Production technological method for boron trifluoride acetonitrile complex solid mixture

A boron trifluoride acetonitrile and production process technology, applied in the field of chemical technology, can solve the problems of no waste gas treatment link and solid recovery link, failure to achieve environmental protection, low output of finished products, etc., and increase the solid recovery link. , Increase the link of waste gas treatment, the effect of increasing the output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

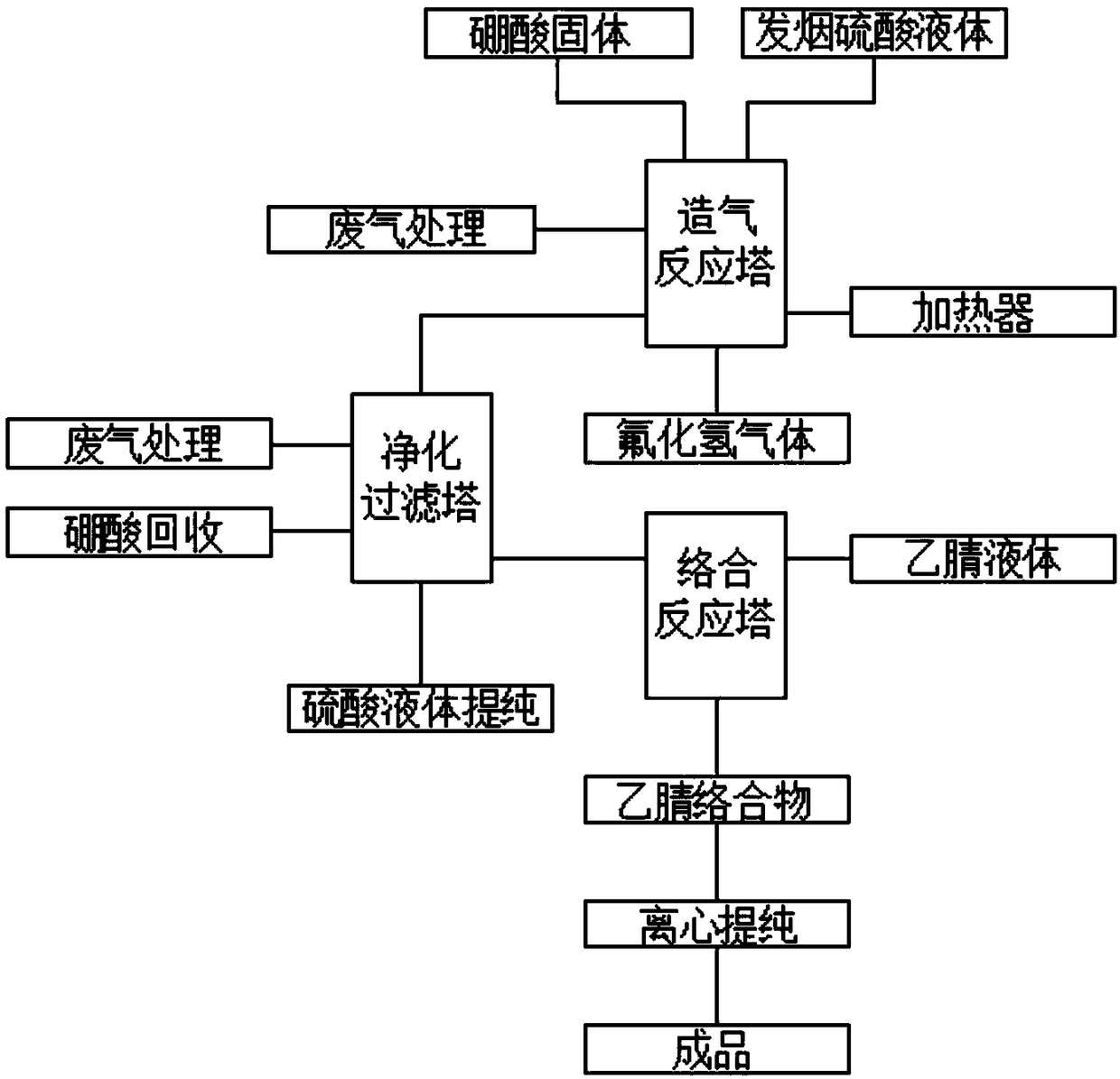

[0022] refer to figure 1 , the production process of boron trifluoride acetonitrile solid mixture, the process is as follows:

[0023] (1) Mixing: Mix the boric acid solid and the fuming sulfuric acid liquid evenly.

[0024] (2) Gas generation reaction: preheat the gas generation reaction tower with a heater for 10 minutes, and control the temperature between 200-300 degrees Celsius, and add the mixed acid of boric acid solid and oleum liquid into the gas generation reaction tower from the top At the same time, the hydrogen fluoride gas is compressed and added to the gas-making reaction tower from the bottom, and the three chemical reactions of oleum, boric acid and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com