Patents

Literature

167results about How to "Achieve environmental goals" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

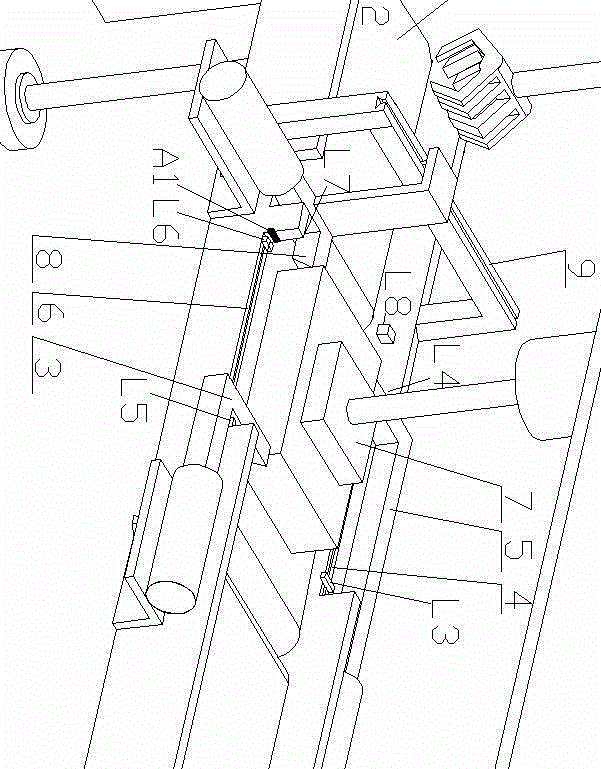

Automatic bag opening machine

InactiveCN104015967AReduce labor intensityImprove work efficiencyArticle unpackingFish mealMaterials processing

The invention discloses an automatic bag opening machine. The automatic bag opening machine comprises a conveyer belt, a bag breaking tool, a bag grabbing device, a fixing device, a material processing channel and a packaging bag recycling bin, wherein the conveyer belt runs in a section manner and is at least divided into three sections, the first section of the conveyer belt is used for conveying material bags, the second section of the conveyer belt is matched with the bag breaking tool to cut the material bags, and the third section of the conveyer belt is matched with the bag grabbing device to achieve separation of the materials and the packaging bags; the bag breaking tool, the bag grabbing device and other movement parts can move on respective movement guide rails, and limit switches are arranged at two ends of each movement guide rail for preventing the parts from moving over the limiting position; photoelectric sensors are arranged at the end of the second section of the conveyer belt, the end of third section of the conveyer belt and the movement guide rail on the material processing channel. The automatic bag opening machine can separate bagged frozen raw materials from bags, and can alleviate labor intensity of workers, improve the working efficiency, reduce the manual bag opening expense, improve the automation production degree of fish meal and achieve the purpose of reasonably recycling the waste bags.

Owner:山东大学(威海)

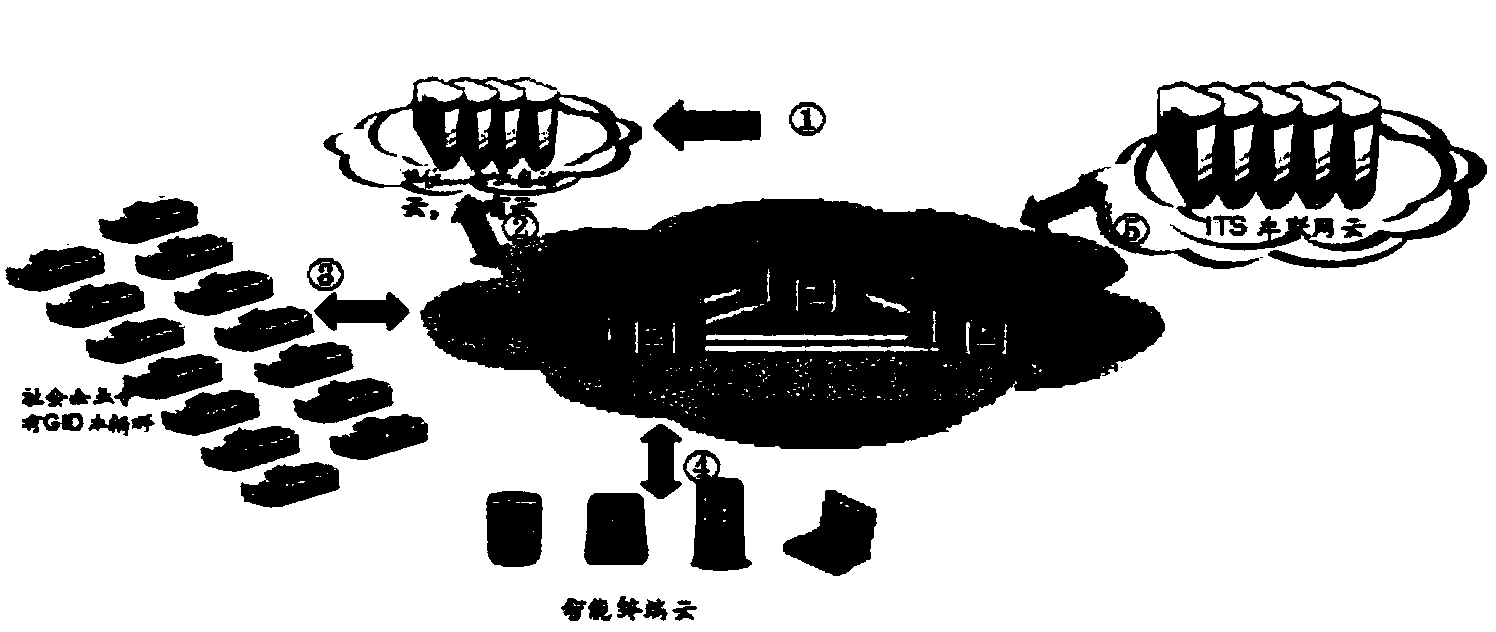

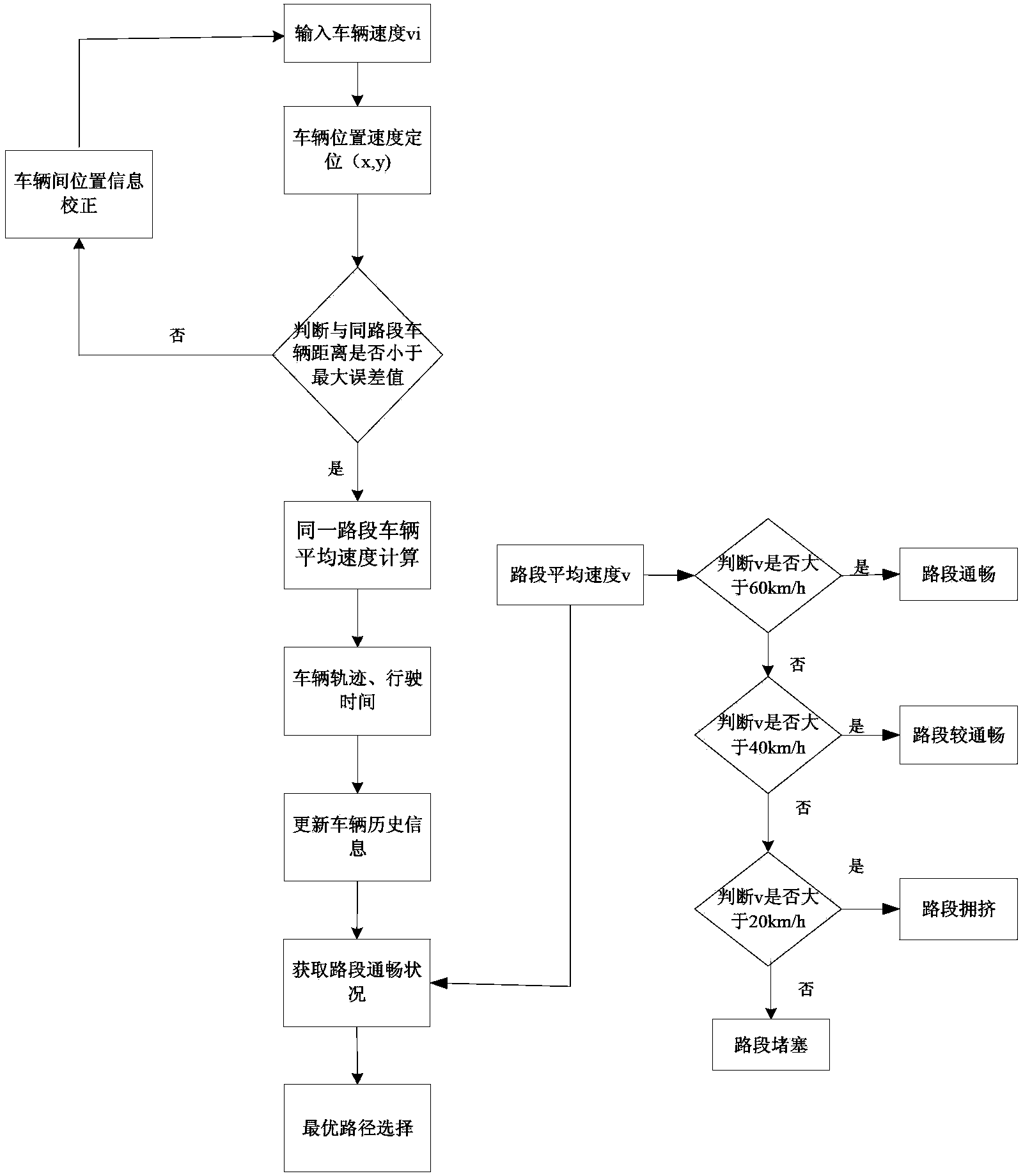

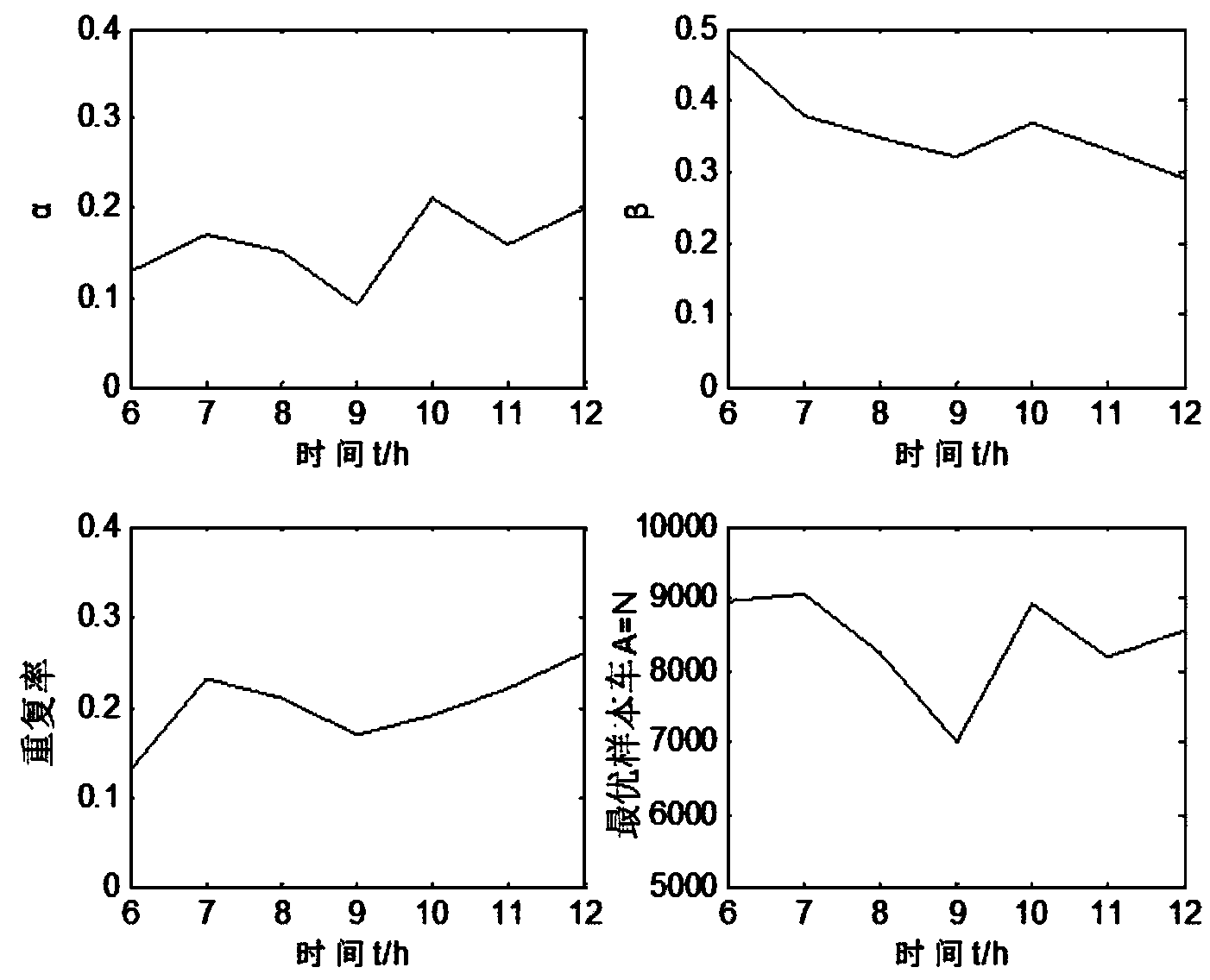

Intelligent traffic solution scheme based on GID

ActiveCN103383811ARealize intelligenceRealize informatizationDetection of traffic movementInformation transmissionComputer terminal

The invention discloses an intelligent traffic solution scheme based on a GID. According to the intelligent traffic solution scheme, a GID terminal is used as a movement speed meter to collect various static and dynamic information such as the speed and the operating state of vehicles, network plate numbers and various positioning technologies are combined, a quick and safe information transmission method depending on an ubiquitous network is used for achieving real-time road condition. According to the technical scheme for solving the technical problems, the achievement of the GID mainly comprises three parts: the first part is a multimode multi-homing and multi-state AP terminal, the second part is the networking mode of the network, the third part is a cloud service platform, and exchange and sharing of the service are conducted. The multimode and multi-homing characteristic of the GID system terminal is achieved through the inherent communication mode and bridging module of the GID system terminal. According to the intelligent traffic solution scheme based on the GID, the mode of 'end-tube-cloud' (namely 'communicating, sensing, computing terminal +network+ cloud computing center platform') is used for establishing a collaborative intelligent traffic three-layer network system.

Owner:NANJING UNIV OF POSTS & TELECOMM

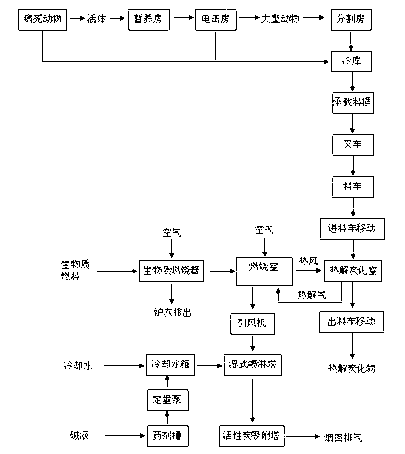

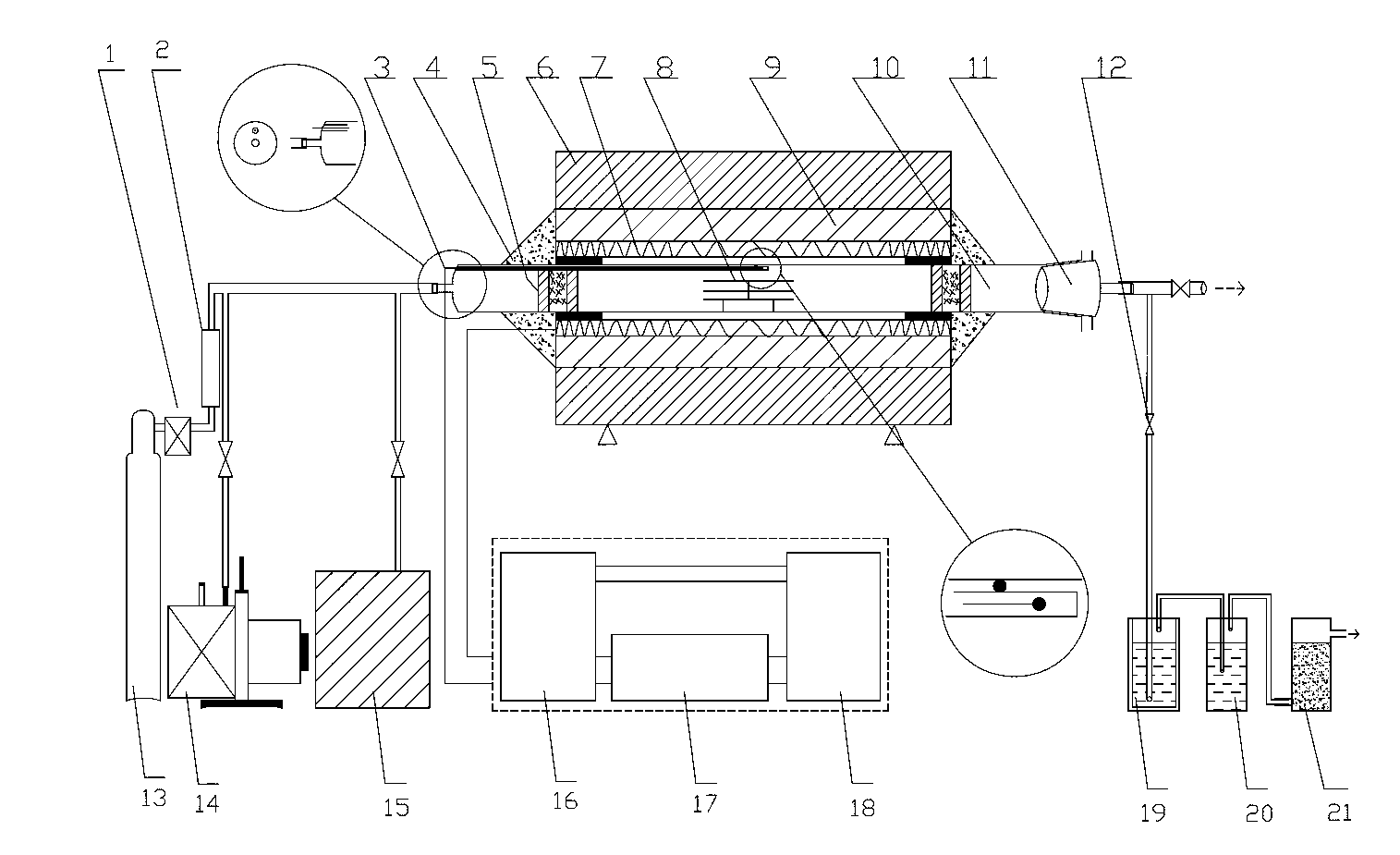

Carbonization treatment process and device thereof of animals died of illness

ActiveCN103254916AReduce post-maintenance costsReduce heat lossSpecial form destructive distillationCombustion chamberFlue gas

The invention relates to a carbonization treatment process and in particular relates to a carbonizing treatment process and device thereof of animals died of illness. The carbonizing treatment process comprises the following steps of: carrying out anaerobic pyrolysis and carbonization treatment for bodies of animals died of illness at the temperature of 300-600 DEG C, automatically outputting combustible pyrolysis gas generated in the pyrolysis and carbonization process and combusting the gas under the condition at the temperature of 800-1300 DEG C, wherein high-temperature flue gas generated by combusting is capable of supporting pyrolysis and carbonization and realizing recycling of heat energy of pyrolysis gas; and subsequently, purifying the flue gas. The device disclosed by the invention comprises a pyrolysis-carbonization device, wherein a pyrolysis-carbonization chamber and a combustion chamber are arranged in the pyrolysis-carbonization device; a pyrolysis-carbonization tank and a cyclic space are arranged in the pyrolysis-carbonization chamber; the pyrolysis-carbonization chamber is connected with a connection opening which is connected with the cyclic space and formed in the pyrolysis-carbonization chamber and the combustion chamber; and a pyrolysis gas exporting tube is connected between the pyrolysis-carbonization tank and the combustion chamber. The carbonization treatment process of animals died of illness can directly treat without need to break the bodies of the animals died of illness, is high in weight and capacity reducing rate, energy-saving and environment-friendly.

