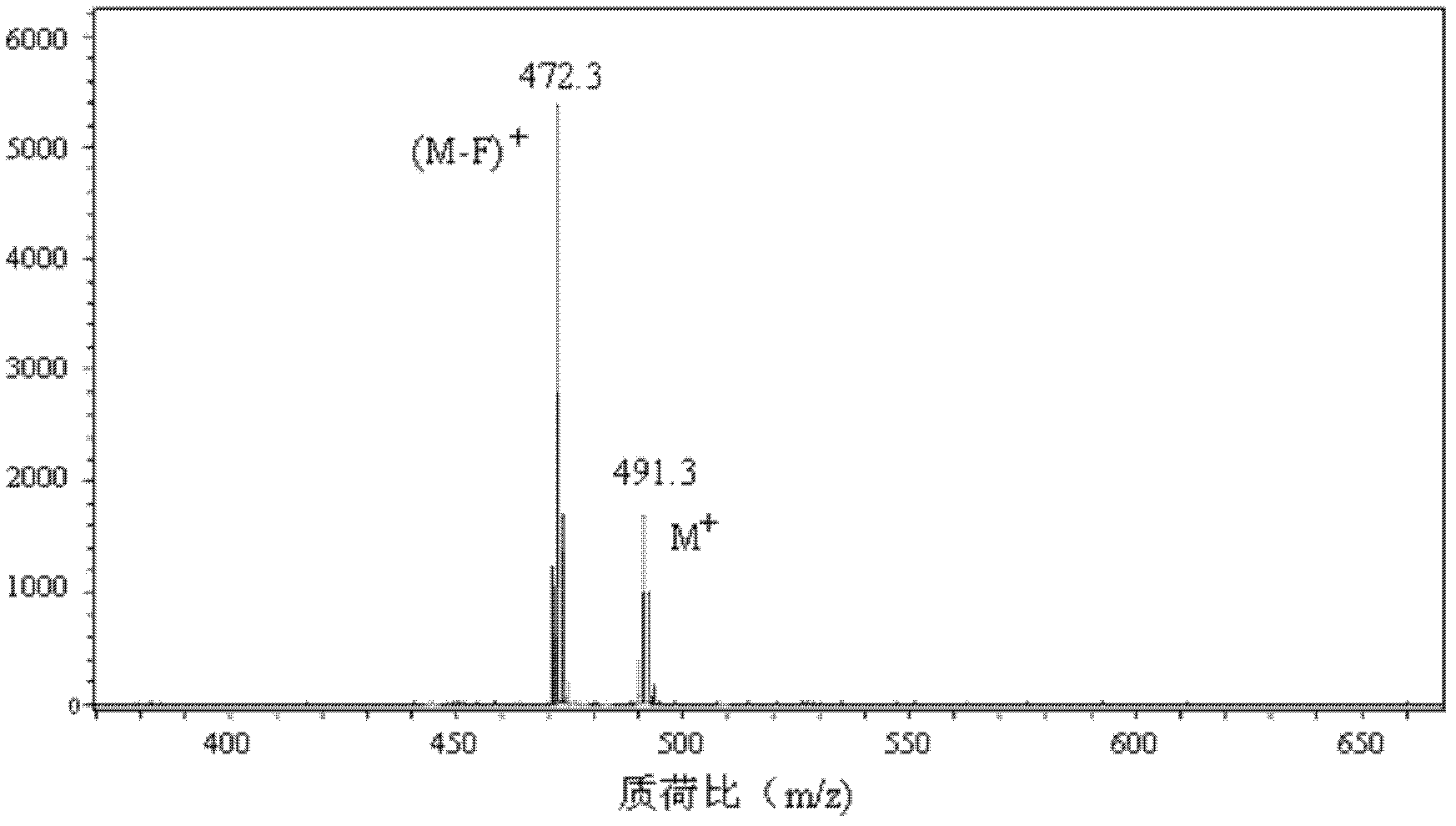

The invention relates to a 1,3,5,7-tetramethyl-8-triphenylamine base pyrrole methane-boron difluoride complex compound and a preparation method thereof, which belong to the technical field of organic synthesis. The existing photocatalysts have few varieties and low conversion rate, and the existing bodipy dye has low infrared fluorescent efficiency and small Stokes displacement. The invention provides the 1,3,5,7-tetramethyl-8-triphenylamine base pyrrole methane-boron difluoride complex compound. The preparation method comprises the steps that: 4-formoxyl tetramethyl and 2,4-dimethyl pyrrole are dissolved in organic solvents, trifluoroacetic acid or monoprop is used as catalysts, and a reaction system is formed; 2,3-dichloro-5,6-dicyan-1,4-para-benzoquinone with the same mol ratio as the 4-formoxyl tetramethyl is taken, is dissolved in the methylene dichloride and is added into the reaction system; and one of triethylamine, triisopropyl amine and N,N-diisopropylethylamine is added into the reaction system, boron trifluoride etherate is added under the ice bath, and final products are generated.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

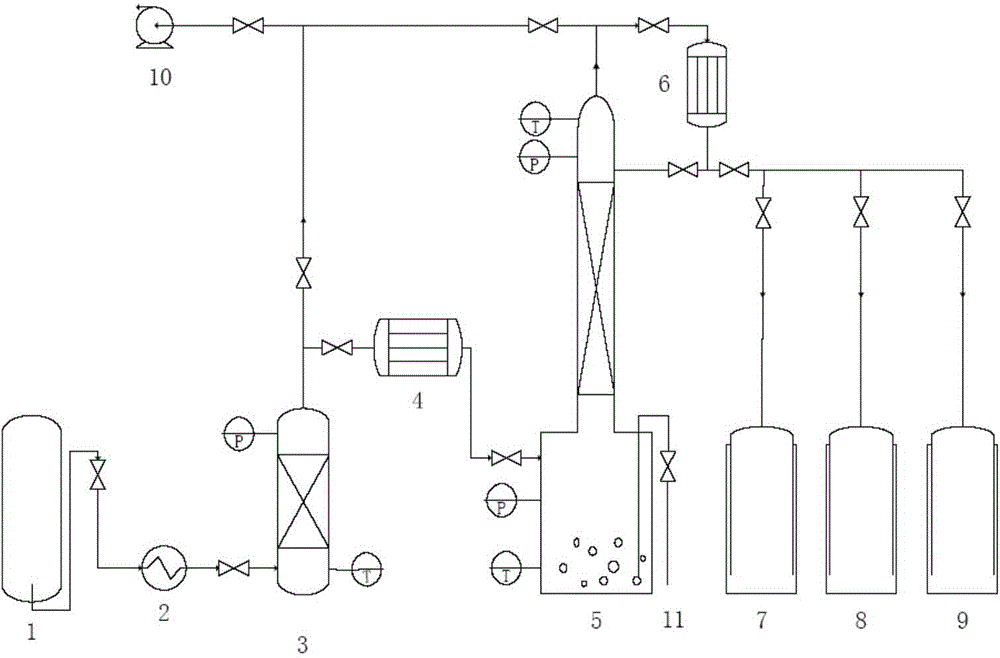

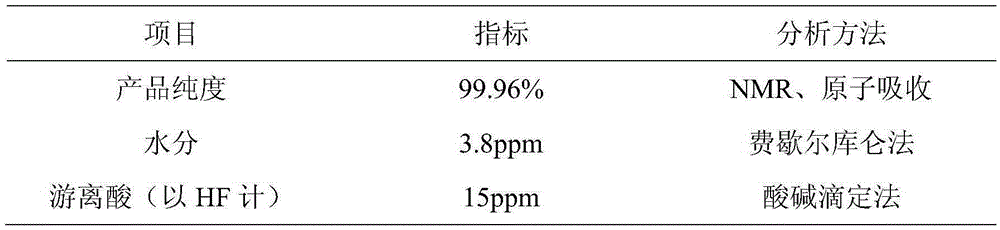

Purification method of chlorine trifluoride

ActiveCN104555927AReduce contentEasy to operateInter-halogen compoundsVacuum pumpingPurification methods

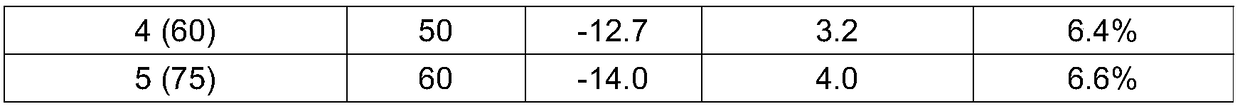

The invention discloses a purification method of chlorine trifluoride, and belongs to the field of fine chemical engineering. The purification method comprises the following steps: introducing chlorine trifluoride crude products into a tower kettle of a rectifying tower; performing vacuum-pumping on the rectifying system, starting to heat the tower kettle after the vacuum degree is stable, and performing total refluxing for 3-15 h to enable the impurity composition of which the boiling point is lower than that of chlorine trifluoride to be gathered at the top of the rectifying tower; when the temperature of the tower kettle is at a temperature of 0-5 DEG C, the temperature of the rectifying tower top is 2-3 DEG C below zero, then collecting front cut fraction at a reflux ratio of 30-300 and condensing and recovering; when the temperature of the tower kettle is 5-8 DEG C, the temperature of the rectifying tower top is 3-6 DEG C, collecting medium fraction at a reflux ratio of 10-90, and condensing and recovering; when the temperature of the tower kettle increases for 2 DEG C, that is, the temperature is 7-10 DEG C, the temperature of the rectifying tower top is 5-8 DEG C, collecting after cut fraction at a reflux ratio of 15-140, and condensing and recovering; when the temperature of the tower kettle is higher than or equal to 15 DEG C, stopping collecting after cut fraction, stopping heating, stopping vacuum-pumping, and finishing rectifying, wherein the medium fraction is the chlorine trifluoride refined product. The method is simple to operate and is high in purification efficiency.

Owner:PERIC SPECIAL GASES CO LTD

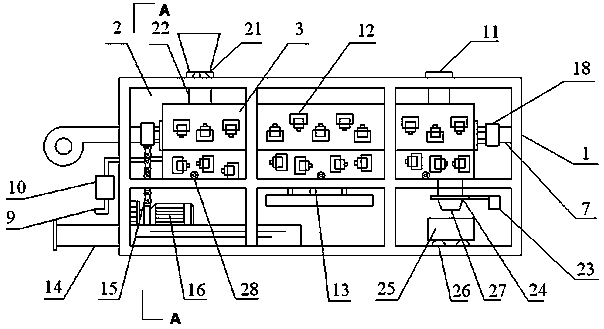

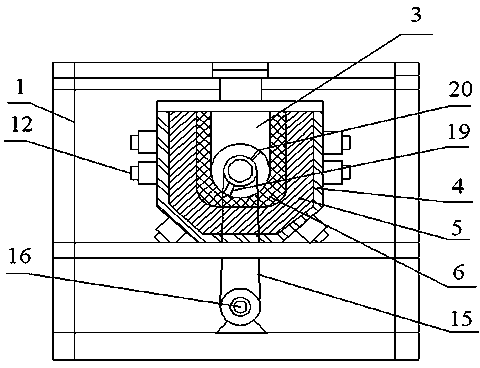

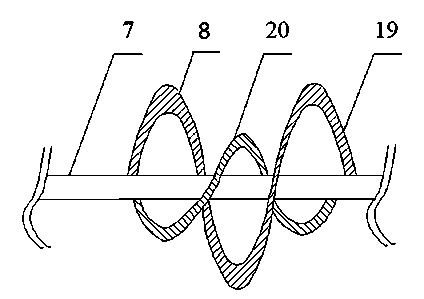

Dynamic high-temperature continuous microwave roasting equipment

The invention relates to dynamic high-temperature continuous microwave roasting equipment, and belongs to the technical field of high-temperature microwave roasting equipment for intermediate material high-temperature sintering and roasting and chlorine trifluoride removal and capable of realizing automatic continuous production in the metallurgical and material industries. The dynamic high-temperature continuous microwave roasting equipment comprises a rack, a furnace body, a microwave heating system, a temperature measurement system, a feeding system, a discharging system, a cooling system, a PLC (programmable logic control) device and a double-helix stirring device, wherein the microwave heating system, the temperature measurement system, the feeding system, the discharging system, the cooling system and the double-helix stirring device are arranged on the furnace body; the double-helix stirring device comprises a blade consisting of an outer helix and an inner helix; the microwave heating system, the temperature measurement system, the feeding system, the discharging system, the cooling system and the PLC device are connected. The equipment is simple in structure, high in automation degree, efficient, clean, convenient and low in cost, and can be used for continuous large-scale production.

Owner:KUNMING UNIV OF SCI & TECH

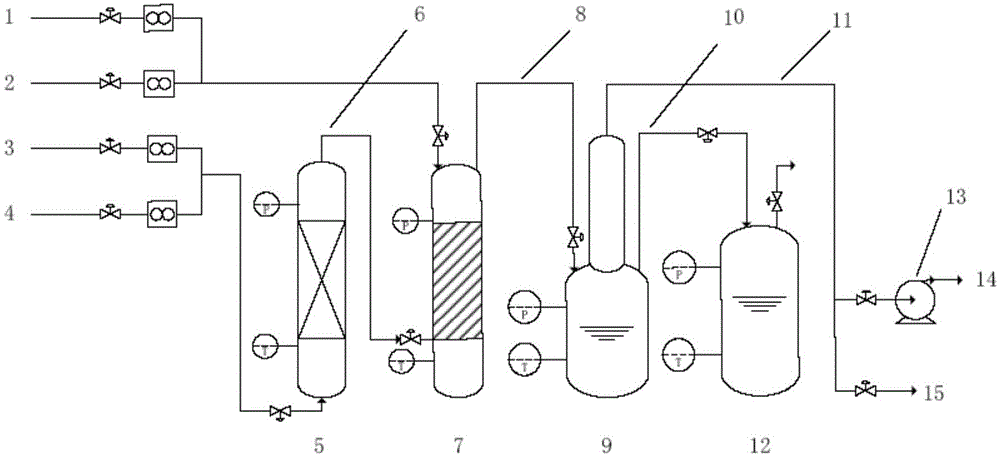

Preparation method of chlorine trifluoride

ActiveCN104477849AStable reaction temperatureTimely supplementInter-halogen compoundsFine chemicalCorrosion

The invention discloses a preparation method of chlorine trifluoride and belongs to the field of fine chemical engineering. The method comprises the following steps: carrying out a bubbling reaction on liquid-phase chloride and fluorine gas at a certain temperature to obtain a product 1; then charging the product 1, a diluent gas and fluorine gas in a synthesis reactor, and reacting at a certain temperature to obtain a product 2; finally carrying out liquidation, lightweight material discharge and vaporization treatments on the product 2 to obtain chlorine trifluoride. The raw materials in the preparation method are low in price and easily available, thus avoiding the adoption of chlorine with high corrosion and high toxicity, improving safety during production, transportation and storage processes; moreover, the reactor is simple in structure and convenient for material charging and discharging; the reaction conversion rate is high; by-products can be easily separated; and the preparation method can be put into industrial production easily.

