Negative electrode material for lithium ion batteries containing surface-fluorinated b-type titanium oxide powder, method for producing same, and lithium ion battery using same

A technology for lithium ion batteries and negative electrode materials, which is applied in battery electrodes, titanium dioxide, titanium oxide/hydroxide, etc., can solve the problems of limited and ineffective charging characteristics, and achieve the effect of increasing charging capacity and high discharging capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Manufacture of Fluorinated Type B Titanium Oxide Powder

[0054] As a starting material, TiO with an average particle size of 100nm was used 2 Anatase (manufactured by Aldrich, with a purity of over 99%) and K 2 CO 3 (Manufactured by Wako Pure Chemical Industries, Ltd., purity 99.8%). First, weigh the TiO 2 Anatase and K 2 CO 3 The molar ratio was set to 4:1, and mixing was performed at 400 rpm for 1 hour using a planetary ball mill, so that the samples were uniformly mixed. Next, the sample was put into an alumina crucible, and fired at 1000° C. in air twice for 24 hours. The obtained samples were each ion-exchanged in 1M HCl at room temperature for 72 hours. After performing ion exchange, washing and filtering were performed, and drying was performed at 80° C. for 24 hours in a vacuum dryer. After drying, dehydration was performed by heat-treating the sample at 500° C. for 30 minutes to synthesize B-type titanium oxide. Then, the synthesized B-type titanium...

Embodiment 2

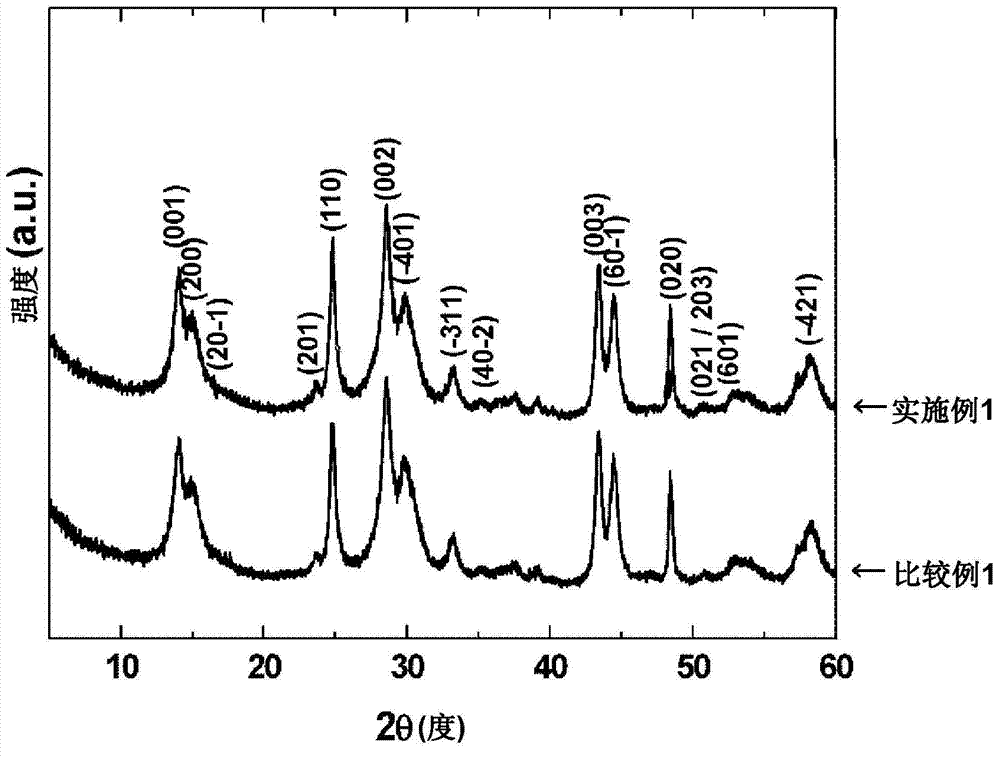

[0059] Analysis of the crystal structure of the powder

[0060] Regarding the B-type titanium oxide powders obtained in Example 1 and Comparative Example 1, the crystal structure of the bulk was analyzed by powder X-ray diffraction (XRD). As a powder X-ray diffractometer, Rint2500 (manufactured by Rigaku Corporation) was used. CuKα was used as the X-ray source, and the measurement was carried out under the conditions of tube voltage 40kV, tube current 200mA, measurement range 5°≤2θ≤60°, light receiving slit 0.3mm, divergence slit 1°, and scattering slit 1°.