Owner:ZHEJIANG WUNENG ENVIRONMENTAL TECH DEV

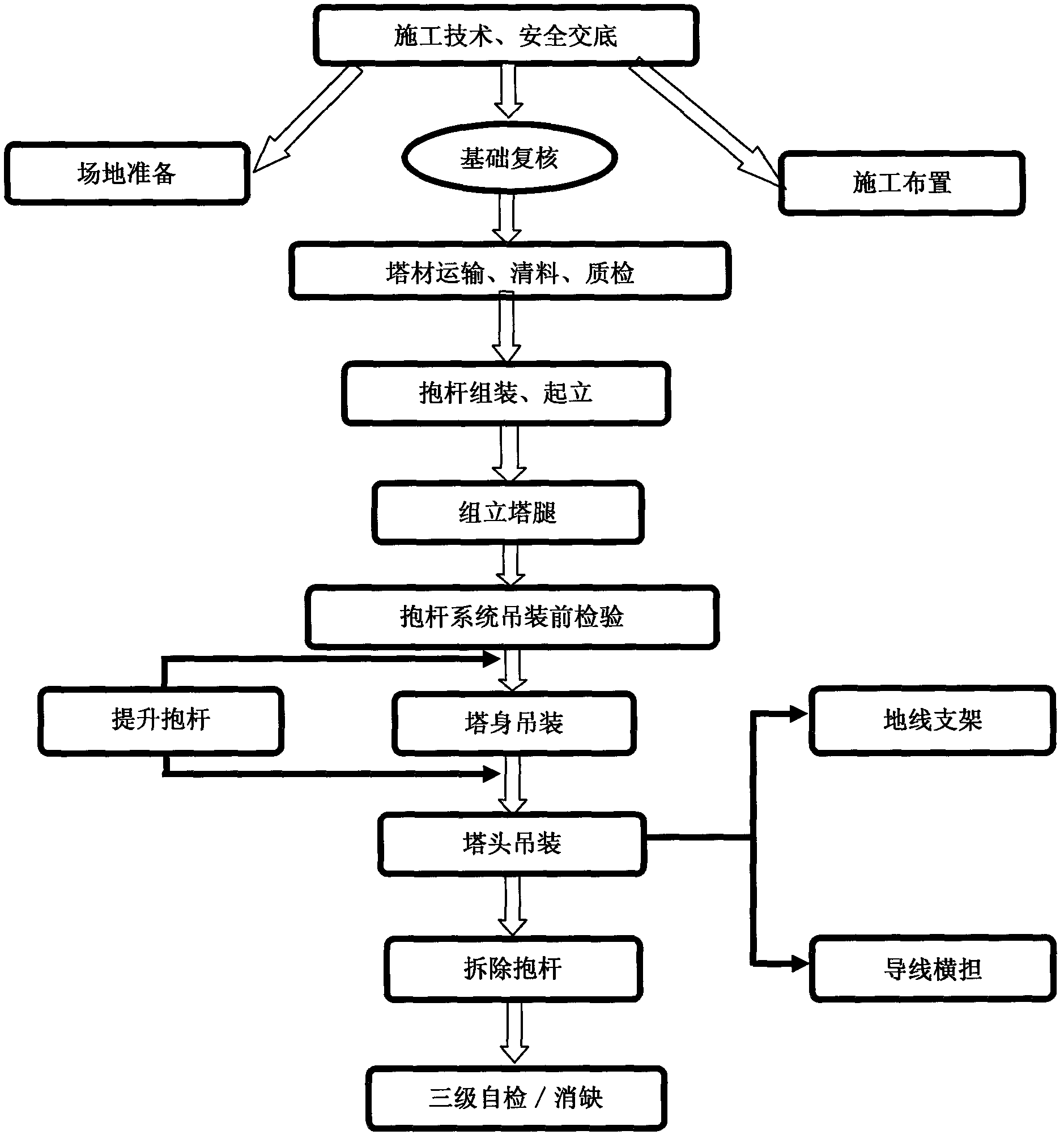

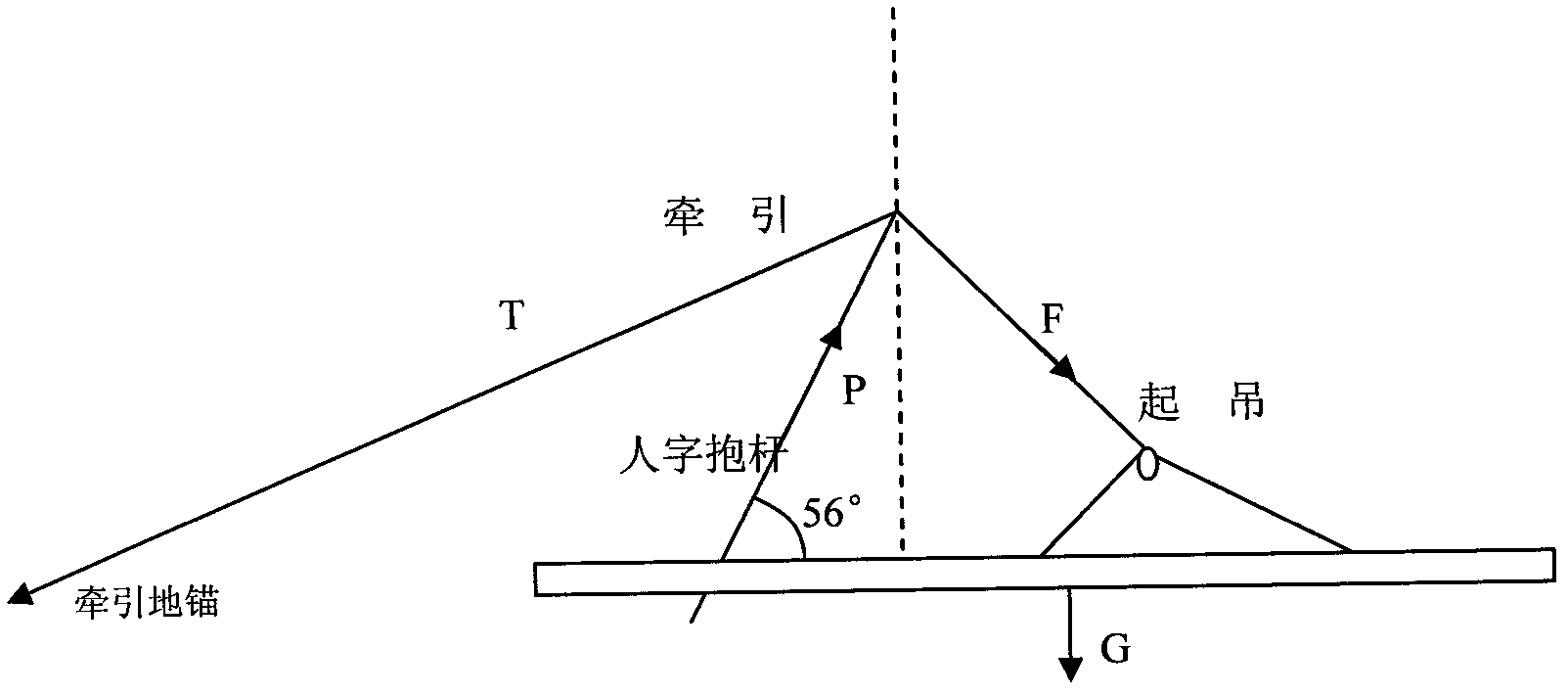

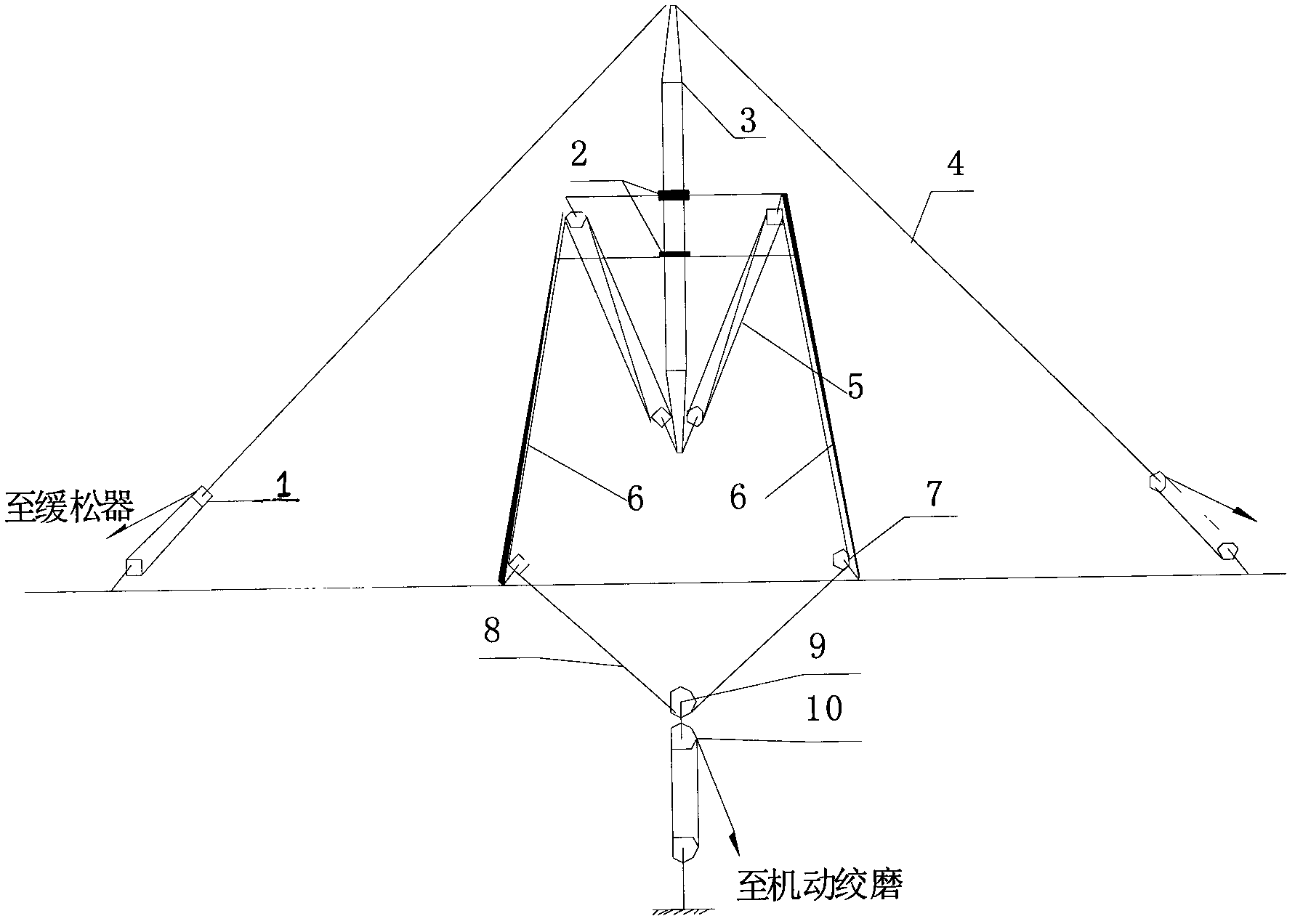

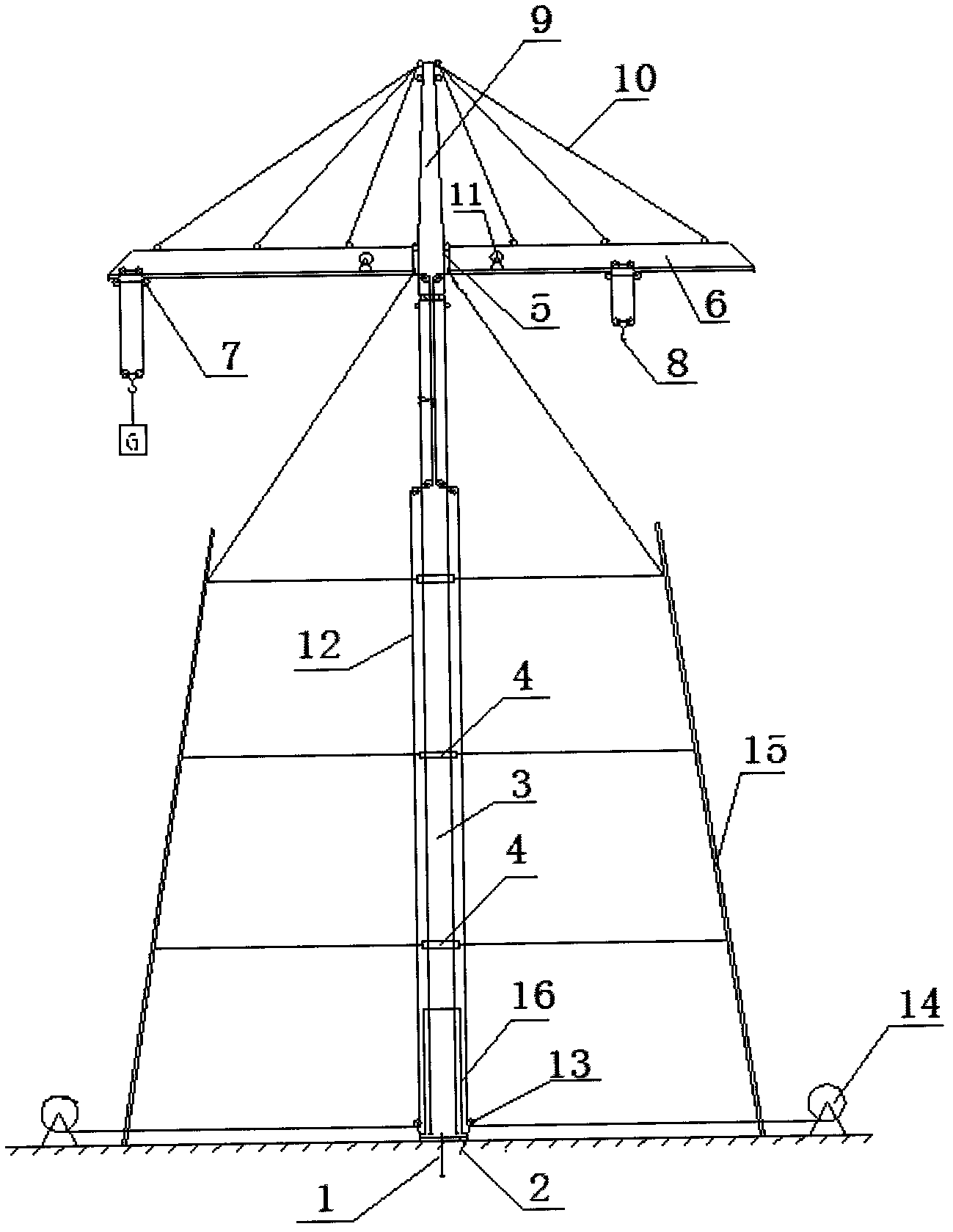

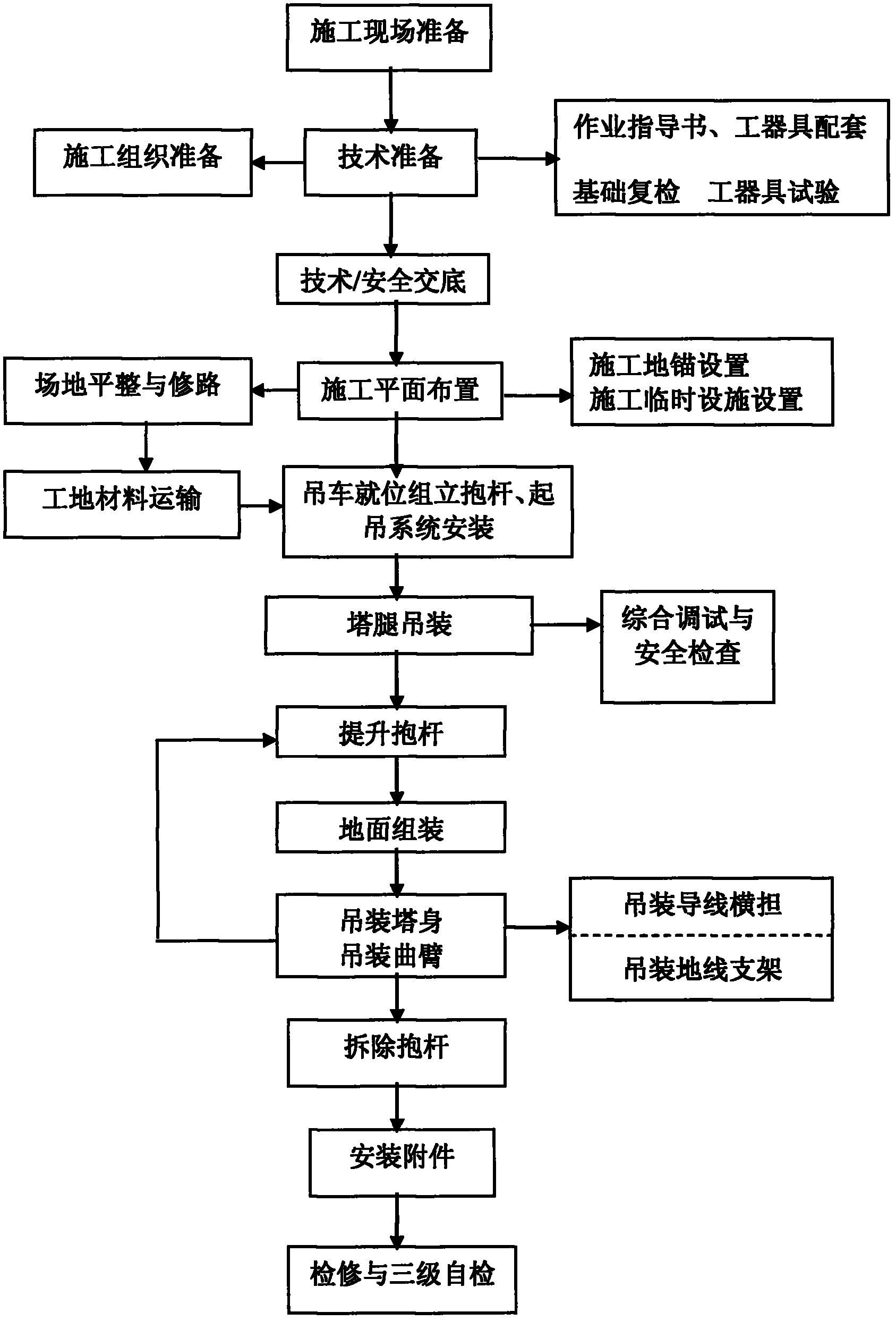

Extra-high voltage common circuit iron tower assembling method

The invention discloses an extra-high voltage common circuit iron tower assembling method, which belongs to the technical field of electric transmission and transformation electric power circuit construction processes. The method comprises the following steps of: 1, performing construction preparation, namely cleaning a construction field, arranging the construction field, preparing a construction ground foundation, and transporting tower materials required by iron tower assembly; 2, assembling a pole, erecting the pole and assembling tower leg lower sections; 3, assembling and erecting towerlegs, lifting the pole, and hoisting iron tower crank arms; and 4, lifting the pole, hoisting a tower head, mounting a ground wire bracket, hoisting iron tower cross arms one by one in a segmentationmode, mounting iron tower accessories and disassembling the pole. The method has the advantages of reducing the working amount of aloft operation, along with a short construction period, a small number of hoisting times and high safety; by the method, safety risks are reduced, required aloft operation personnel is greatly reduced, and labor cost is reduced; and the method has extremely good economic and social benefits.

Owner:HUBEI ELECTRIC POWER TRANSMISSION & DISTRIBUTION ENG

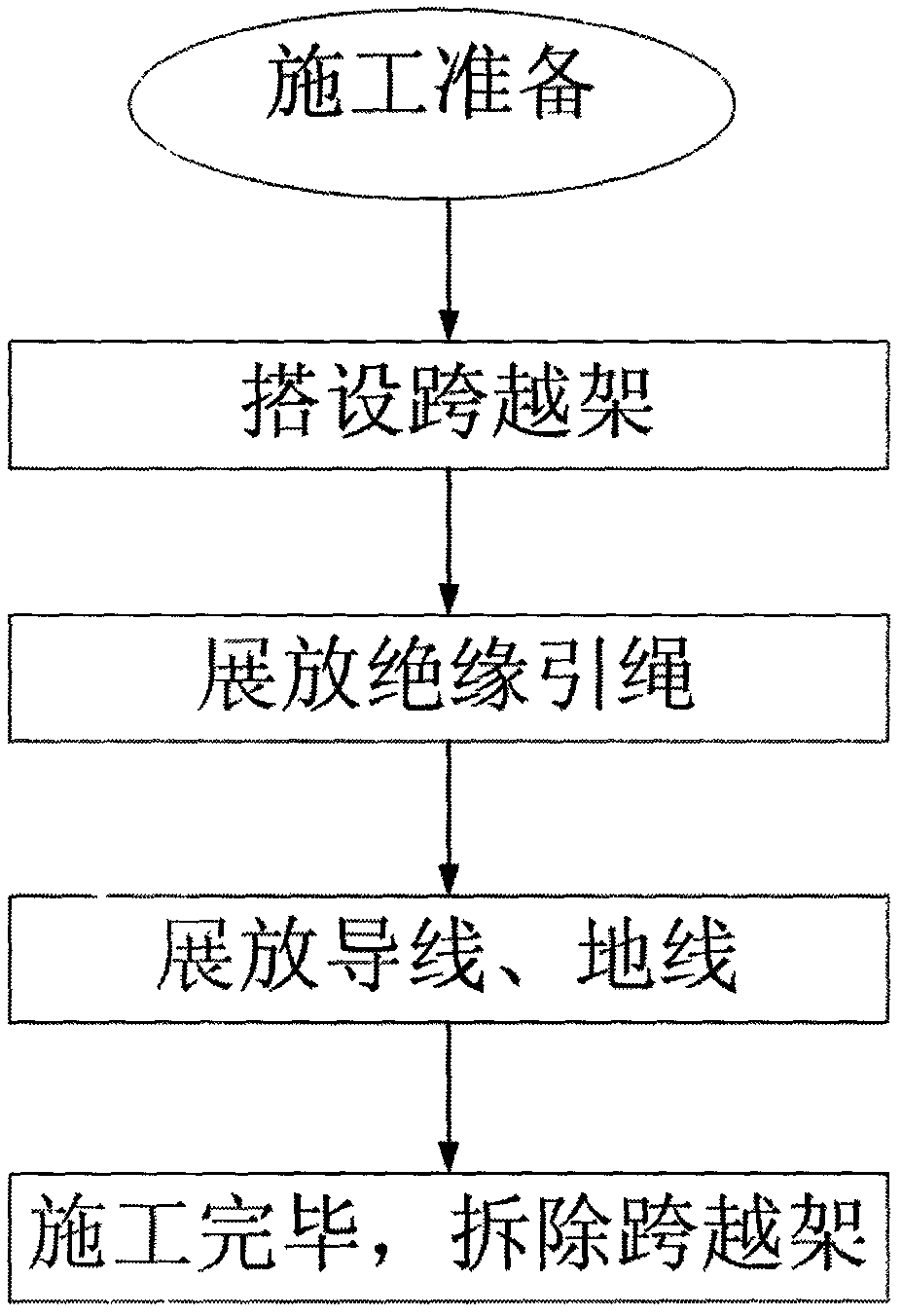

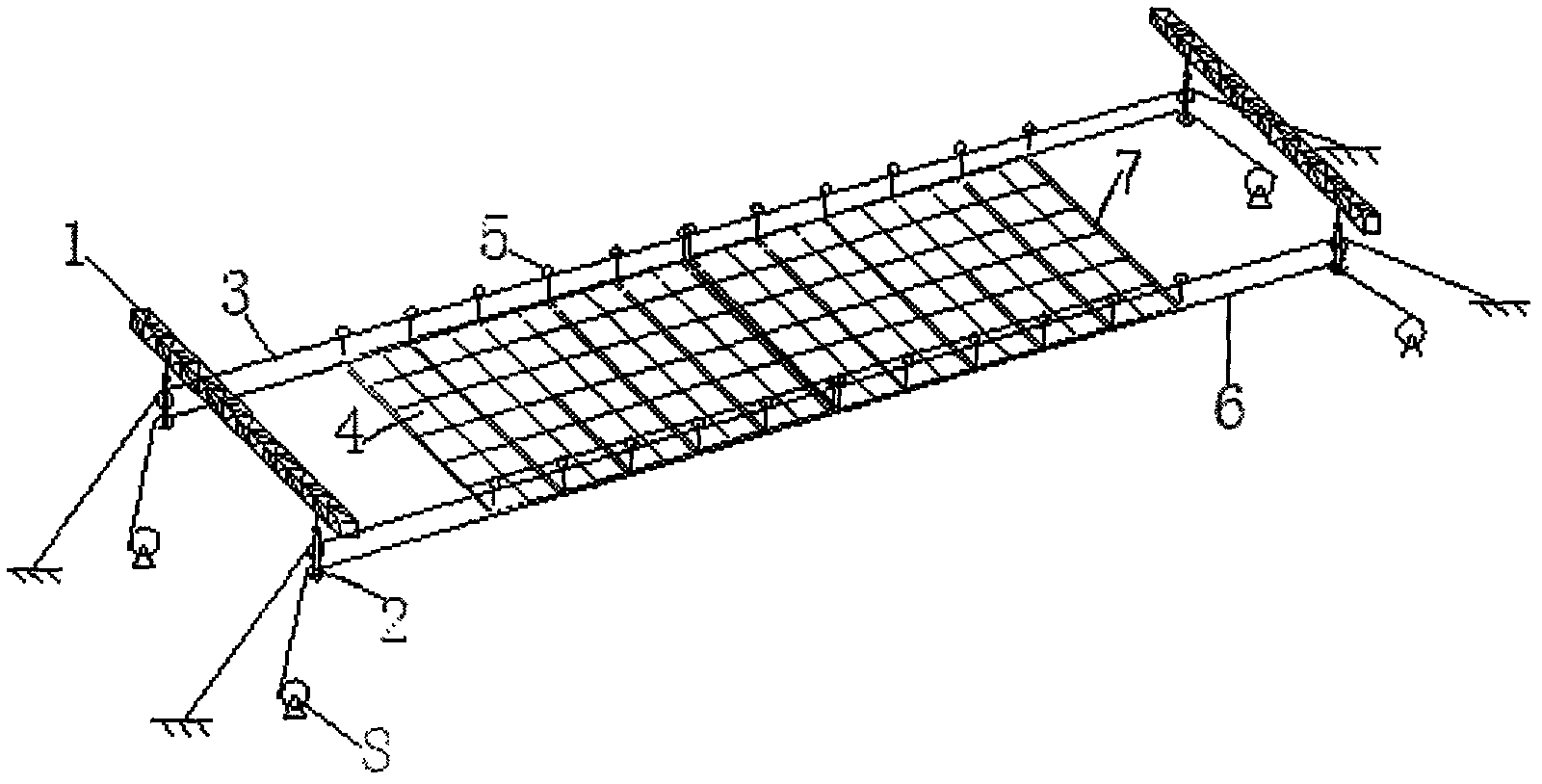

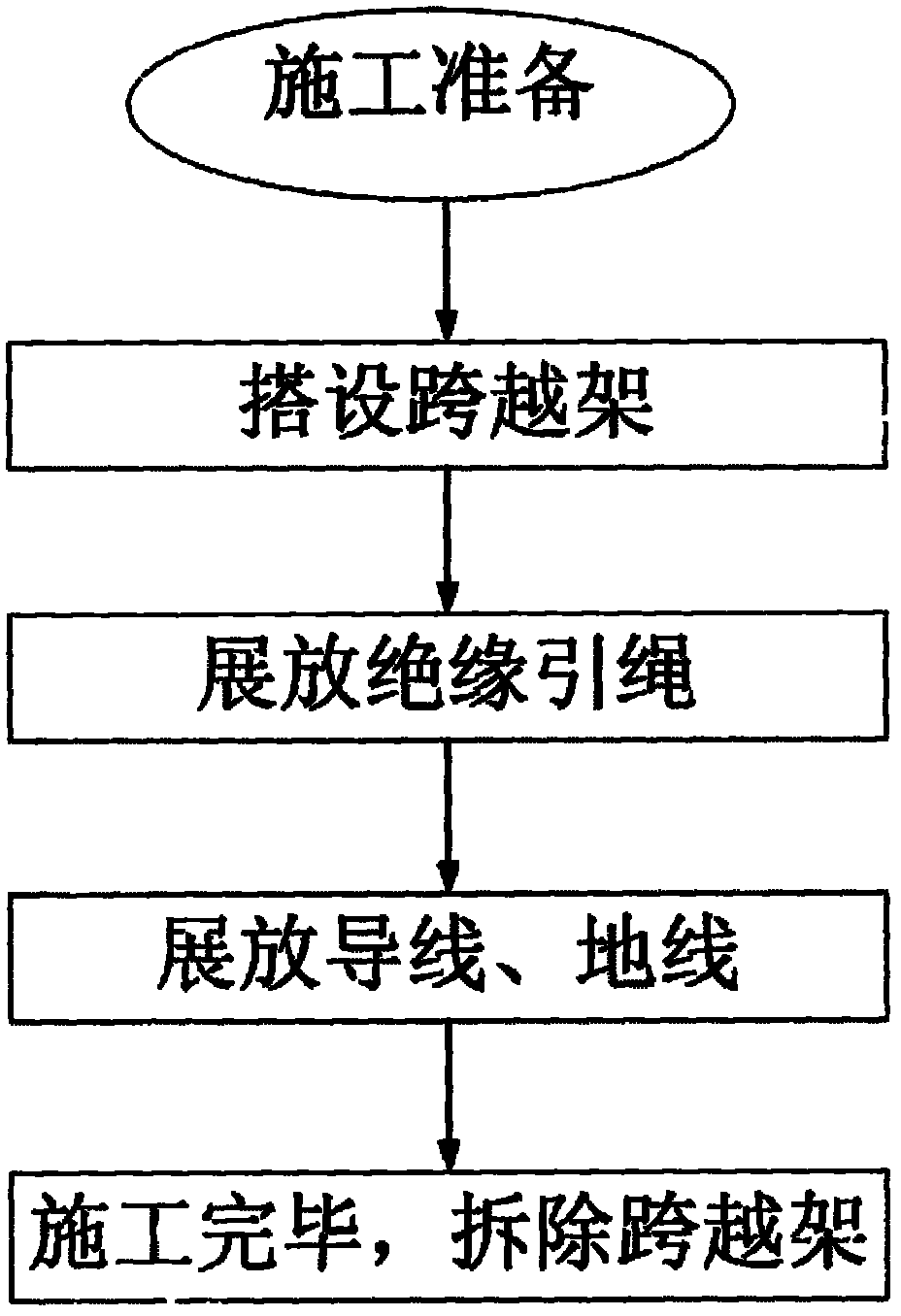

Method for electrified spanning construction of high-voltage power transmission and transformation line

InactiveCN102324712AIncrease speedImprove efficacyApparatus for overhead lines/cablesSafety netEconomic benefits

The invention discloses a method for electrified spanning construction of a high-voltage power transmission and transformation line. The method comprises the following steps of: (1) preparation for construction: computing the position, the height and the width of a spanning frame; (2) building of the spanning frame: according to the designed spanning frame model, installing an auxiliary lifting pole for suspending pulleys on towers at two sides of a span of a newly-built line, suspending double-layer pulleys on the lifting pole, penetrating the double-layer pulleys by Deenyma ropes to form ropeways which are regarded as carrying ropes of a safety net and suspending the safety net under the carrying ropes through suspending belts and small pulleys; (3) extension of insulation guide ropes; (4) extension of conducting wires and ground wires: extending the conducting wires, the ground wires and installation accessories above the safety net by utilizing the insulation guide ropes; and (5) dismantling of the built spanning frame after the electrified spanning construction is finished. By applying the method disclosed by the invention, the advantages of cost saving in renting the spanning frame, high construction speed, good insulation strength, high reliability, high practicability, high superiority and better social and economic benefits are achieved.