Owner:PERIC SPECIAL GASES CO LTD

Preparation method and device of chlorine trifluoride

ActiveCN104477850ASimple production processAvoid corrosionInter-halogen compoundsBoron trifluorideReaction temperature

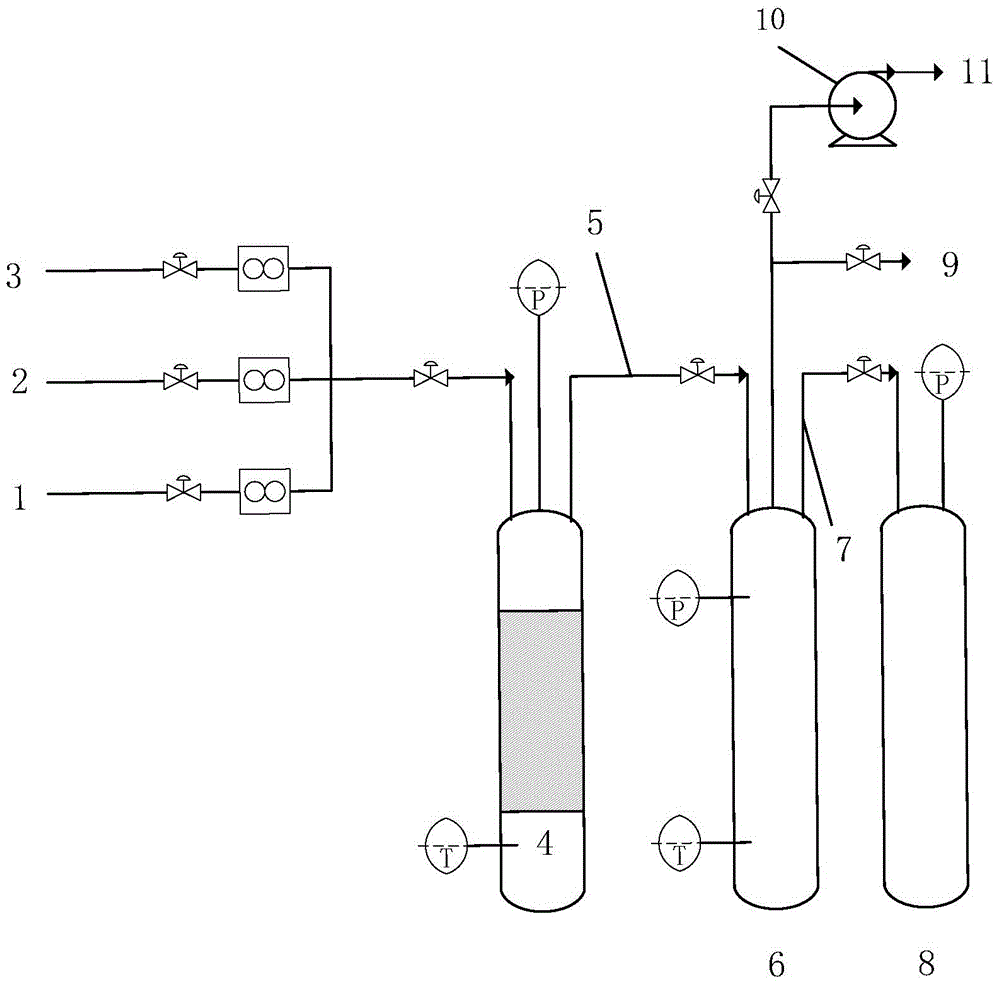

The invention discloses a preparation method and device of chlorine trifluoride and belongs to the field of fine chemical engineering. The method comprises the following steps: mixing chlorine gas, fluorine gas and a diluent gas, and then charging the mixed gas in a reactor filled with a catalyst, and reacting at 100-400 DEG C to obtain a product 1; then carrying out cooling, liquidation, lightweight material discharge and vaporization treatments on the product 1 to obtain the chlorine trifluoride. The device comprises a catalytic reactor, a low-temperature collector, a chlorine trifluoride storage tank and a vacuum pump, wherein the catalytic reactor, the low-temperature collector and the chlorine trifluoride storage tank are sequentially connected through pipelines. The process is low in reaction temperature, short in reaction time and high in product yield; the device has the advantages that the length of the reactor is greatly shortened and the production process of chlorine trifluoride is simplified.

Owner:PERIC SPECIAL GASES CO LTD

Preparation method of in-situ generated mullite whisker ceramic material

The invention discloses a preparation method of an in-situ generated mullite whisker ceramic material. According to the preparation method, coal gangue and high bauxite are used as raw materials, polycrystal mullite fibers are added and used as seed crystals, chlorine trifluoride is added and used as a whisker growth catalyst, and generation of mullite whiskers in the sintering process is promoted; the crystal structure of acidized potassium feldspar is damaged, the liquid-phase formation temperature of a ceramic blank system is lowered, fusion of substances in ceramic blank is promoted, formation and growth of mullite crystals are promoted, the aim of lowering the ceramic sintering temperature is achieved, and energy consumption is lowered; through gel injection molding and two-segment high-temperature sintering, in-situ generated mullite whiskers develop completely, a three-dimensional network structure is formed in the ceramic material, the ceramic material has high porosity, a gelinjection molding technology is adopted at the same time, the pore distribution state of final ceramic can be adjusted and controlled, and the light heat insulation performance of the ceramic materialis improved.

Owner:马鞍山科润冶金材料有限公司

Perfluoro polymer fiber and preparation method thereof

ActiveCN102140706ALarge specific surface areaStrong adsorption functionFilament/thread formingConjugated synthetic polymer artificial filamentsCorrosion reactionSodium hydroxide

The invention discloses a perfluoro polymer fiber and a preparation method thereof. The fiber spinning system comprises the following components in percentage by weight: 40 to 60 percent of perfluoro polymer, 30 to 40 percent of composite porogen and 10 to 30 percent of organic liquid; interfingered dissolution micropores and stretching micropores with the pore diameter of 0.1 to 5mu m are formedon the surface of the fiber; and the fiber is suitable to be continuously used in a temperature range of 85 to 200 DEG C, is subjected to corrosion reaction with a fluorine element at a high temperature, melted sodium hydroxide metal or chlorine trifluoride, and is not subjected to corrosion reaction when contacted with other chemical medicines. The spinning system and a process are adopted in the preparation method, and the process comprises the following steps of: forcibly mixing the composite porogen and the organic liquid; uniformly mixing a mixture and the perfluoro polymer, injecting into a double-screw extruder, and performing melt spinning at the temperature higher than the melting point of the perfluoro polymer to obtain a porous as-spun fiber; and extracting, washing, and stretching.

Owner:TIANJIN POLYTECHNIC UNIV

Method for preparing chlorine trifluoride

PendingCN112723313AFully contactedIncrease contact timeInter-halogen compoundsChemical industryPtru catalyst

The invention belongs to the technical field of inorganic fluorine chemical industry, and particularly relates to a method for preparing chlorine trifluoride, which comprises the following steps: respectively preheating fluorine gas and chlorine gas, sufficiently mixing, and reacting at normal pressure to obtain chlorine trifluoride mixed gas; condensing the chlorine trifluoride mixed gas to obtain a chlorine trifluoride crude product; and rectifying, purifying and condensing the chlorine trifluoride crude product to obtain a chlorine trifluoride product. According to the method, chlorine trifluoride can be prepared in one step under the conditions of no catalyst and normal pressure, the process operation is simple, the reaction time is short, the temperature and pressure are easy to control, the reaction process is safe, and industrial production can be realized.

Owner:SICHUAN HONGHUA IND

Preparation method of polyisobutene with medium molecular weight in boron trifluoride initiating system

InactiveCN102050901AImprove conversion rateHigh Molecular Weight DistributionCationic polymerizationSolvent

The invention relates to a preparation method of polyisobutene with a medium molecular weight in a boron trifluoride initiating system. The preparation method comprises the following steps: adding Lewis acid BF3 and a nucleophilic reagent into a liquid phase polymerization system of isobutene monomer and solvent normal hexane or hexane fraction to form an initiating system with alcohol or ether, and initiating isobutene cationic polymerization to obtain the medium-molecular weight polyisobutene product with a viscometric average molecular weight (MV) of 30000-100000. By adding the nucleophilic reagent, the negative effect of water can be effectively inhibited, so that chain initiation and chain growth during isobutene cationic polymerization can be effectively controlled.

Owner:PETROCHINA CO LTD

Electronic-grade chlorine trifluoride rectification purification system control method

ActiveCN112919419AImproved reflux ratio parameter stabilityRealize wide dynamic balance operationSolidificationLiquefactionHydrogen fluorideTemperature control

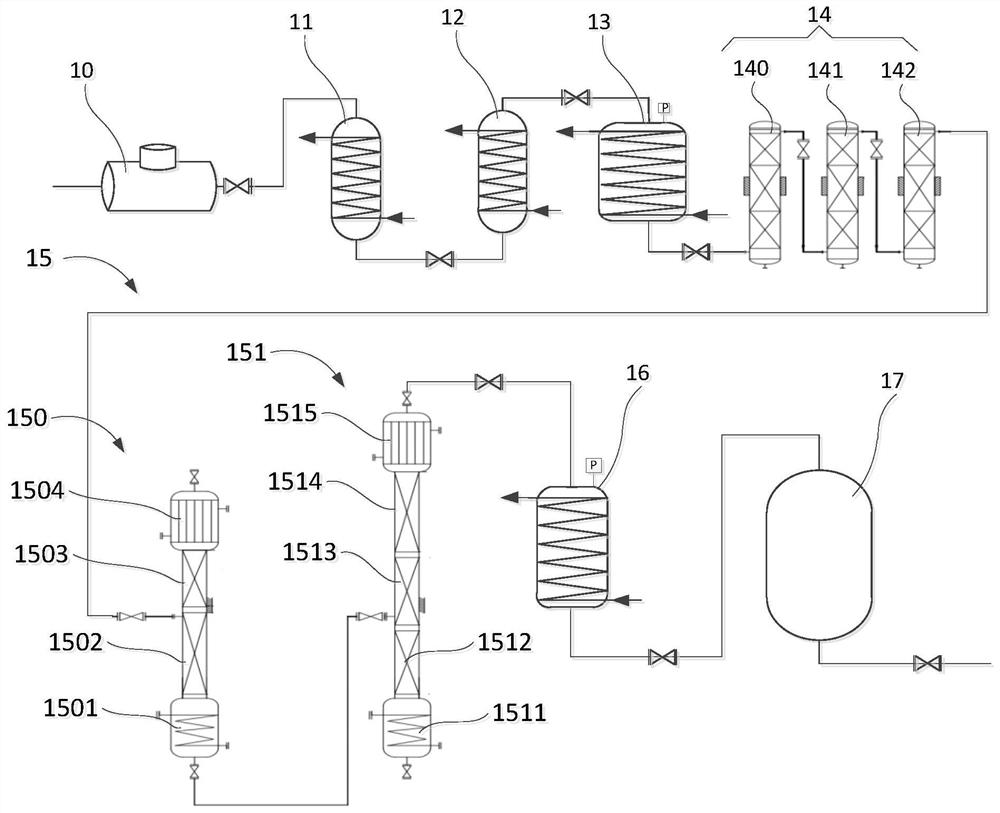

The invention provides an electronic-grade chlorine trifluoride rectification purification system control method and an electronic-grade chlorine trifluoride rectification device. The electronic-grade chlorine trifluoride rectification device comprises a secondary low-temperature rectification device which comprises a low-boiling tower and a high-boiling tower, and the econdary low-temperature rectification device comprises anextraction agent which is used for further dispersing hydrogen fluoride and chlorine trifluoride associated molecules, so that the requirements of electronic-grade chlorine trifluoride are met; the stability of reflux ratio parameters of a vapor-liquid (chlorine trifluoride-hydrogen fluoride) phase equilibrium system can be effectively improved through a tower plate temperature control method, and wide dynamic equilibrium operation under various working conditions is realized; according to the tower plate temperature control method, effective separation of chlorine trifluoride and various impurity components can be realized through a deep rectification technology, and electronic-grade chlorine trifluoride is purified.

Owner:FUJIAN DEER TECH CORP

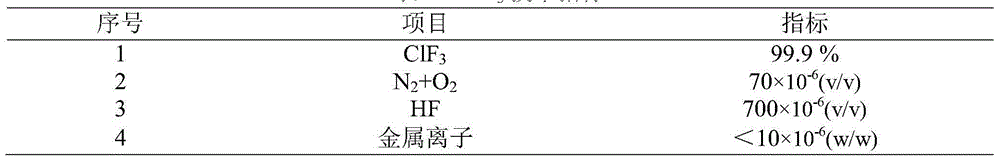

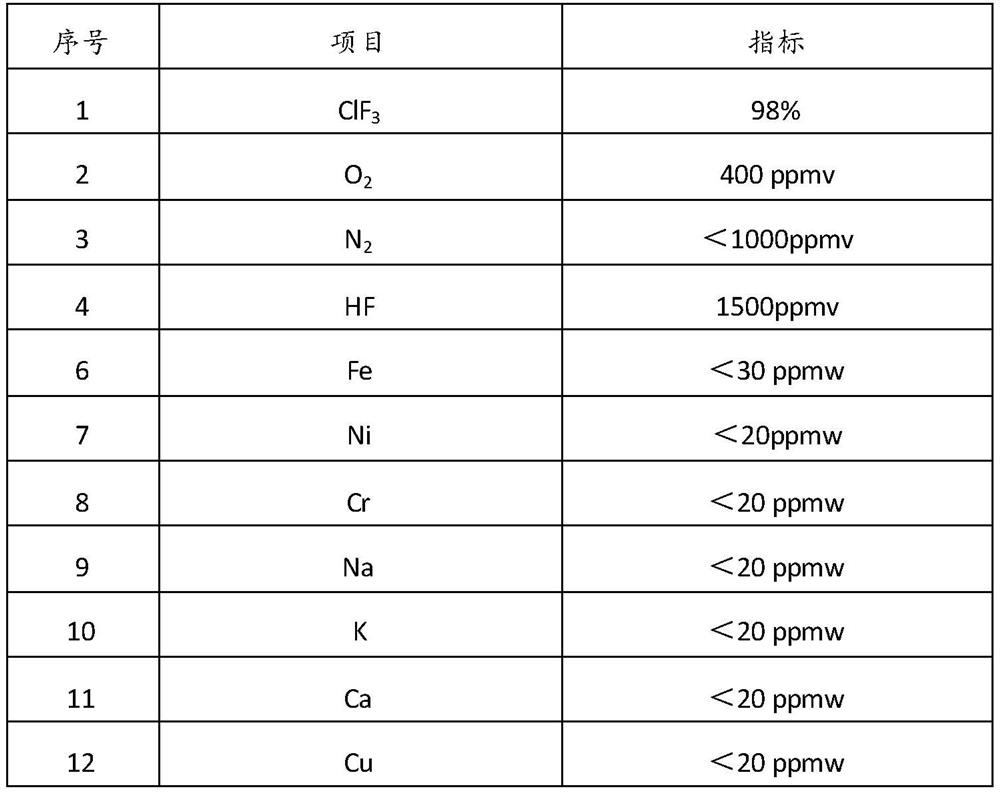

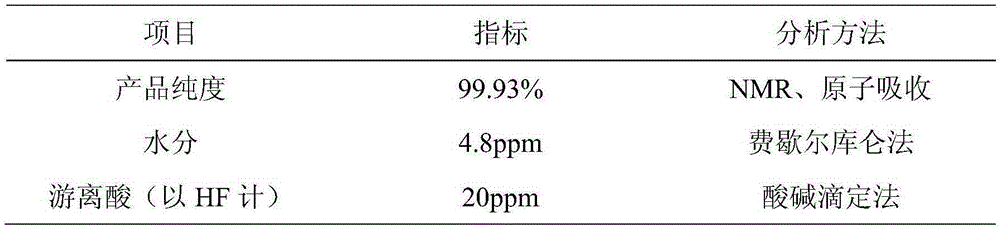

Purification method and purification system of chlorine trifluoride

The invention provides a purification method of chlorine trifluoride, which comprises the following steps: S1) pressurizing and vaporizing a chlorine trifluoride crude product, and adsorbing with an adsorbent to obtain chlorine trifluoride gas without hydrogen fluoride, wherein the adsorbent is fluoride salt, S2) condensing the chlorine trifluoride gas from which hydrogen fluoride is removed to obtain condensed chlorine trifluoride liquid, and S3) carrying out two-stage rectification on the condensed chlorine trifluoride liquid to obtain high-purity chlorine trifluoride. Compared with the prior art, the method has the advantages that adsorption condensation and two-stage rectification are combined, the chlorine trifluoride crude product is firstly subjected to adsorption to remove part ofhydrogen fluoride and then is subjected to two-stage continuous rectification, hydrogen fluoride, oxygen, nitrogen and metal ions can be removed to reach very high purity, and the removal control of metal ion impurities can be further increased, so that the purity of the chlorine trifluoride crude product is improved. The method can be continuously carried out, the operation is stable, and the 3N-purity chlorine trifluoride product used in the semiconductor industry is obtained.