[0061] The results of the analysis are as figure 1 As shown, in Example 1 and Comparative Example 1, no change in XRD peak shape or peak shift was observed, and it was confirmed that the main structure of the B-type titanium oxide powder was not changed by the fluorination treatment.

Embodiment 3

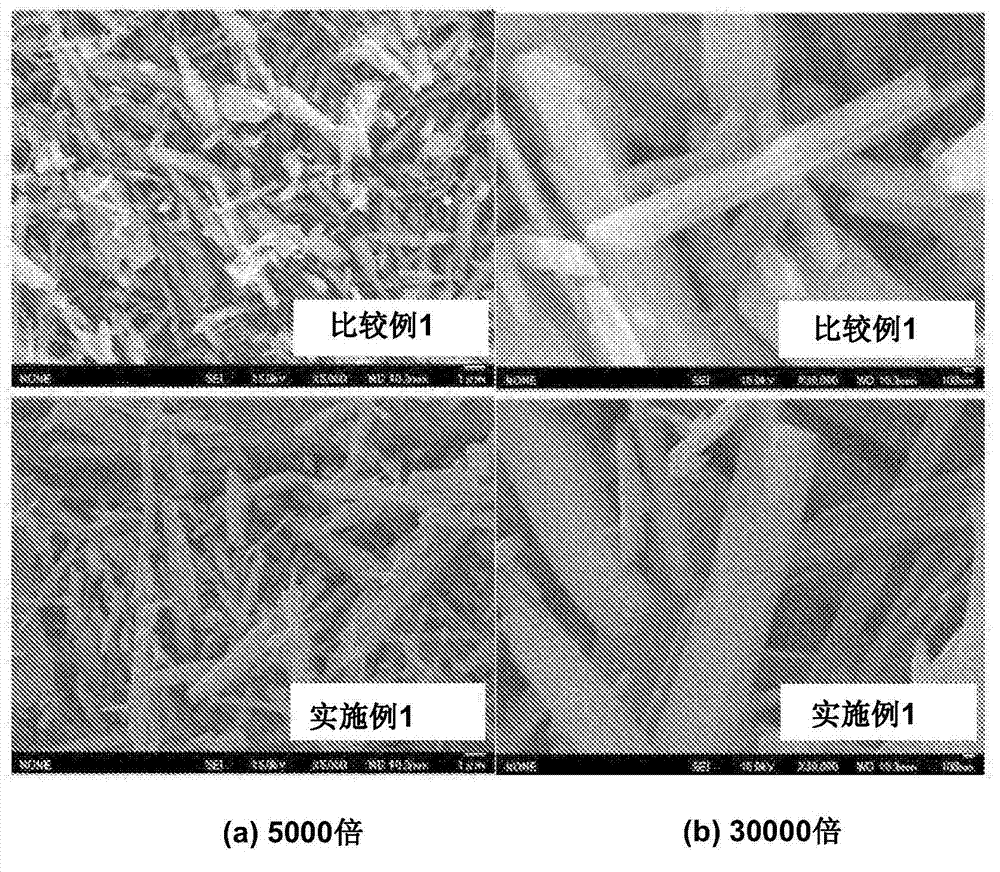

[0063] Observation of the surface morphology of the powder

[0064] The surface morphology of the B-type titanium oxide powders obtained in Example 1 and Comparative Example 1 was observed using a field emission scanning electron microscope (FE-SEM). As the electron microscope, JSM7001FD manufactured by JEOL Ltd. was used. Since the electron conductivity of the sample was low, after performing gold sputtering, surface observation was performed at an acceleration voltage of 15 kV.

[0065] The observed results are as figure 2 As shown in (a), no significant change in surface morphology was observed in Example 1 and Comparative Example 1 in 5000-magnification observation. Additionally, if figure 2 As shown in (b), it was confirmed that the surface of the powder of Example 1 was slightly smoother than the surface of the powder of Comparative Example 1 in observation at 30000 magnification.

[0066] In addition, the specific surface area of the B-type titanium oxide powd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com