Owner:HUBEI ELECTRIC POWER TRANSMISSION & DISTRIBUTION ENG +1

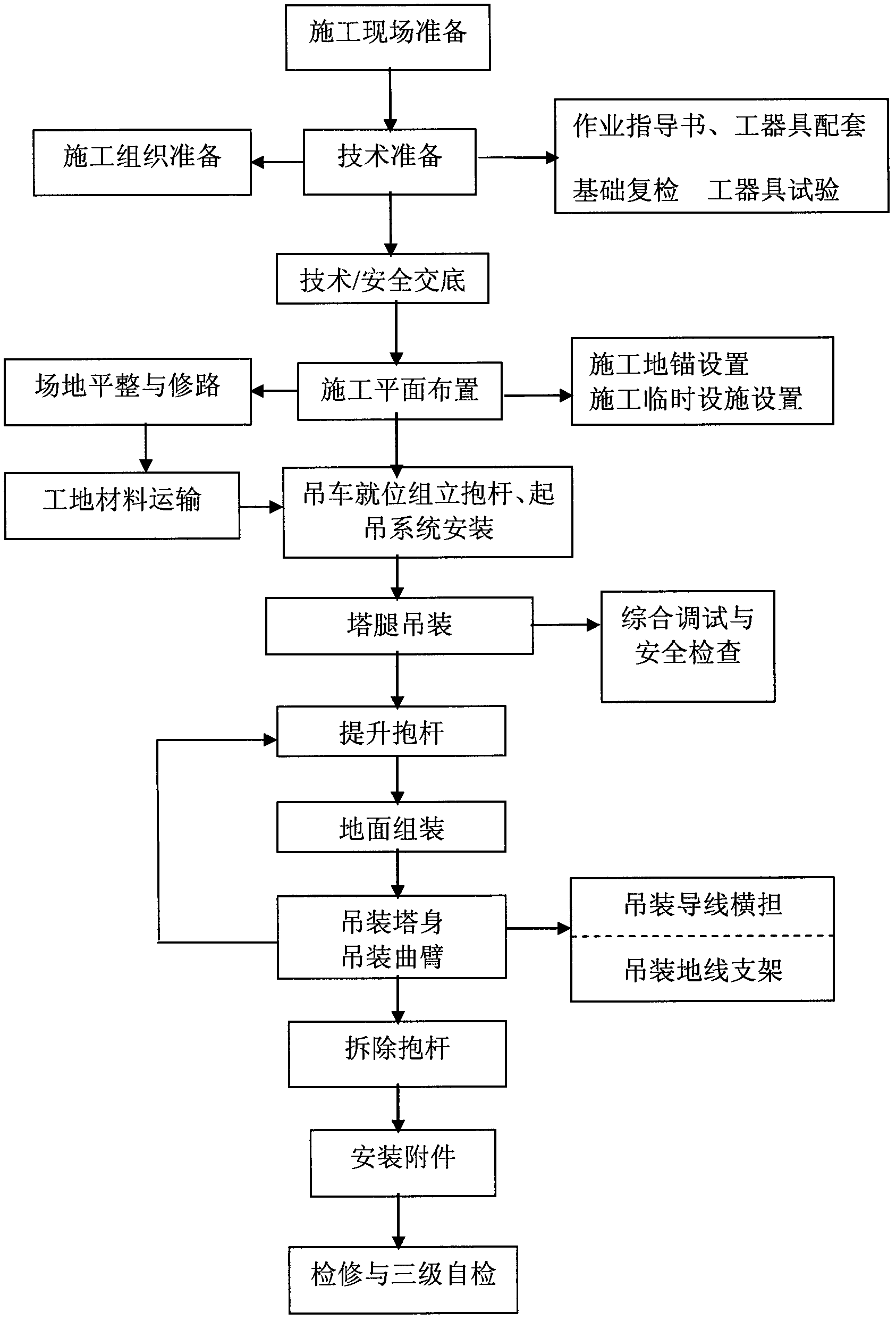

Extra-high voltage large-span iron tower assembling method

The invention discloses an extra-high voltage large-span iron tower assembling method, which belongs to the technical field of electric transmission and transformation electric power circuit construction processes. The method comprises the following steps of: 1, arranging a construction site, namely arranging a ground anchor, performing pole foundation construction, and arranging main material single pieces and tower sheets of an assembled iron tower body on the ground; 2, assembling a pole, mounting a hoisting system, and hoisting iron tower legs, wherein the assembled pole is a spinning self-elevating ground pole which is provided with horizontal double arms and a hydraulic downward jacking stock; 3, lifting the pole, hoisting the iron tower body section by section, and finally hoistingiron tower cross arms one by one in a segmentation mode; and 4, mounting iron tower accessories, disassembling the pole, and finally overhauling and self-checking to finish the construction. The method has the advantages of reducing the working amount of aloft operation, along with a short construction period, a small number of hoisting times and high safety; by the method, safety risks are reduced, required aloft operation personnel is greatly reduced, and labor cost is reduced; and the method has extremely good economic and social benefits.

Owner:HUBEI ELECTRIC POWER TRANSMISSION & DISTRIBUTION ENG

Environment-friendly composite material applied to heat preservation of pipeline and preparation method thereof

InactiveCN102167898AEasy to operateSimple processThermal insulationPipe protection by thermal insulationPolyesterPolyol

The invention relates to an environment-friendly composite material applied to heat preservation of a pipeline. The environment-friendly composite material consists of a component A and a component B, wherein the component A consists of polyether polyol, polyester polyol, a foam stabilizer, a chemical foaming agent, a catalyst and a physical foaming agent; and the component B is polymerized diphenyl methane diisocyanate. When the environment-friendly composite material is used, environment-friendly polyurethane foam applied to the heat preservation of the pipeline can be prepared by mixing the component A and the component B. The environment-friendly polyurethane foam material applied to the heat preservation of the pipeline is prepared from the component A and the component B at normal temperature and normal pressure, so the process is simple and easy to operate. A c-pentane and HFC-365 / 227 (according to a ratio of 87:13) mixed type foaming agent serving as the physical foaming agent is used for preparing pipeline heat preservation composite polyether, so the environment-friendly aim is fulfilled, heat conductivity coefficient of foam is reduced, and properties, such as flowability, dimensional stability, adhesion stress and the like, of the foam are improved, and various indexes reach the requirements of national standard.

Owner:山东东大聚合物股份有限公司

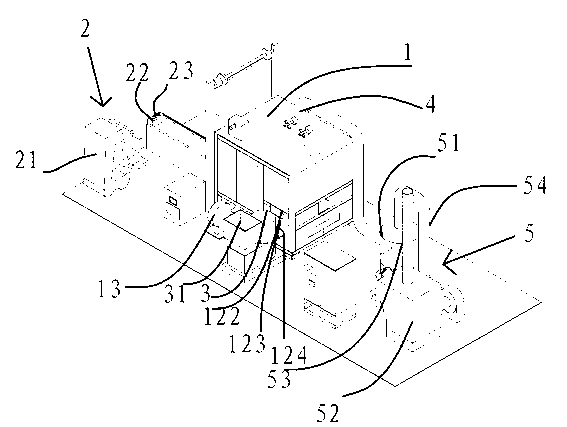

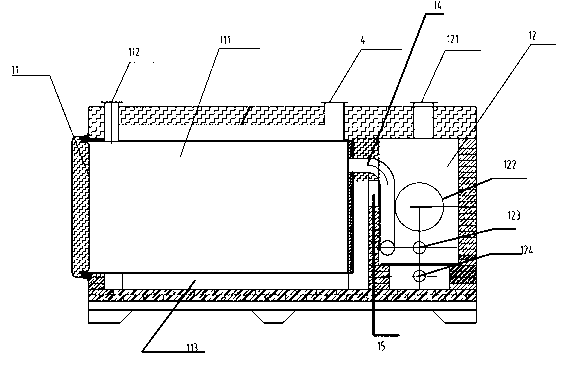

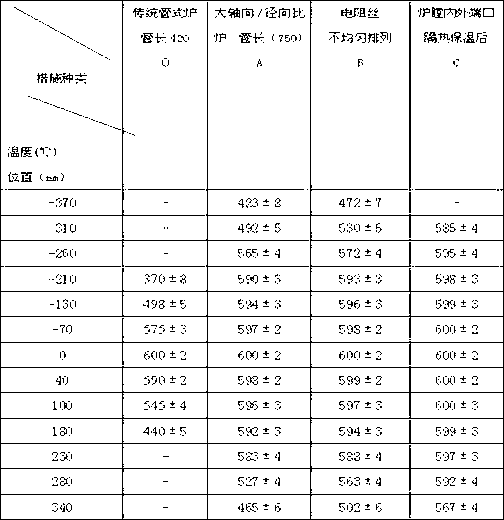

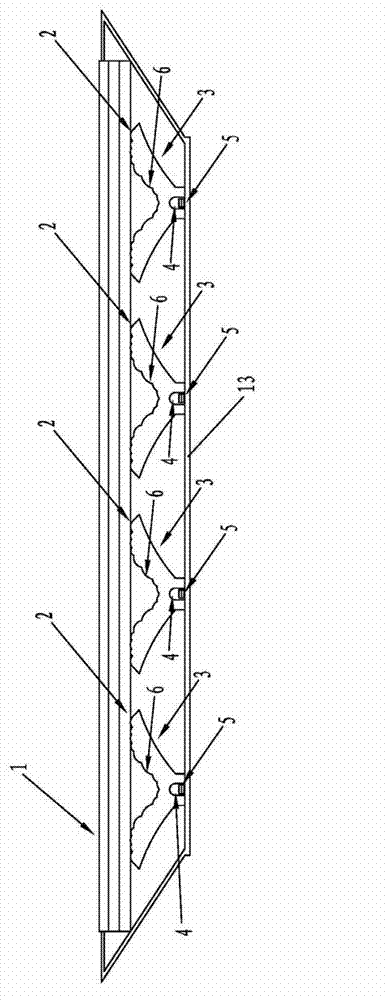

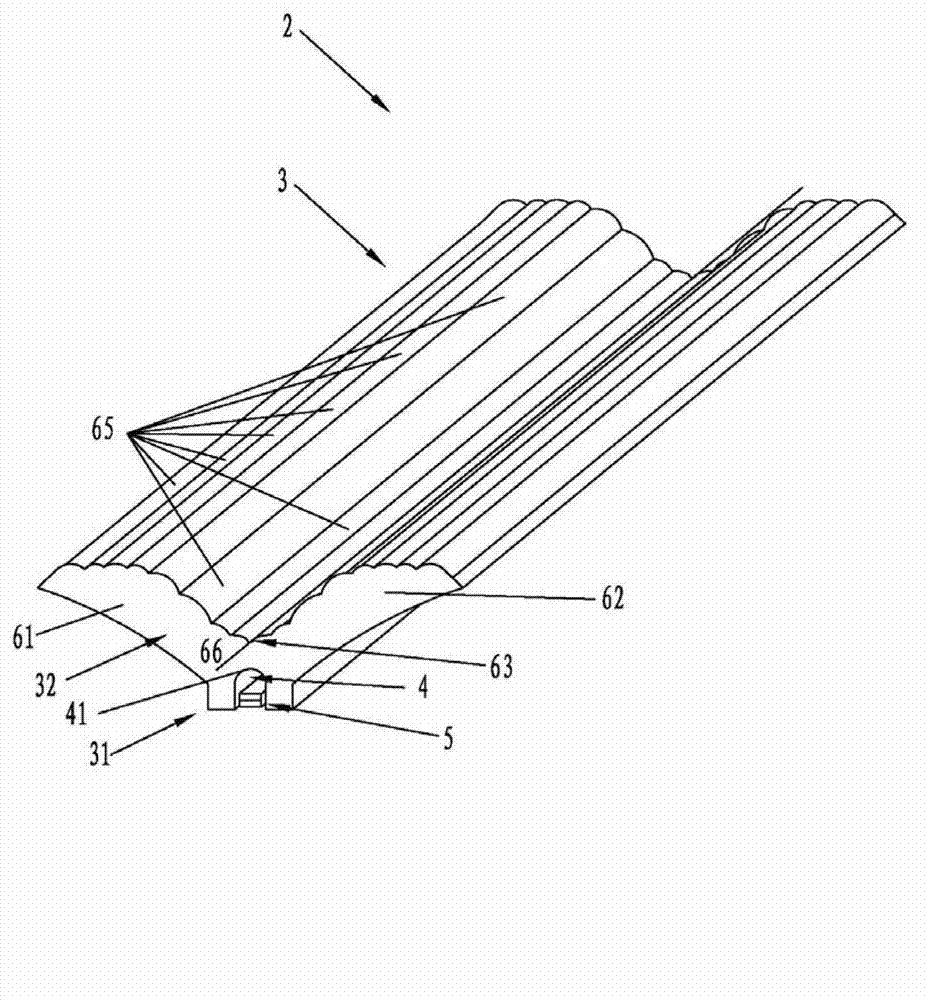

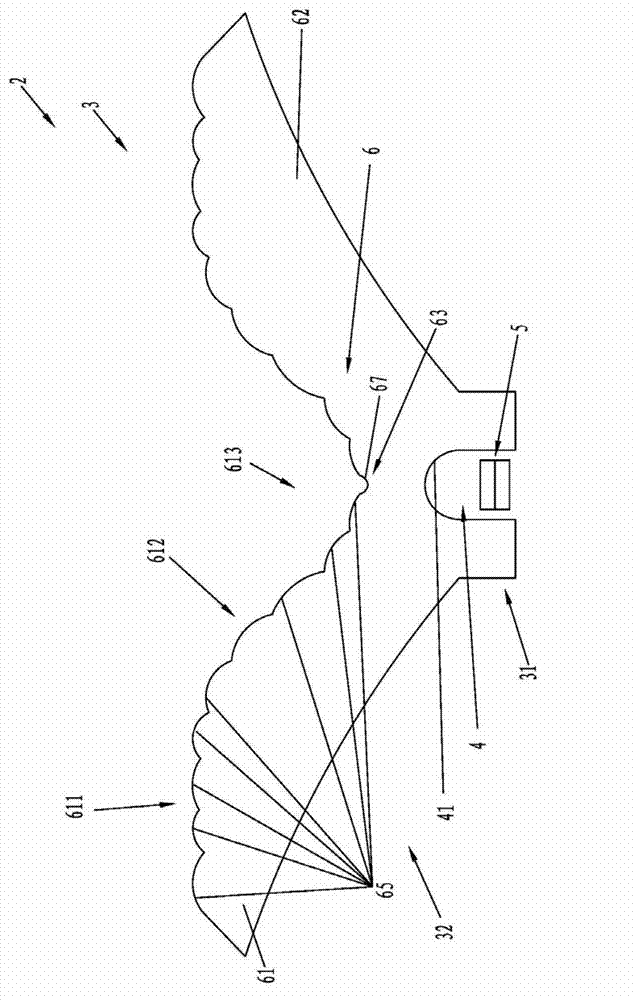

Environment-friendly automatic-temperature-control quartz tube furnace device for pyrolysis of high polymer

InactiveCN103017524AImprove insulation effectUniform temperature distributionHeat treatmentsFurnace typesTube furnaceEngineering

Tube furnaces for pyrolyzing or sintering are large in axial heat radiation, nonuniform in hearth temperature and low in machining amount. The invention discloses an environment-friendly automatic-temperature-control quartz tube furnace device for pyrolysis of high polymer, wherein the environment-friendly automatic-temperature-control quartz tube furnace device comprises a quartz glass tube furnace, a sample stand, a heat-isolation ventilation assembly, a fireproof heat-insulation furnace body, an automatic-heating temperature control device, a safety protection device and a tail gas treatment device. Different from other tube furnaces, the quartz tube furnace device is characterized in that a furnace body structure is improved by taking heat insulation measures additionally for inner and outer ports of a hearth, the axial-radial ratio of the tube furnace is high up to 12.5, resistance wires are arranged in a nonuniform winding manner and are arranged densely at the ports and sparsely in the middle, in addition, a safety protection bag and a tail gas purification column are arranged, and the furnace is internally vacuumized and is introduced with nitrogen. The environment-friendly automatic-temperature-control quartz tube furnace device disclosed by the invention is simple in equipment, low in investment, good in gas tightness, high in vacuum degree, convenient for heating as well as temperature measuring and controlling, and good in heat insulation effect, and is safe, energy-saving and environment-friendly, and an intra-furnace pyrolysis region is long and uniform in temperature, so that pyrolysis and doping reaction effects are good, and the processing amount is large. The environment-friendly automatic-temperature-control quartz tube furnace device can also be applied to other high-temperature reaction processes.

Owner:HARBIN UNIV OF COMMERCE

Special environment-friendly combined polyether for sprayed pipeline and preparation method of special environment-friendly combined polyether

The invention discloses special environment-friendly combined polyether for a sprayed pipeline and a preparation method of the special environment-friendly combined polyether. The special environment-friendly combined polyether is composed of a component A and a component B, wherein the component A is composed of polyethylene-polypropylene glycol, polyester polyol, a crosslinking agent, a foam stabilizer, a catalyst and a foaming agent; the component B is polymethylene polyphenyl polyisocyanate. By using the special environment-friendly combined polyether, the problems of inside cracking, heart rot and surface roughness of sprayed foam are solved, the aim of completely protecting the environment is achieved, meanwhile, the bonding property of the foam and a base material is improved, and the production requirement of the process is met.

Owner:SHANDONG INOV NEW MATERIALS CO LTD

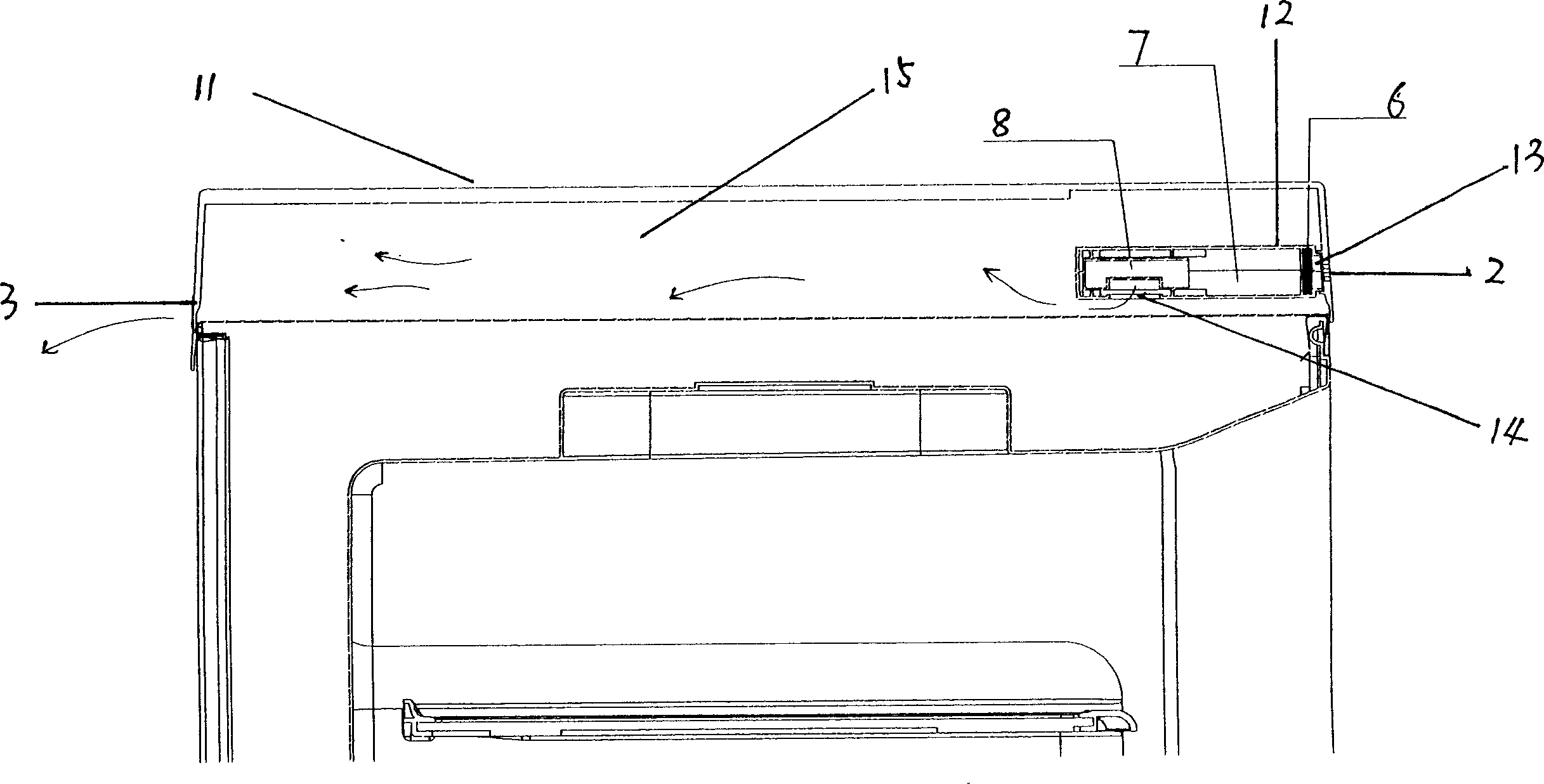

Dodging lens, backlight module using dodging lens and display device

ActiveCN103032817ASimple molding processGood light uniformityPoint-like light sourceElongate light sourcesDisplay deviceLight source

The invention provides a dodging lens, a backlight module using the dodging lens and a display device. The dodging lens comprises a containing part for containing a light source and a diffusion part, wherein a cavity chamber is internally arranged in the containing part; and a V-shaped slot is formed at the external surface of the diffusion part. The backlight module using the dodging lens comprises an optical film material and a light source device which is arranged at one side of the back surface of the optical film material; and the light source device comprises the dodging lens and a light source. The display device comprises the backlight module using the dodging lens. The dodging lens is different from a round second lens; the length of the dodging lens is determined according to different sizes; the shaping technology is simple; and the dodging effect is excellent. Because the backlight module using the dodging lens adopts the dodging lens provided by the invention, the light emitting effect is better, and the cost is greatly reduced. Because the display device adopts the backlight module provided by the invention, the quality of a product can be greatly improved.

Owner:BOE TECH GRP CO LTD +1

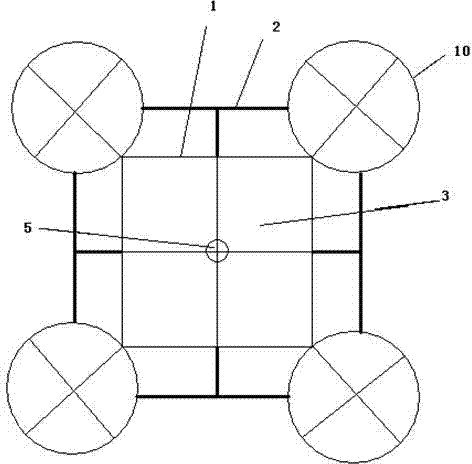

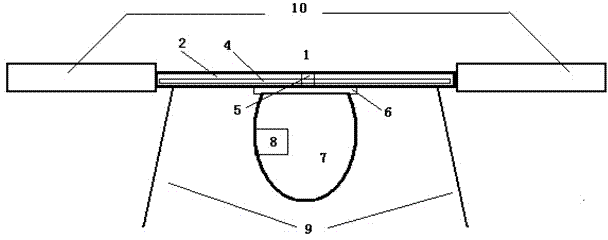

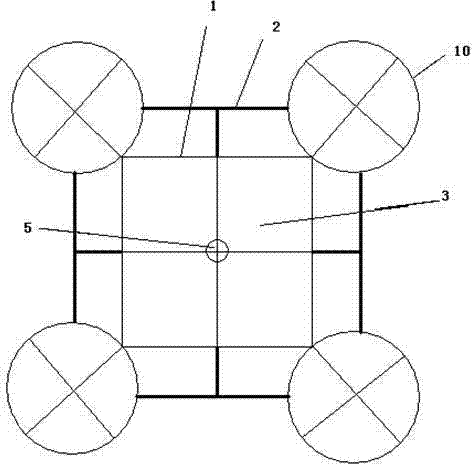

Solar electric helicopter

InactiveCN102602540AMeet environmental protection and energy savingImprove flight capacityEfficient propulsion technologiesDepending on number of propellersPropellerElectric equipment

The invention relates to a helicopter using solar energy and storage batteries, which comprises a body, a frame, a solar panel and a storage battery set. The frame is fixed on the body. The solar panel is disposed on the upper surface of the storage battery set which is mounted on the body and / or the frame. A propeller is fixed on the frame. A cab is hinged to the body through rotary shafts. A controller for controlling rotation of the propeller and the cab is disposed in the cab. A landing support for stabilizing the helicopter in landing is connected with the frame. The helicopter is powered by electric energy only, using the solar panel to generate power supplied to electric equipment in the helicopter in real time can meet the double requirements of environmental friendliness and energy conservation and greatly improved flying capacity, and the helicopter is low in manufacturing process requirements, simple and accurate in operation, convenient in management, low in maintenance, environment-friendly, energy-saving, high in flying capacity, long in airborne period, high in reliability, high in energy conservation rate, widely applicable to civil fields of practical flying training, aerial surveillance.

