Mechanical flocking plant

A technology of flocking and flocking box, applied in the field of flocking machinery, can solve the problems of serious environmental pollution, polluted workshop environment, poor flocking effect, etc., to achieve high energy utilization, improve quality, and good flocking effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with specific examples.

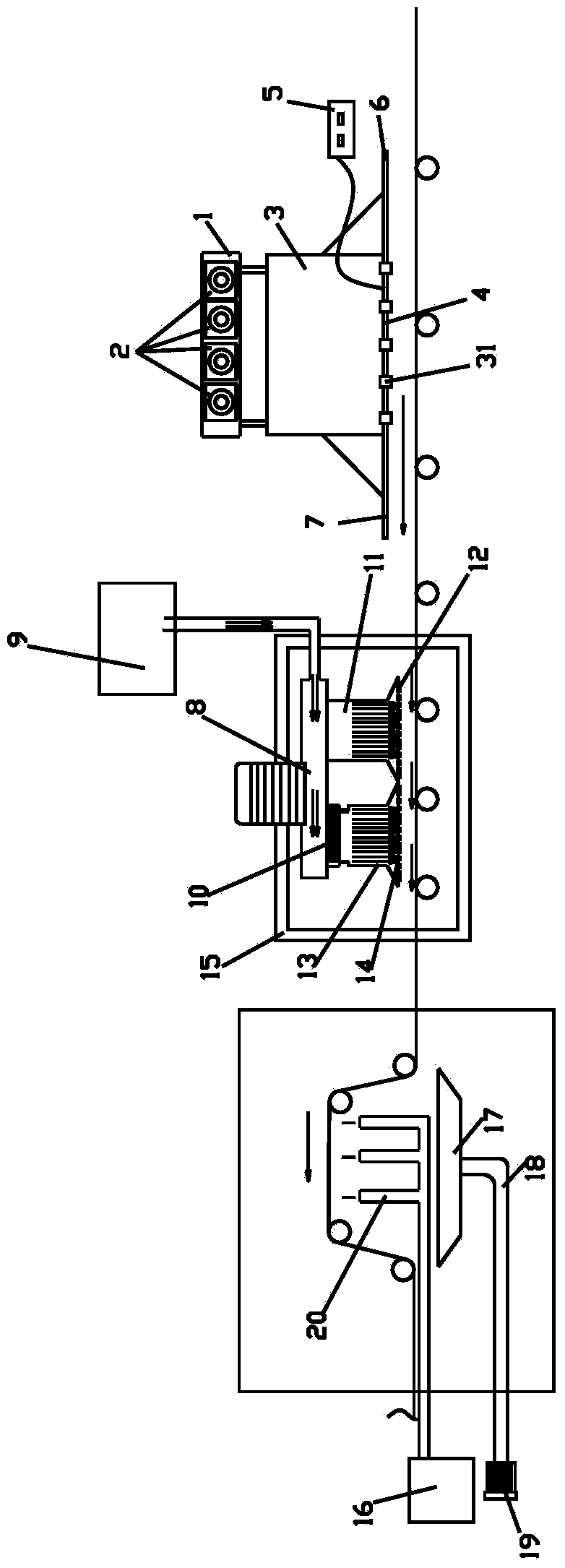

[0026] Such as figure 1 As shown, a mechanized flocking device includes a support frame with a circular conveyor belt, a needle plate fixed on the conveyor belt and moving with the conveyor belt, and a flocking device sequentially arranged on the conveyor belt of the support frame. device, baking device, and cleaning device; drive motors for driving the conveyor belt to rotate are respectively provided at both ends of the conveyor belt. The whole process from electrostatic flocking to drying to fluff removal is fully automatic, which greatly improves the production efficiency and product quality of printing, facilitates the management of the production line, and realizes the purpose of environmental protection.

[0027] The flocking device is mainly composed of a hopper 1 and a flocking box 3 arranged below the hopper 1; an electrostatic plate 4 is arranged below the flocking...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com