Owner:SUZHOU JINHONG GAS CO LTD

Preparation method of catalyzed synthesis of mesophase pitch

ActiveCN106497591AMild responseMild reaction conditionsWorking-up pitch/asphalt/bitumen by chemical meansControllabilityHeating temperature

The invention relates to a preparation method of catalyzed synthesis of mesophase pitch. The method comprises the steps that catalytic polymerization of purified pitch, a pure aromatic compound and boron trifluoride or boron trifluoride diethyl etherate, the catalyst boron trifluoride etherate or boron trifluoride are added into a low-temperature reaction kettle according to the reaction mass ratio being 1:100-1:200, the heating temperature is 100-260 DEG C, the pressure is controlled to 0.5-2 Mpa to perform a reaction, pyridine is added into a cooled solid phase component, the temperature is increased to 100-150 DEG C, solids generated in the reaction are filtered out, and boron trifluoride is removed to obtain high-purity polymerized pitch; then, further thermal polymerization and micromolecule removal are performed to obtain the mesophase pitch. The reaction controllability is good, the catalyst is good in safety, the pitch can be recycled, and a polytetrafluoroethylene liner and a graphite liner are adopted to obtain the high-quality synthesis mesophase pitch. The problem that a catalyst existing in an existing method of catalytic synthesis of mesophase pitch is large in toxin and hard to remove is solved.

Owner:湖南东映碳材料科技股份有限公司

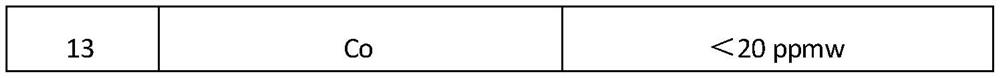

Preparation method of lithium difluoro(oxalato)borate

InactiveCN105399761AEasy to prepareOvercoming reactivityGroup 3/13 element organic compoundsReaction temperatureChemistry

The invention discloses a preparation method of lithium difluoro(oxalato)borate. The method comprises the following steps: adding lithium oxalate and anhydrous HF to a fluorine lining reaction kettle, and fully stirring to make lithium oxalate be fully dissolved in HF; introducing a boron trifluoride gas to the reaction kettle, controlling the flow velocity of boron trifluoride to be 0.5-2L / min, the reaction temperature to be 0-90DEG C, the reaction pressure to be 0-0.5MPa and the molar ratio of boron trifluoride to lithium oxalate to be 2.2-2:1, continuously stirring and reacting for 2-24h after introduction of the boron trifluoride gas is finished, and evaporating and crystallizing the above obtained reaction product o obtain crude lithium difluoro(oxalato)borate; and fast drying, adding an organic solvent, dissolving, filtering, and drying to obtain the lithium difluoro(oxalato)borate product, wherein the organic solvent adopts one or more of esters, ethers, alcohols and nitriles, the use amount of the organic solvent guarantees that lithium tetrafluoroborate can be completely dissolved in the organic solvent, and lithium difluoro(oxalato)borate cannot be completely dissolved in the organic solvent. The method is simple and practical, and can realize large-scale industrial production of lithium difluoro(oxalato)borate.