Owner:SOUTH CHINA NORMAL UNIVERSITY

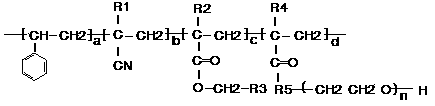

Processless thermal sensitive plate used for direct printing on printer

ActiveCN105372935AHigh molecular weightAchieve environmental goalsPhotosensitive materials for photomechanical apparatusChemistryOptical radiation

The invention discloses a processless thermal sensitive plate used for direct printing on a printer. The processless thermal sensitive plate comprises a support body, a thermal sensitive layer and a protective layer, wherein the thermal sensitive layer mainly comprises 30-70% of water soluble thermo-crosslinking polymer, 1-15% of cross-linking agent, 10-30% of polyfunctional group monomer, 1-20% of thermal sensitive initator and 1-20% of infrared light radiation absorbing dye according to percentage by weight based on the composition solid total weight. The shortcomings of low plate developing capacity and bad printing durability in the existing processless thermal sensitive CTP (computer to plate) technology are solved.

Owner:LUCKY HUAGUANG GRAPHICS +1

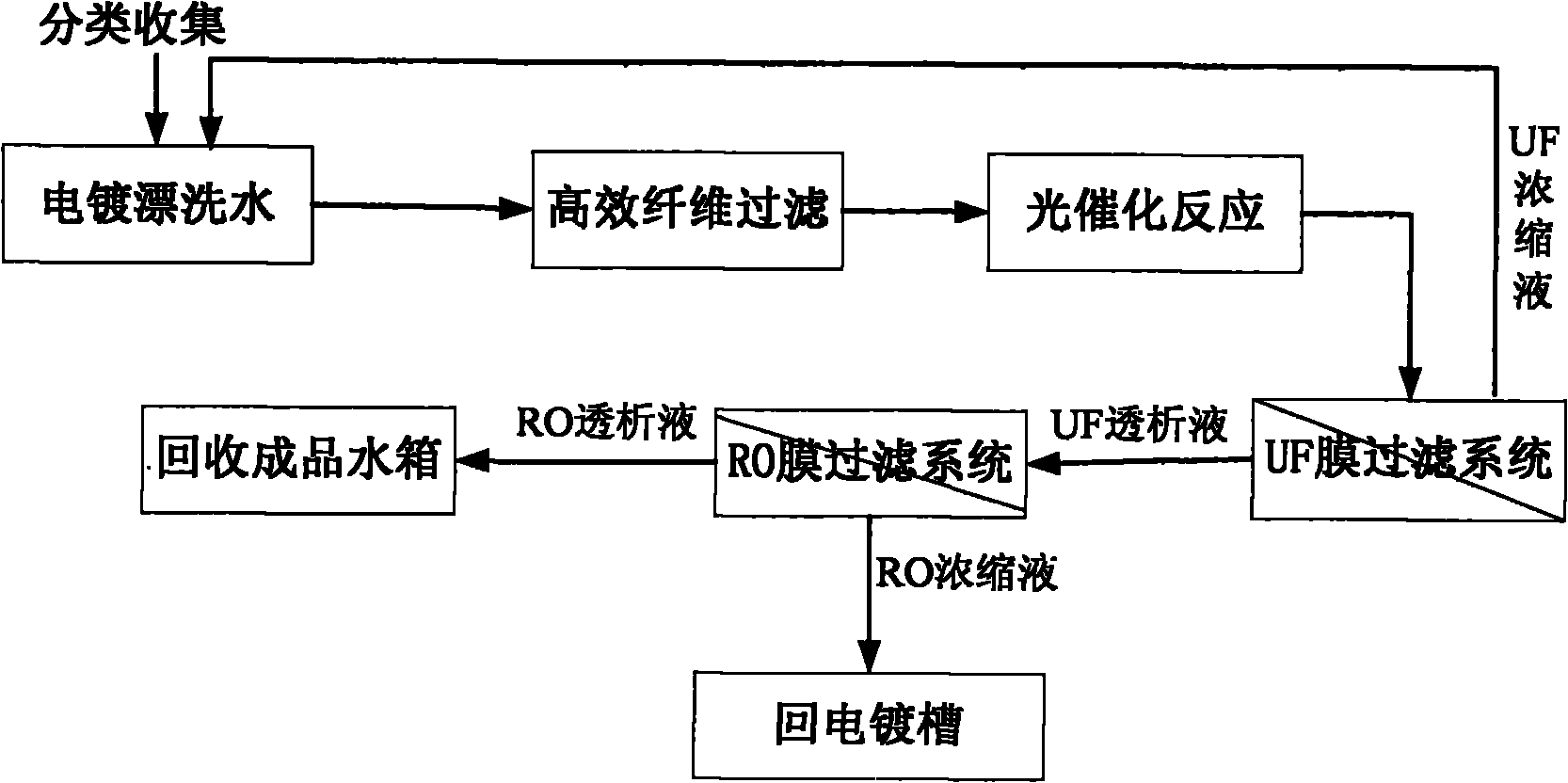

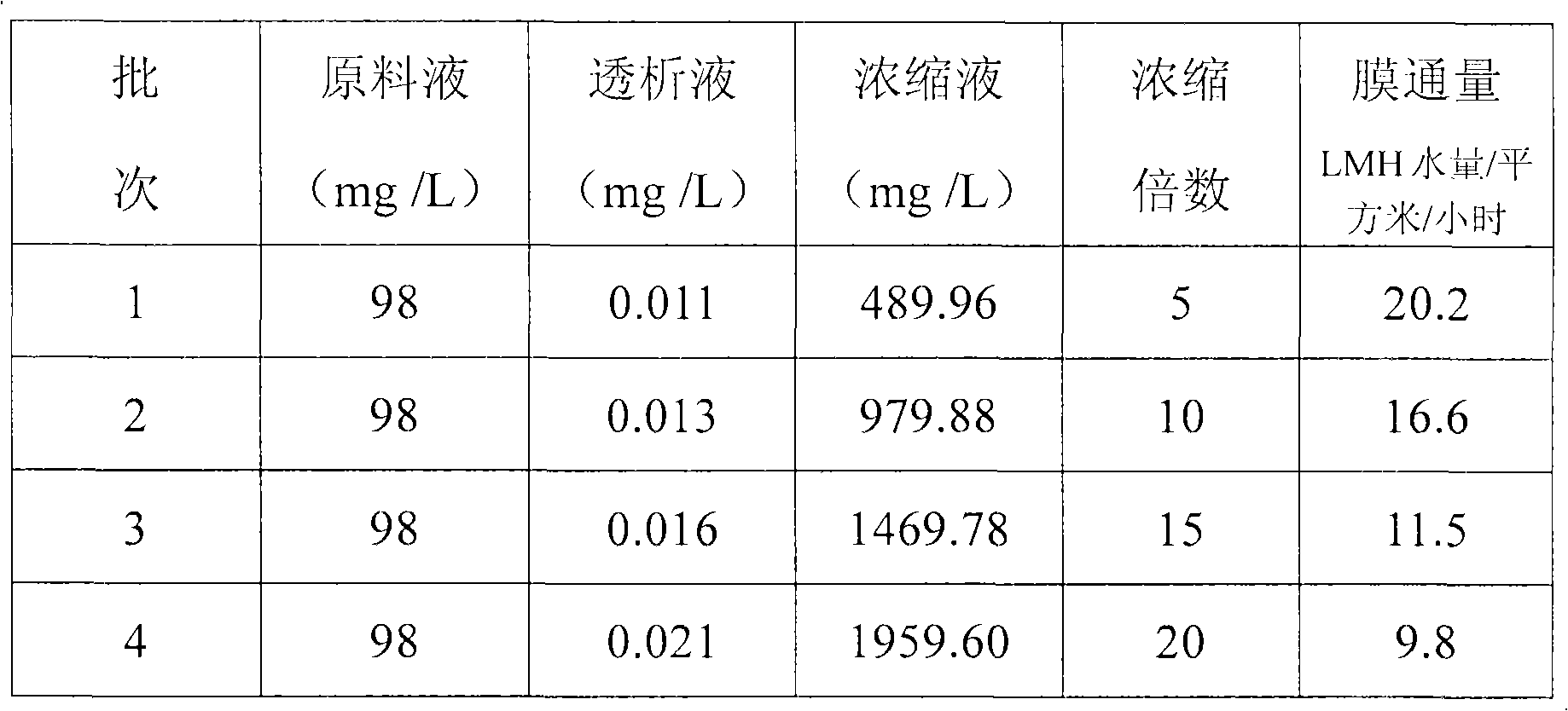

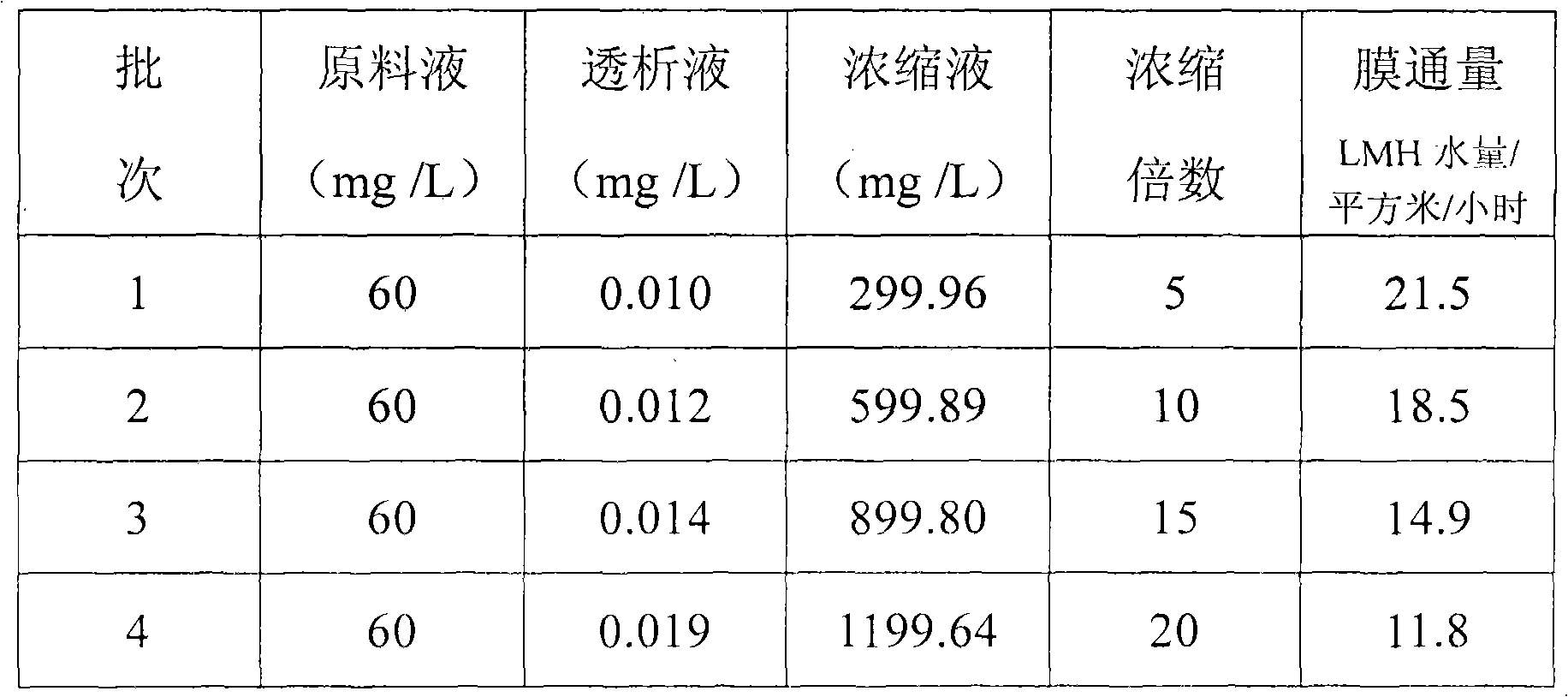

Method for treating electroplate rinsing wastewater

InactiveCN102020385AReduce dosageConducive to expansion needsWater/sewage treatment by irradiationWater/sewage treatment bu osmosis/dialysisFiberPhotocatalytic reaction

The invention provides a method for treating electroplate rinsing wastewater, mainly comprising the following steps: (1) classification and collection of electroplate rinsing water; (2) efficient fiber filtration; (3) light-catalyzed reaction; (4) ultrafiltration (UF) by a filtering system; (5) membrane filtration by a reverse osmosis (RO) system; (6) separation of dialysis fluid by an RO membrane and recovery of the dialysis fluid in a finished-product water tank; and (7) separation of strong liquor recovery by an RO membrane and recovery. The method for treating the electroplate rinsing wastewater is used to realize wastewater recycling, reduce the rinsing water usage amount, achieve the zero emission requirement of the wastewater, and decrease the scale of biochemical and physical treatment; the method for treating the electroplate rinsing wastewater is beneficial to the expansion requirement of enterprises, and is used to recycle useful metal ions, thus leading the enterprises to generate benefits at the same time of achieving the purpose of being environment-friendly; and the system is convenient for operation, and occupies less area.

Owner:广州凯膜过滤设备有限公司

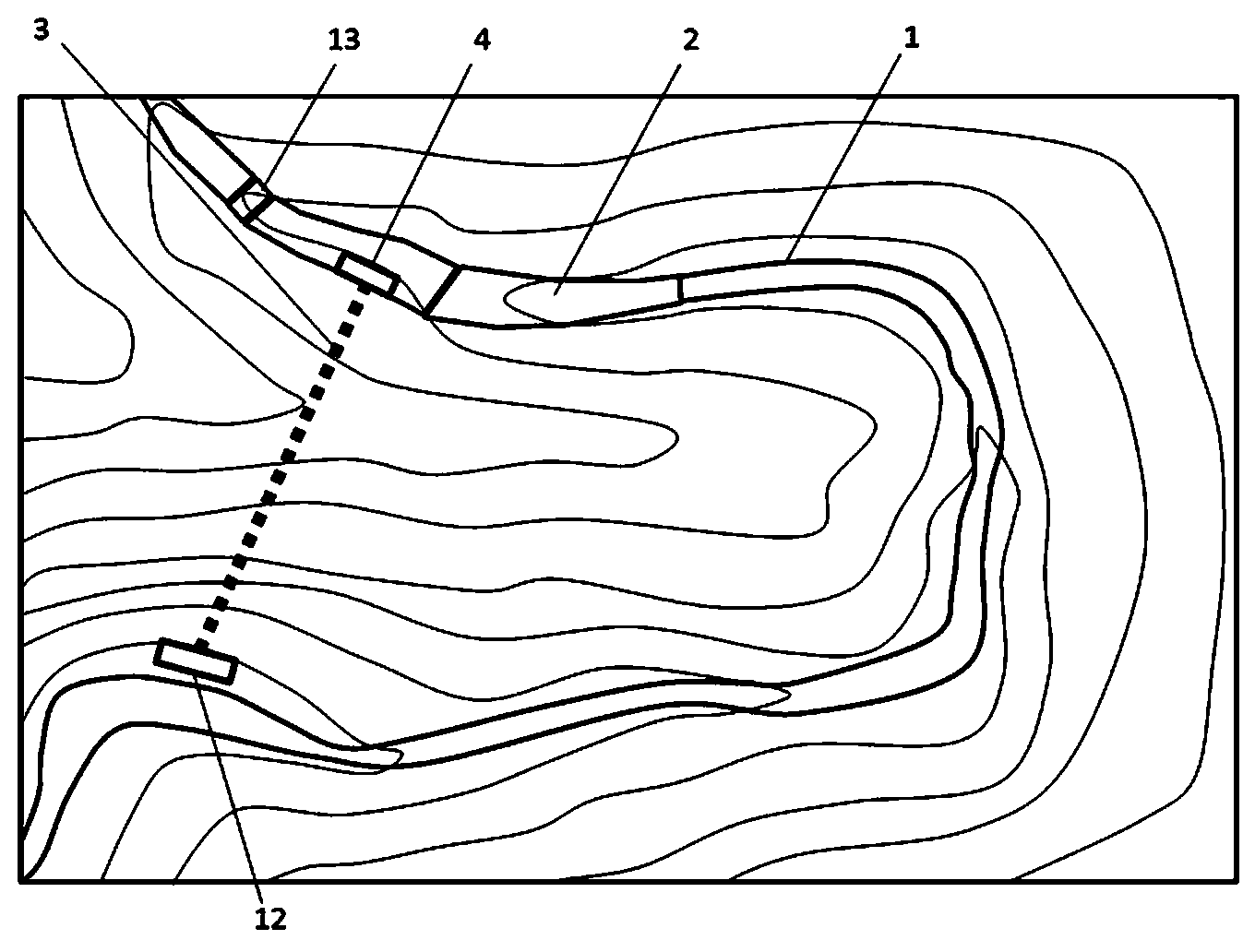

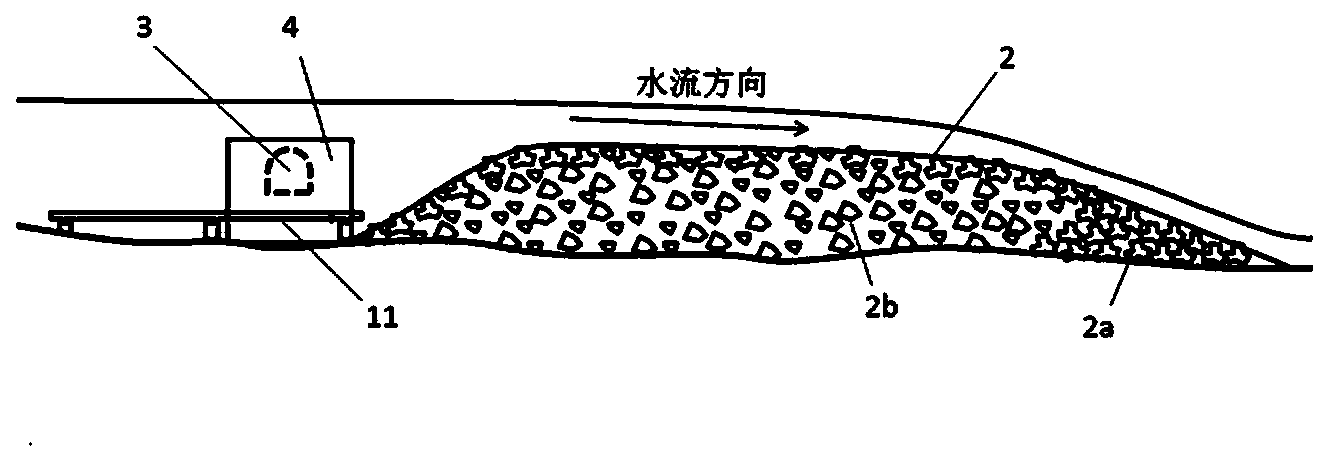

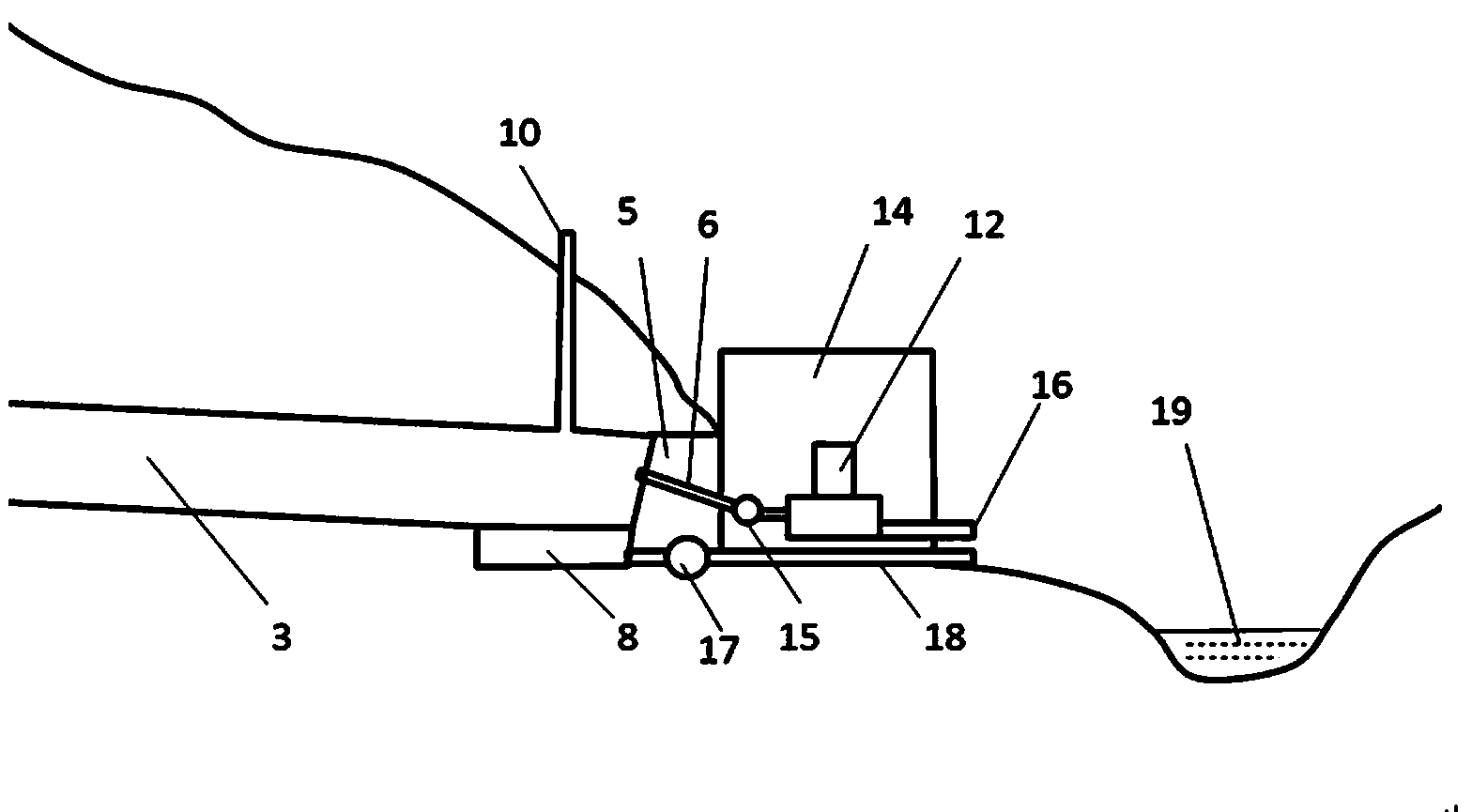

Low overflow dam cave depot type hydropower station

InactiveCN103510493AAvoid cut-offAvoid destructionWater-power plantsHydro energy generationWater turbineWater diversion

The invention relates to a low overflow dam cave depot type hydropower station. An low overflow dam is built at the upstream position of a river with an arc-shaped way; a water diversion tunnel cave depot of which the water diversion amount reaches or exceeds the annual average runoff of the river is built between the upstream position and the downstream position of the arc-shaped way of the river; the water inlet of the cave depot is positioned at the upstream position of the low overflow dam; a submerged front pool of which the top is lower than the body of the low overflow is built, or a channel of which the diameter is greater than that of the opening of the cave depot is built at the front end of the water inlet of the cave depot for water diversion from the cave depot, and a gate is built on the channel; a blocking wall body and a longitudinal water diversion pipeline are arranged at the water outlet tail end of the cave depot; the longitudinal water diversion pipeline is arranged in the blocking wall and used for connecting the cave depot with a water-turbine generator set outside the cave depot; the low overflow dam refers to that the dam body can be partially percolated by river water, part of the river water can overflow the top of the low overflow damp to flow downstreams in the high water period, and part of the river water seeps from the dam body and flows towards a dam body at the downstream position. The low overflow dam cave depot type hydropower station does not need to cut off the river, can be built on a river with a small or even very small head drop, further increases the utilization ratio of hydropower resources, and is low in construction difficulty.

