High-concentration chlorine trifluoride tail gas treatment device and treatment method

A chlorine trifluoride and tail gas treatment technology, which is applied in gas treatment, chemical instruments and methods, separation methods, etc., can solve problems such as backflow, and achieve the effects of avoiding treatment, high safety, and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to facilitate those skilled in the art to understand the technical solution of the present invention, the technical solution of the present invention will be further described in conjunction with the accompanying drawings.

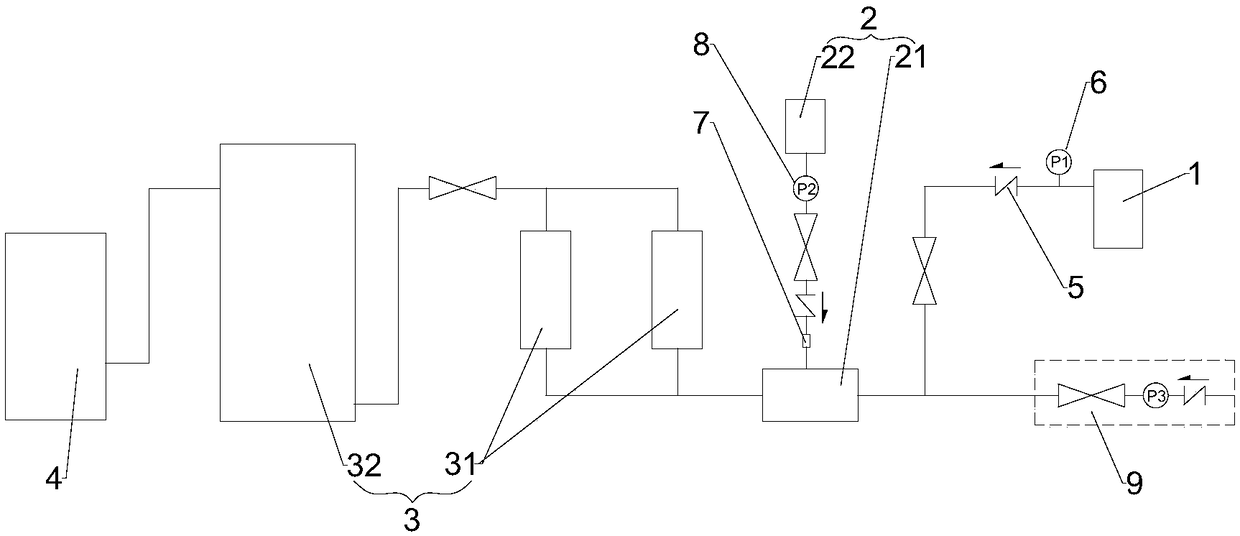

[0020] refer to figure 1 , a high-concentration chlorine trifluoride tail gas treatment device disclosed in this embodiment includes a tail gas source 1 , a dilution system 2 , a dry treatment system 3 and a spray system 4 .

[0021] The tail gas source 1 in this embodiment is chlorine trifluoride cylinder gas, such as the residual cylinder gas left over from the etching process in the integrated circuit industry.

[0022] The dilution system 2 includes a Venturi vacuum generator 21 and a nitrogen source 22, and the Venturi vacuum generator 21 is provided with an adsorption chamber inlet (not shown in the figure) and a compressed gas inlet (not shown in the figure), The inlet of the adsorption chamber is connected to the steel cylinder, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com