Owner:CNOOC TIANJIN CHEM RES & DESIGN INST +1

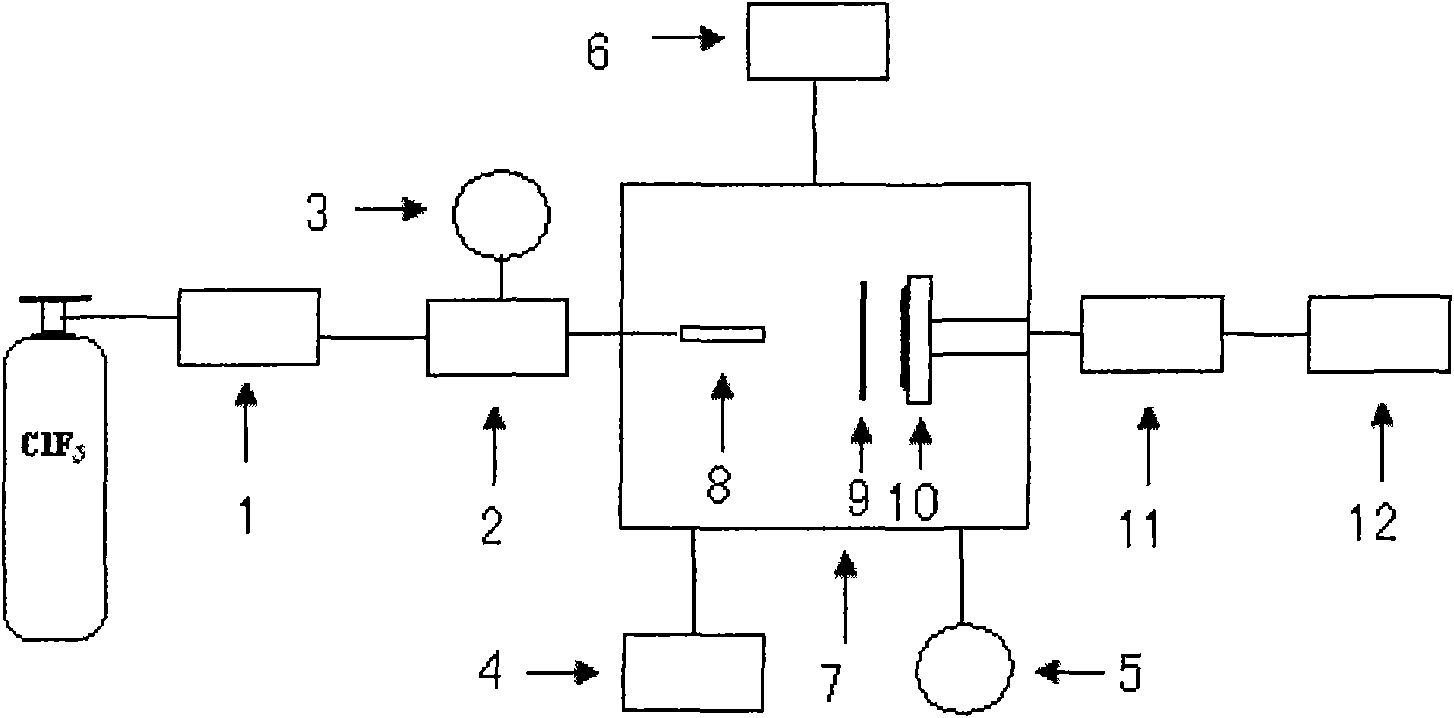

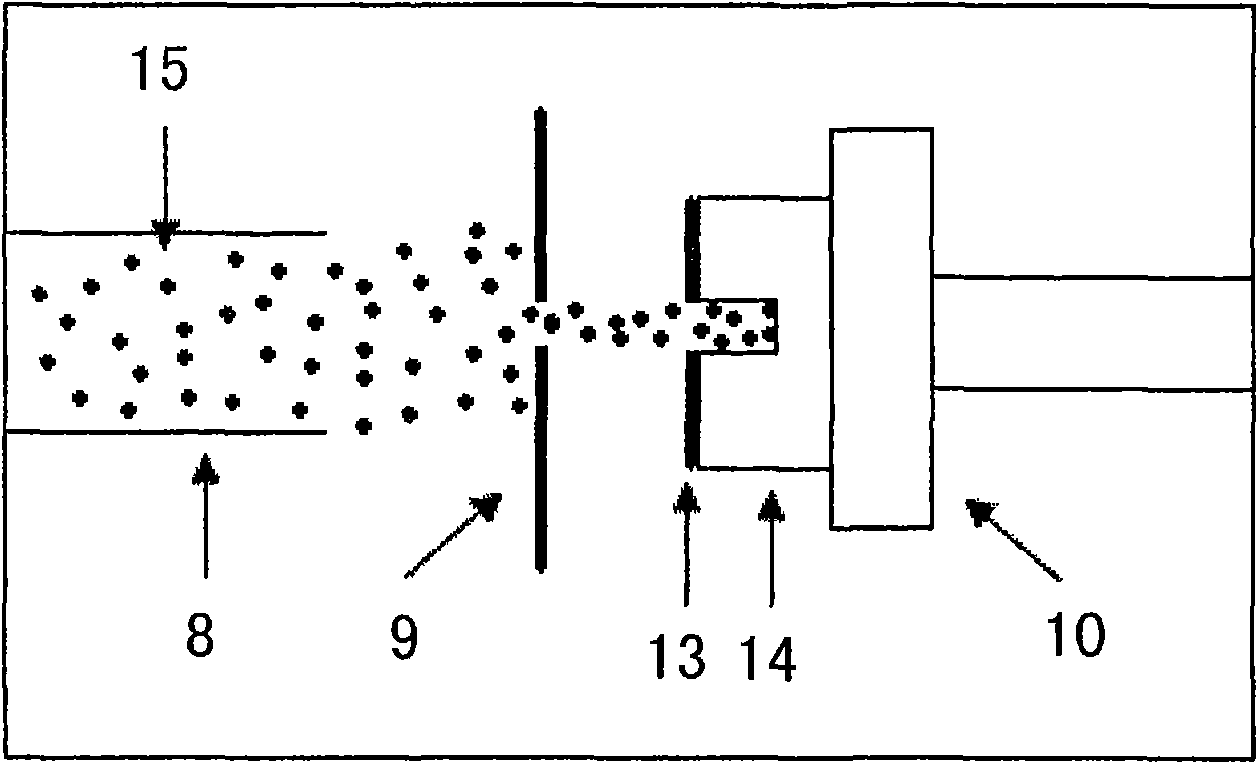

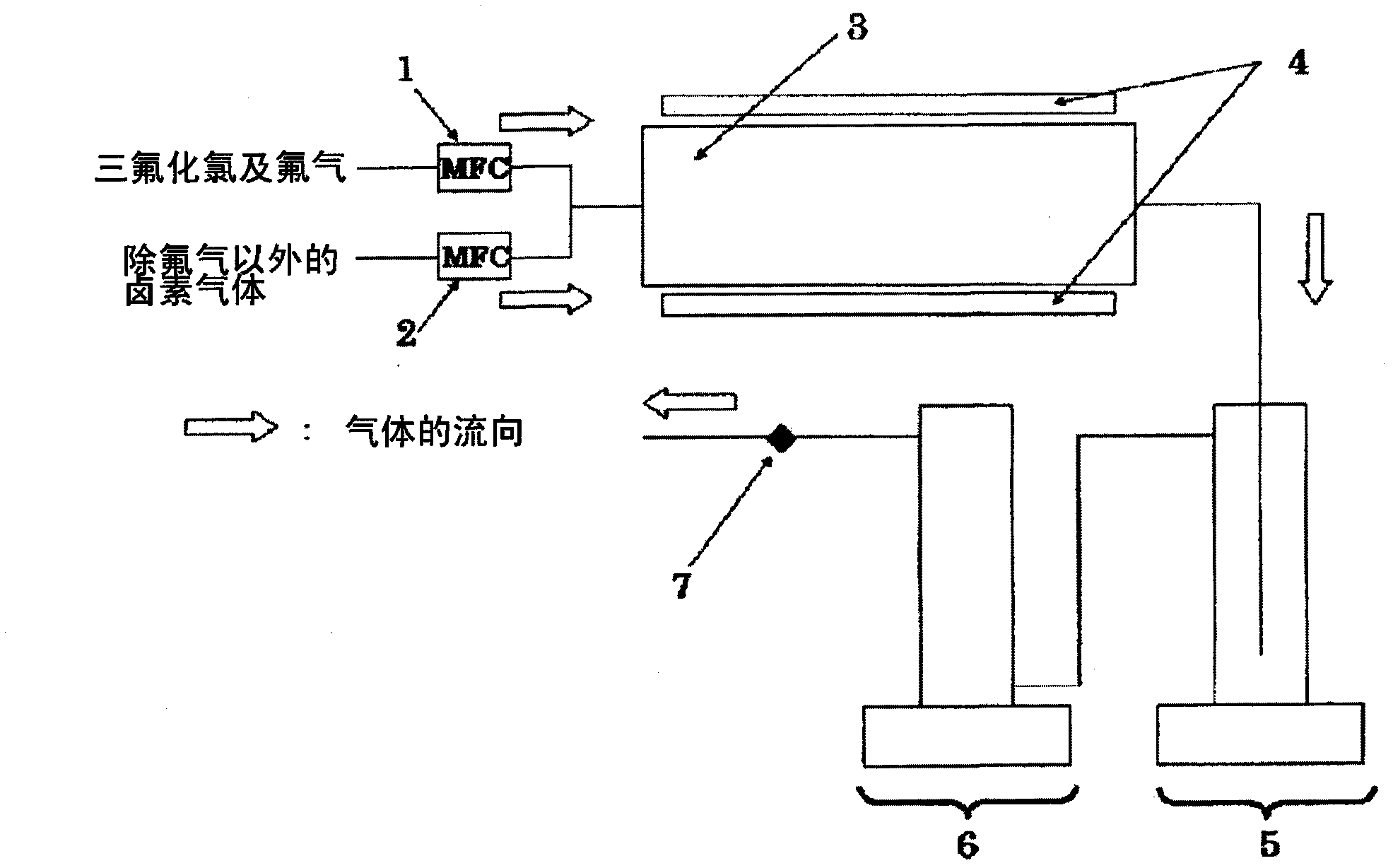

Device for gas linear cutting of silicon slice

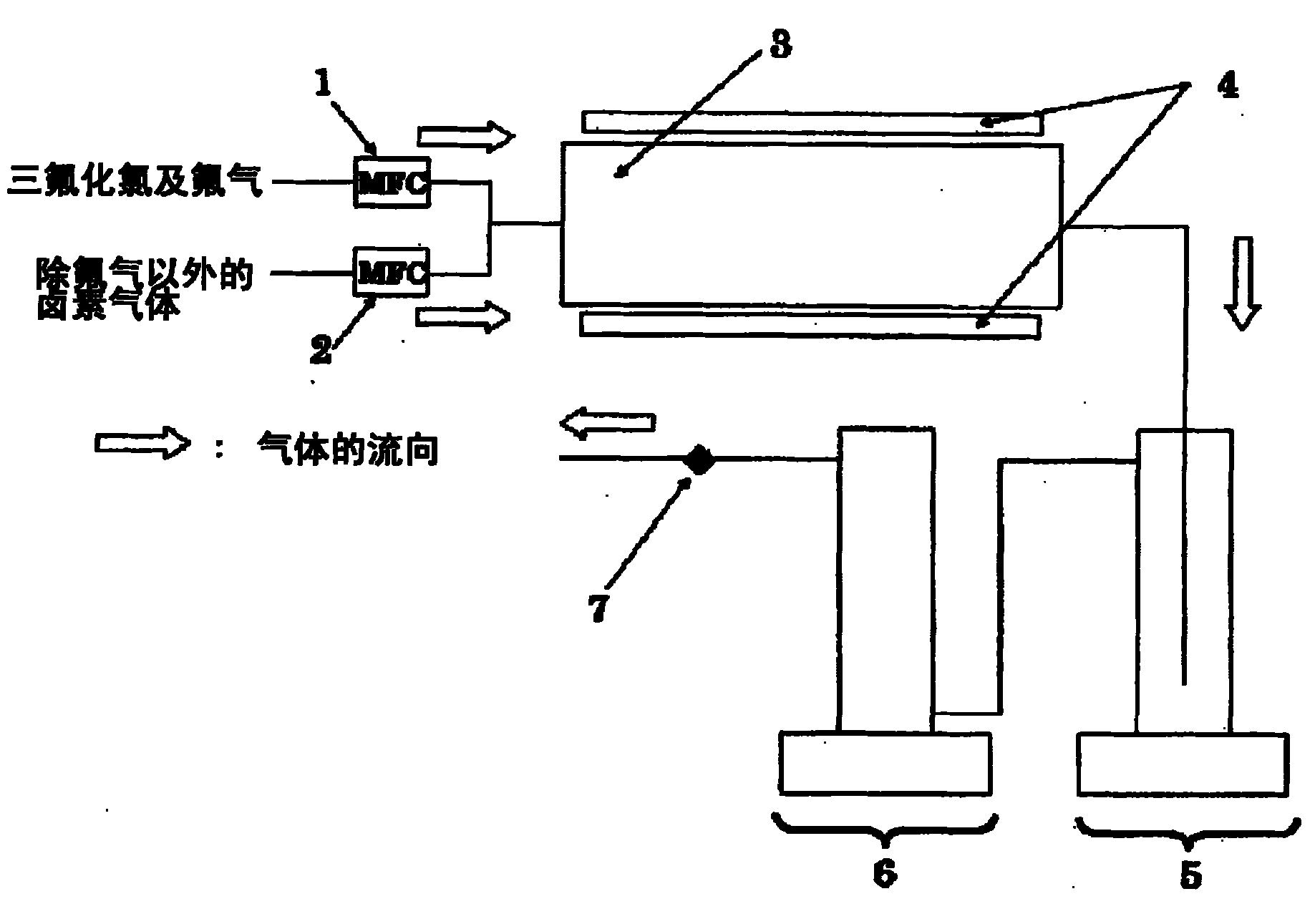

InactiveCN101880878AFast etch rateHigh smoothness of the sectionSemi-permeable membranesSemiconductor/solid-state device manufacturingTemperature controlRoom temperature

The invention discloses a device for the gas linear cutting of a silicon slice, which comprises a flow controller, a pressure reducing valve, a pressure gauge, a vacuum pump, a vacuum-cavity pressure gauge, a vacuum-cavity temperature control device, a vacuum chamber, a spray head, a masking plate, a silicon slice frame, a post pump and a tail gas processing device, wherein the pressure reducing valve, the vacuum pump, the vacuum-cavity pressure gauge, the vacuum-cavity temperature control device and the post pump are respectively connected with the vacuum chamber, gas enters the vacuum chamber after sequentially passing through the flow controller, the pressure reducing valve and the spray head, then the silicon slice on the silicon slice frame is cut through the masking and the beam convergence and regulation of the masking plate, the temperature of the vacuum chamber is controlled to be under a room temperature environment through the vacuum-cavity temperature control device, and etched tail gas is pumped out of the vacuum chamber through the post pump and enters the tail gas processing device through the post pump. In the invention, chlorine trifluoride is used as etching reaction gas for carrying out cutting processing for the silicon slice, and the problems existing in a traditional technology can be well solved.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

