Method for treating electroplate rinsing wastewater

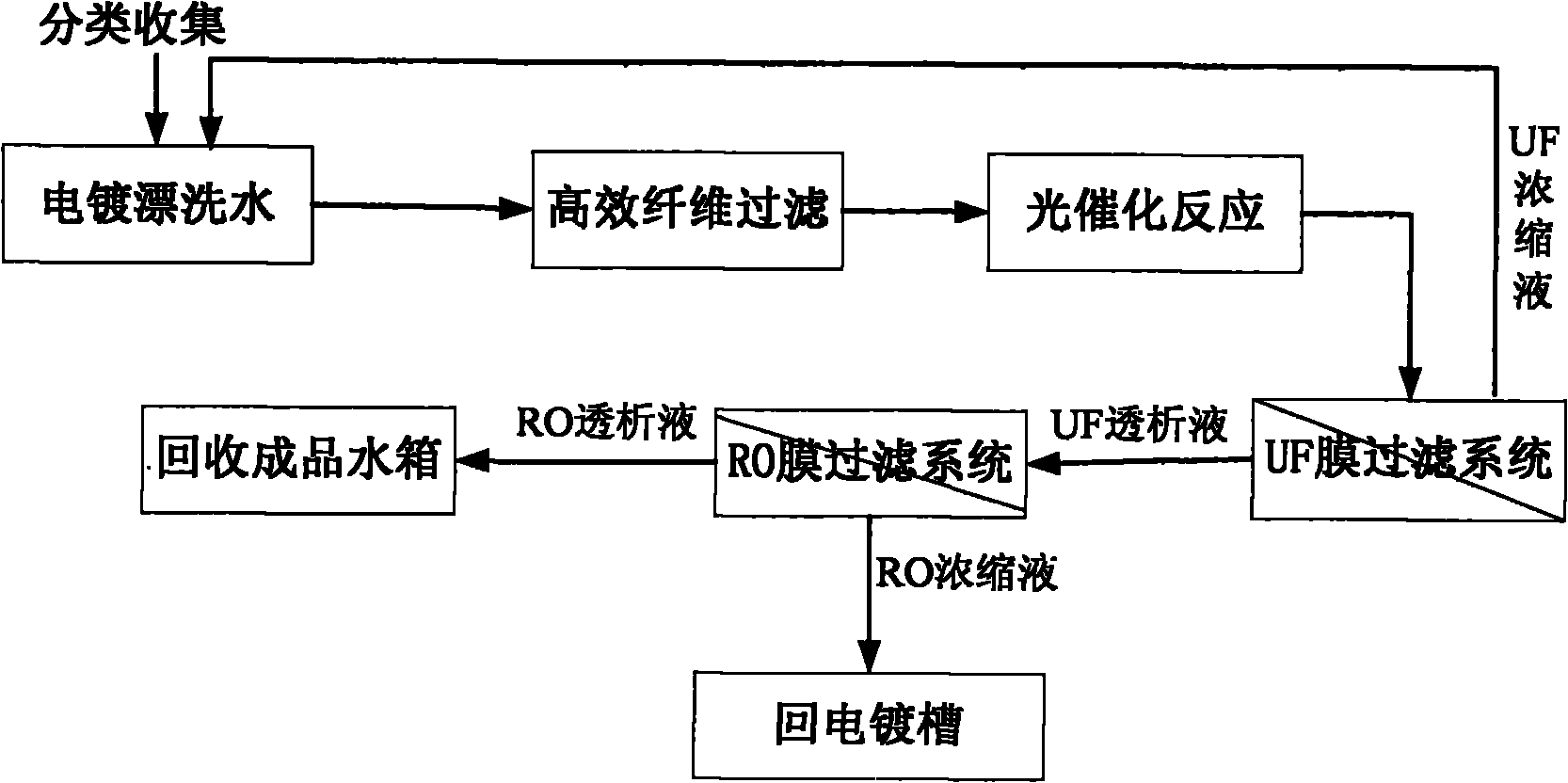

A waste water treatment and rinsing technology, applied in water/sewage multi-stage treatment, light water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of complex treatment process, poor operation stability and high operation cost, and achieve The system is easy to operate, occupies a small area, and has the effect of short payback period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

