PCCP pipe core vertical molding method automatic production line

A technology of production line and molding method, applied in the field of automatic production line of PCCP die vertical molding method, can solve the problems of large movement of personnel, low production efficiency, poor working environment, etc., achieve advanced technology, improve production efficiency, reduce The effect of production floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

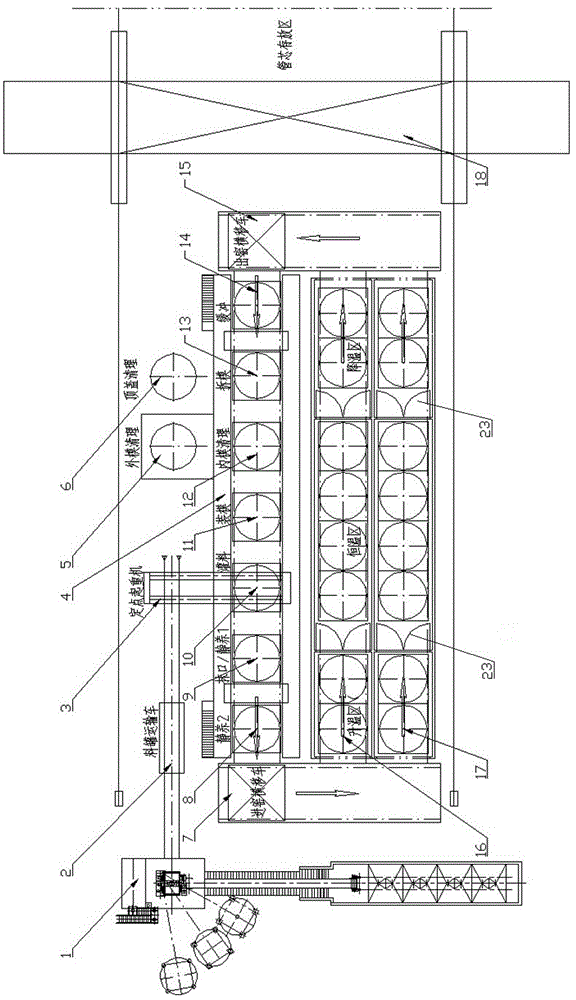

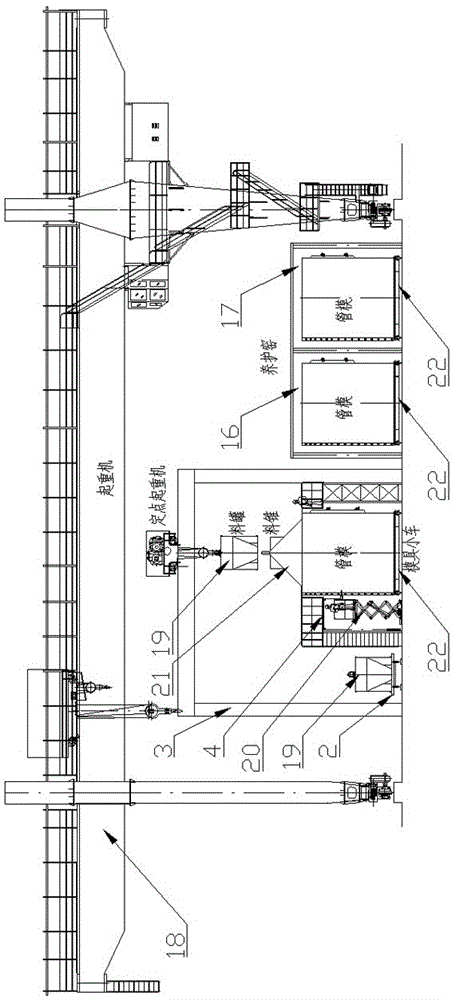

[0024] join figure 1 , the automated production line used in this example adopts a three-line system, that is, one operation line and three maintenance lines, of which one operation line and two maintenance lines 16 and 17, and the production line is equipped with 7 PCCP molds, and the maintenance line is equipped with 8 PCCP molds .

[0025] The description of each station of PCCP die vertical molding automatic production line is as follows:

[0026] 1. Work platform 4

[0027] Working platforms 4 are arranged on both sides of the operation line, consisting of two working platforms 4 on the outside and inside. Personnel go up and down via the ladder of the working platform 4 on the outside, and there is a trestle between the two working platforms 4 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com