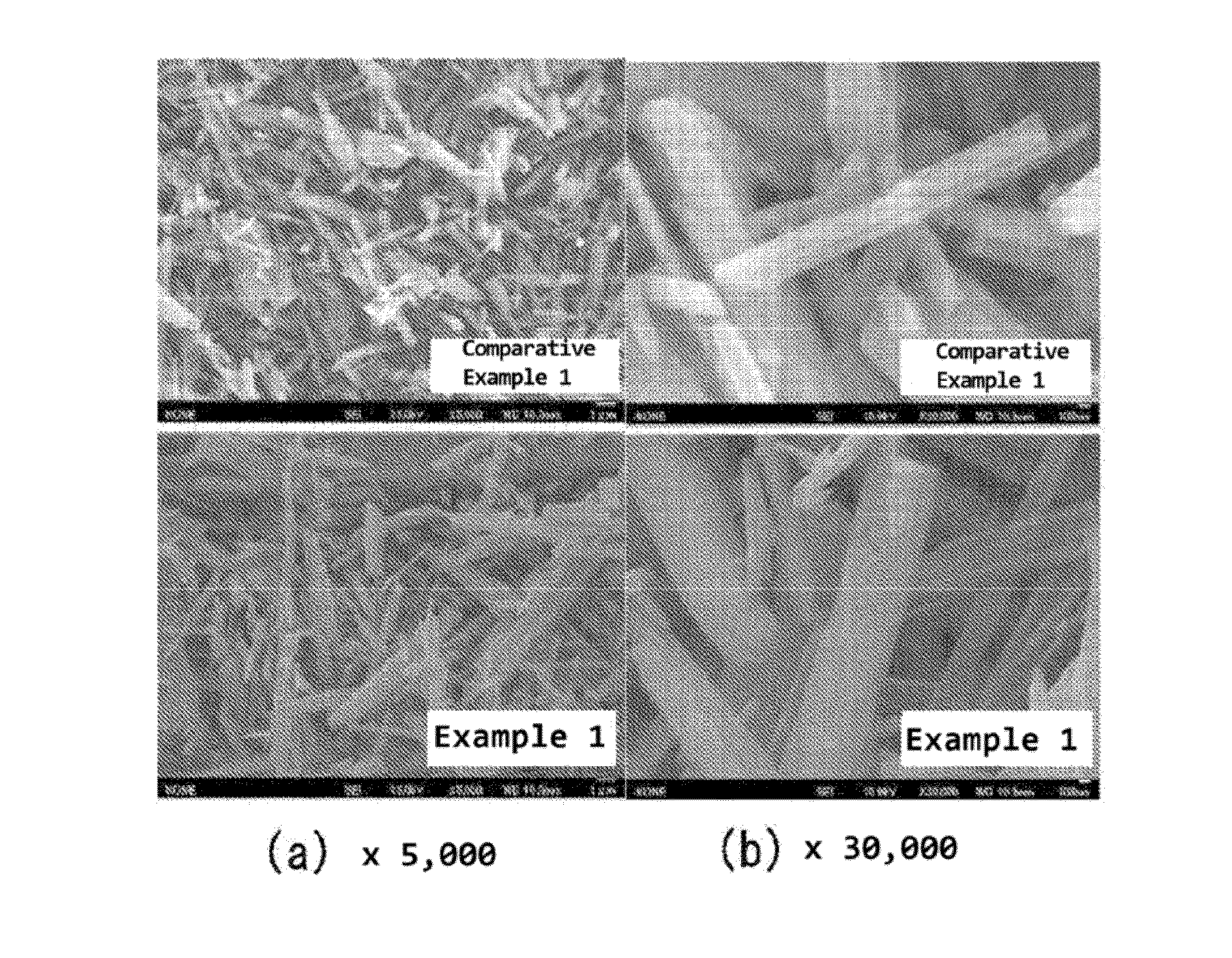

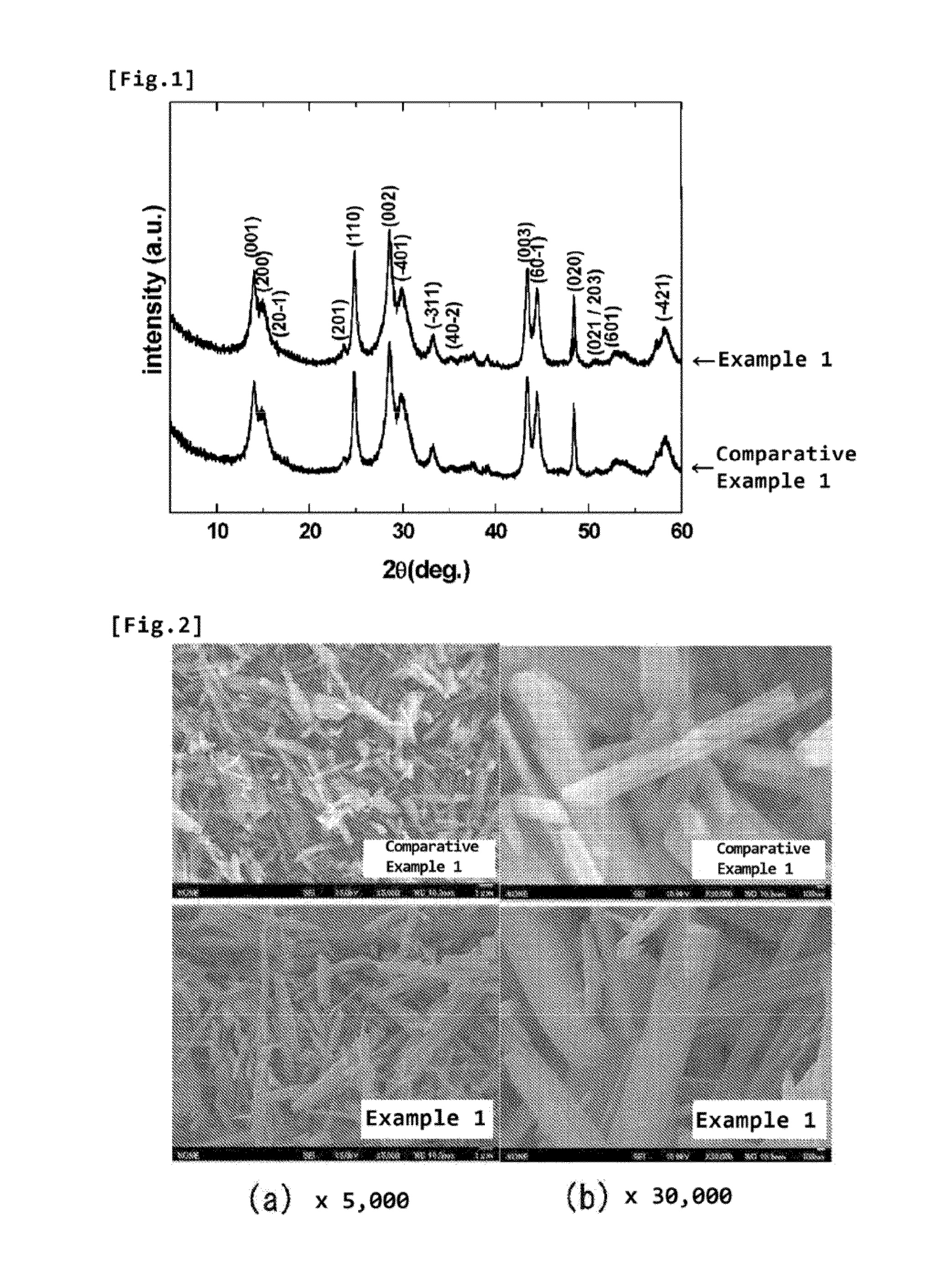

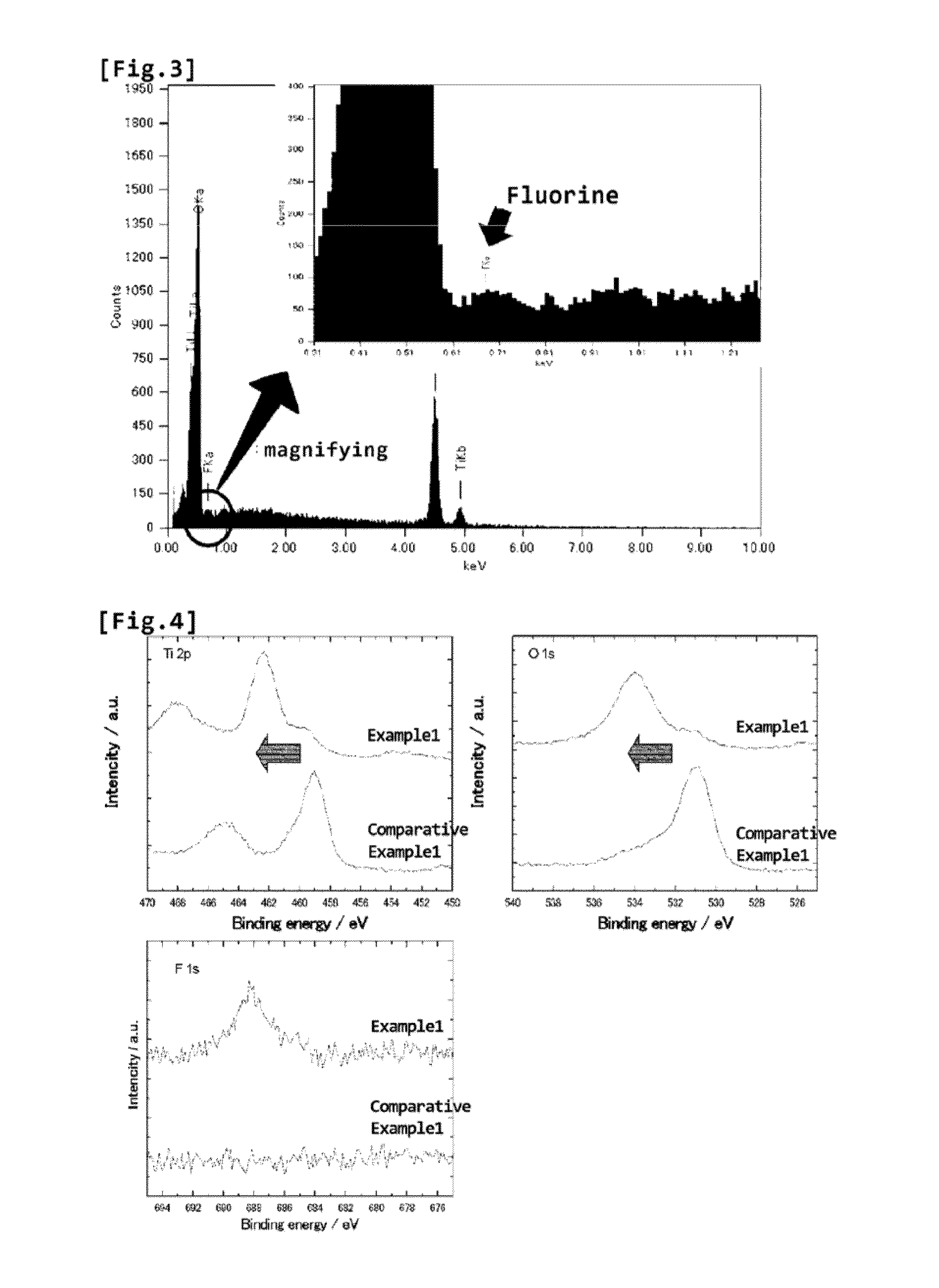

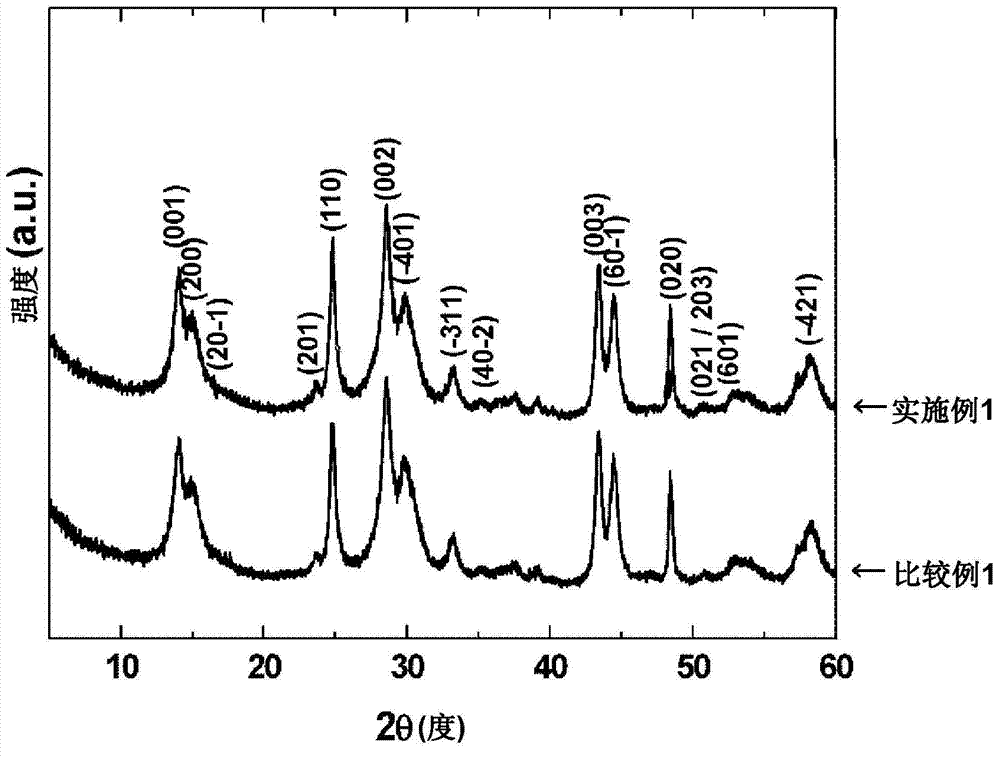

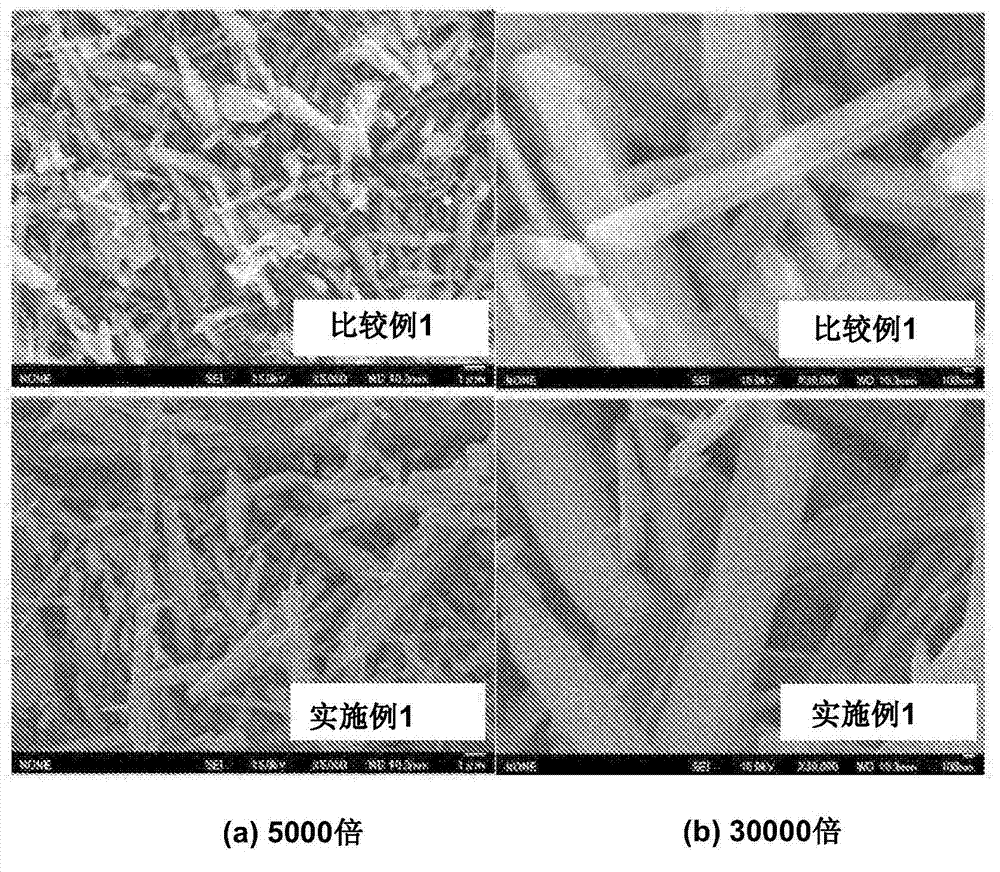

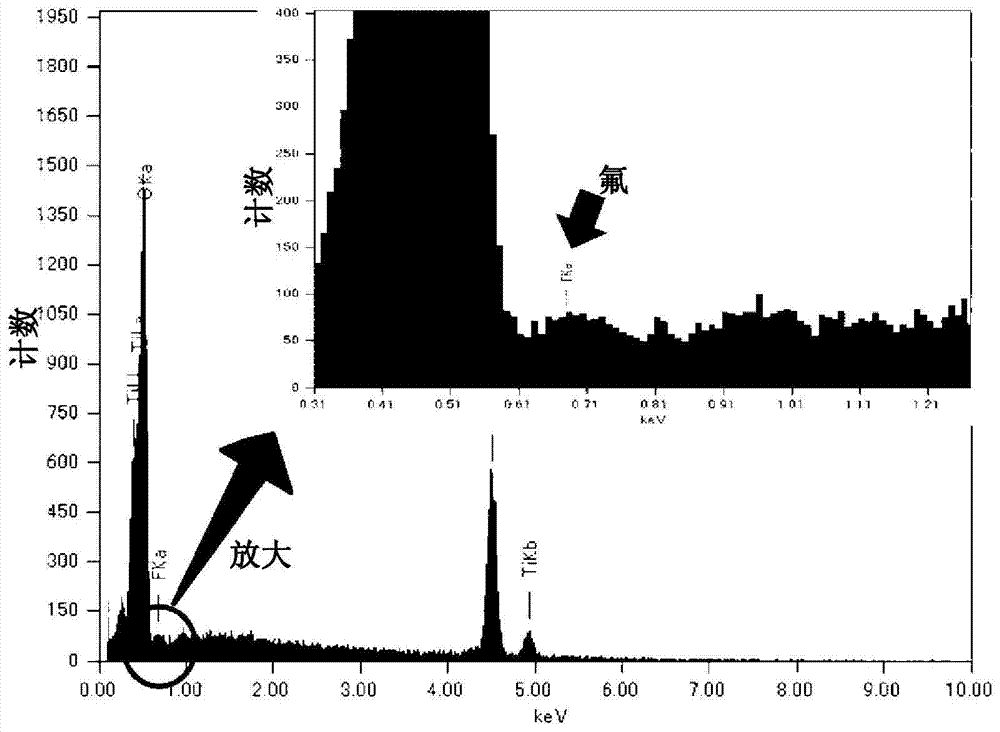

Negative electrode material for lithium ion batteries containing surface-fluorinated b-type titanium oxide powder, method for producing same, and lithium ion battery using same

InactiveUS20140170497A1Improve discharge capacityImprove charging effectNegative electrodesSecondary cellsCompounds of fluorineLithium-ion battery

A problem to be solved is to enhance the charge and discharge characteristics and rate characteristics of a B-type titanium oxide (TiO2(B)) powder by a simple treatment and to provide a B-type titanium oxide powder that can be suitably used as a negative electrode material for a lithium ion battery. A B-type titanium oxide powder is allowed to undergo a reaction under a fluorine-containing gas atmosphere at 0° C. to 200° C. for 1 minute to 10 days to obtain a surface-fluorinated B-type titanium oxide powder. It is preferred that the fluorination treatment is performed at 0.01 atm to 2 atm. It is preferred that a gas containing a fluorine compound selected from a fluorine (F2) gas, a nitrogen trifluoride (NF3) gas, a perfluorotrimethylamine (N(CF3)3) gas, a chlorine trifluoride (ClF3) gas and the like is used as the fluorine-containing gas.

Owner:DOSHISHA CO LTD +1

Device and method for producing chlorine trifluoride and system for etching semiconductor substrates using this device

InactiveUS8382940B2Avoid hoardingElectric discharge tubesDecorative surface effectsHigh densityGas supply

A device (6) and a method for generating chlorine trifluoride is described, a high-density plasma (105) being generated in the interior of a plasma reactor (100) using plasma generating means (110, 120, 130, 150, 155, 160, 170, 180), and a first gas and a second gas, which react with one another under the influence of the high-density plasma (105) in the plasma reactor (100) under the formation of chlorine trifluoride, being supplied to the plasma reactor (100) via gas supply means (21, 22, 25, 26). In addition, a gas outlet (20) is provided, via which the generated chlorine trifluoride can be removed from the plasma reactor (100). Finally, a system (5) for etching semiconductor substrates (30), silicon wafers in particular, is described including such an upstream device (6), the system (5) having a process chamber (10) which is connected to the plasma reactor (100) via the gas outlet (20), and the semiconductor substrate (30) being situated in the process chamber (10) and exposed to the gaseous chlorine trifluoride generated by the device (6).

Owner:ROBERT BOSCH GMBH

Detoxifying method of chlorine trifluoride

ActiveCN102143793AFluorine reductionGas treatmentDispersed particle separationHalogenBoron trifluoride

The invention discloses a detoxifying method which is a method for eliminating unwanted substances from a mixed gas composed of at least chlorine trifluoride and fluorine with a wet scrubber. As a pre-treatment step for the elimination of unwanted substances with the wet scrubber, the method involves a step of adding a halogen gas (X2) (wherein X represents Cl, Br or I) to the mixed gas to cause the reaction between fluorine contained in the mixed gas with the halogen gas (X2) (wherein X represents Cl, Br or I), thereby reducing the content of fluorine in the mixed gas and preventing the generation of perchloryl fluoride (ClO3F) in the wet scrubber.

Owner:CENT GLASS CO LTD

Low temperature preparation method of boron trifluoride dimethyl carbonate complex compound

InactiveCN103044474AReduce reaction energy consumptionLow reaction temperatureGroup 3/13 element organic compoundsRaw materialCrystal

The invention belongs to a chemical engineering product, a boron trifluoride dimethyl carbonate complex compound, in particular relates to a low temperature preparation method of the boron trifluoride dimethyl carbonate complex compound. The preparation method comprises the following steps: in a gas generating container, using boric acid and anhydrous hydrofluoric acid as raw materials, dehydrating and generating boron trifluoride gas, and sulfur trioxide is used as an dehydrating agent; in a purification container, purifying the boron trifluoride gas generated through concentrated sulphuric acid; in a complexing container, performing a complexing reaction of the purified boron trifluoride gas and the dimethyl carbonate; and in a filter, cooling down and crystallizing the liquid reactant of the complexing reaction, and the solid gathered is the boron trifluoride dimethyl carbonate complex compound. The technical scheme provided by the invention enables the temperature of the gas generating reaction and complexing reaction to be close to the room temperature, decreases energy consumption during production process and is low-carbon and environment friendly; the production process is safer and more controllable; and the boron trifluoride dimethyl carbonate complex compound is a solid white crystal, wherein the content of boron trifluoride is 40-43 percent in weight and the property of the boron trifluoride is stable.

Owner:SHANDONG HEYI GAS CO LTD DONGYING CITY +1

Negative electrode material for lithium ion batteries containing surface-fluorinated b-type titanium oxide powder, method for producing same, and lithium ion battery using same

InactiveCN103782421AImprove discharge capacityNegative electrodesSecondary cellsSodium-ion batteryCompounds of fluorine

The present invention addresses the problem of providing a B-type titanium oxide (TiO2(B)) powder which can be suitable for use as a negative electrode material for lithium ion batteries by improving the charge and discharge characteristics and the rate characteristics of the B-type titanium oxide powder by a simple treatment. A surface-fluorinated B-type titanium oxide powder is obtained by reacting a B-type titanium oxide powder in a fluorine-containing gas atmosphere at 0-200 DEG C for 1 minute to 10 days. The fluorination treatment is preferably carried out at 0.01-2 atm. It is preferable to use, as the fluorine-containing gas, a gas that contains a fluorine compound, said gas being selected from among a fluorine (F2) gas, a nitrogen trifluoride (NF3) gas, a perfluorotrimethylamine (N(CF3)3) gas, a chlorine trifluoride (ClF3) gas and the like.

Owner:DOSHISHA CO LTD +1

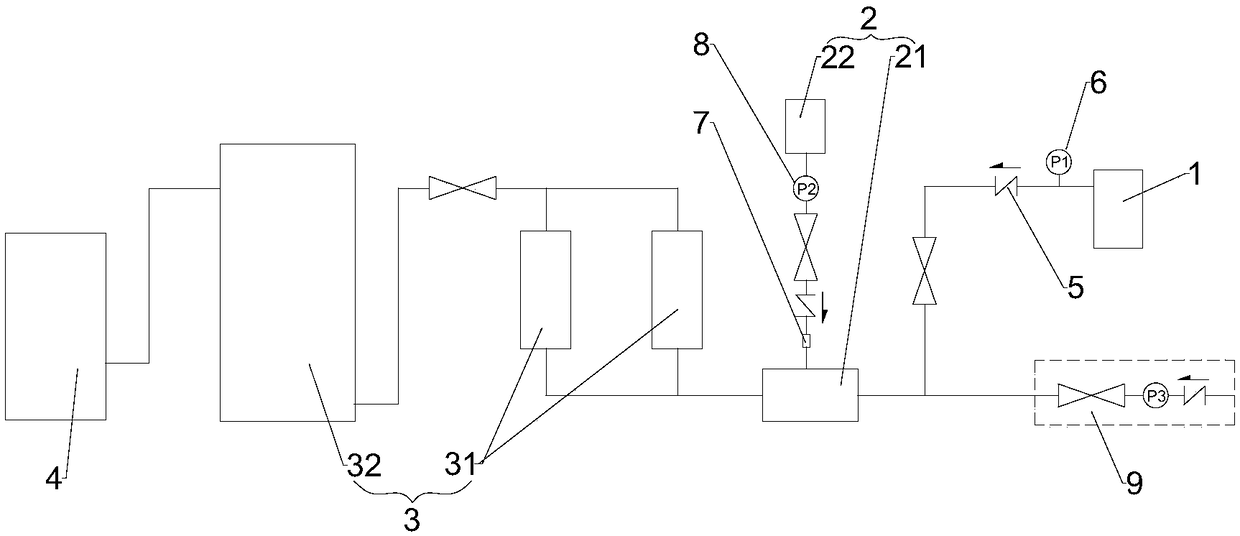

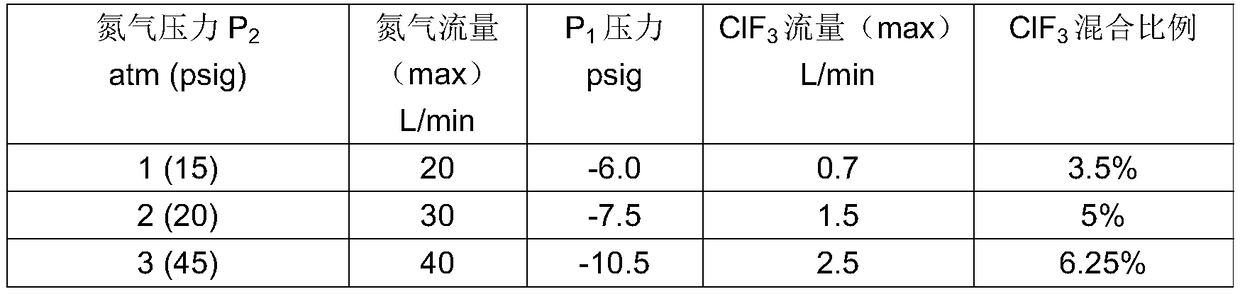

Feeding process of chlorine fluoride

ActiveUS20190055124A1Keep for a long timeShorten the timeHollow article cleaningSolid-state devicesGas cylinderEthyl Chloride