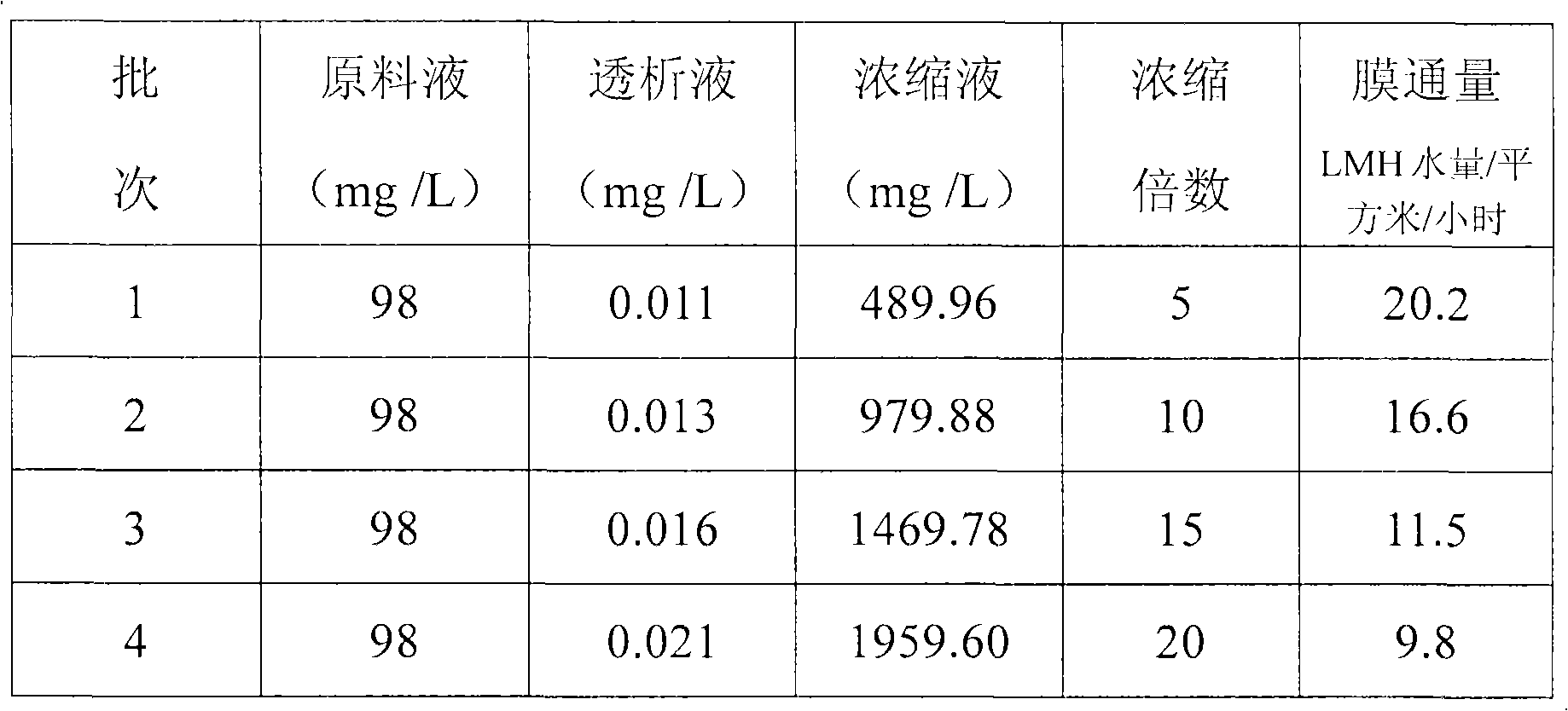

Embodiment 1

[0025] Embodiment 1: (1) the nickel electroplating rinsing water collected by a certain electroplating enterprise is regulated and processed by PH6.5-7.5;

[0026] (2) High-efficiency fiber filtration: perform high-efficiency fiber filtration on the electroplating rinsing wastewater with adjusted pH value to remove particles, macromolecular organic matter, and active additive flocculation lumps with a particle diameter of more than 10-4mm suspended matter in the electroplating rinsing wastewater Finally, the pollution index (SDI) of the filtered water is controlled below 5.

[0027] (3) Photocatalytic reaction: through the ultraviolet sterilizing effect, the filtered wastewater is sterilized and algae-killed, and COD, TOC, and organic matter are reduced, so that it is not easy to form organic matter pollution on the surface of the membrane, and delay the blockage caused by organic matter pollution of the membrane element. Irreversible cleaning with reduced water flux.

[0028...

