Automatic bag opening machine

A bag unpacking machine, automatic technology, applied in packaging, transportation and packaging, unsealing of objects, etc., to achieve the effect of improving the degree of automated production, reducing labor intensity, and saving manual bag unpacking costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

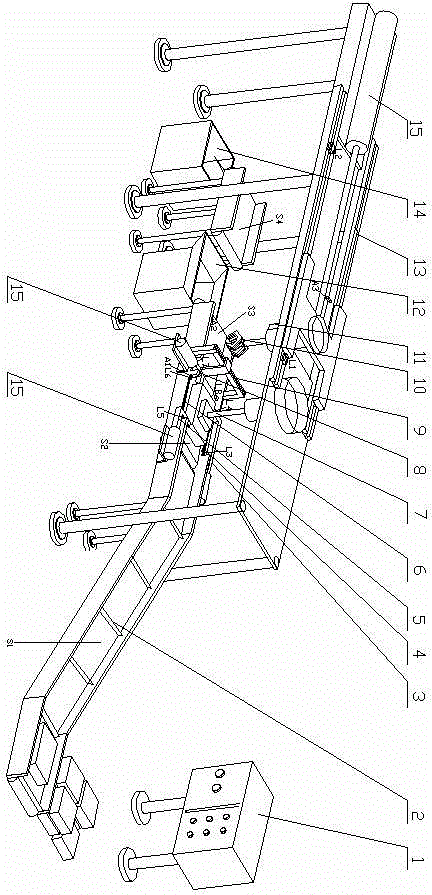

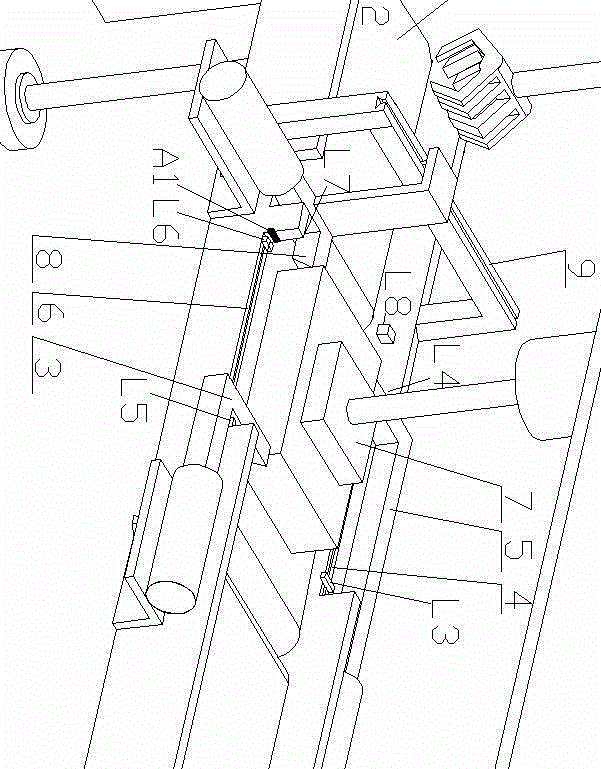

[0016] The structure of this embodiment is as figure 1 and figure 2 As shown, the automatic bag unpacking machine of the present invention has four sections of conveyor belts S1, S2, S3, S4. The first section of conveyor belt S1 is used to convey material bags, and an anti-skid baffle 2 is also arranged on this section of the conveyor belt, and its main function is to prevent the frozen material bags from sliding down during the feeding process. The anti-skid baffle is fixed on the conveyor belt S1 and moves together with the conveyor belt, and the distance between the front and rear plates of the anti-skid baffle is greater than the length of the bag.

[0017] The top of the second section conveyor belt S2 is provided with a solid bag expansion and contraction platen 7, which relies on the driving of the hydraulic cylinder to realize the fixed bag effect of the bag breaking process. The front end of the conveyor belt S2 is provided with a bag breaking cutter 8, which can m...

Embodiment 2

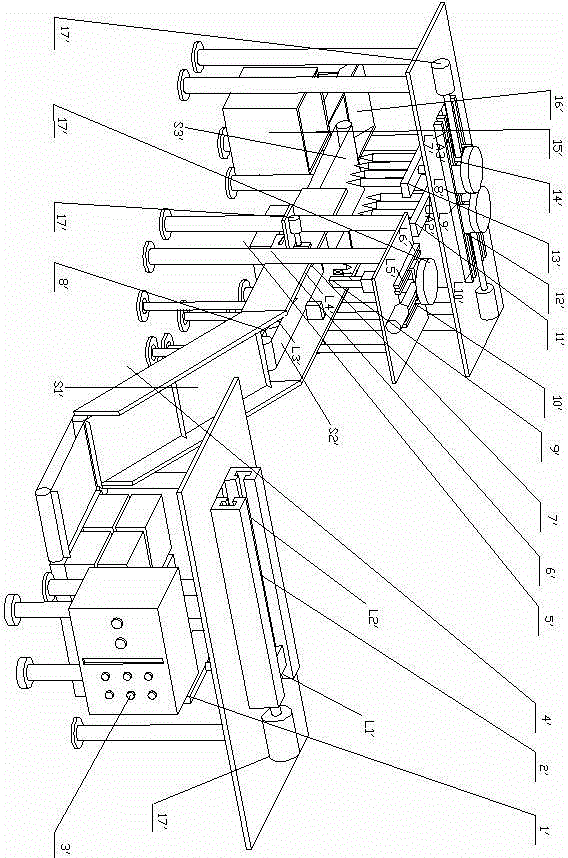

[0021] The structure of this embodiment is as image 3 and Figure 4 As shown, the automatic bag unpacking machine has three sections of conveyor belts S1', S2', S3'. The first section of conveyor belt S1' is used for conveying material bags, and an automatic feeding device is arranged in front of the conveyor belt. An anti-skid baffle 4' is also installed above the conveyor belt S1' to prevent the frozen material bags from slipping off the conveyor belt during material conveyance. The automatic feeding device consists of a push plate 1', a moving guide rail 2' and limit switches L1' and L2' installed at the two ends of the moving guide rail. The frozen material can be pushed onto the first conveyor belt S1' by the push plate 1' moving on the guide rail 2'.

[0022] The left and right sides of the second section conveyor belt S2' are equipped with solid bag expansion and contraction platens 6' and 7' running oppositely, which can be fixed on the conveyor belt when the froze...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com