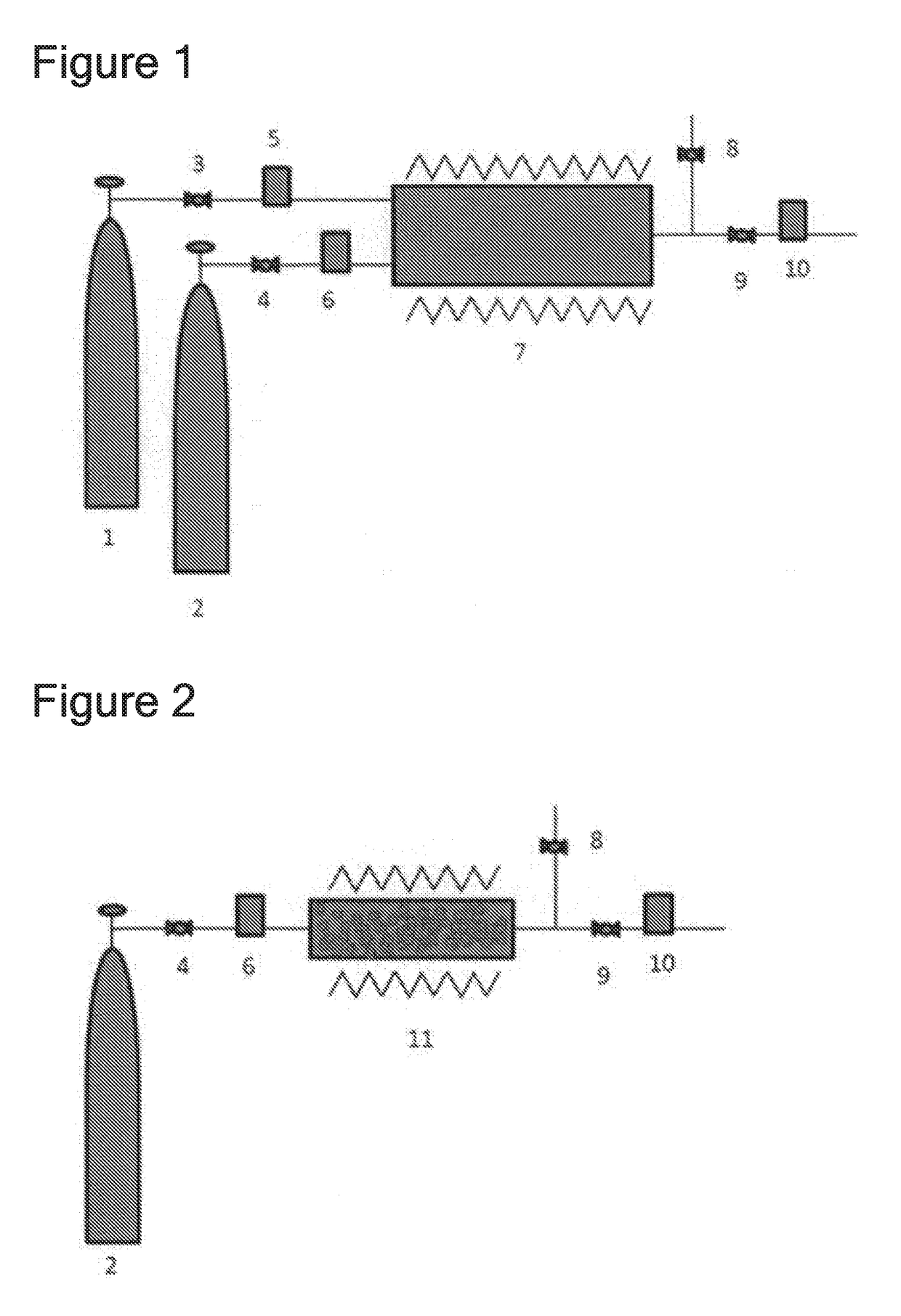

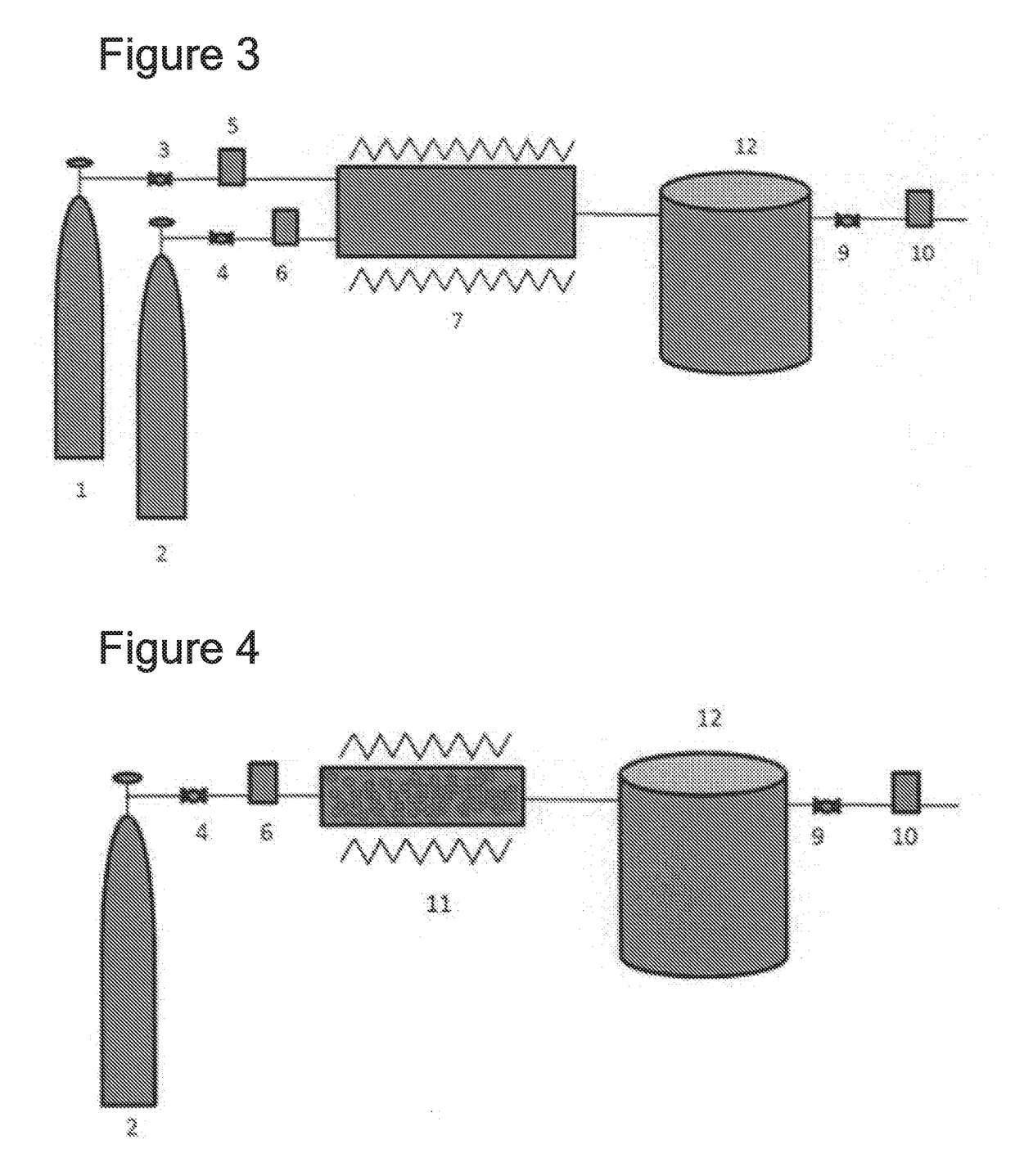

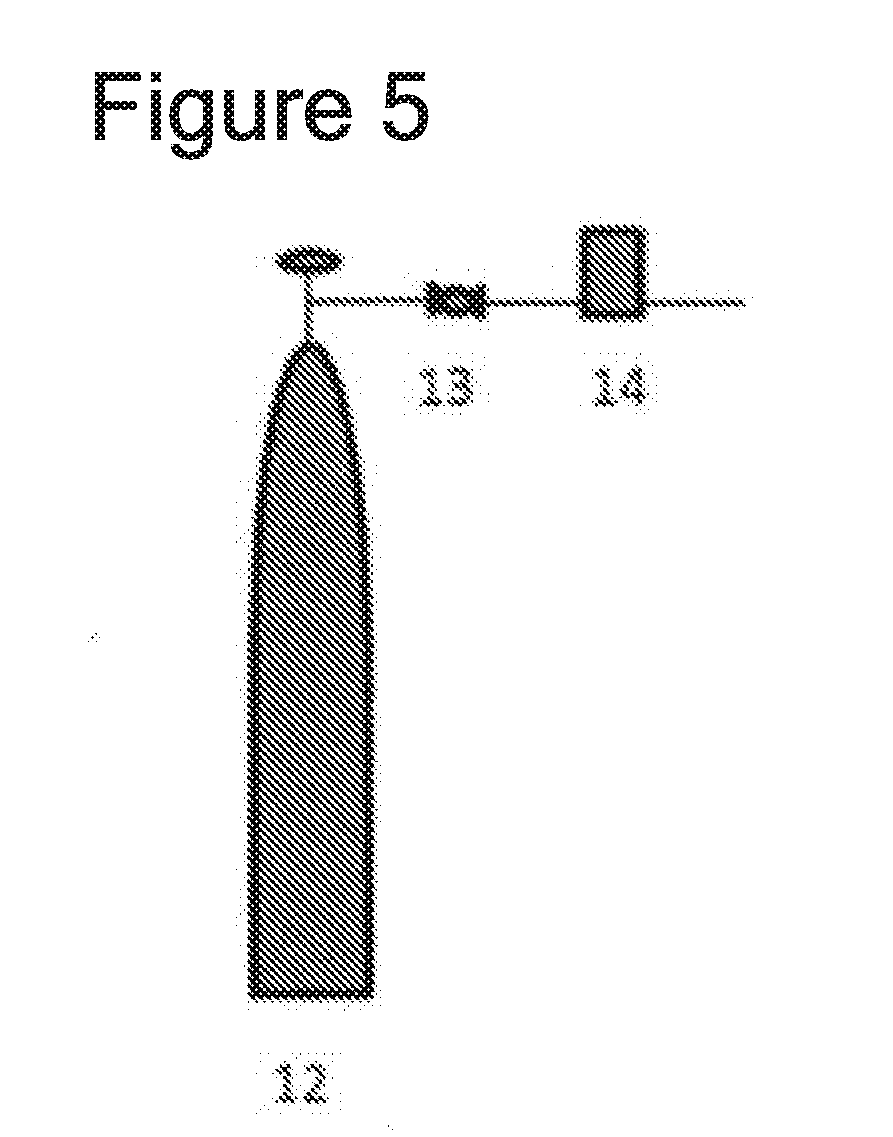

A chlorine fluoride feeding device and feeding process are provided that can stably generate industrially applicable chlorine fluoride (ClF), control flow rate, and provide continual feed.The feeding process of chlorine fluoride of this invention is a feeding process to feed chlorine fluoride generated by loading a gas that contains fluorine atoms and a gas that contains chlorine atoms to a flow-type heat reactor or a plasma reactor, and it can stably generate and safely feed chlorine fluoride for a long time by reacting chlorine fluoride that is difficult to pack at a high pressure, such that an amount that can be packed in a gas container such as a gas cylinder is limited, with two or more types of gas materials that can be packed safely in a gas container by liquefaction, or with such gas material and a solid material.

Owner:KANTO DENKA IND CO LTD

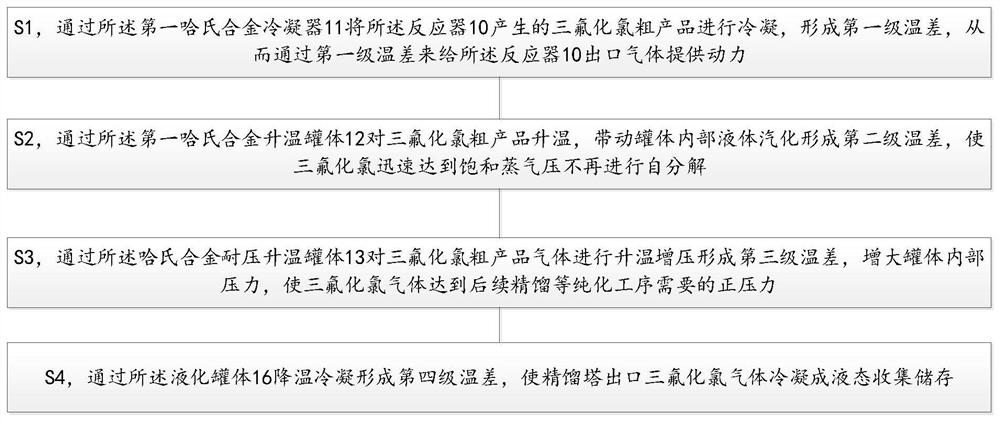

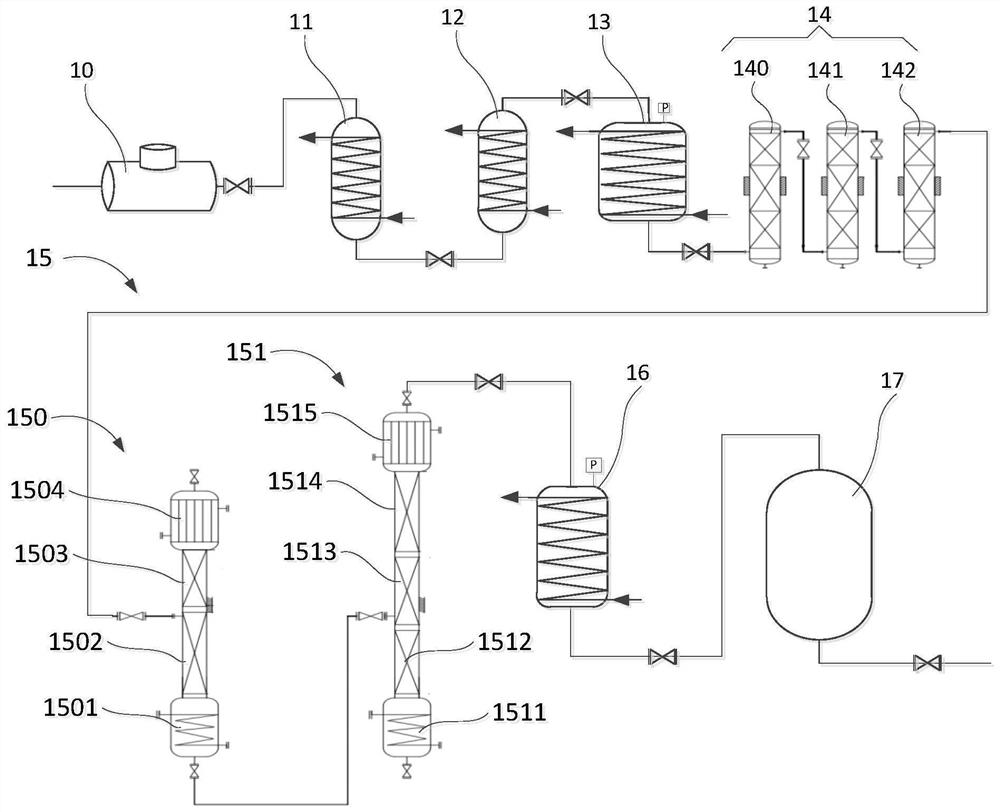

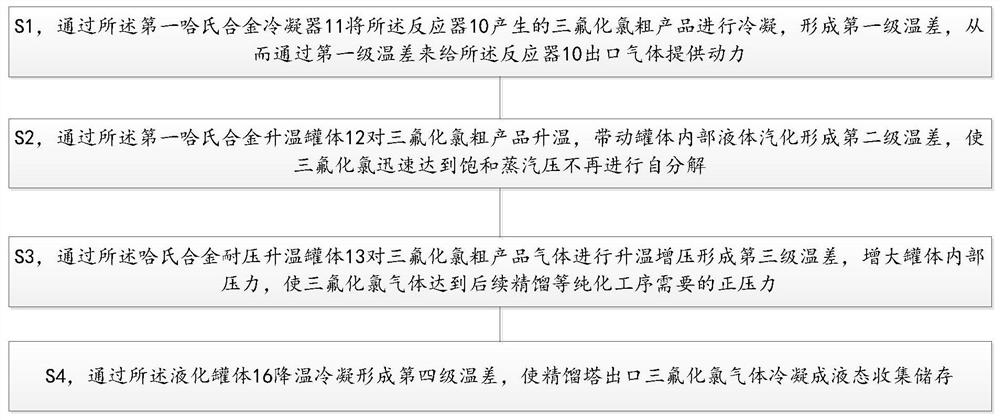

Electronic grade chlorine trifluoride purification system and temperature difference power control method thereof

