Extra-high voltage large-span iron tower assembling method

A technology for tower assembly and large span, applied in the direction of tower, building type, building, etc., can solve the problems of inconvenient installation and dismantling of the boom, large size of UHV large span iron tower components, and heavy lifting weight, etc. And the effect of convenient dismantling, reducing the workload of aerial work and increasing construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0027] The specific technical scheme of the present invention is illustrated with the test of the UHV iron tower assembly process on the 1000kV UHV test base.

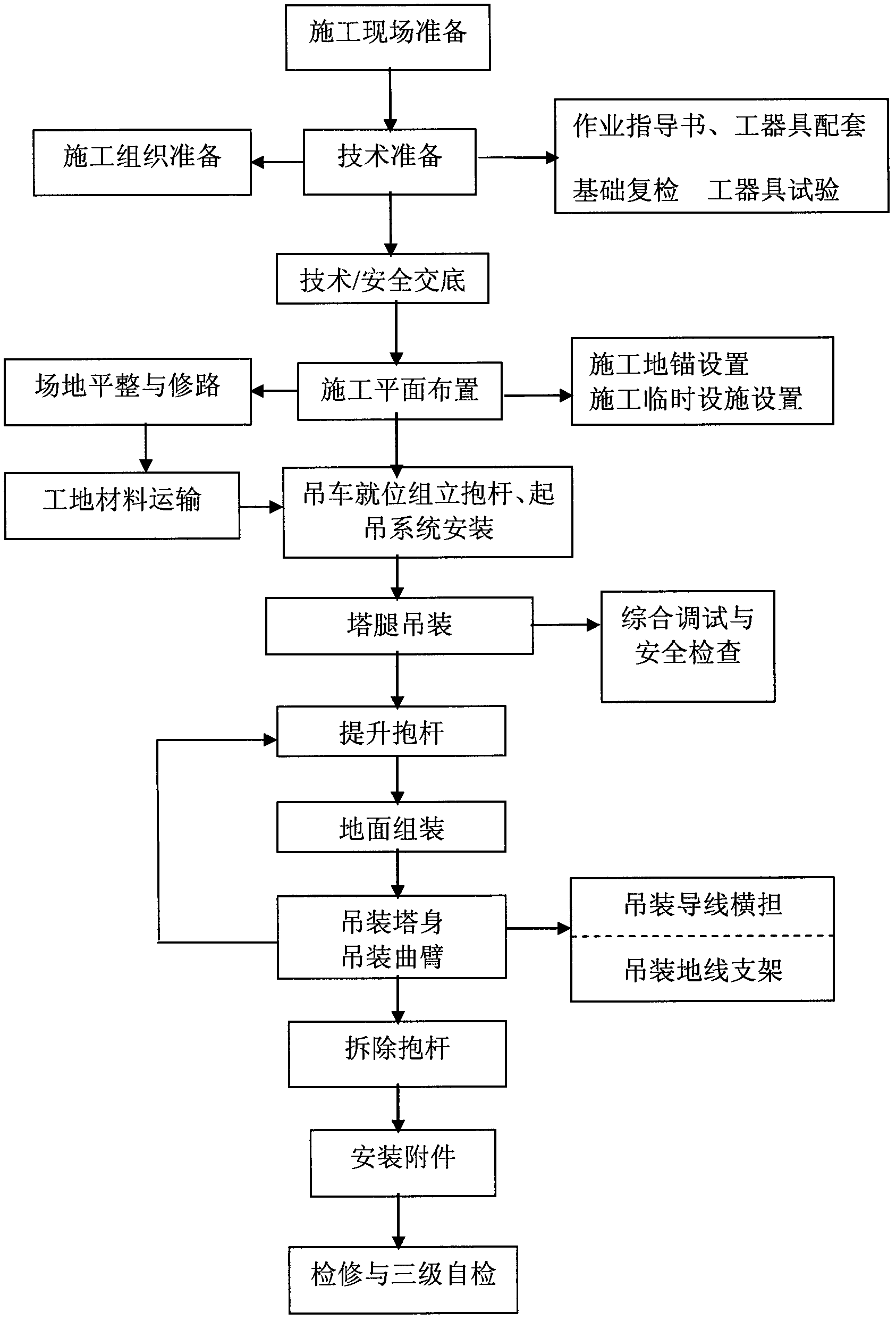

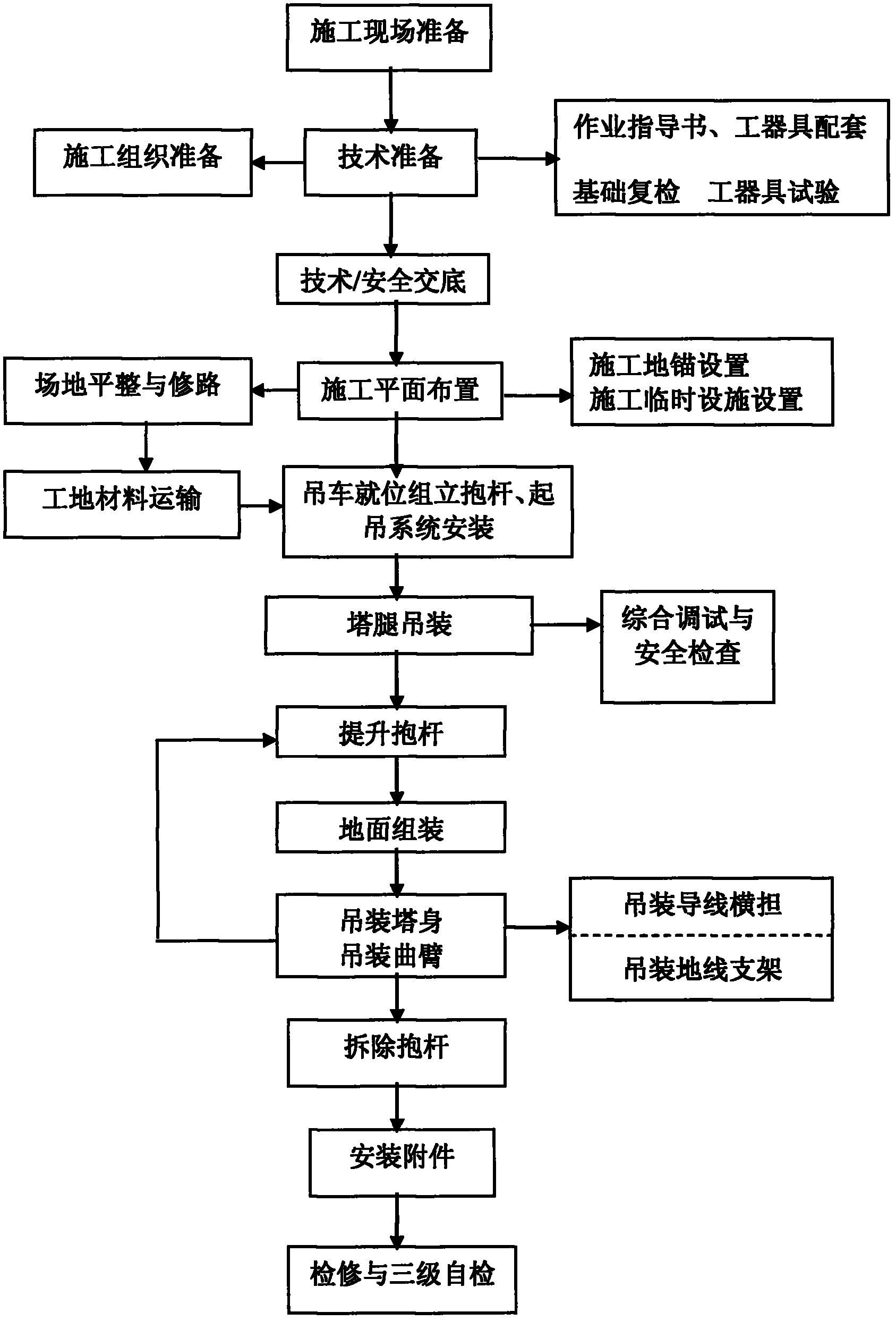

[0028] 1. Arranging the construction site

[0029] Arrangement of ground anchors: cast-in-place concrete is adopted for the site layout of ground anchors, and the ground anchors are constructed simultaneously with the foundation construction of the iron tower; and ground anchor pull rings are buried on the foundation to facilitate tower construction.