Owner:贵州道轮水电科技开发有限公司

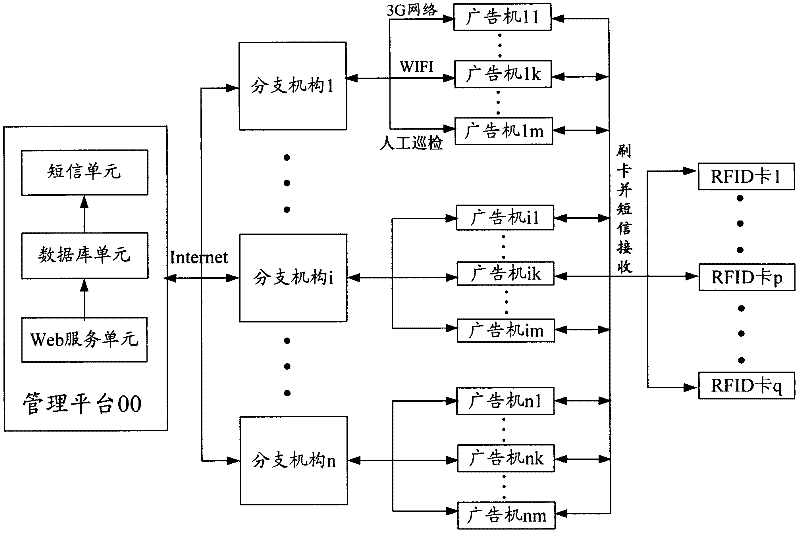

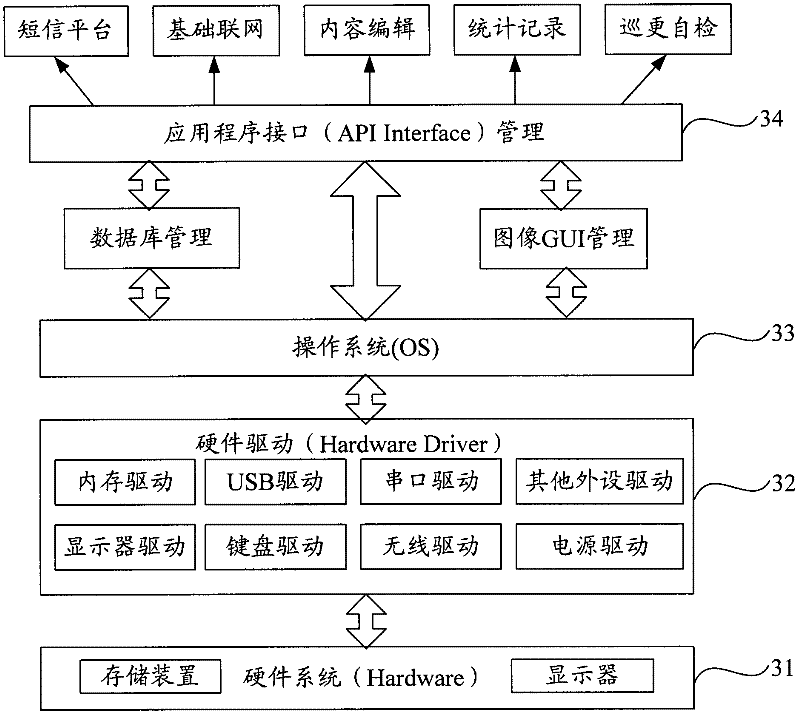

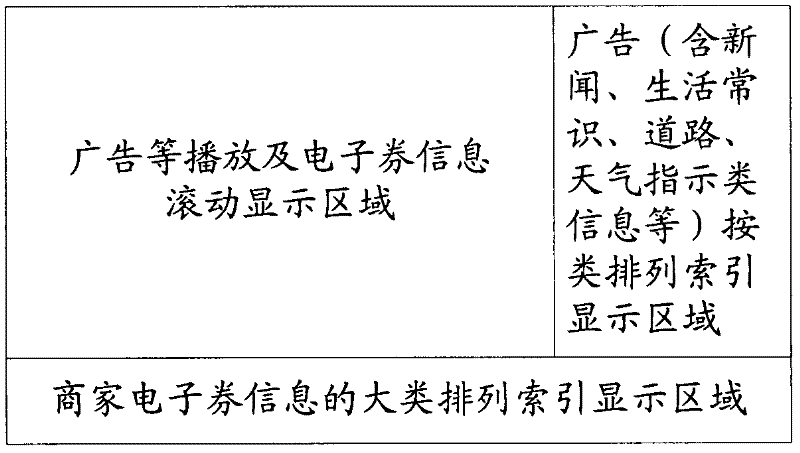

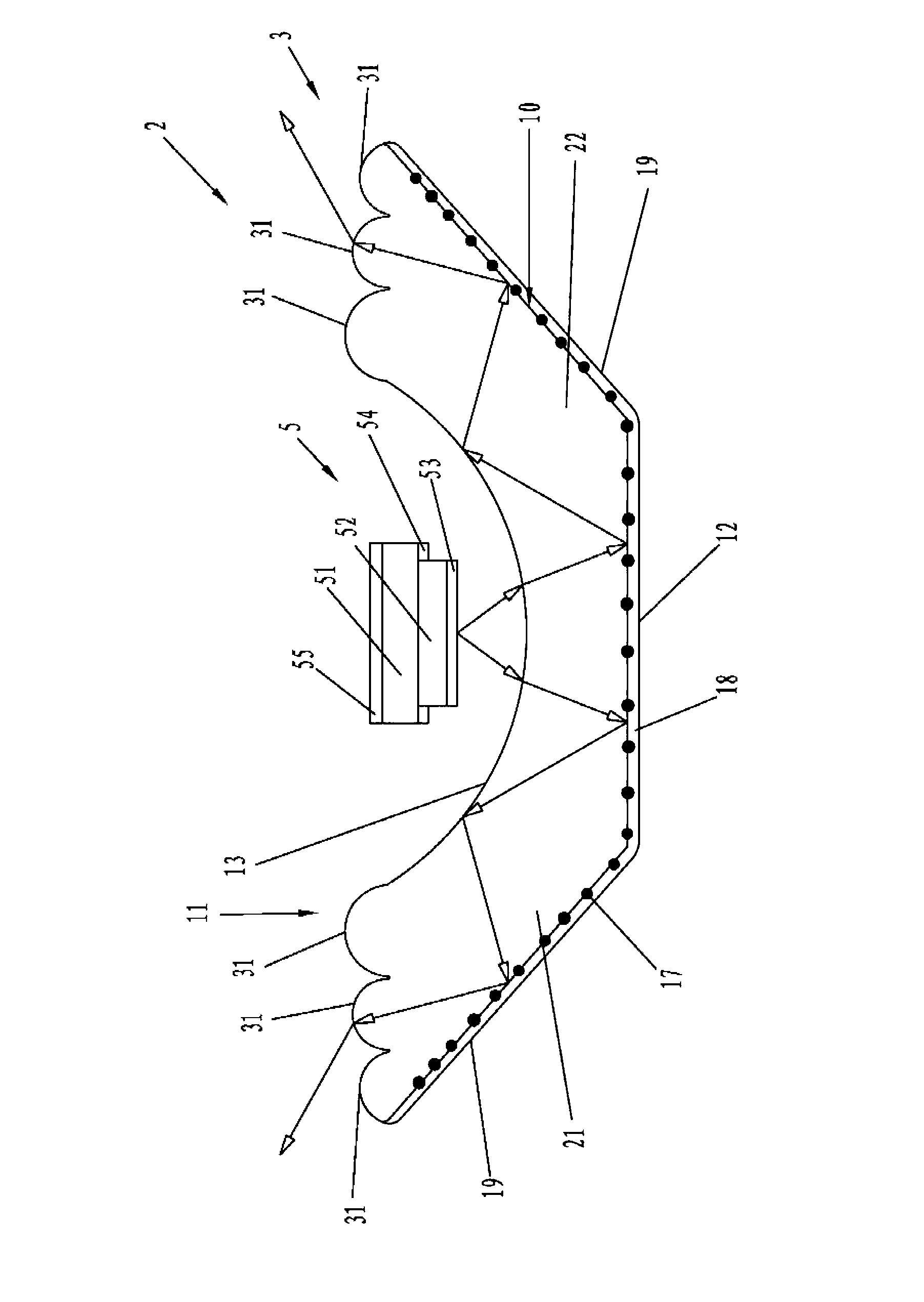

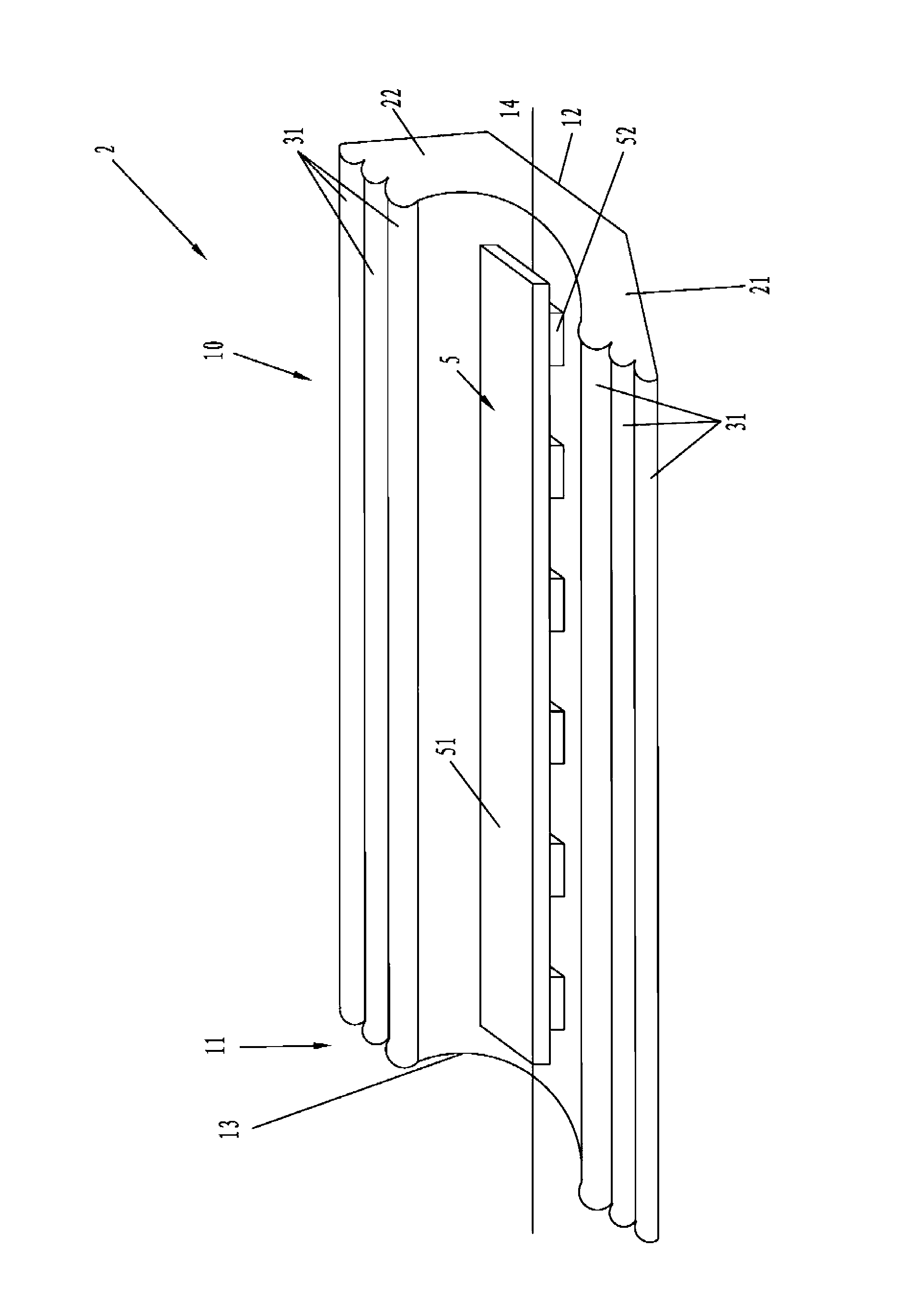

RFID-technology-based electronic coupon distribution system and use method thereof

InactiveCN102592238AReduce the burden onSave operating timeMessaging/mailboxes/announcementsMarketingDistribution systemMobile phone

The invention provides an RFID-technology-based (Radio Frequency Identification) electronic coupon distribution system and a use method of the electronic coupon distribution system. Electric coupon information and advertisement are gathered by a management platform and an advertisement machine and are displayed on the corresponding advertisement machine, then a user holds a mobile-number-based RFID card registered and verified by the management platform in a hand, swipes the card on the advertisement machine and selects an electronic coupon, then a mobile phone receives an electric coupon short message, and the acquired electronic coupon is used as a voucher of goods purchase and replaces the traditional advertisement machine and paper discount advertisement, discount coupons / cards, consumption coupons / cards, exchange coupons / cards, etc. in the prior art. Therefore, the resource waste is reduced, and a simple and convenient merchant electronic coupon information downloading method, which is targeted, is formed to achieve the purpose of environmental protection, alleviate the load of consumers to maintain various hard discount cards, and improve the traditional mode of business information dissemination and consumption.

Owner:上海真灼科技股份有限公司

Reflecting lens, backlight module using reflecting lens and display device

ActiveCN103017085ASimple molding processEasy to assemblePoint-like light sourceNon-linear opticsDisplay deviceOptoelectronics

The invention provides a reflecting lens, a backlight module using the reflecting lens and a display device, wherein the reflecting lens comprises a lens body having a reverse frustum shape; a larger-area first surface of the lens body is a light-emergent surface; a groove is arranged on the first surface; a first side wall and a second side wall of the groove are opposite to each other; a second surface and two side surfaces are reflecting surfaces; the backlight module comprises a diffuser plate and a light source device; the light source device comprises the reflecting lens provided by the invention and a light source arranged in the groove of the reflecting lens; and the display device provided by the invention comprises the backlight module using the reflecting lens provided by the invention. The reflecting lens provided by the invention can be excellently applied to a straight falling type backlight module as well as a corner type backlight module. The backlight module using the reflecting lens provided by the invention achieves an effect of increasing a light-emergent angle, is matched with a downward illuminating light source and has better light-emergent quality. The backlight module provided by the invention is adopted by the display device provided by the invention, so that the display quality is greatly increased.

Owner:BOE TECH GRP CO LTD +1

Automatic flocking machine

InactiveCN102580896AIncrease productivityEasy to manageLiquid spraying plantsLiquid surface applicatorsTextile printerDrive motor

The invention discloses equipment for the clothing industry, and particularly relates to an automatic flocking machine, which is used for flocking on cloth. The automatic flocking machine is characterized by comprising a support, a platform, a textile printing device, a lift flocking device, a drying device, a fluff suction device and driving motors. The support is provided with a circular conveying belt, the platform is fixedly arranged on the conveying belt and moves along with the conveying belt simultaneously, the textile printing device is arranged on the conveying belt of the support, the lift flocking device is arranged on one side of the textile printing device in front of the conveying belt, the drying device is arranged on one side of the lift flocking device in front of the conveying belt, the fluff suction device is arranged on one side of the drying device in front of the conveying belt, the driving motors driving the conveying belt to rotate are arranged at two ends of the conveying belt respectively. Besides, the textile printing device is arranged above the platform, the lift flocking device is arranged above the platform, the drying device is arranged above the platform, and the fluff suction device is arranged above the platform. The automatic flocking machine is high in production efficiency, easy to manage and is cost-saving and environment-friendly.