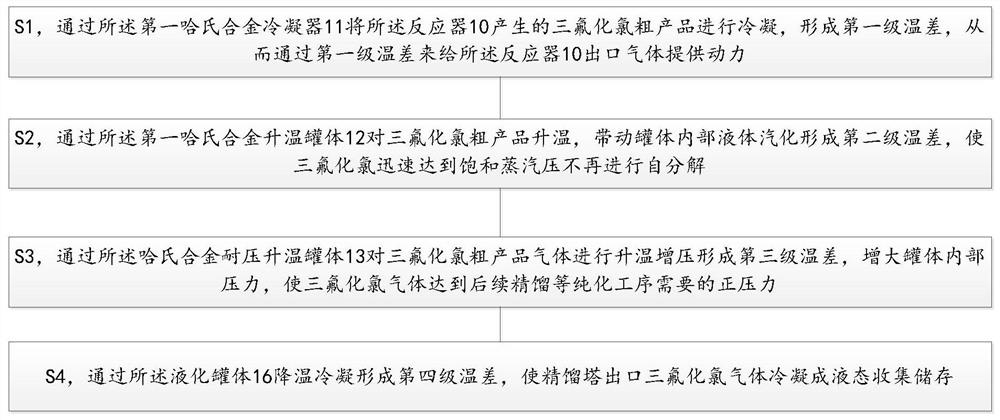

InactiveCN112875648ASolve power problemsWon't cause entryInter-halogen compoundsThermodynamicsPressure stabilization

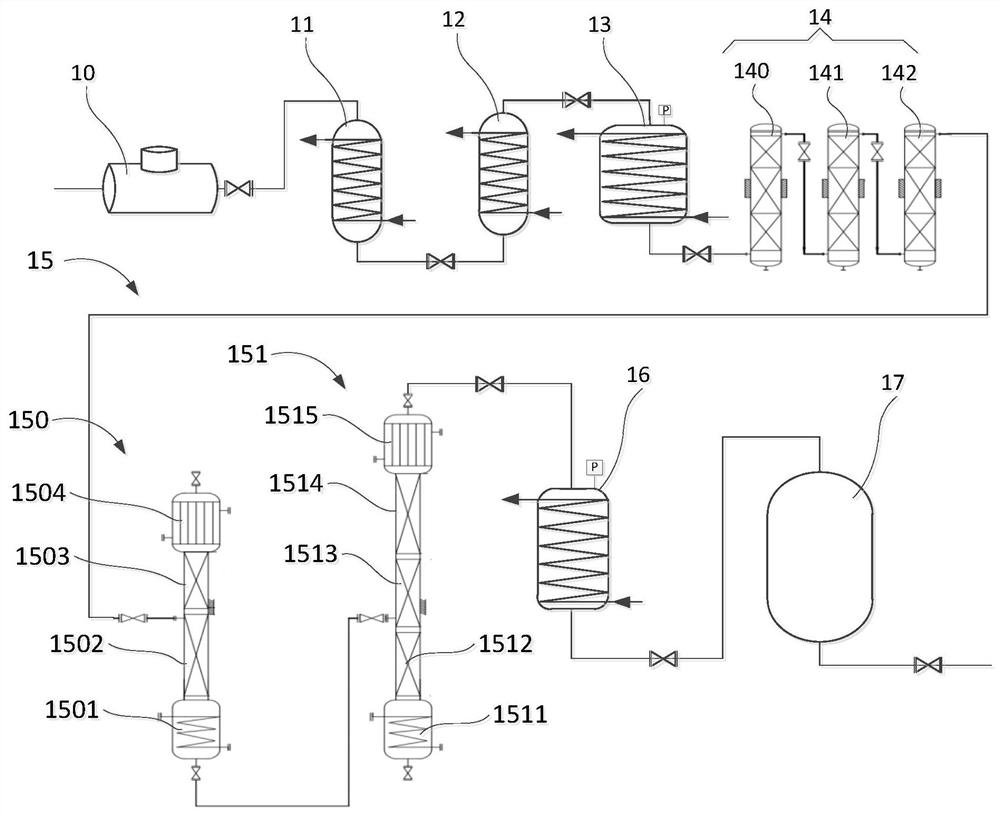

The invention provides an electronic grade chlorine trifluoride purification system and a temperature difference power control method. The purification system comprises a first hastelloy condenser, a first hastelloy heating tank body, a hastelloy pressure-resistant heating tank body, a three-stage metal adsorbent layer bed, a two-stage low-temperature rectification device, a liquefaction tank body and a pressure stabilization tank body which are connected in sequence, wherein the feeding end of the first hastelloy condenser is arranged at the top end of the first hastelloy condenser and is communicated with the reactor, and the discharging end of the first hastelloy condenser is arranged at the bottom end of the first hastelloy condenser and is connected with the feeding end of the first hastelloy heating tank body; and the first hastelloy condenser is used for condensing a chlorine trifluoride crude product generated by the reactor, so that power is provided for gas at an outlet of the reactor through temperature difference.

Owner:FUJIAN DEER TECH CORP

High-concentration chlorine trifluoride tail gas treatment device and treatment method

InactiveCN109012092AReduce processingDry handling of handling avoidsGas treatmentDispersed particle separationHigh concentrationNitrogen source

The invention discloses a high-concentration chlorine trichloride tail gas treatment device which comprises a dilution system, a dry treatment system and a spray system which are sequentially connected. The dilution system comprises a venturi vacuum generator and a nitrogen source. The venturi vacuum generator is provided with an adsorption chamber inlet and a compressed gas inlet, the adsorptionchamber inlet is connected with an exhaust gas source, a one-way check valve is arranged between the adsorption chamber inlet and the exhaust gas source; the compressed gas inlet is connected with thenitrogen source; the dry treatment system includes a pretreatment device and a main treatment device, the gas inlet end of the pretreatment device is connected to the gas outlet end of the venturi vacuum generator, and the gas intake end of the main treatment device is connected to the outlet end of the pretreatment device, and the pretreatment device and the main treatment device have the same structure, both includes a casing, and the casing is filled with an alkaline reactant. The invention also discloses a high-concentration chlorine trichloride tail gas treatment method, and the high-concentration chlorine trichloride tail gas treatment method has the advantages of prevention of backflow and high safety of completion of chlorine trifluoride gas absorption treatment after gradient dilution and reaction.

Owner:QUANJIAO NANDA PHOTOELECTRIC MATERIAL

Preparation method of chlorine trifluoride

PendingCN113562700AImprove securityLower activation energyInter-halogen compoundsChemical synthesisPtru catalyst

The invention provides a preparation method of chlorine trifluoride, and relates to the technical field of chemical synthesis. The preparation method of chlorine trifluoride comprises the steps of carrying out primary condensation, secondary condensation, alkali metal adsorption and filtration on fluorine-containing mixed gas generated by electrolysis to obtain purified fluorine gas; adding the purified fluorine gas and high-purity chlorine gas into a reactor containing a catalyst, and reacting to obtain a chlorine trifluoride crude product; and carrying out liquefaction, vaporization, adsorption and rectification on the chlorine trifluoride crude product to obtain high-purity chlorine trifluoride. According to the preparation method disclosed by the invention, high-purity chlorine trifluoride can be prepared.

Owner:鹤壁德瑞科技有限公司

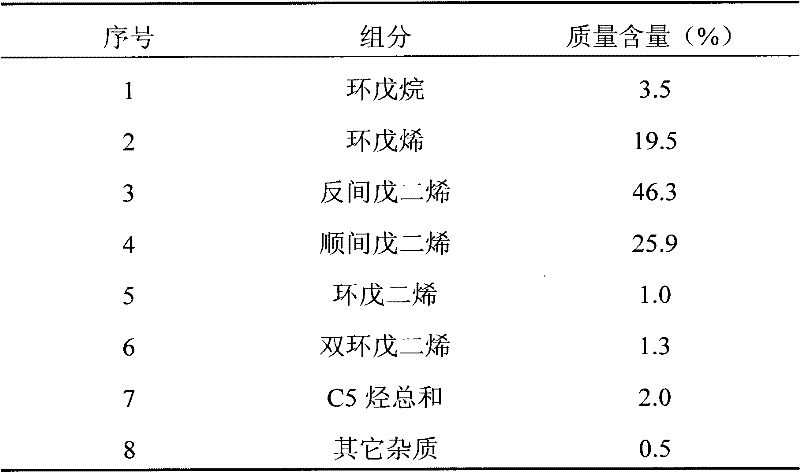

Preparation method for pentadiene petroleum resin

The invention relates to a preparation method for pentadiene petroleum resin. The method comprises the following step of: synthesizing pentadiene petroleum resin by taking a pentadiene concentrate as a raw material and taking a boron trifluoride complex as a catalyst, wherein the catalyst consists of boron trifluoride and a complexing agent; the complexing agent consists of C1-C10 alcohol and benzene alkyl ether C6H5-OR; in the formula, R is methyl, ethyl or butyl; the molar ratio of the C1-C10 alcohol to the benzene alkyl ether is 2-8; the molar ratio of the boron triflouride to the complexing agent is 0.5-0.8; and a preparation method for the boron triflouride complex serving as the catalyst comprises the following steps of: adding the C1-C10 alcohol and the benzene alkyl ether into a reactor; cooling the materials in the reactor to 0 DEG C to 30 DEG C below zero while stirring; introducing boron triflouride gas into a container within 2-6 hours; and controlling the reaction temperature at -15+ / -5 DEG C. The color phase (Fe-Co) of the pentadiene petroleum resin produced with the method is less than or equal to 5, and the softening point is 89 DEG C.

Owner:PETROCHINA CO LTD

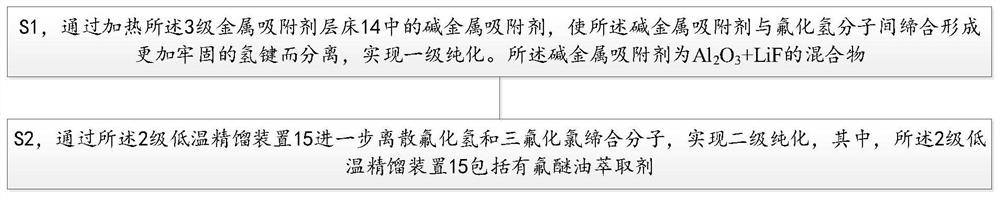

Separation device and separation method of electronic-grade chlorine trifluoride

ActiveCN114538381AEffective discreteRealize separation and purificationDistillation regulation/controlChemical industryHydrogen fluoridePhysical chemistry

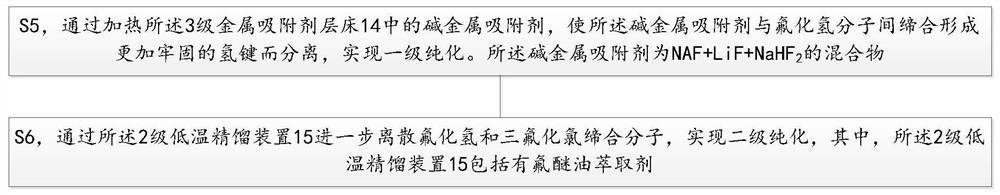

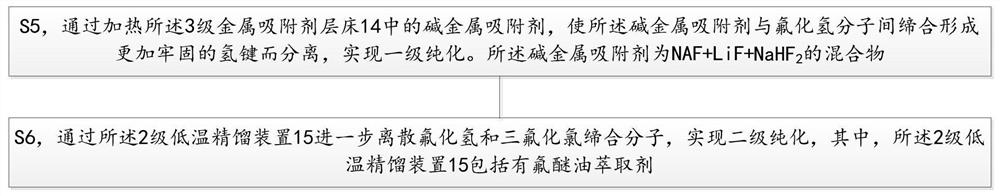

The invention provides a separation device and a separation method of electronic-grade chlorine trifluoride. The separation method comprises the following steps: S1, heating an alkali metal adsorbent in the three-stage metal adsorbent layer bed, so that the alkali metal adsorbent and hydrogen fluoride molecules are associated to form a firmer hydrogen bond for separation, and primary purification is realized; and S2, further dispersing associated molecules of hydrogen fluoride and chlorine trifluoride through the second-stage low-temperature rectification device to realize second-stage purification.

