Dynamic high-temperature continuous microwave roasting equipment

A dynamic, high-temperature technology, applied in the direction of lighting and heating equipment, furnace types, furnaces, etc., can solve the problems of large energy dissipation, inability to mix materials evenly and heat evenly, and lack of insulation devices, etc., to achieve low cost and automation The effect of high and simple equipment structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

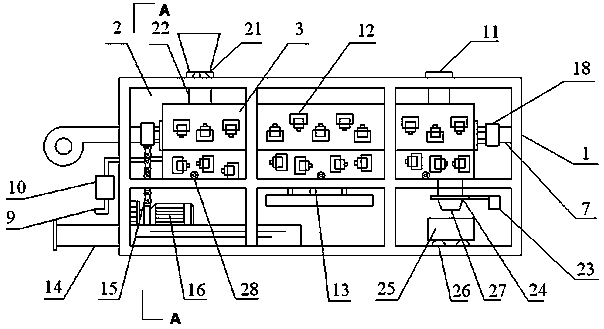

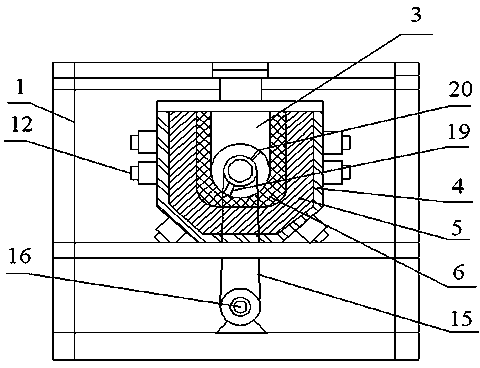

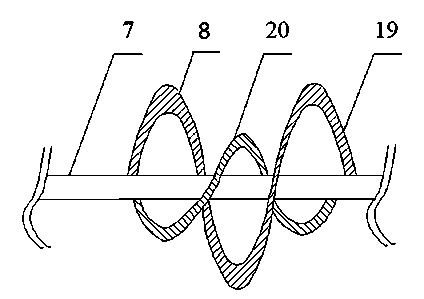

[0032] Such as Figures 1 to 3 As shown, the microwave dynamic high-temperature continuous roasting equipment includes a frame 1, a furnace body, a microwave heating system, a temperature measurement system, a feeding system, a discharging system, a cooling system, a PLC control device 14 and a double-helix stirring device. The microwave heating system includes a microwave heating cavity 3 and a magnetron 12, the temperature measurement system includes a thermocouple 28, the cooling system includes a circulating cooling water pipe 13, and the double-helix stirring device includes a stirring shaft 7, an external spiral 19 and an internal spiral 20. Blades 8, chains 15, screw motors 16 and bearings 18, the frame 1 supports the furnace body, the material of the furnace body is stainless steel 4, the cross-section of the ports at both ends of the furnace body is a symmetrical hexagon, and the inside of the furnace body is close to the stainless steel 4 The furnace wall is successi...

Embodiment 2

[0036] Such as Figures 1 to 3 As shown, the microwave dynamic high-temperature continuous roasting equipment includes a frame 1, a furnace body, a microwave heating system, a temperature measurement system, a feeding system, a discharging system, a cooling system, a PLC control device 14 and a double-helix stirring device. The microwave heating system includes a microwave heating cavity 3 and a magnetron 12, the temperature measurement system includes a thermocouple 28, the cooling system includes a circulating cooling water pipe 13, and the double-helix stirring device includes a stirring shaft 7, an external spiral 19 and an internal spiral 20. Blades 8, chains 15, screw motors 16 and bearings 18, the frame 1 supports the furnace body, the material of the furnace body is stainless steel 4, the cross-section of the ports at both ends of the furnace body is a symmetrical hexagon, and the inside of the furnace body is close to the stainless steel 4 The furnace wall is successi...

Embodiment 3

[0040] Such as Figures 1 to 3 As shown, the microwave dynamic high-temperature continuous roasting equipment includes a frame 1, a furnace body, a microwave heating system, a temperature measurement system, a feeding system, a discharging system, a cooling system, a PLC control device 14 and a double-helix stirring device. The microwave heating system includes a microwave heating cavity 3 and a magnetron 12, the temperature measurement system includes a thermocouple 28, the cooling system includes a circulating cooling water pipe 13, and the double-helix stirring device includes a stirring shaft 7, an external spiral 19 and an internal spiral 20. Blades 8, chains 15, screw motors 16 and bearings 18, the frame 1 supports the furnace body, the material of the furnace body is stainless steel 4, the cross-section of the ports at both ends of the furnace body is a symmetrical hexagon, and the inside of the furnace body is close to the stainless steel 4 The furnace wall is successi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com