Reflecting lens, backlight module using reflecting lens and display device

A reflective lens and backlight module technology, which is applied to lighting devices, fixed lighting devices, components of lighting devices, etc., can solve the problems of inability to achieve one-to-many matching, difficulty in cost reduction, melting and deformation of light guide plates, etc. Achieve the effect of avoiding melting deformation, reducing difficulty and high uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

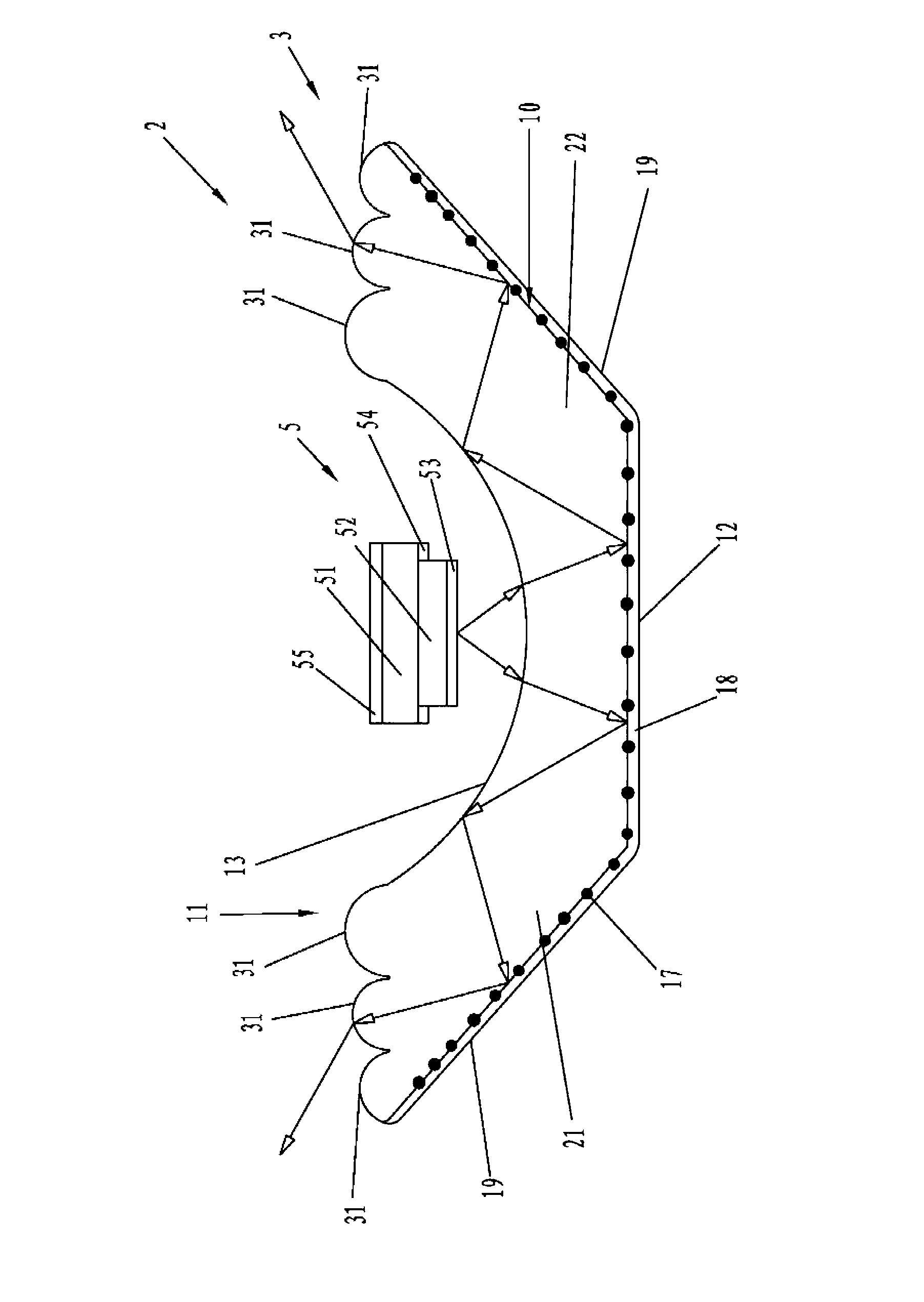

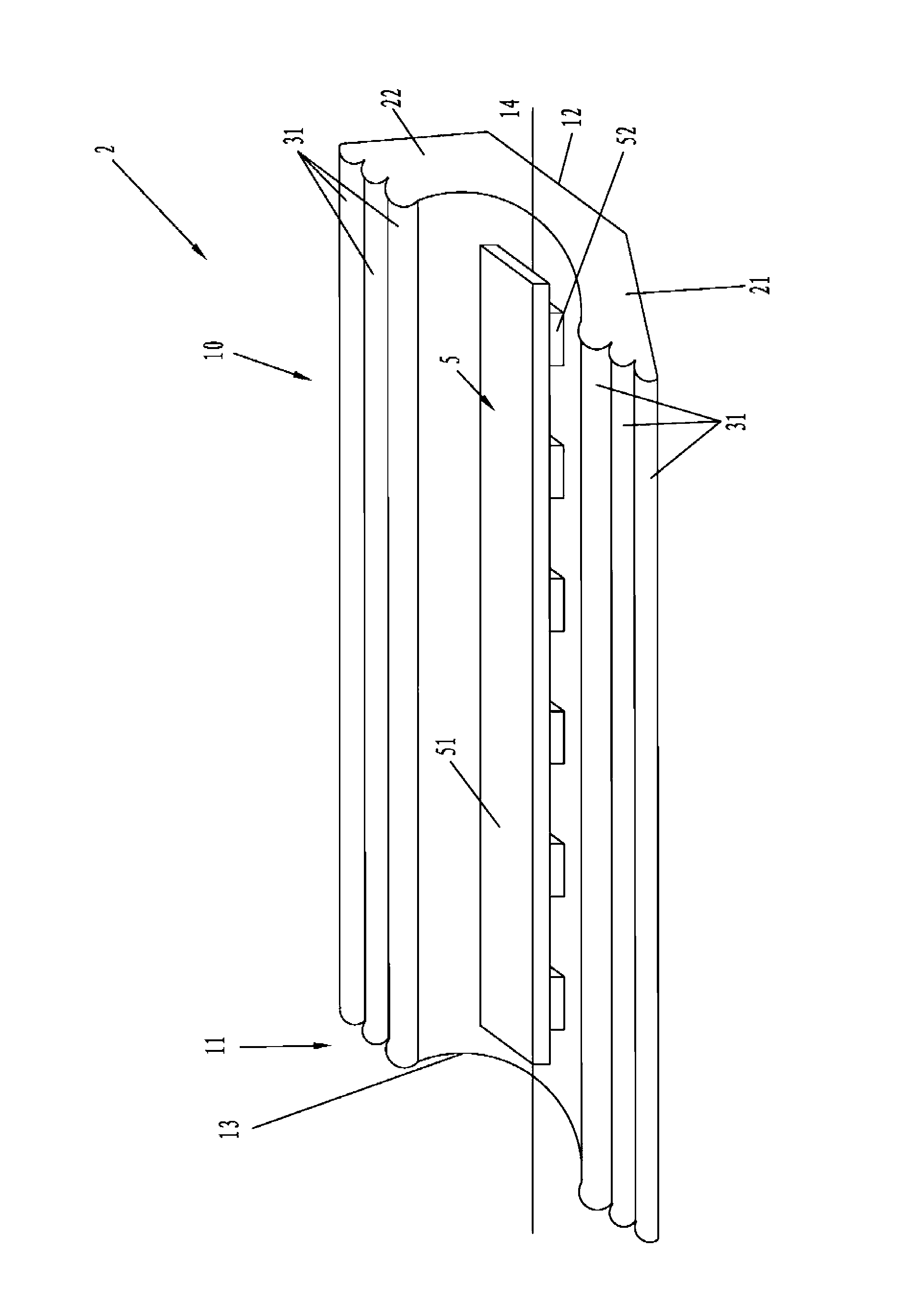

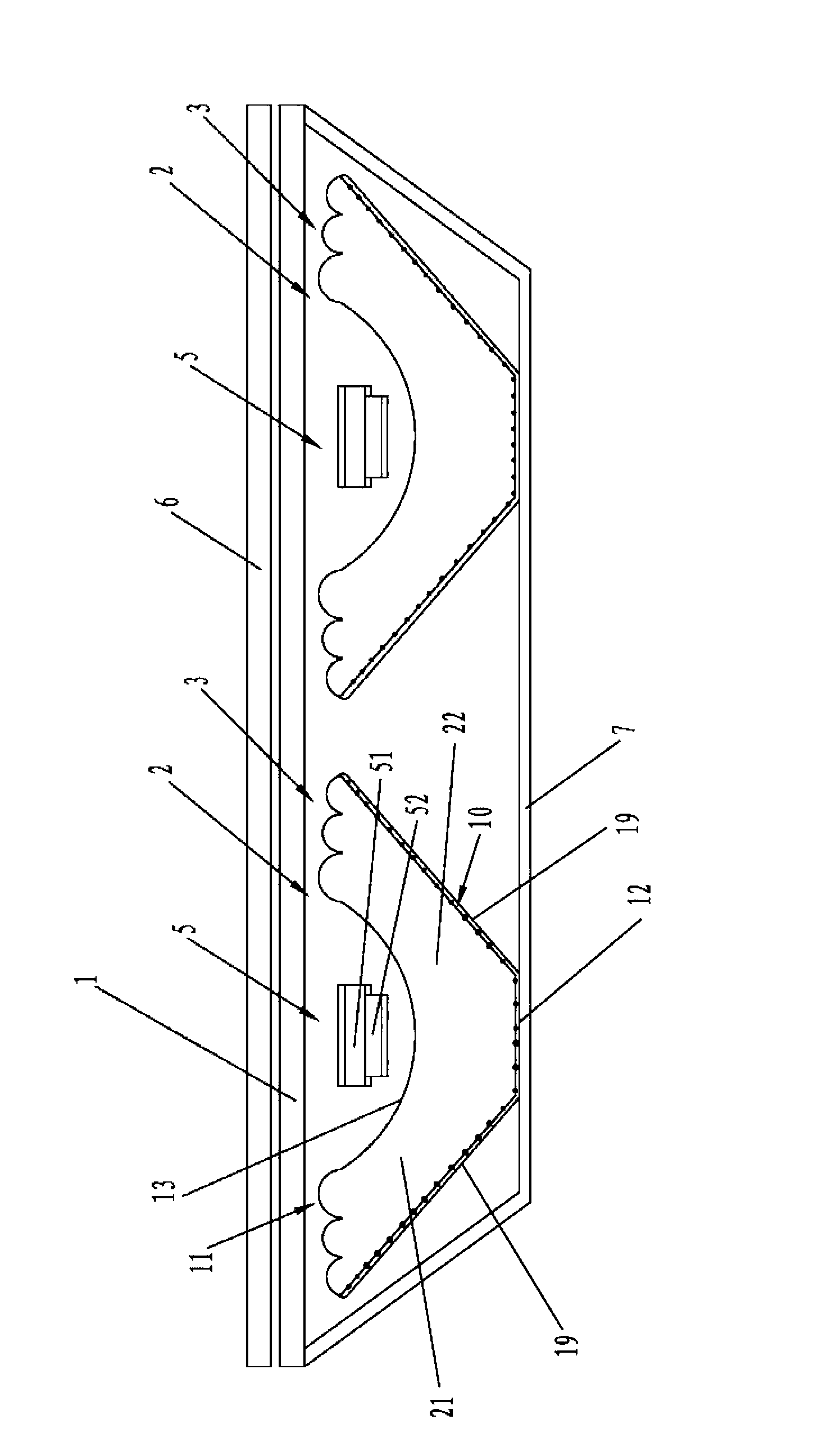

[0044] Such as figure 1 , figure 2 , image 3As shown, the embodiment of the backlight module using reflective lens of the present invention includes a diffuser plate 1 and a light source device 2 disposed on the back side of the diffuser plate 1 . The