Owner:FUJIAN DEER TECH CORP

Method for treating inner surface of chlorine trifluoride supply path in device using chlorine trifluoride

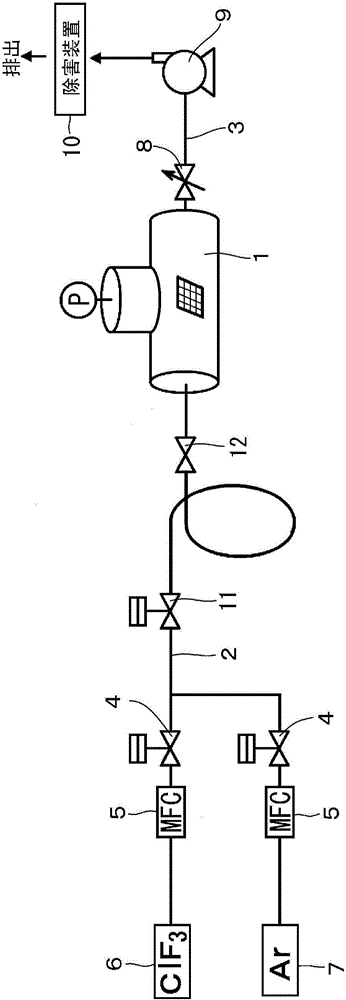

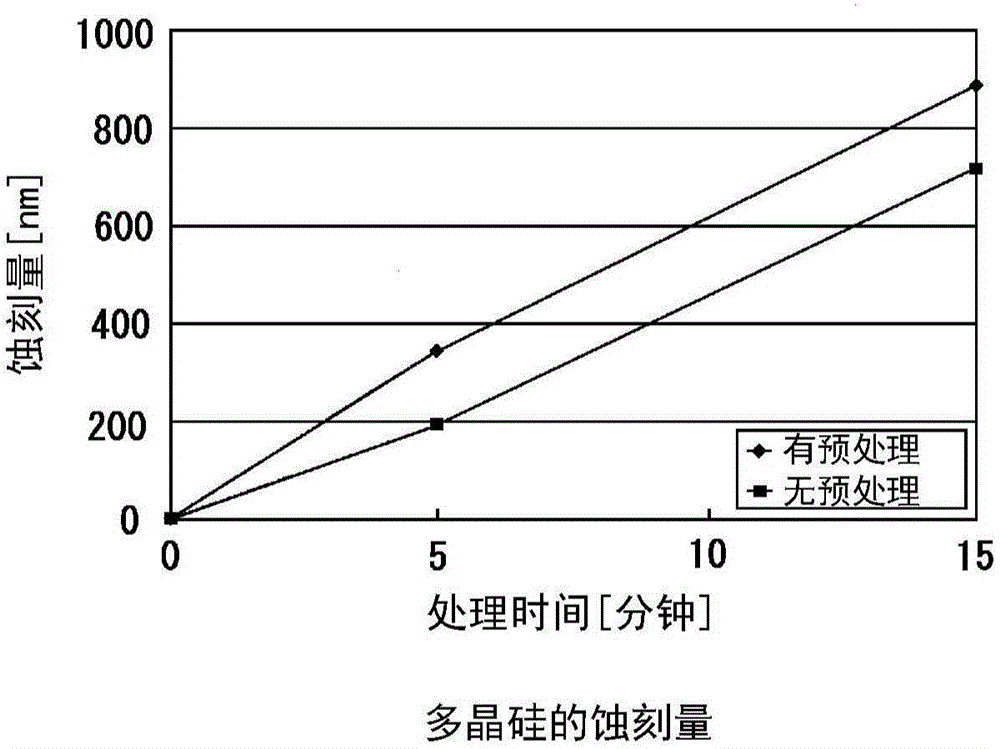

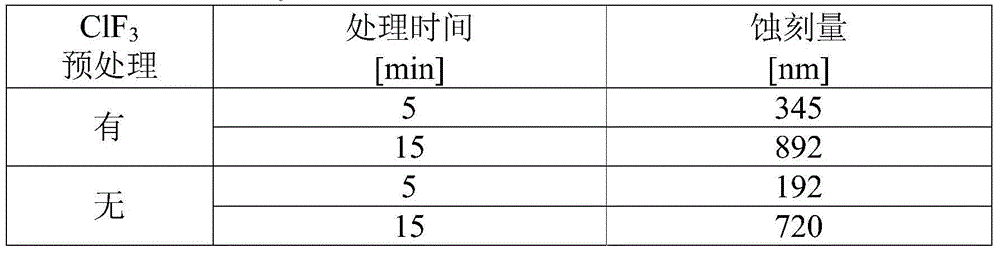

ActiveCN104040699AReduce concentrationForm evenlySemiconductor/solid-state device manufacturingChemical vapor deposition coatingBromine trifluorideFluoride

Provided is a method for treating the inner surface of a chlorine trifluoride supply path that enables reliable suppression of drops in the concentration of ClF3 in a reaction chamber during treatment work. A gas supply path (2) and a gas discharge path (3) are integrally connected to a treatment chamber (1) of a treatment device in which chlorine trifluoride is used as an etching gas. Chlorine trifluoride gas with a concentration equal to or greater than the concentration of the chlorine trifluoride gas supplied during etching treatment operation is allowed to act on the inner surfaces of at least the treatment chamber (1) and the gas supply path (2) from among the treatment chamber (1), the gas supply path (2), and the gas discharge path (3), thus coating the inner surfaces of at least the treatment chamber (1) and the gas supply path (2) with a fluoride film.

Owner:IWATANI CORP

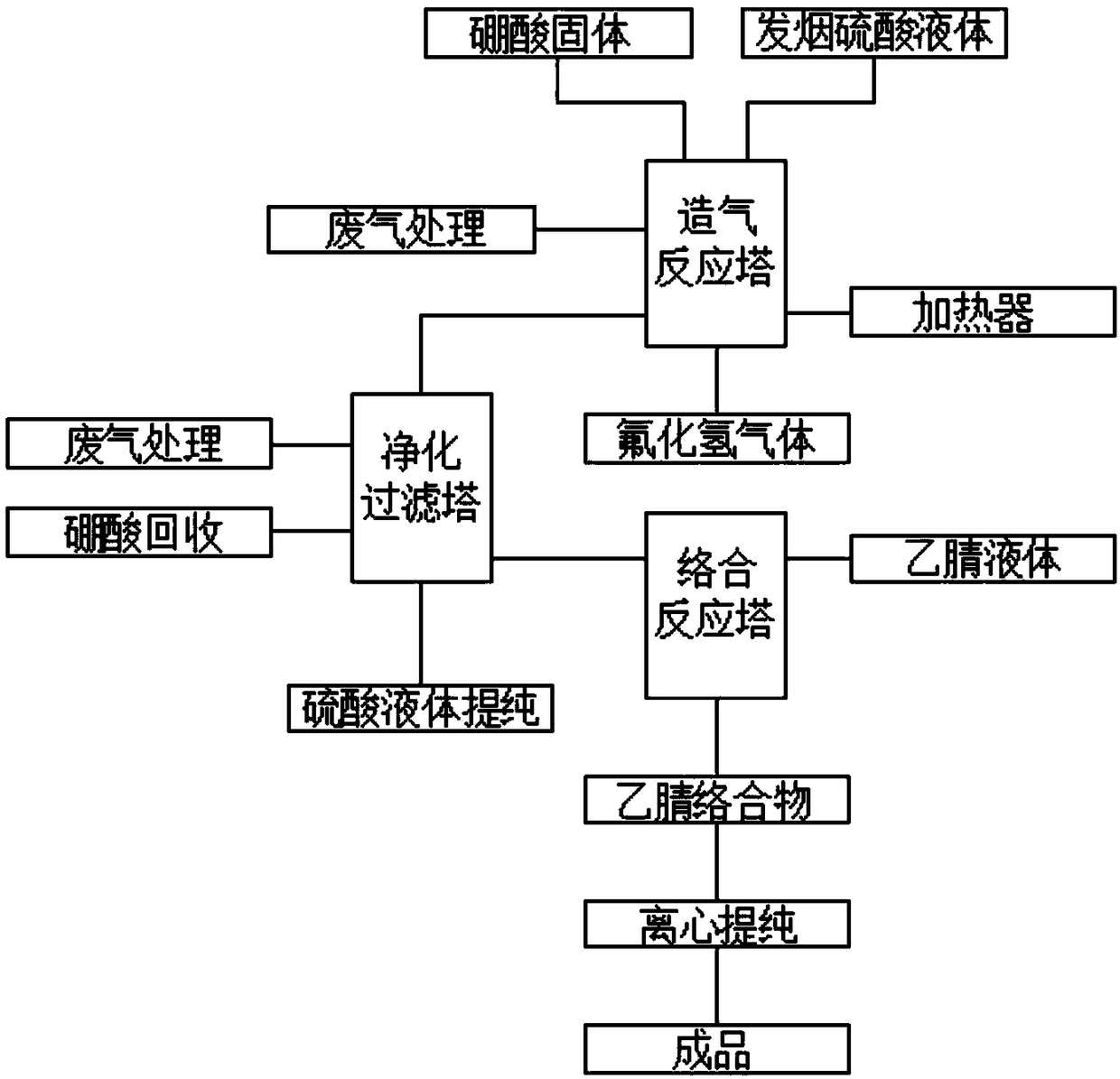

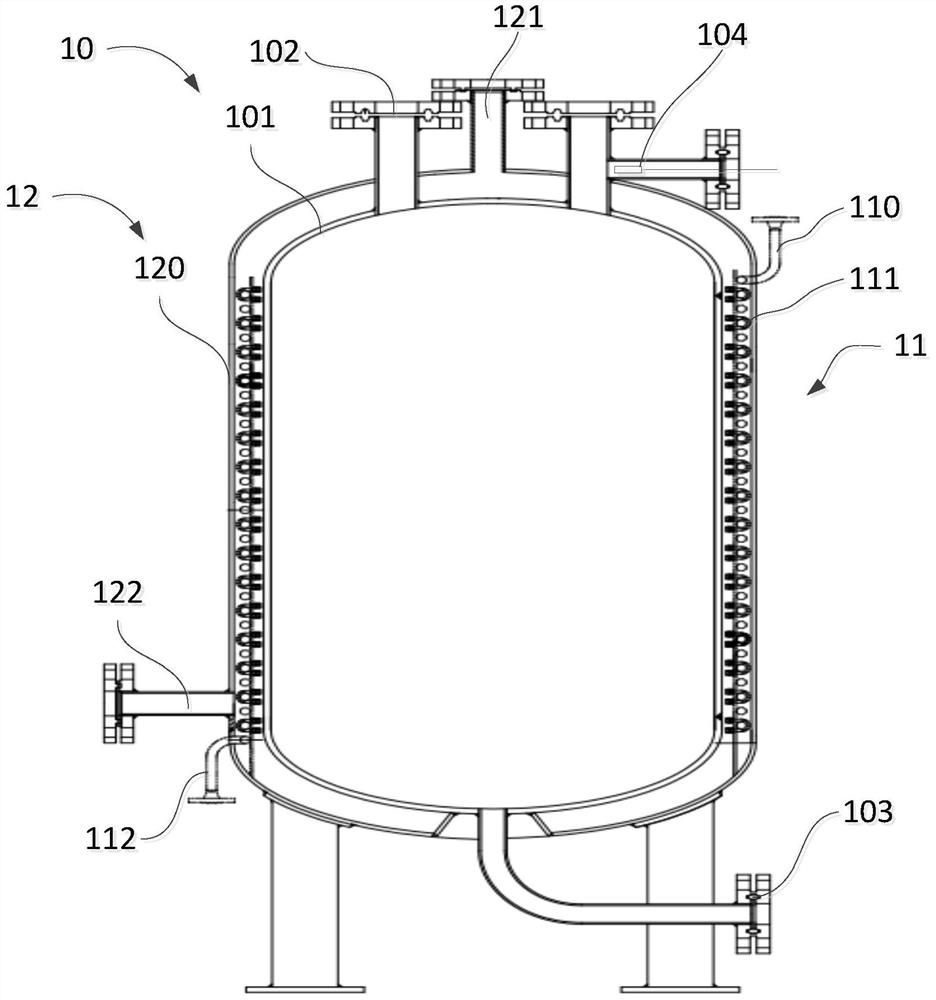

Production technological method for boron trifluoride acetonitrile complex solid mixture

InactiveCN108864163AIncrease productionAdd process stepsGroup 3/13 element organic compoundsEnvironmental resistancePollution

The invention belongs to the field of chemical technologies, and particularly relates to a production technological method for a boron trifluoride acetonitrile complex solid mixture. The method aims at solving the problems that the existing production process flow is relatively simple, the yield of finished products is relatively small, the resource waste is easily caused, in addition, the waste gas treatment link and the solid recovery link do not exist in the production process, the pollution to the environment is caused, the environmental protection purpose is not achieved, and the like. According to the method, boric acid solid and fuming sulfuric acid liquid are uniformly mixed, a gas-making reaction tower is preheated for 10 minutes through a heater, the temperature is controlled tobe within 200-300 DEG C, mixed acid of the boric acid solid and the fuming sulfuric acid liquid is added into the gas-making reaction tower from the top, and meanwhile, hydrogen fluoride gas is compressed and then is added into the gas making reaction tower from the bottom. The method has the advantages that the yield of the finished products is increased, the resource waste is avoided, the wastegas treatment link and the solid recovery link are increased, the pollution to the environment is avoided, and the environmental protection purpose is achieved.

Owner:珠海市格特生物科技有限公司

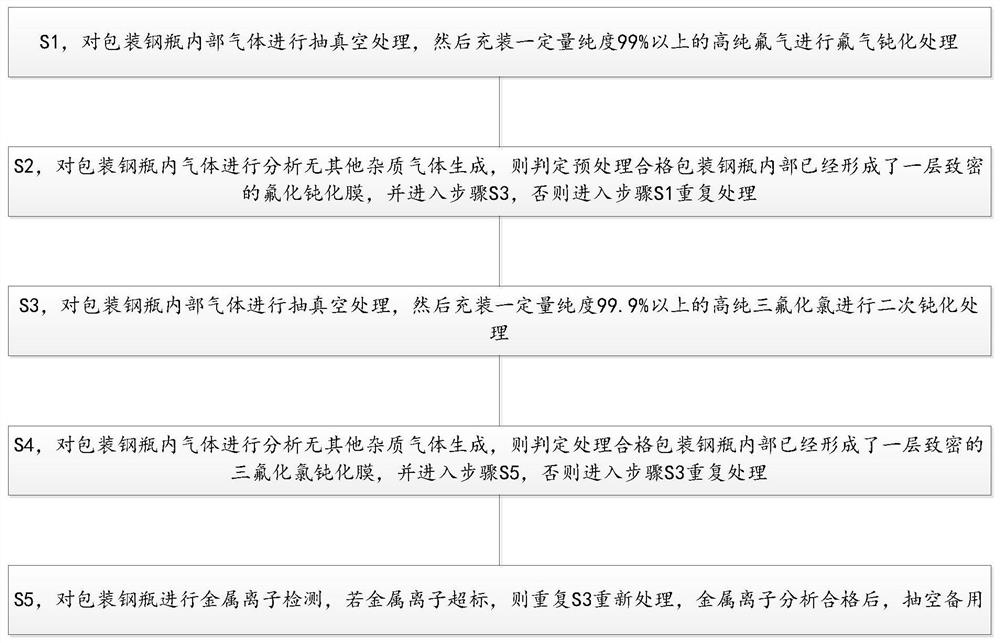

Processing method of electronic-grade chlorine trifluoride packaging steel cylinder

ActiveCN113005389AReduce leak rateUnderstand integritySolid state diffusion coatingPumping vacuumImpurity

The invention provides a processing method of an electronic-grade chlorine trifluoride packaging steel cylinder. The method comprises the following steps of S1, vacuumizing a gas in the packaging steel cylinder, and then filling a certain amount of high-purity fluorine gas with the purity of 99% or above for fluorine gas passivation treatment; S2, analyzing the gas in the packaging steel cylinder, if no other impurity gas is generated, entering S3, and otherwise, entering the S1 for repeated treatment; S3, vacuumizing the gas in the packaging steel cylinder, and then filling a certain amount of high-purity chlorine trifluoride with the purity of 99.9% or above for secondary passivation treatment; S4, analyzing the gas in the packaging steel cylinder, if no other impurity gas is generated, judging that a layer of compact chlorine trifluoride passivation film is formed in the qualified packaging steel cylinder, entering S5, and otherwise, entering the S3 for repeated treatment; S5, conducting metal ion detection on the packaging steel cylinder, if metal ions exceed the standard, repeating the S3 for retreatment, and after the metal ions are analyzed to be qualified, conducting evacuation for standby application.

Owner:FUJIAN DEER TECH CORP

Production method of high purity silver tetrafluoroborate

InactiveUS8501138B2High purityPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesBoron halidesHydrofluoric acidSilver tetrafluoroborate

A production method of high purity silver tetrafluoroborate, capable of producing silver tetrafluoroborate (AgBF4) at purity higher than the conventional, without using an organic solvent. The production method of the present invention is characterized in that the method comprises the step of: reacting silver fluoride with boron trifluoride in the presence of anhydrous hydrofluoric acid. Boron trifluoride is delivered into a solution obtained by dissolving or suspending silver fluoride in an anhydrous hydrofluoric acid solution.

Owner:STELLA CHEMIFA CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com