[0030] Arrangement of the traction system: a centralized steering system is set on the pole base. The traction rope and the adjustable arm rope turn to the power field through the centralized steering system. The power field adopts centralized monitoring and electronic control operation to ensure accurate and synchronous actions, realize safe locking and prevent misoperation.

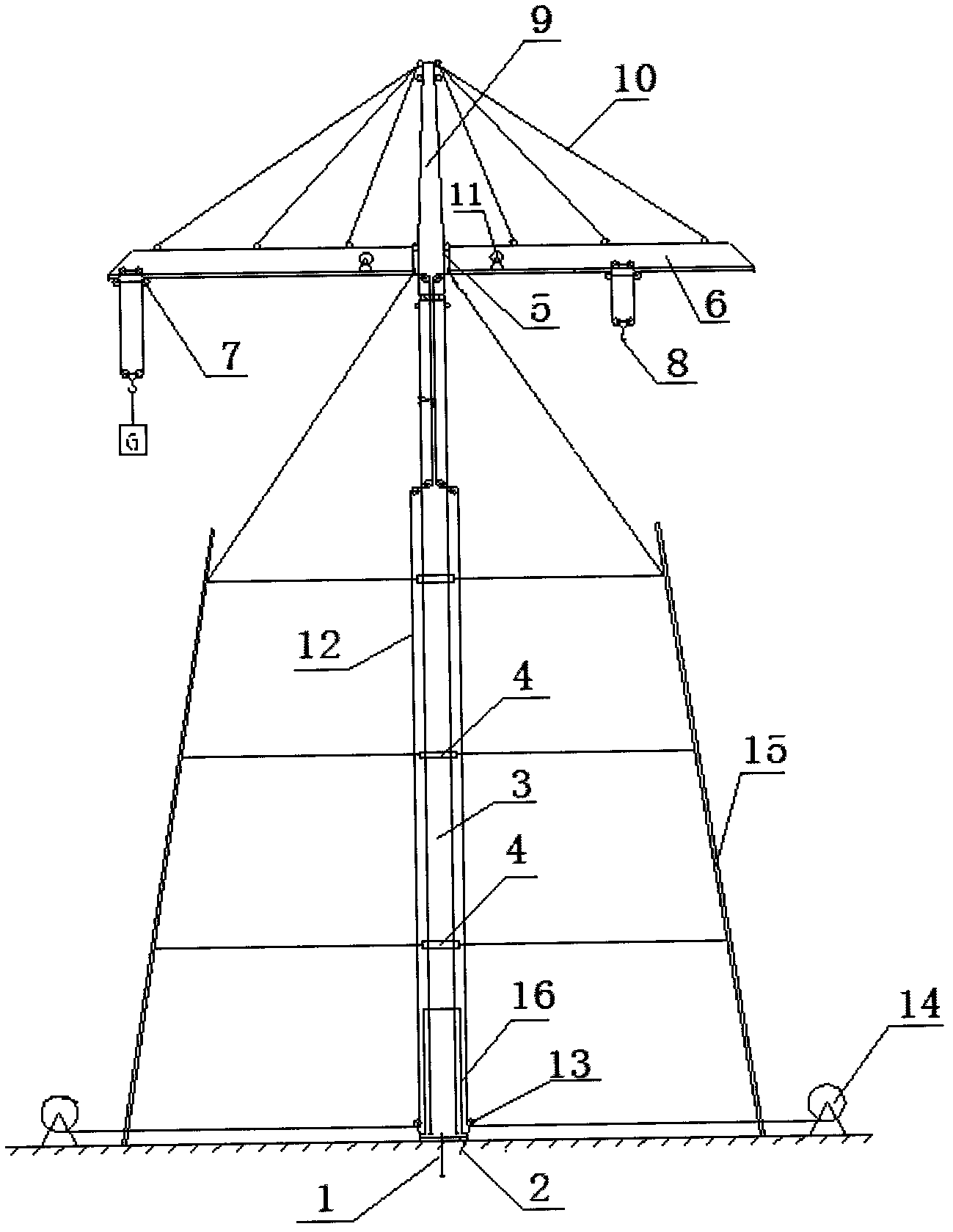

[0031] To set up the pole system:

[0032] a. Pole-holding wire: The pole-holding foundatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com