light source device 2 includes a reflective lens 3 according to an embodiment of the present invention and a light source 5 disposed inside a groove 13 of the reflective lens 3 , and the groove 13 of the reflective lens 3 faces the back of the diffuser plate 1 . The bottom of the reflective lens 3 is provided with a reflective plate 7 . An optical film 6 is provided on the front side (light-emitting surface) of the diffusion plate 1 .

[0045] The reflective lens 3 of the embodiment of the present invention includes a mirror body 10 in the shape of an inverted truncated cone. The first surface 11 with a larger area of the mirror body 10 is a light-emitting surface, and the first surface 11 is provided with a groove 13 rec...

Embodiment 2

[0075] combine Figure 10 , Figure 11 As shown, the reflective lens of the present invention can also be applied to corner-type backlight modules. The backlight module using the reflective lens in this embodiment is a corner type backlight module. The backlight module using a reflective lens in this embodiment includes a light guide plate 1' and a light source device 2' disposed on at least one side of the light guide plate 1'. The light source device 2' includes a reflective lens 3' according to the embodiment of the present invention and a light source 5' disposed inside the groove 13' of the reflective lens 3'.

[0076] The reflective lens 3' of the present embodiment has the same structure as the reflective lens 3 of the first embodiment, except that the longitudinal length of the reflective lens 3' of the present embodiment is shorter than that of the reflective lens 3 of the first embodiment.

[0077]The groove 13' of the reflective lens 3' faces the light guide plat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com