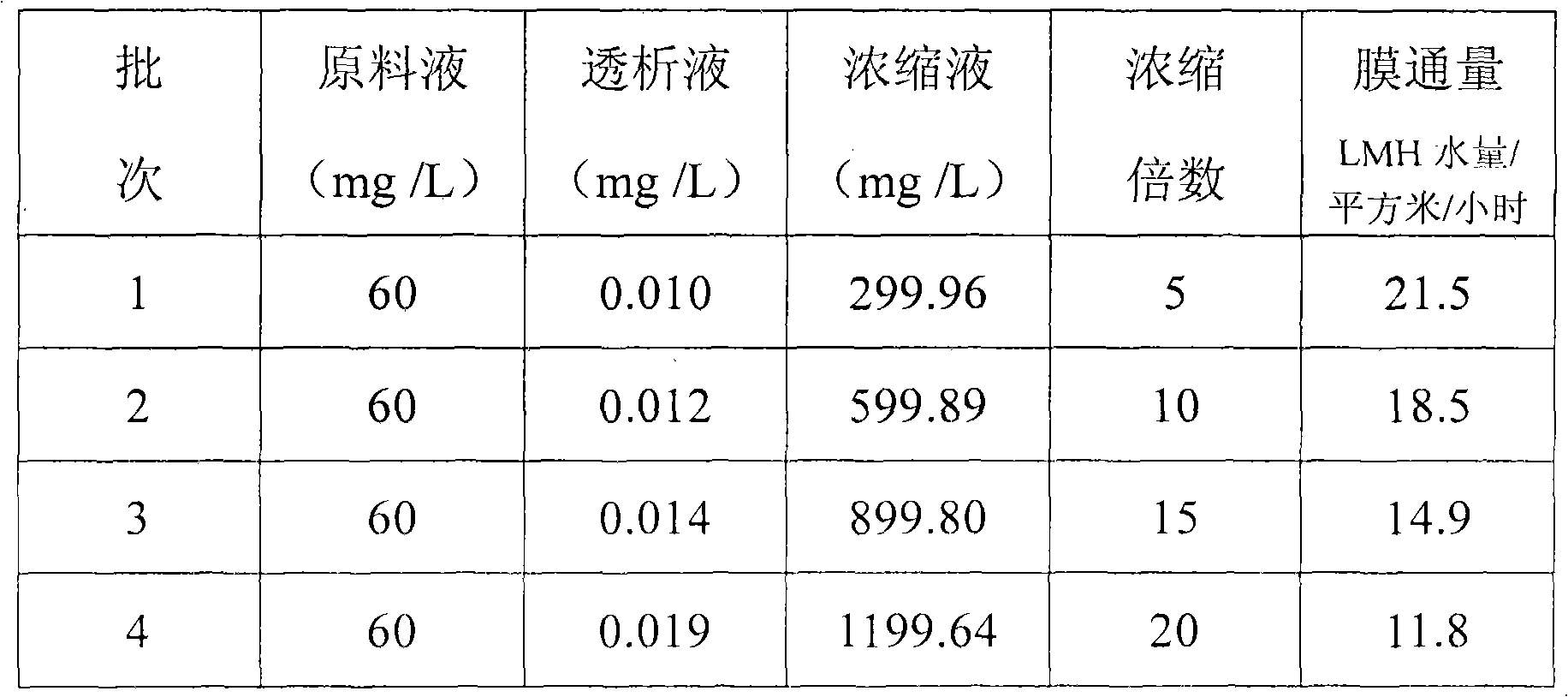

Embodiment 2

[0034] Embodiment 2: repeat the operation steps of embodiment 1, the nickel ion content in the dialysate after the ultrafiltration filtration system is 60mg / L. The concentration of nickel ions treated by the reverse osmosis membrane integrated process system is 1199.64 mg / L, and the concentration factor is 20 times (see Table 2).

[0035]

[0036] Table 2: Experimental data of nickel ion concentration of 60 mg / L in ultrafiltration dialysate

Embodiment 3

[0037] Embodiment 3: Repeat the operation steps of Embodiment 1, the nickel ion content in the dialysate after the ultrafiltration filtration system is 150mg / L. The concentration of nickel ions treated by the reverse osmosis membrane integrated process system is 2999.22 mg / L, and the concentration factor is 20 times (see Table 3).

[0038]

[0039] Table 3: Experimental data of nickel ion concentration in ultrafiltration dialysate at 150mg / L

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com