Owner:余兴东

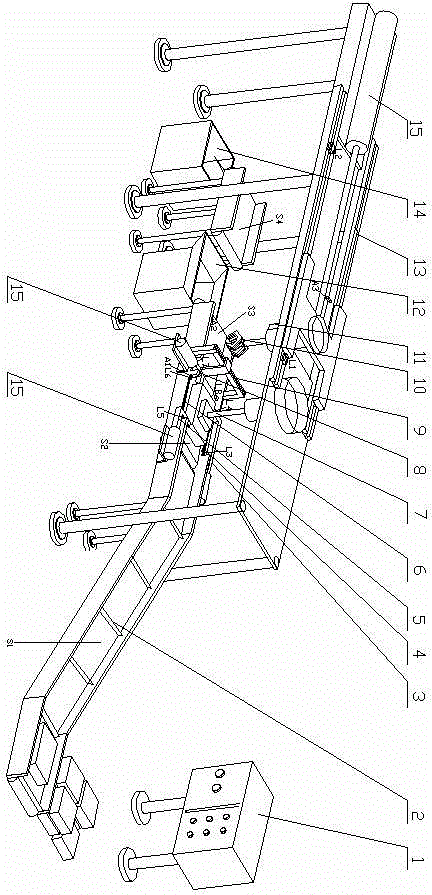

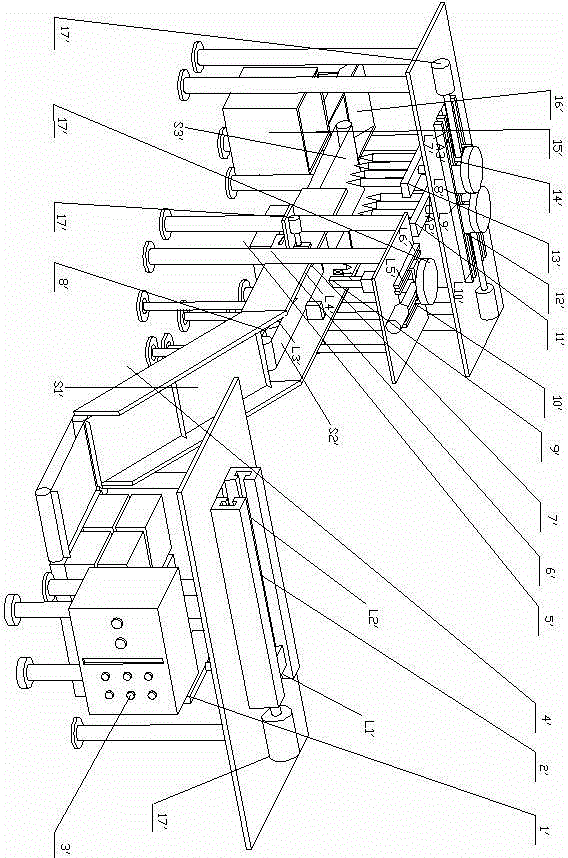

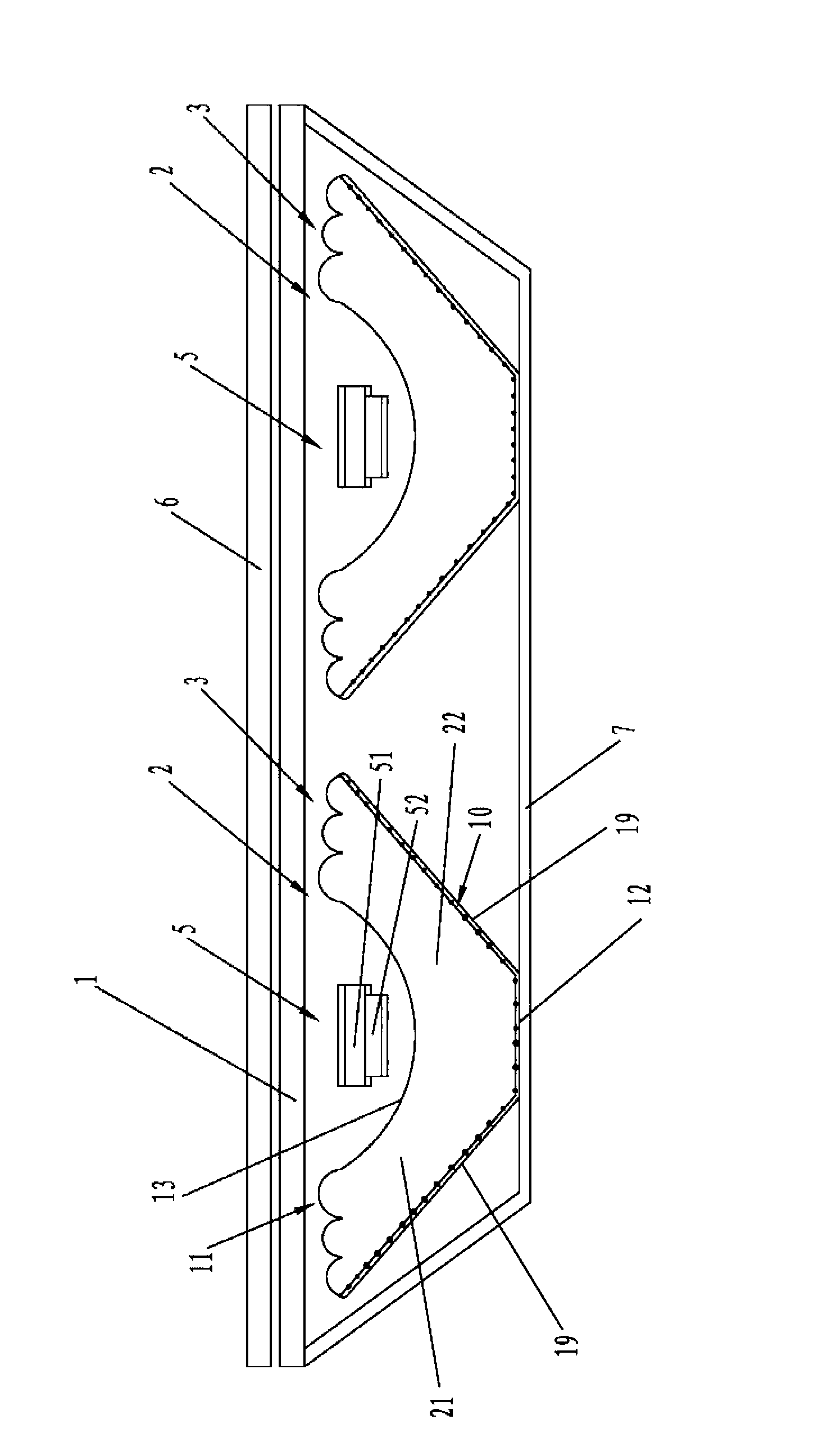

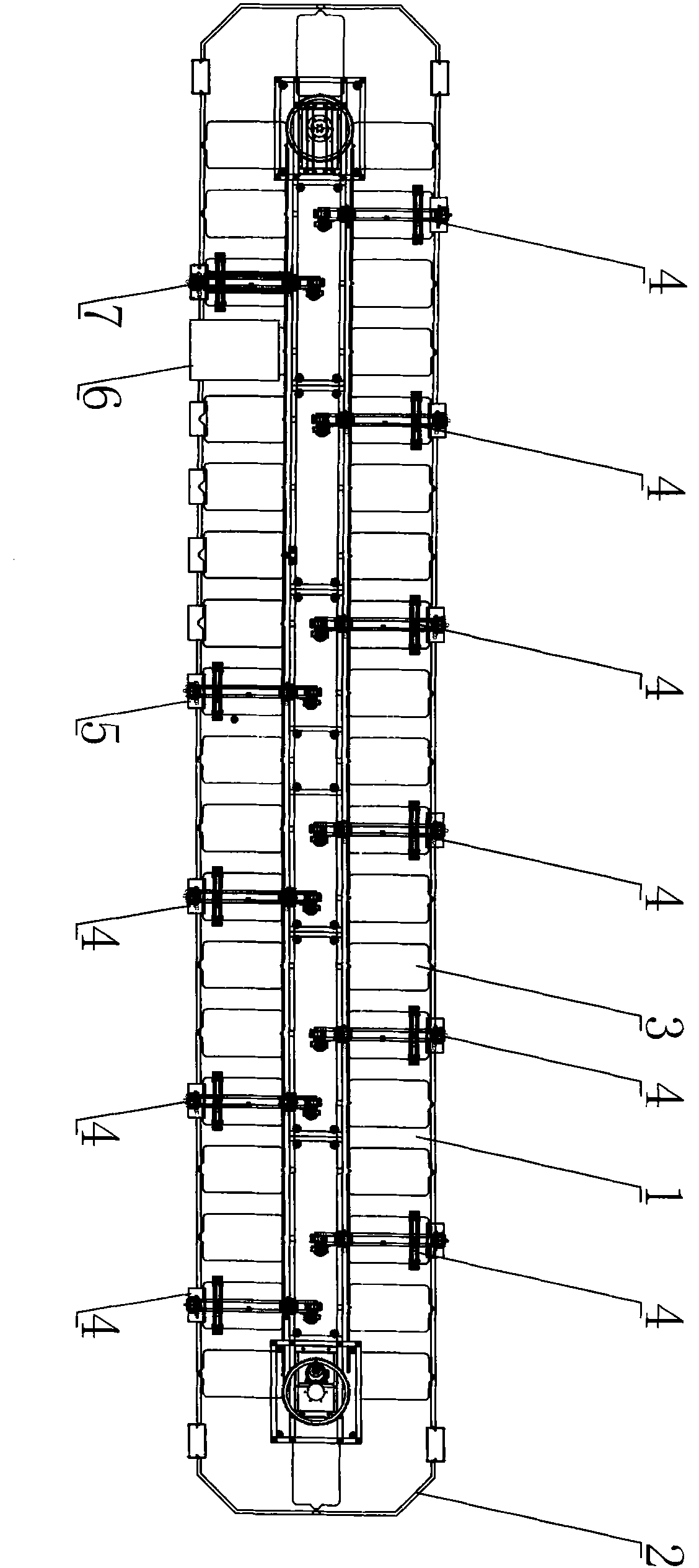

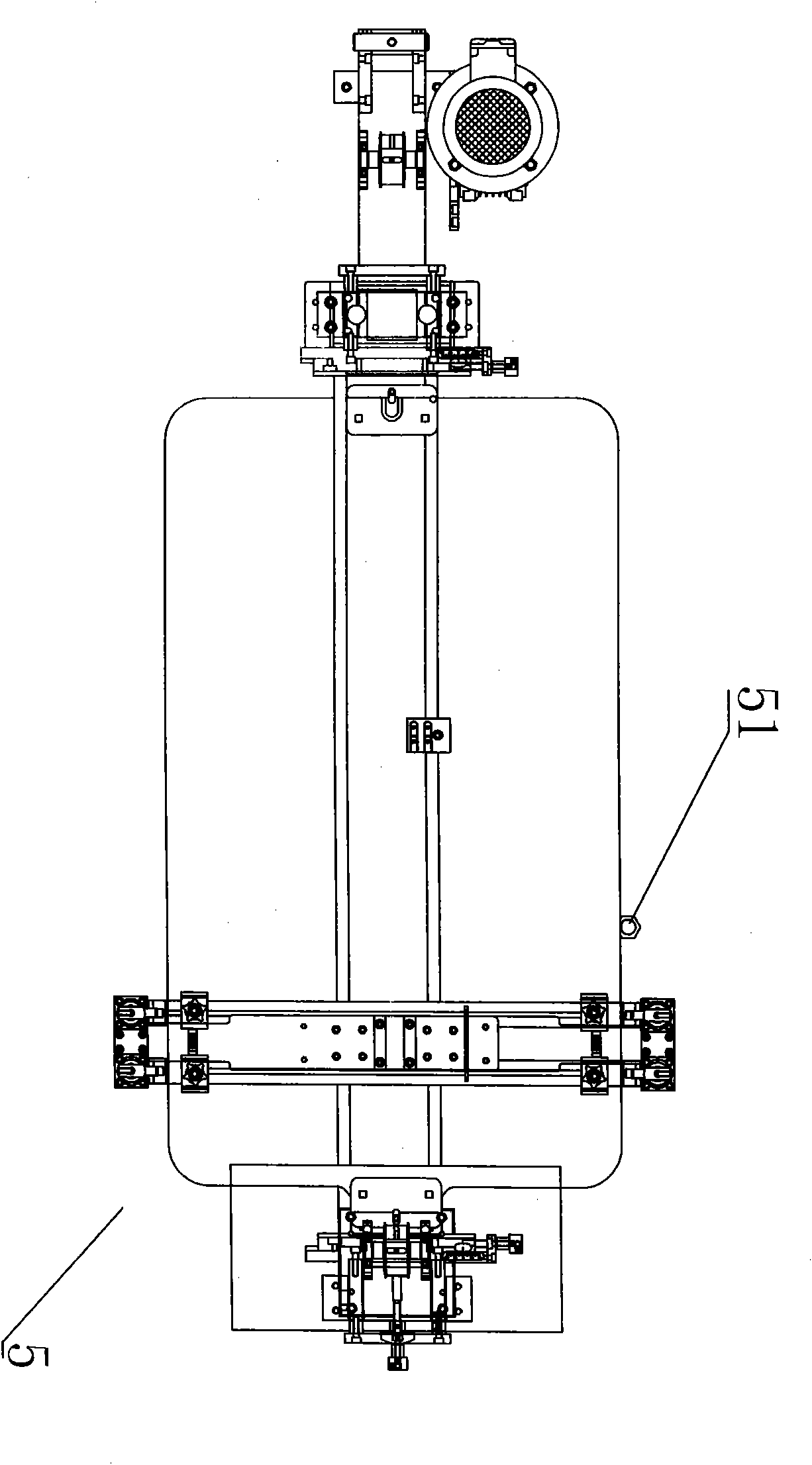

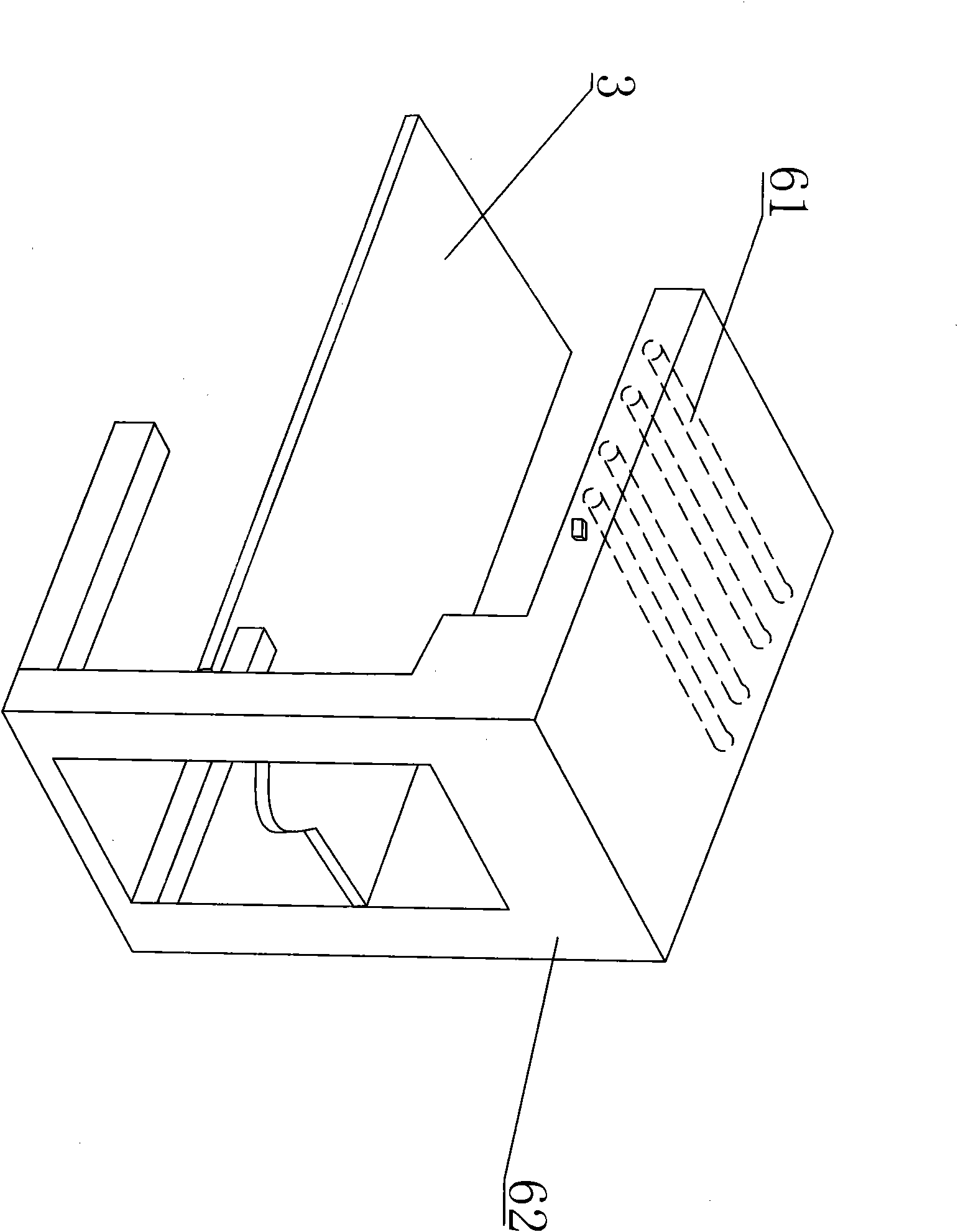

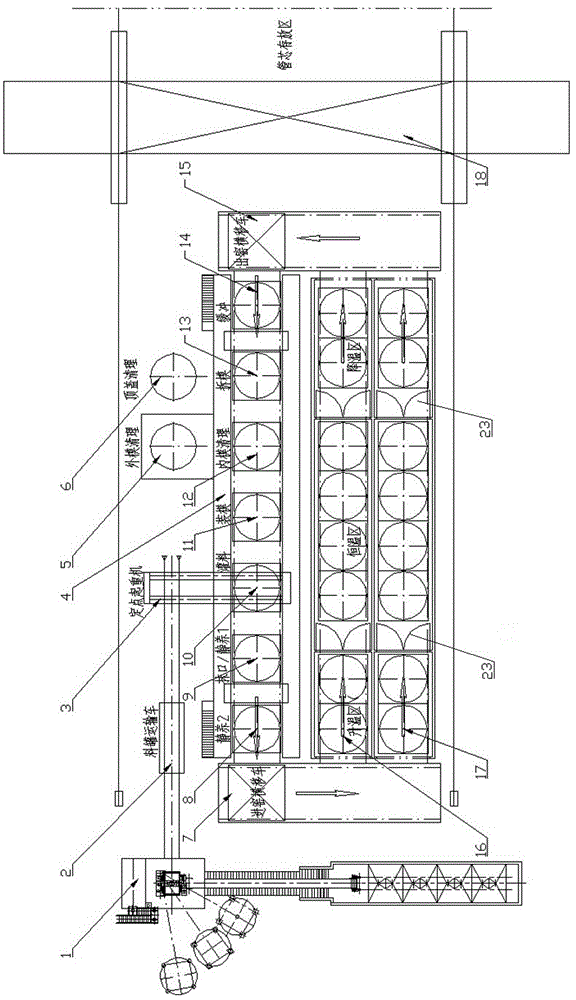

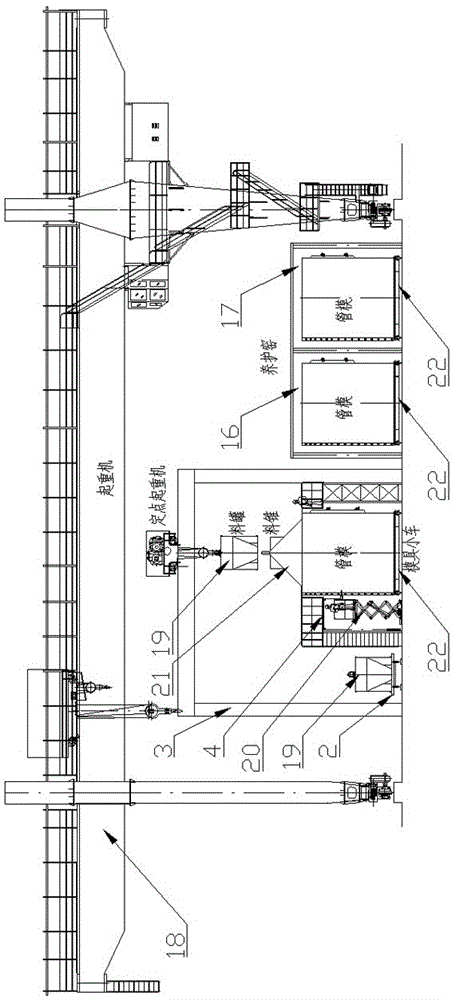

PCCP pipe core vertical molding method automatic production line

InactiveCN105922437AAdvanced technologyReduce manual labor intensityCeramic shaping plantsAuxillary shaping apparatusManufacturing engineeringControl system

The invention provides a PCCP pipe core vertical molding method automatic production line; and the PCCP pipe core vertical molding method automatic production line has such characteristics as stable performance, good reliability, easy maintenance, high safety, automation, high information degree and high production efficiency. The PCCP pipe core vertical molding method automatic production line comprises more than one operation lines, more than one maintenance lines, mold pushing devices, concrete loading and casting systems, mold transfer cars, transverse moving ferry vehicles, a maintenance line control system and a PLC production line control system; multiple sets of PCCP molds are arranged on the operation lines and the maintenance lines; the mold pushing devices are arranged on the operation lines and the maintenance lines; the mold transfer cars can move on the operation lines and the maintenance lines; the transverse moving ferry vehicles are matched with the operation lines and the maintenance lines; the concrete loading and casting systems are arranged on the operation lines for casting PCCP molds on the operation lines; the maintenance line control system is used for performing steam control for molds on the maintenance lines; and the PLC production line control system is used for interworking of all systems to finish prefabricating of PCCP pipe cores.

Owner:SHANDONG ELECTRIC POWER PIPELINE ENG

Mechanical flocking plant

InactiveCN103521405AIncrease productivityImprove product qualityLiquid spraying plantsLiquid surface applicatorsProduction lineDrive motor

The invention relates to a mechanical flocking plant and belongs to the technical field of flocking machines. The mechanical flocking plant comprises a supporting frame, a faller, a flocking device, a baking device and a cleaning device. The supporting frame is provided with a circulation conveyor belt, the faller is fixedly arranged on the conveyor belt and simultaneously moves along with the conveyor belt, and the flocking device, the baking device and the cleaning device are arranged on the conveyor belt of the supporting frame in sequence. Drive motors are arranged at the two ends of the conveyor belt respectively and drive the conveyor belt to rotate. The whole processes from electrostatic flocking and drying to fluff removing are operated in a full automation mode, production efficiency and product quality of prints are greatly improved, besides, management of a production line is facilitated, and the purpose of protecting the environment is achieved.

Owner:JIASHAN YIXIN FLOCKING

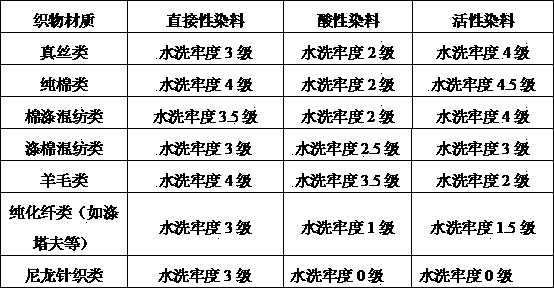

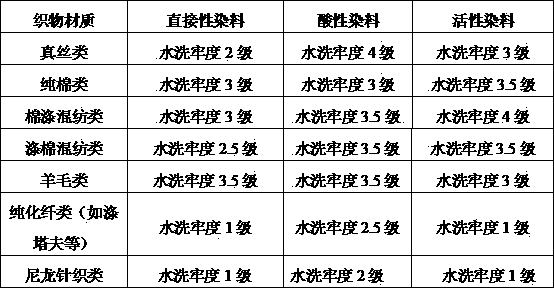

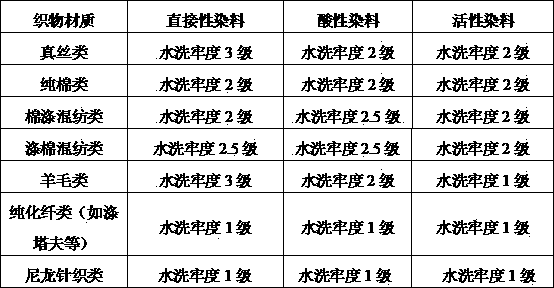

Treating agent for digital printing and dying as well as preparation method and application method of treating agent

ActiveCN103628333ASimple dyeing and finishingLess waste waterDyeing processDigital printingChemistry

The invention discloses a treating agent for digital printing and dying as well as a preparation method and an application method of the treating agent. A coupling cationic graft modification agent is prepared by using a cationic auxiliary agent, a cationic etherifying agent, a humectants, an organic solvent and water, and is sprayed on the back of pretreated fabric; the fabric is dried and subjected to digital printing, and is soaked in a coupled reaction agent prepared from a reactant, organic acid and water, a color developing agent reaction solution prepared from a color developing agent and water, and a dye-fixing reaction solution prepared from a dye-fixing agent and water respectively for 30 seconds to react for being dyed; finally, watering is carried out. The treating agent as well as the preparation method and the application method of the treating agent have the advantages that the digital dyeing treatment can be completed quickly at normal temperature, high temperature is not required, and various fibers can be dyed by using direct dyes, acid dyes and reactive dyes.

Owner:舜天嘉诚(天津)新材料科技发展股份有限公司

Energy-saving refrigerator with air purification function

ActiveCN1837726ASpeed up the flowImprove cooling effectDomestic cooling apparatusLighting and heating apparatusAir purifiersRefrigeration

The invention relates to an energy-saving refrigerator with air purifying function. Wherein, the refrigerator has an interlayer at top and contains an air purifier with whose ventilation function to adsorb and purify the indoor air to be blown out. And said air can accelerate the convection between the condenser and around air to improve the efficiency refrigeration system, reduce the energy consumption and avoid cross pollution between the indoor air and the refrigerator air.

Owner:HAIER GRP CORP +1

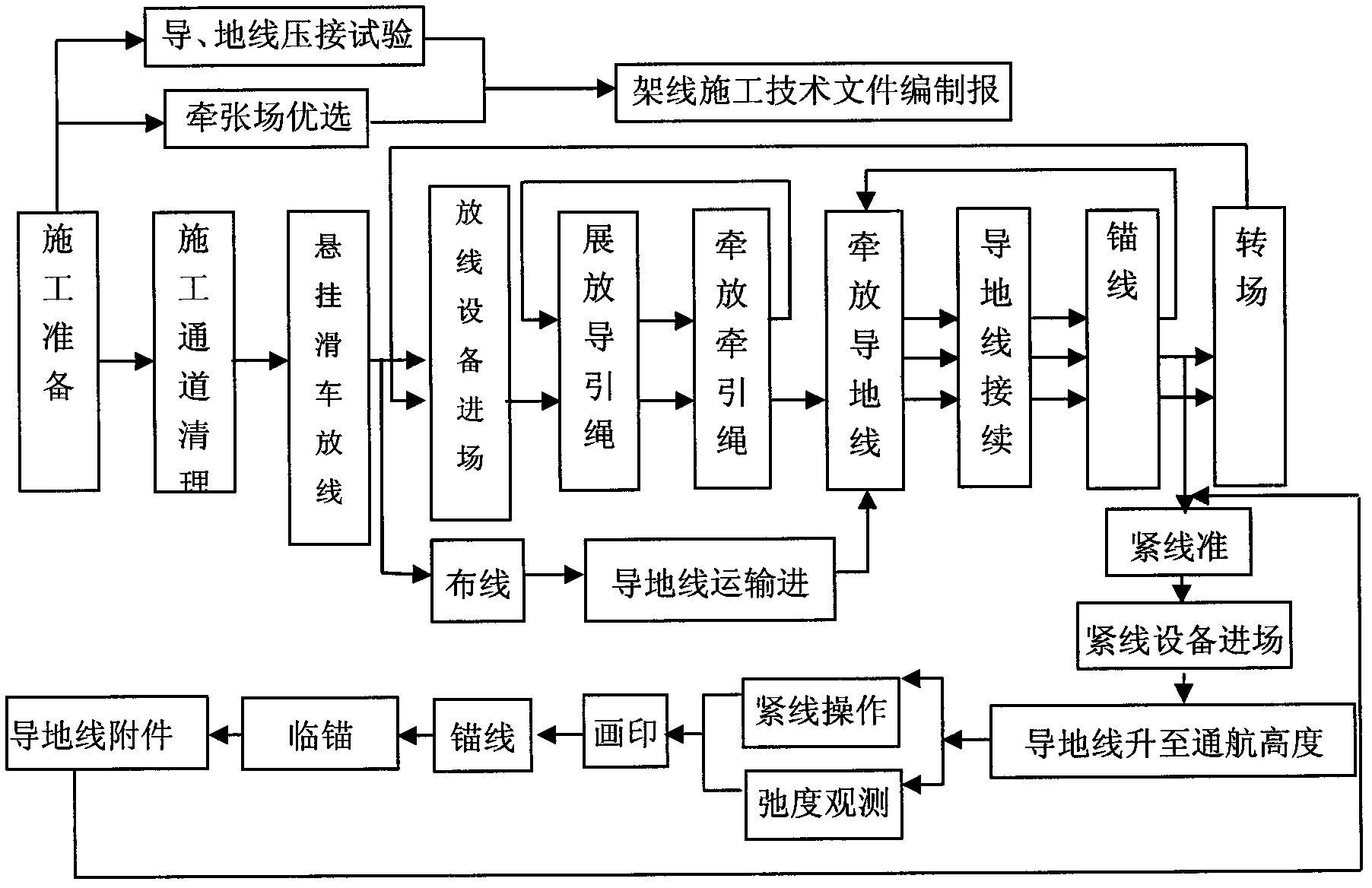

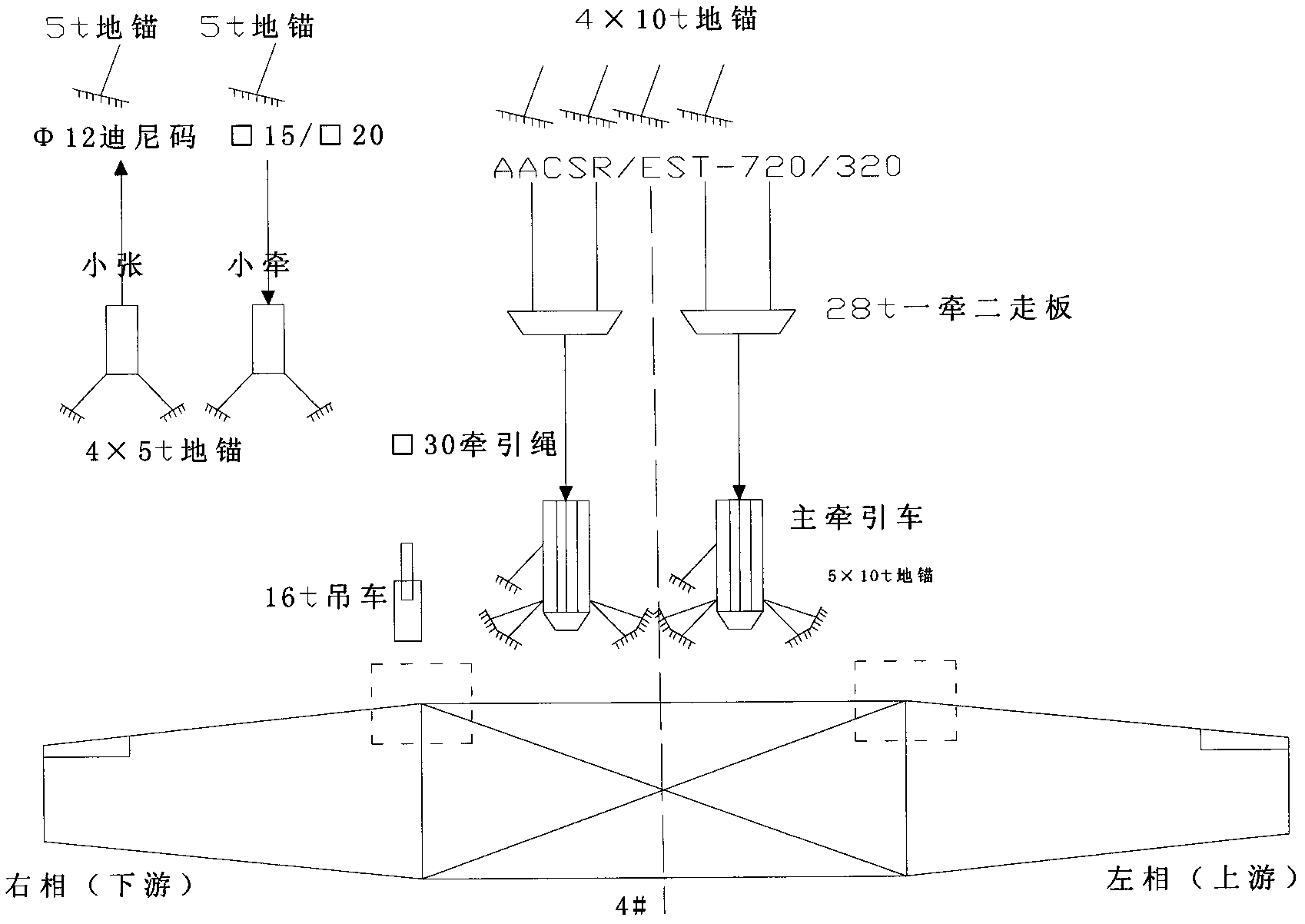

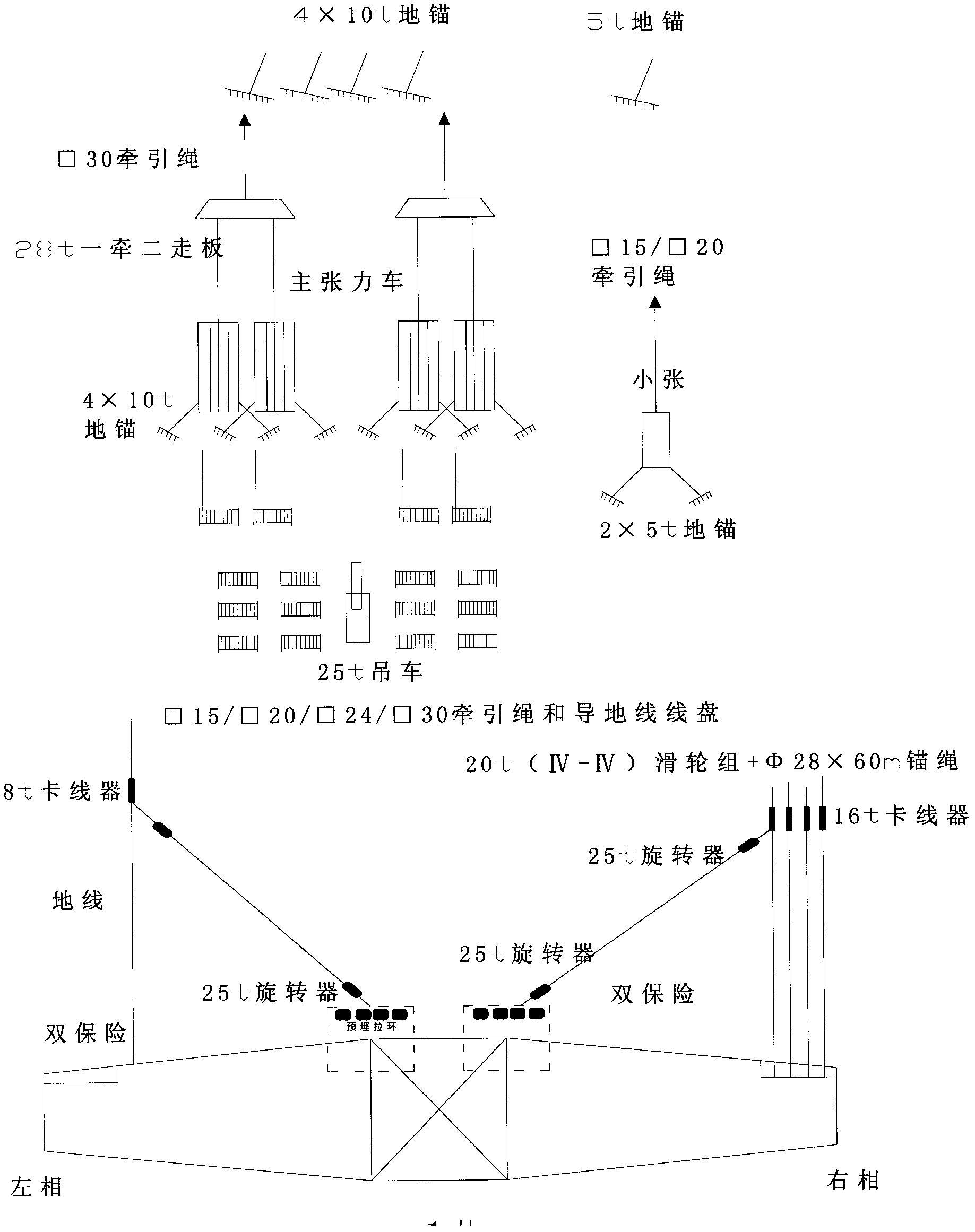

One-pulling-two expansion and construction process of large-section lead

ActiveCN102593759AGuarantee the construction qualityAvoid sag inconsistenciesApparatus for laying cablesArchitectural engineeringSmall footprint

The invention discloses a one-pulling-two expansion and construction process of a large-section lead. The expansion and construction process is characterized by comprising the following steps of: (1) construction preparation: performing crimping test on a lead and an earth wire, arranging a tension field space and a traction field space, and cleaning a construction channel; (2) hanging a tackle; (3) carrying out span construction; (4) carrying out tension stringing, expanding the earth wire and the lead, and carrying out temporary anchoring in time; and (5) crimping the lead, performing stringing, observing looseness, and lashing wires to complete the whole construction. According to the invention, the same-phase leads are guaranteed to have identical stringing tension, and the stringing construction quality is guaranteed; furthermore, the construction processes of stringing, tackle hanging, lead leading and traction rope expansion, lead expansion, stringing, accessory installation and the like are optimized, and the tension stringing construction efficiency is effectively improved; the manpower and time wastes are reduced, the required equipment quantity is small, the occupied area is small; and the one-pulling-two expansion and construction process has higher social economy.

