Electronic-grade chlorine trifluoride rectification purification system control method

A chlorine trifluoride, electronic-grade technology is applied in the control field of the rectification and purification system of electronic-grade chlorine trifluoride, which can solve the problems of not using an efficient extraction agent, application, and inability to meet actual needs, and improve the reflux ratio. The effect of parameter stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A rectification device for electronic grade chlorine trifluoride, comprising: a two-stage low-temperature rectification device, the two-stage low-temperature rectification device includes a low-boiling tower and a high-boiling tower, and the two-stage low-temperature rectification device is equipped with An extractant that associates molecules of discrete hydrogen fluoride and chlorine trifluoride to meet electronic grade chlorine trifluoride requirements. The low boiling column includes a first reboiler, a first low boiling column packing section, a second low boiling column packing section and a first condenser from bottom to top. The high boiling column includes a second reboiler, a first high boiling column packing section, a second high boiling column packing section, a third high boiling column packing section and a second condenser from bottom to top. An extraction agent is provided in each packing section for further separating the associated molecules of hydrog...

Embodiment 2

[0045] The present invention further provides the rectification method of the rectification device of above-mentioned electronic grade chlorine trifluoride, this rectification device comprises the technical feature in embodiment 1, and this method comprises the following steps:

[0046] S1, controlling the temperature of the second tray at the upper end of the first reboiler to be 10-12°C, and controlling the temperature of the second tray at the lower end of the first condenser to be -22.5-24°C;

[0047] S2, controlling the temperature at the upper end of the second reboiler to be 11-12°C, and controlling the temperature at the lower end of the second condenser to be -6--4°C.

Embodiment 3

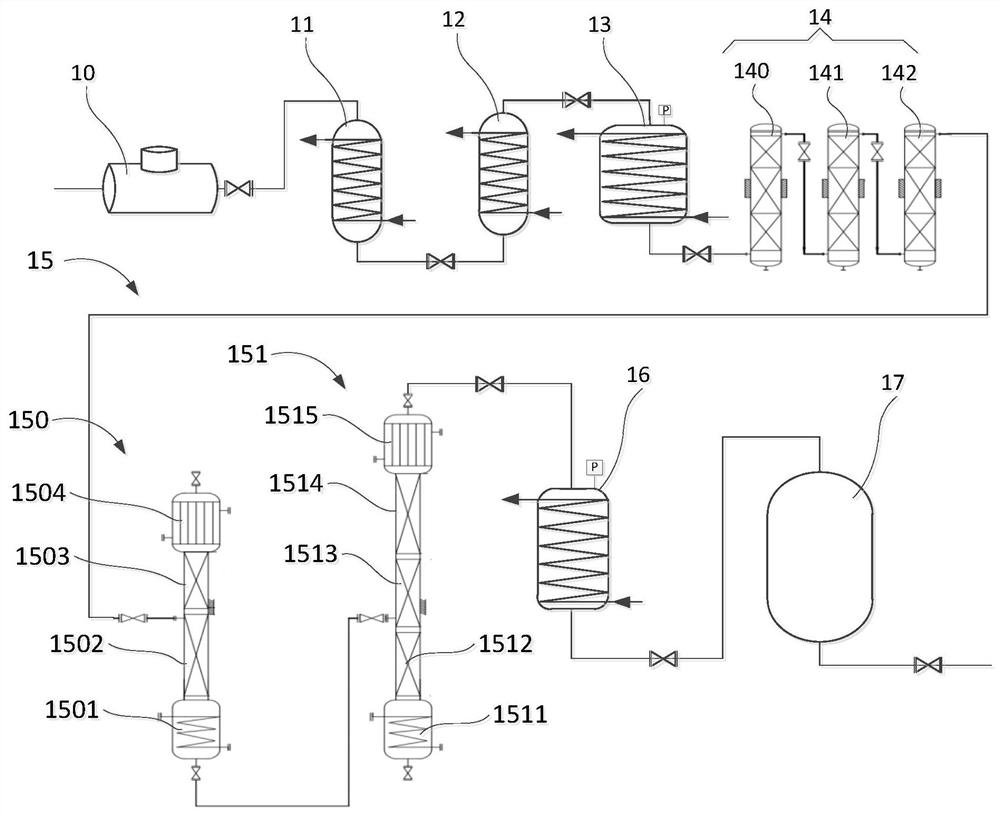

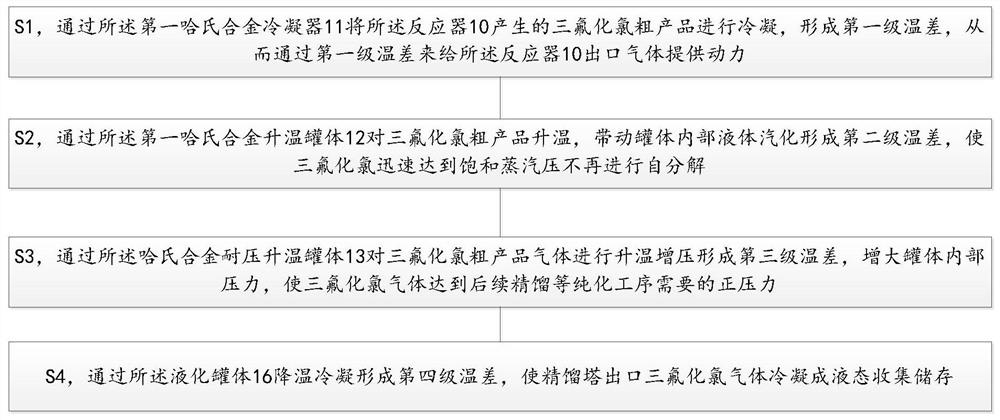

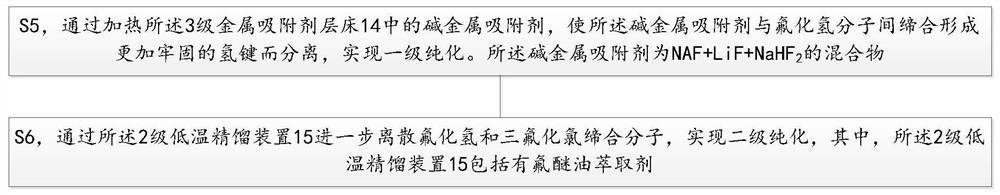

[0049] refer to figure 1 As shown, the present invention provides a purification system for electronic grade chlorine trifluoride, comprising: a sequentially connected first Hastelloy condenser 11, a first Hastelloy heating tank 12, and a Hastelloy pressure heating tank 13. Three-stage metal adsorbent layer bed 14 , rectification device for electronic grade chlorine trifluoride in Example 1, liquefaction tank 16 and pressure stabilizing tank 17 .

[0050] The feed end of the first Hastelloy condenser 11 is arranged at its top and communicates with the reactor 10, and the discharge end of the first Hastelloy condenser 11 is arranged at its bottom and connected with the first Hastelloy condenser 11. The feed end of a Hastelloy heating tank body 12 is connected. The first Hastelloy condenser 11 is used to condense the crude chlorine trifluoride produced by the reactor 10, so as to provide power to the outlet gas of the reactor 10 through temperature difference (generating negati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com