Purification method and purification system of chlorine trifluoride

A technology of chlorine trifluoride and purification method, which is applied in the direction of interhalogen compounds, etc., and can solve the problems that the removal of light impurity components cannot be carried out at the same time, continuous rectification cannot be performed, and the content of metal ions is difficult to control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Use high-purity nitrogen to purge and replace the entire system, and use a vacuum pump to evacuate the system to a negative pressure of 0.5Pa.

[0058] Carry out helium leak detection on the system, because the chlorine trifluoride active agent is extremely toxic, it is necessary to ensure that the system is leak-free, and the system leak rate is lower than 1.0×10 -9 mbarL / s;

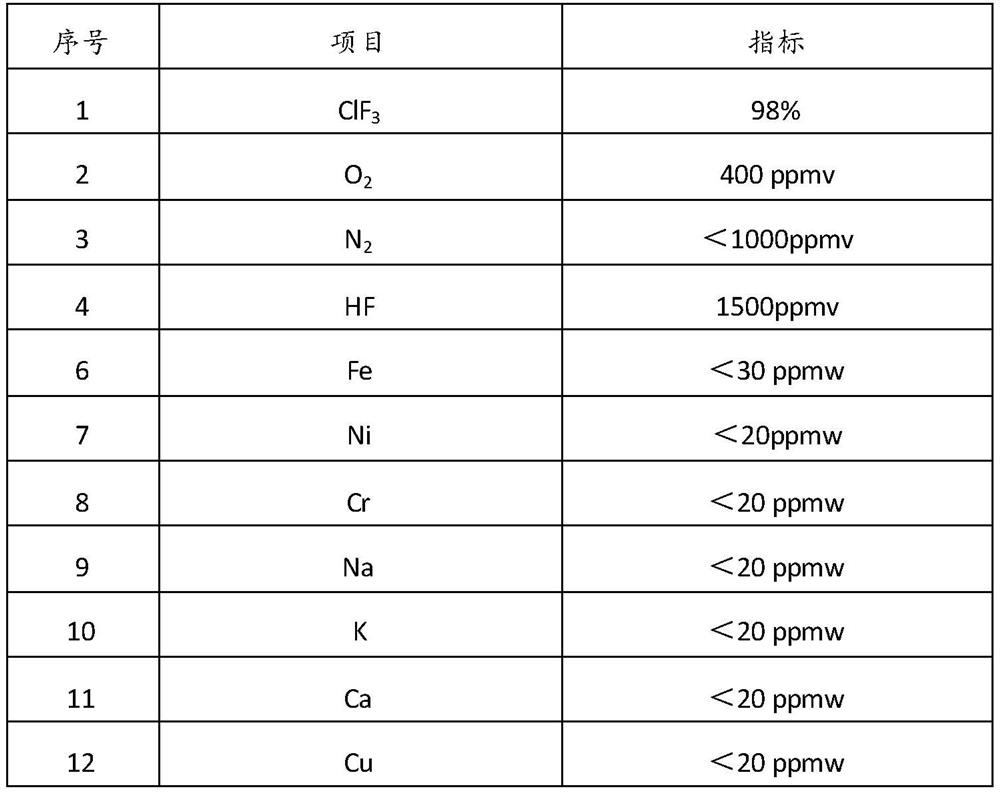

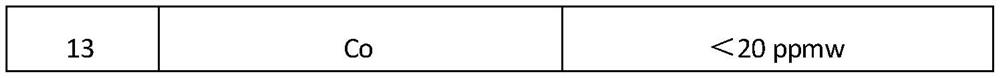

[0059] The liquid chlorine trifluoride crude product (its composition is shown in Table 2) from the chlorine trifluoride raw material storage tank is pressurized to 2.2 barg by the booster pump, and after passing through the vaporizer gasification, the outlet gas pressure is controlled to 2.2 barg, and the flow control is 5kg / h ;

[0060] The pressurized chlorine trifluoride gas enters the DN50mm×2000mm adsorption tower to absorb hydrogen fluoride (the adsorbent is sodium fluoride, potassium fluoride and calcium fluoride, the mass ratio is 5:3:2; the adsorbent is spherical and the particle size ...

Embodiment 2

[0065] Use high-purity nitrogen to purge and replace the entire system, and use a vacuum pump to evacuate the system to a negative pressure of 1pa.

[0066] Carry out helium leak detection on the system, because the chlorine trifluoride active agent is extremely toxic, it is necessary to ensure that the system is leak-free, and the system leak rate is lower than 1.0×10 -9 mbarL / s;

[0067] The liquid chlorine trifluoride crude product from the chlorine trifluoride raw material storage tank is pressurized to 2.2 barg by the booster pump, and the outlet gas pressure is controlled to be 2.2 barg after being vaporized by the vaporizer, and the flow rate is controlled to be 5kg / h;

[0068] The pressurized chlorine trifluoride gas enters the DN50mm×2000mm adsorption tower to absorb hydrogen fluoride (the mass ratio of the adsorbent is sodium fluoride, potassium fluoride and calcium fluoride is 6:2:2, the spherical particle size is 4-5mm, the average Pore size 0.4nm; specific surf...

Embodiment 3

[0073] Use high-purity nitrogen to purge and replace the entire system, and use a vacuum pump to evacuate the system to a negative pressure of 1Pa.

[0074] Carry out helium leak detection on the system, because the chlorine trifluoride active agent is extremely toxic, it is necessary to ensure that the system is leak-free, and the system leak rate is lower than 1.0×10 -9 mbarL / s;

[0075] The liquid chlorine trifluoride crude product from the chlorine trifluoride raw material storage tank is pressurized to 2.2 barg by the booster pump, and the outlet gas pressure is controlled to be 2.2 barg after being vaporized by the vaporizer, and the flow rate is controlled to be 5kg / h;

[0076] The pressurized chlorine trifluoride gas enters the DN50mm×2000mm adsorption tower to absorb hydrogen fluoride (the mass ratio of the adsorbent is sodium fluoride, potassium fluoride and calcium fluoride is 3:2:2, the spherical particle size is 4-5mm, the average Pore size 0.4nm; specific surf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com