Owner:HUBEI ELECTRIC POWER TRANSMISSION & DISTRIBUTION ENG

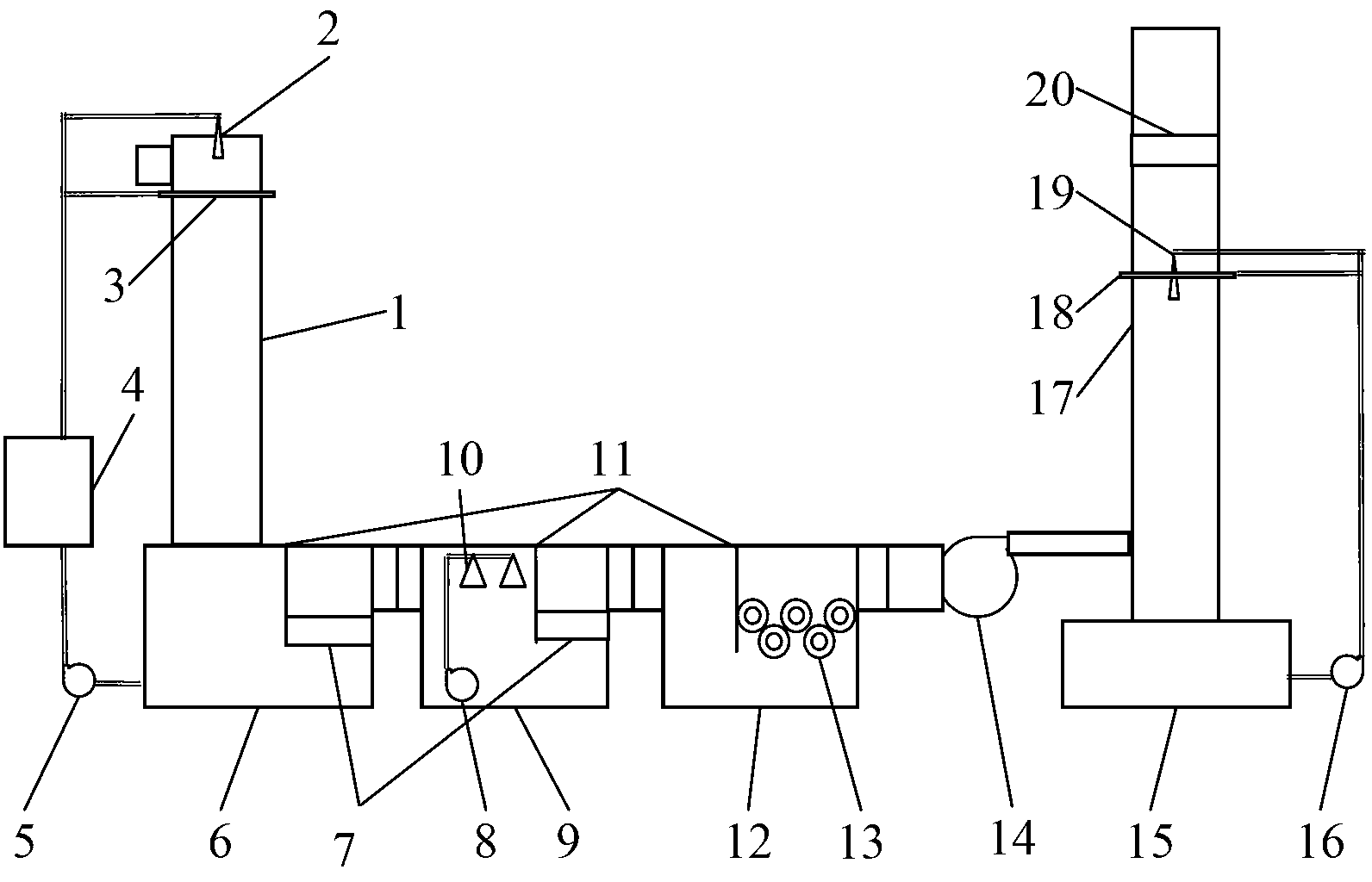

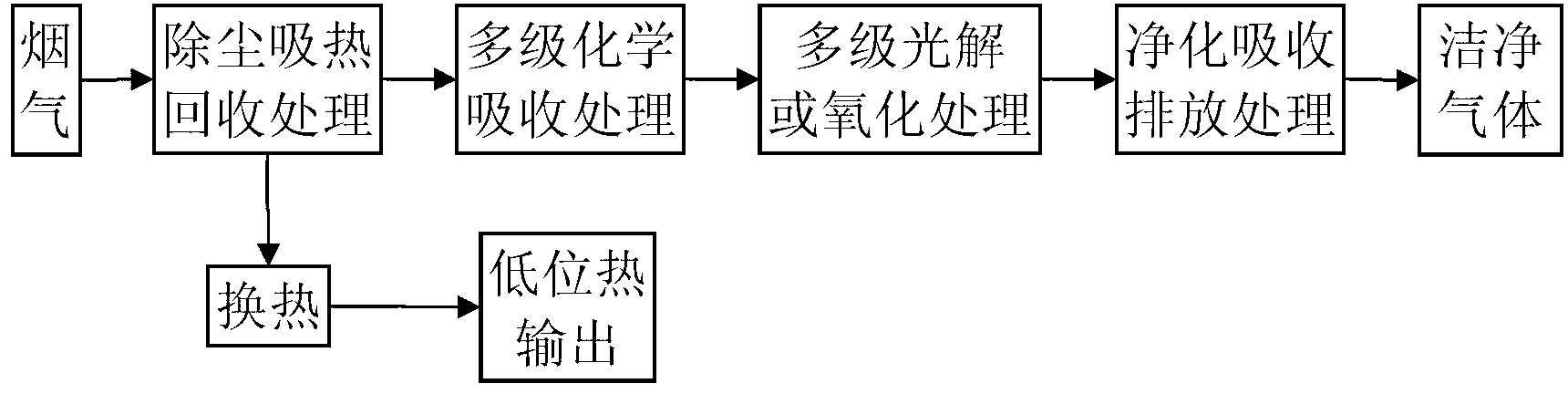

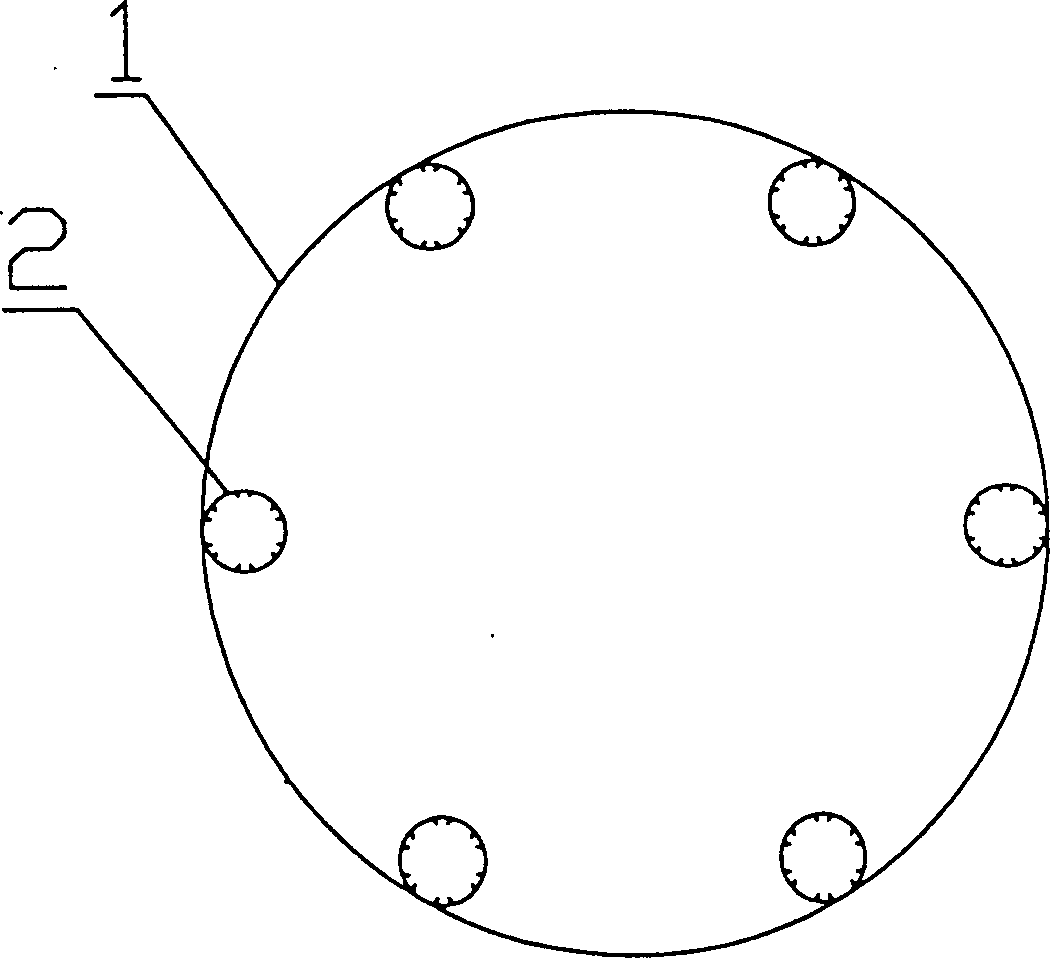

Sectional-type flue gas purifying treatment and waste heat recovery system device, and using method thereof

InactiveCN102836623AImprove purification efficiencySimple structureCombination devicesSulfur dioxideProcess engineering

The invention provides a sectional-type flue gas purifying treatment and waste heat recovery system device and a using method of the system device. A recovering tower, a spraying gas tank, a photolysis gas tank and a discharging tower in the system device are flexibly combined according to the components of the flue gas to be treated, different medicals are allocated or photolysis and oxidization techniques are adopted to treat so as to completely clean the flue gas with complex components, purify dust particles and toxic and harmful gas such as sulfur dioxide and hydrogen sulfide, and synchronously recover waste heat of flue gas and steam, in this way, the environment protection object of flue gas clean emission is reached. The sectional-type flue gas purifying treatment and waste heat recovery system device has the following beneficial effects that the flue gas is subjected to dust particle cleaning and waste heat recovering and then is subjected to multiple chemicals sectional reaction and absorption, and multi-stage photolysis and oxidizations so as to treat the toxic and harmful gas in the flue gas, finally the qualified gas is exhausted in air. The system device is suitable for the flue gas generated in industrial incinerations and industrial drying treatments, and is further suitable for the flue gas generated in incinerations of garbage and other substances.

Owner:TIANJIN WANBO WEIYE TECH DEV

Ornamental plant cultivating root-coutrolling container

InactiveCN1774991AReduced post-management costsWide range of promotion and applicationCultivating equipmentsReceptacle cultivationFertilizerWoven fabric

The Present invention relates to a root-controlling container for garden plant cultivation. It is a special-purpose container, its exterior is a container made of non-woven fabric, its interior is equipped with several breather-tubes, on the tube wall of every breather-tube the air pores are cut, and the breather-tube is connected with inner wall of non-woven fabric container by means of fixing band. Said container has the characteristics of insulating heat, retaining moisture, holding fertilizer and sterilization, etc. The plant can be easily transplanted and its survival rate is high.

Owner:胡志超

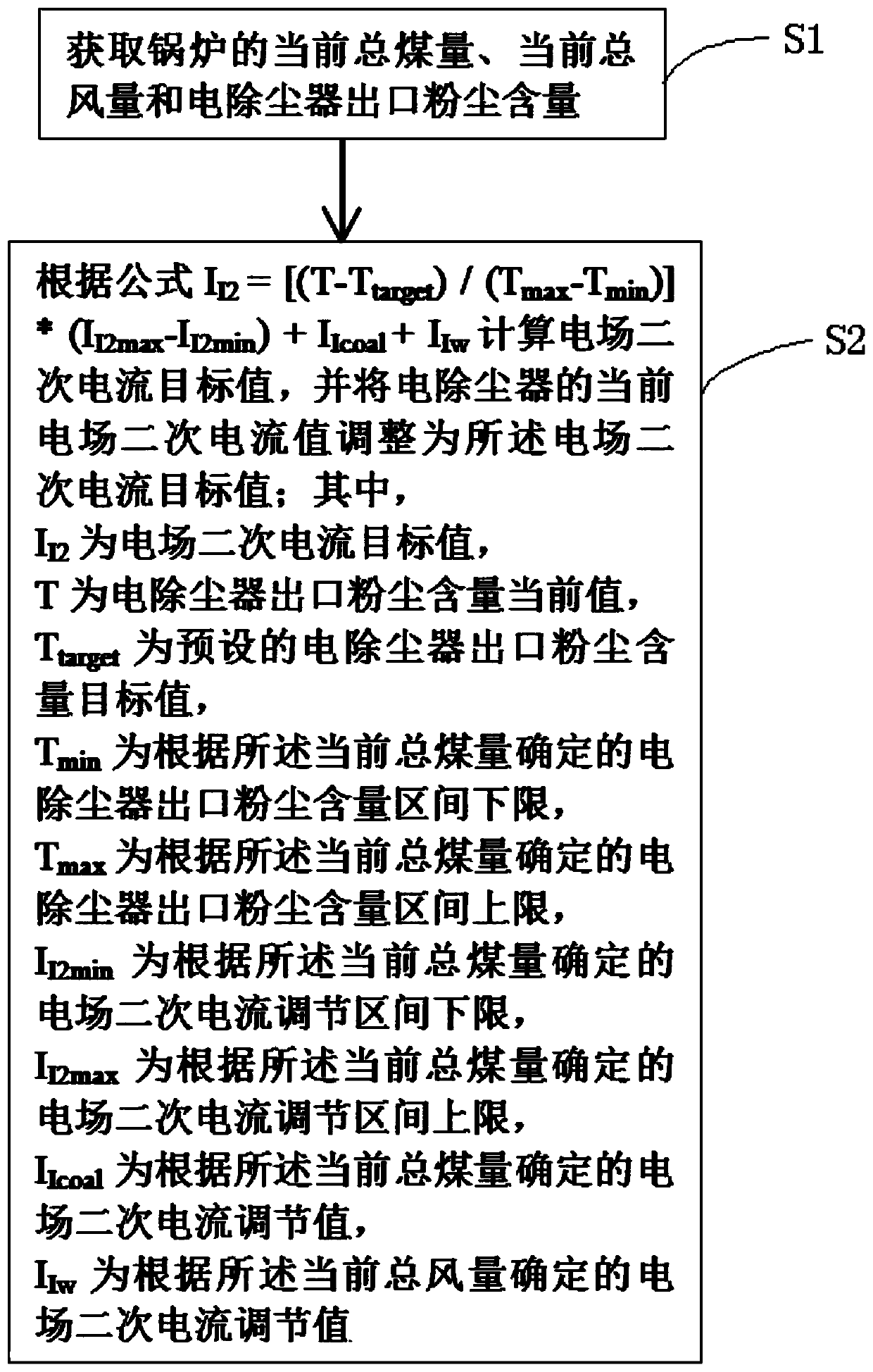

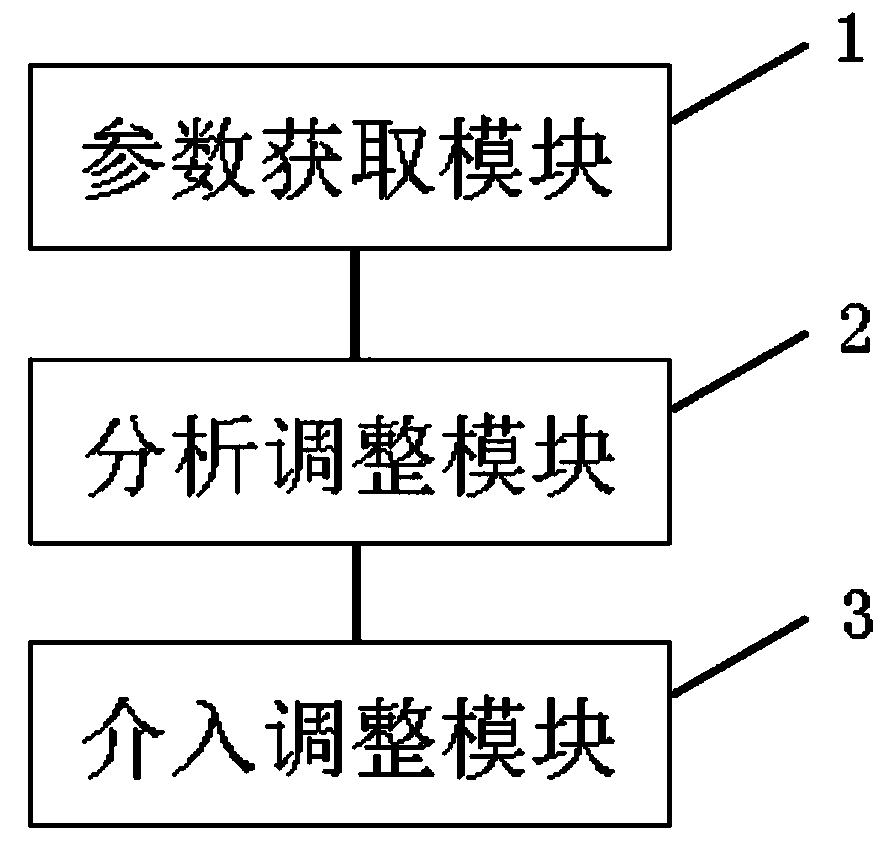

Electric precipitation energy-saving control method and system based on coal quantity and air quantity of boiler

ActiveCN111570093AAccurate measurementOvercoming control biasElectric supply techniquesUnit loadAutomatic control

The invention discloses an electric precipitation energy-saving control method based on the coal quantity and the air quantity of a boiler. The method comprises the steps: obtaining current total coalquantity and current total air quantity of the boiler and electric precipitator outlet dust content; and calculating an electric field secondary current target value according to a formula II2=[(T-Ttarget) / (Tmax-Tmin)]*(II2max-II2min)+IIcoal+IIw, and adjusting the current electric field secondary current value of the electric precipitator to an electric field secondary current target value. Therefore, the total coal quantity of the boiler is used to replace the unit load to control the electric precipitation parameters, the control deviation caused by coal quality change can be overcome, andthe real-time performance is better than that of the unit load; meanwhile, the total air quantity of the boiler serves as a feedforward signal, and a dynamic control effect of dust in the unit load dynamic change process can be improved; and therefore, the automatic control effect of the electric precipitator can be improved, excessive dust emission of a power plant is prevented, the environment-friendly purpose is achieved, the power utilization rate of the power plant is reduced, and the energy-saving purpose is achieved. The invention further discloses an electric precipitation energy-saving control system based on the coal quantity and the air quantity of the boiler, and the beneficial effects are as mentioned above.

Owner:HUANENG PINGLIANG POWER GENERATION CO LTD

Unit type assembly and erection method of extra-high-voltage power transmission iron pylon

InactiveCN105822132AMeet the requirements of standardized constructionImprove ergonomicsTowersEngineeringUnit type

The invention discloses a unit type assembly and erection method of an extra-high-voltage power transmission iron pylon. The unit type assembly and erection method of the extra-high-voltage power transmission iron pylon comprises the following steps of firstly cleaning and arranging a construction site and a construction ground foundation, and transporting pylon materials needed for the assembly and the erection of the iron pylon to a corresponding place; afterwards, assembling and erecting a derrick, raising the derrick, assembling the lower sections of pylon legs, wherein the side width of the cross section of an assembled and erected derrick is 800mm to 900mm; when the derrick is raised, connecting the four corners of the bottom of the derrick onto the foundation by using jacks, fixedly arranging a stay wire and a pulley at the top of the derrick, and guaranteeing that the center of the derrick and a traction ground anchor are on one straight line; assembling and raising the pylon legs, hoisting the derrick, lifting components one by one, hoisting the derrick, slinging a pylon head, mounting an earth wire bracket, slinging cross arms of the iron pylon piecewise one by one, mounting attachments of the iron pylon, and then disassembling the derrick. The unit type assembly and erection method of the extra-high-voltage power transmission iron pylon has the beneficial effects that, by using the unit type assembly and erection method of the extra-high-voltage power transmission iron pylon, technical support for realizing a safe construction, improving the work efficiency and achieving an environmental protection target is provided for an extra-high-voltage experiment and demonstration project.

Owner:SHANDONG HUAAN TOWER CO LTD

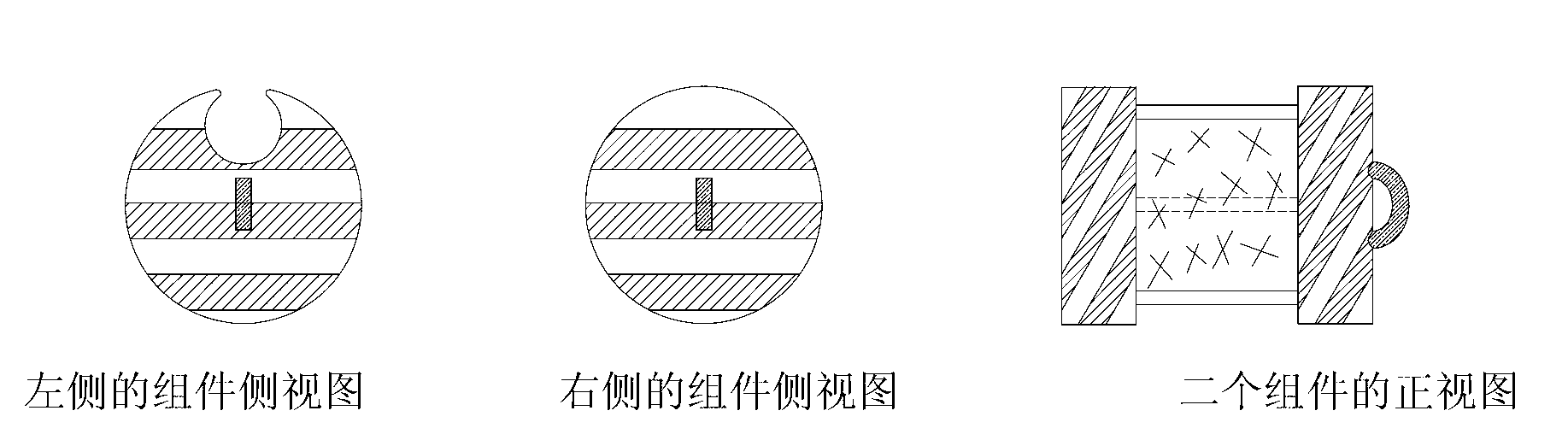

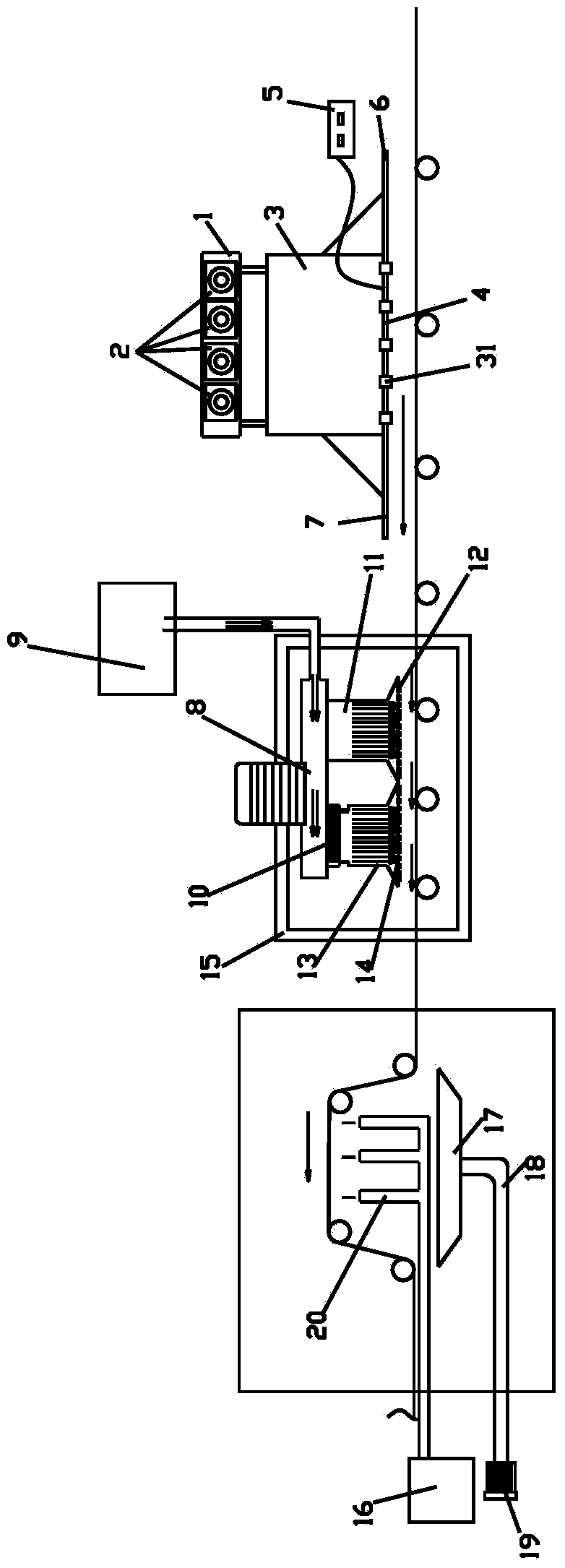

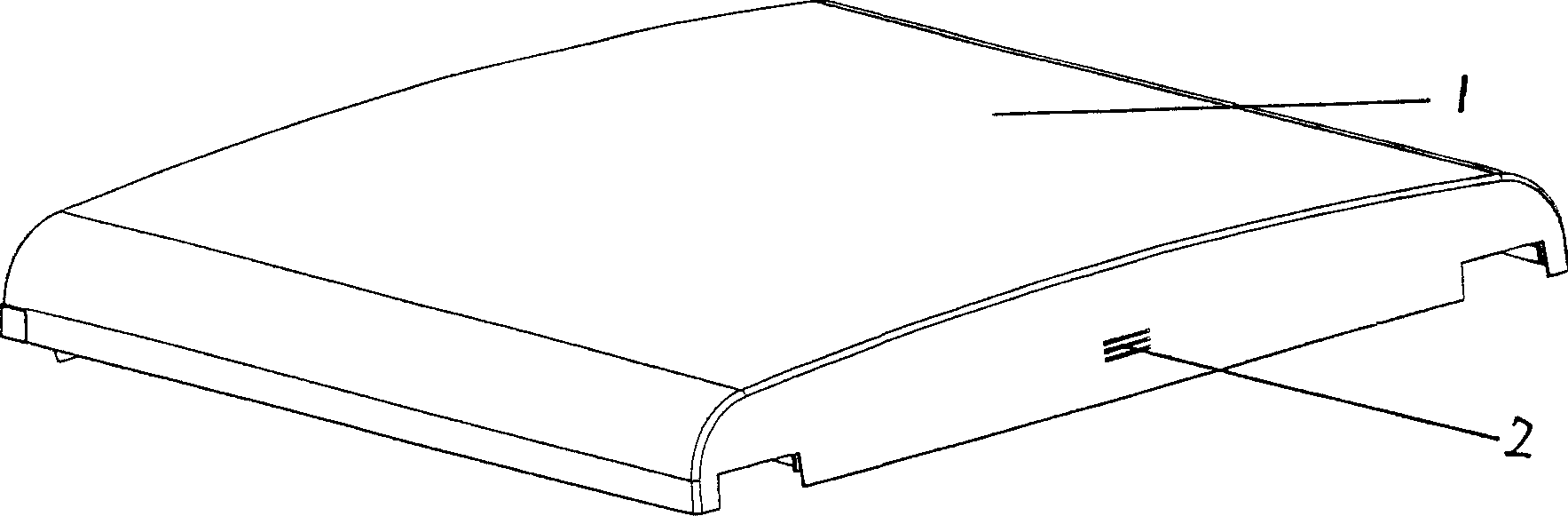

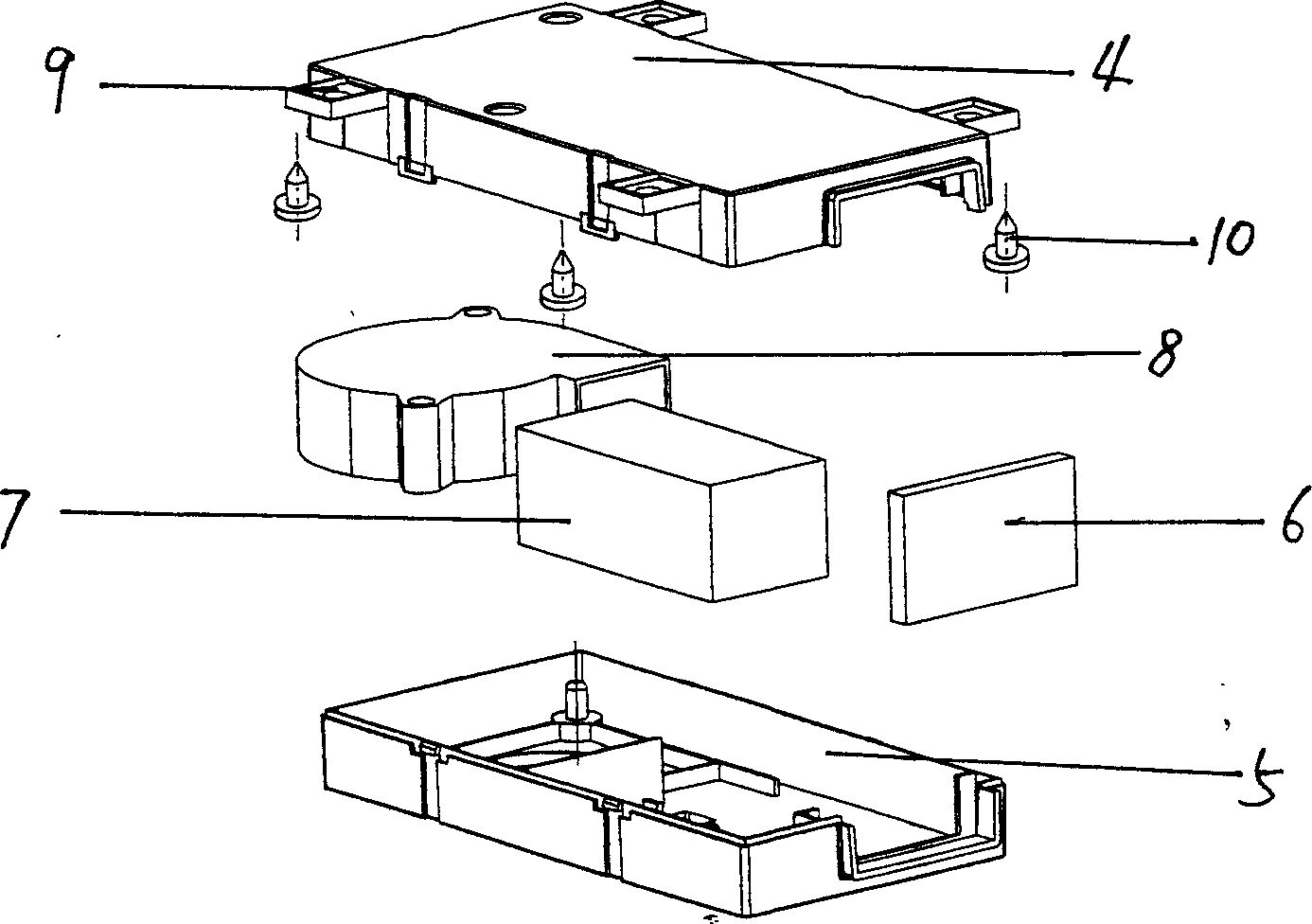

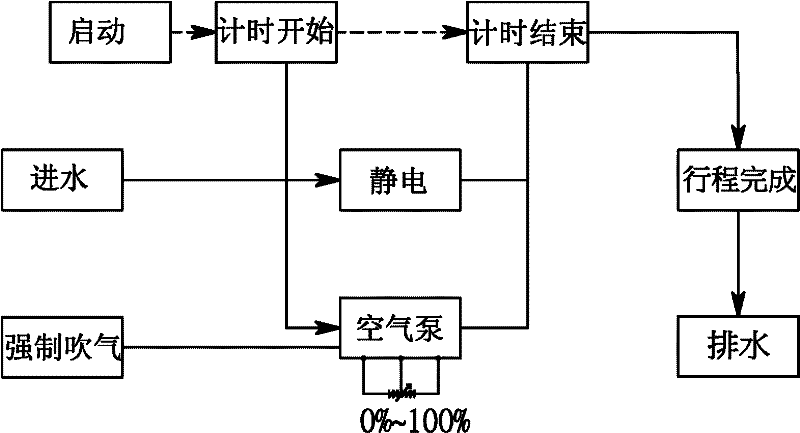

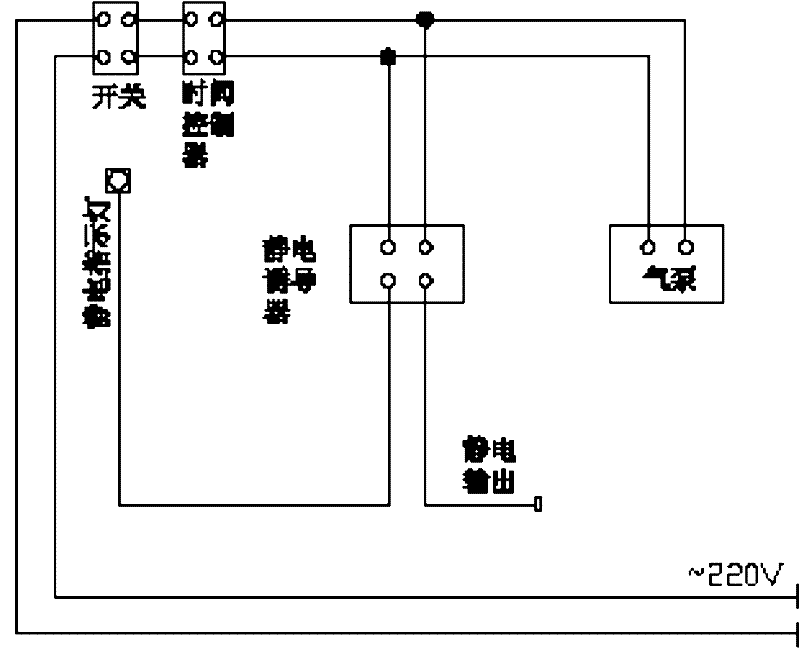

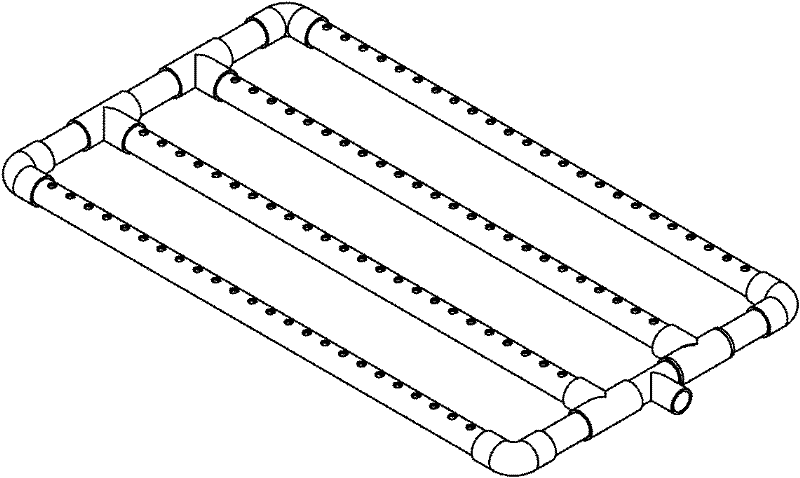

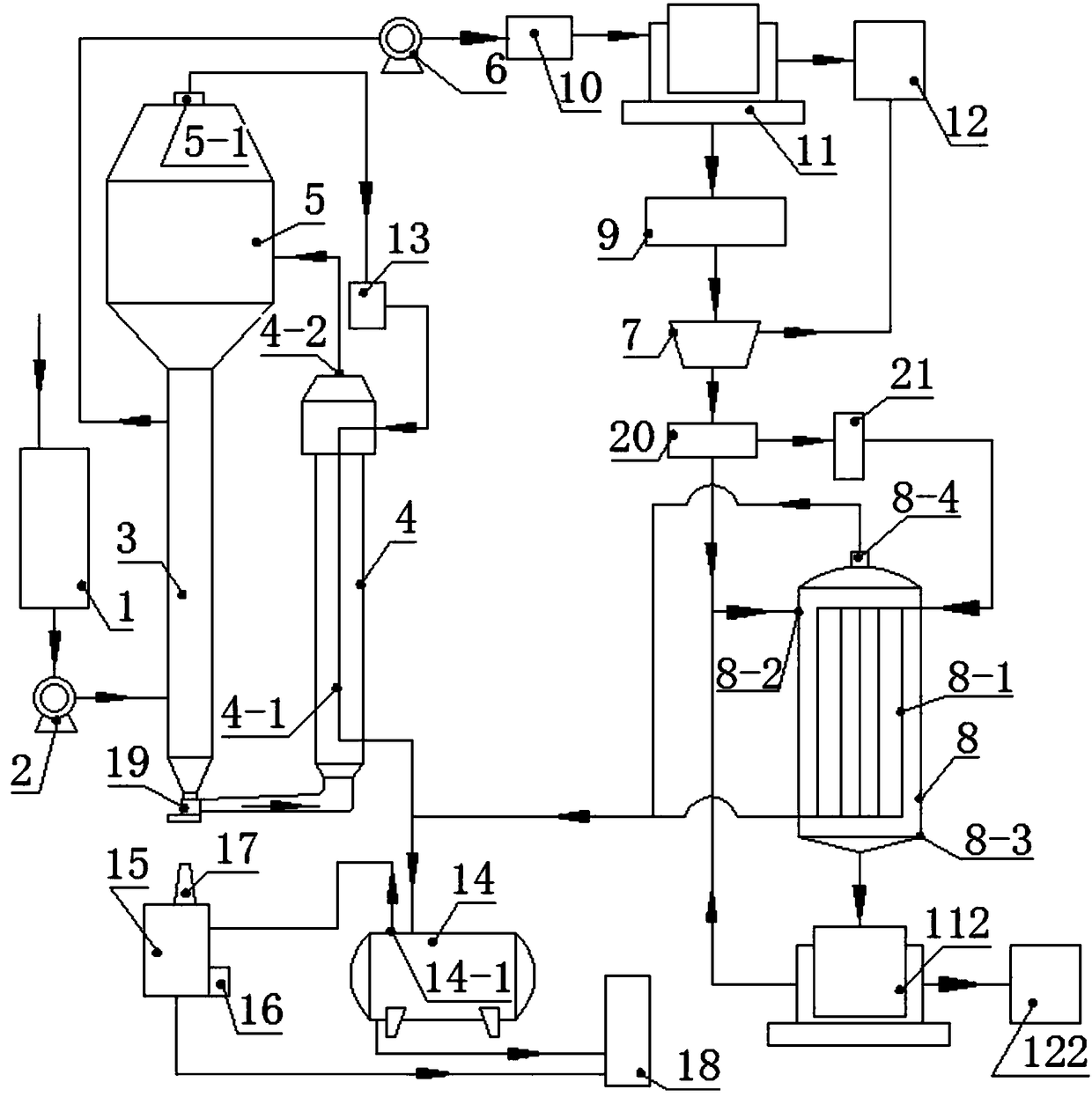

Electrostatic induced water unfreezing method and device for food

The invention discloses an electrostatic induced water unfreezing method and an electrostatic induced water unfreezing device for food. The device is characterized in that: a storage net made of conductive material is arranged in a water tank which is full of water and made of conductive material; the water tank is connected with a body shell through an insulated support seat arranged at the bottom of the body shell and made of insulating material and / or an insulated support frame arranged at the upper part of the water tank, and a proper blocking distance is kept between the side wall of the water tank and the side wall of the body shell, so that the water tank is insulated with the body shell; an electrostatic induction device capable of generating a high-voltage electrostatic field is connected to the water tank through a lead; and an air pump is connected with an air injection pipe arranged at the bottom of the water tank and provided with air injection holes through an air inlet pipe, and the air pump is used for pumping air to form bubbles.

Owner:NEW DEFROST TECH

Preparation method of brewing tea tablet for treating common cold due to wind cold

InactiveCN106362126AExcellent effectReduce manufacturing costDispersion deliveryPre-extraction tea treatmentDiseaseCommon cold

The invention belongs to the technical field of medicines and relates to a preparation method of a brewing tea tablet for treating common cold due to wind cold. The brewing tea tablet adopts fresh ginger, fresh onion, fresh purple perilla, fresh moringa leaves, mosla hangchouensis, mountain mint, Chinese ligusticum rhizome, black tea, Arabic gum solution, curdlan, sodium bicarbonate and agar as raw materials and is prepared by preparation methods such as freezing, pulping, crushing, sterilizing, forming, freeze drying, spraying, baking and the like. The brewing tea tablet has obvious effect on treating the common cold due to wine cold, especially on preventing the development of the common cold disease when the cold is caught and achieving quick recovery.

Owner:DONGGUAN MENGCHUANG HEALTH CARE TECH CO LTD

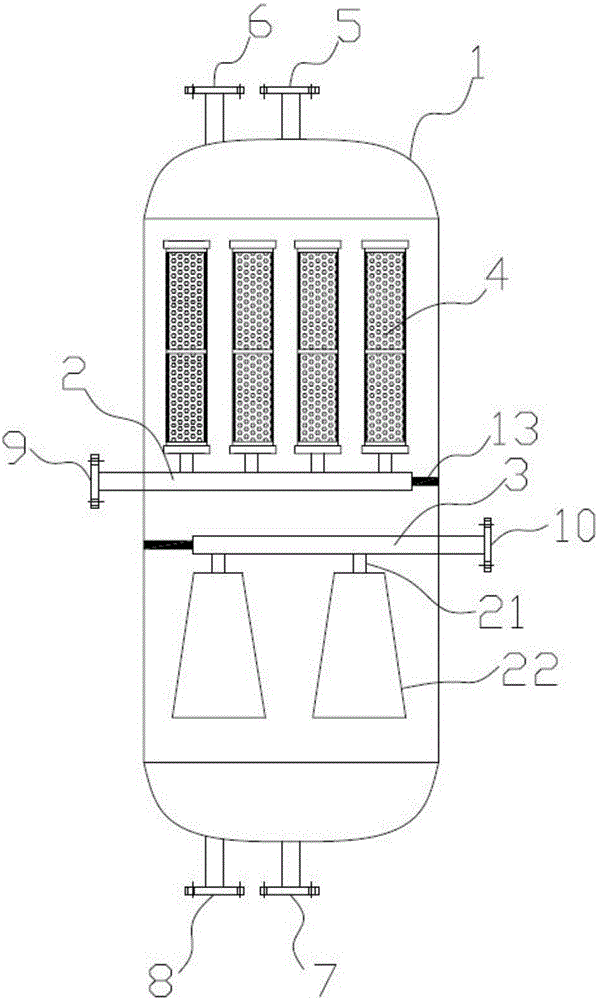

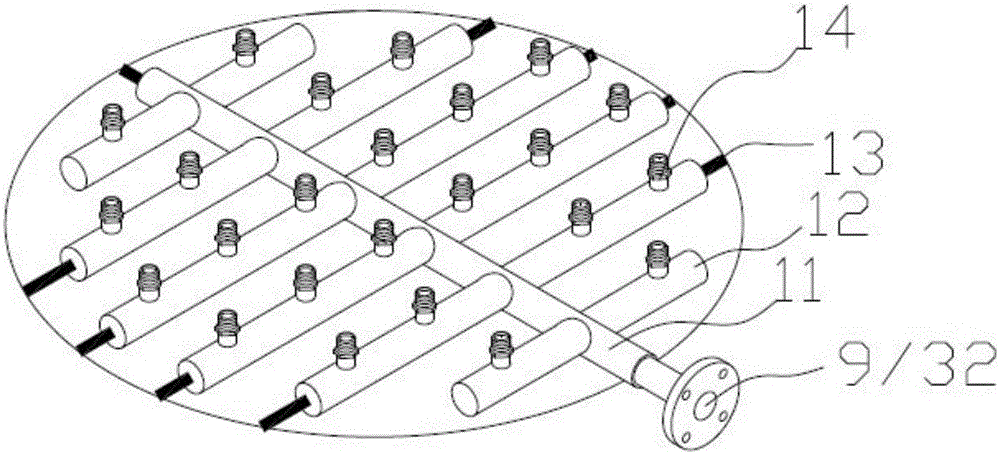

High salinity organic wastewater treatment equipment

PendingCN108178410ASimple processReduce energy consumptionWater/sewage treatment by centrifugal separationWater contaminantsNanofiltrationMulti effect

The invention discloses high salinity organic wastewater treatment equipment. The equipment consists of a raw water tank, a feeding pump, an MVR evaporator, a discharge pump, a magma tank, a centrifuge A, a refrigeration tank, a filter, a nanofiltration membrane separation instrument, a fluidized bed boiler, a vacuum evaporator and a centrifuge B. The raw water tank is connected to the MVR evaporator, the water outlet of the MVR evaporator is connected to the magma tank, the discharge port of the magma tank is connected to the centrifuge A, the liquid discharge port of the centrifuge A is connected to the refrigeration tank, the refrigeration tank is connected to the nanofiltration membrane separation instrument through the filter, the organic wastewater outlet of the nanofiltration membrane separation instrument is connected to the fluidized bed boiler, the vacuum evaporator is internally equipped with a heating pipeline, the vacuum evaporator is provided with a water inlet, a discharge port and a secondary steam outlet, and the steam outlet of the fluidized bed boiler is connected to the heating pipeline. The high salinity organic wastewater treatment equipment provided by the invention employs the novel MVR evaporator to replace the traditional multi-effect evaporator, combines the evaporation process with refrigeration process, combines vacuum evaporation for salt making with high temperature incineration of organic matters, simplifies the process, and reduces the energy consumption.

Owner:山东特保罗环保节能科技有限公司

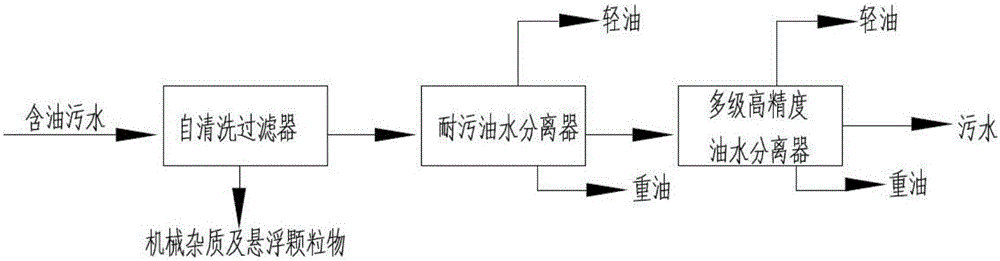

United multistage oil-water separation process

ActiveCN106045088AEasy to separateNo secondary pollutantsFatty/oily/floating substances removal devicesTreatment involving filtrationEconomic benefitsSewage

The invention discloses a united multistage oil-water separation process. The united multistage oil-water separation process comprises the specific steps of 1 pretreatment, 2 primary separation and 3 secondary separation, wherein united multistage treatment is conducted on oily sewage by serially connecting a self-cleaning filter, a stain-resisting oil-water separator and a multistage high-precision oil-water separator, oil in oily sewage, especially dispersed oil, emulsified oil and the like, are rapidly separated in a pure physical mode, and oil recycling is achieved. The united multistage oil-water separation process comprises simple steps, is low in operating cost, good in operability and good in separation accuracy, can greatly improve the oil-water separation efficiency and effect and achieve recycling of various types of oil, can also produce remarkable economic benefits while achieving the environmental protection purpose and is suitable for industrialized application.

Owner:湖州深净环境科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com