Extra-high voltage common circuit iron tower assembling method

An iron tower assembly, UHV technology, applied in the direction of tower, building type, building, etc., can solve the problem of limited inclination of the pole, achieve good safety, reduce the workload of high-altitude work, and facilitate the installation and removal of the boom. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0031] The specific technical scheme of the present invention is illustrated with the test of the iron tower assembly process of the UHV ordinary line on the 1000kV UHV test base.

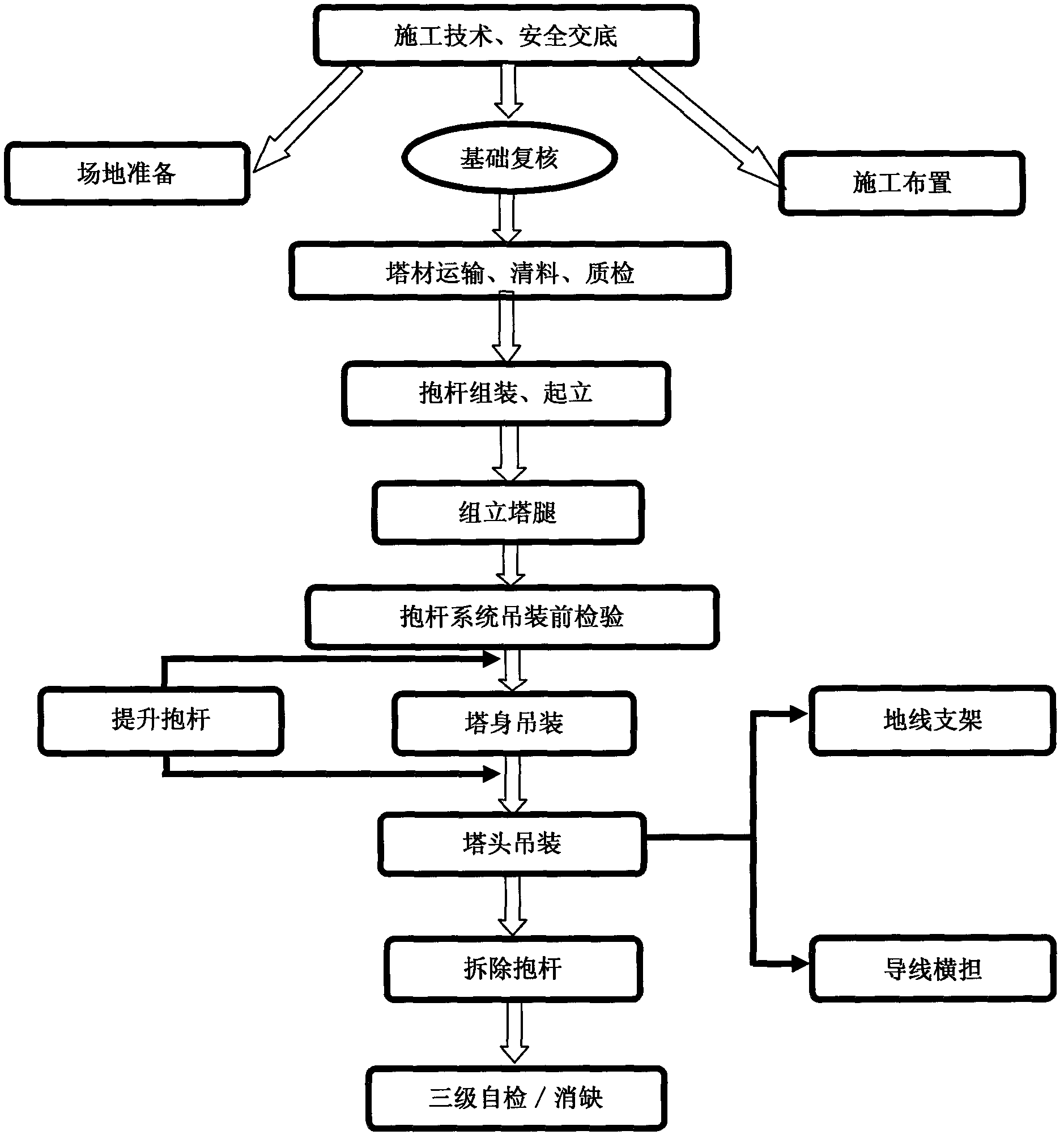

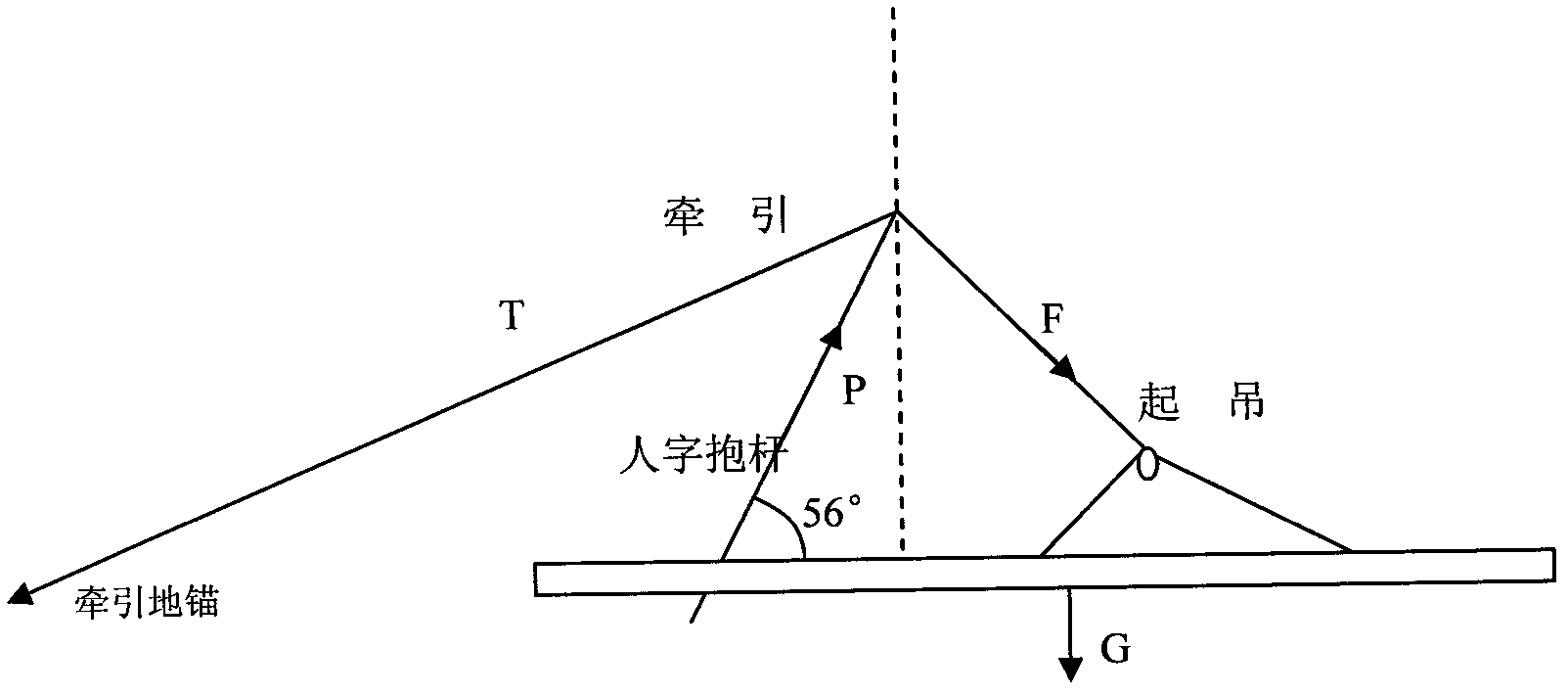

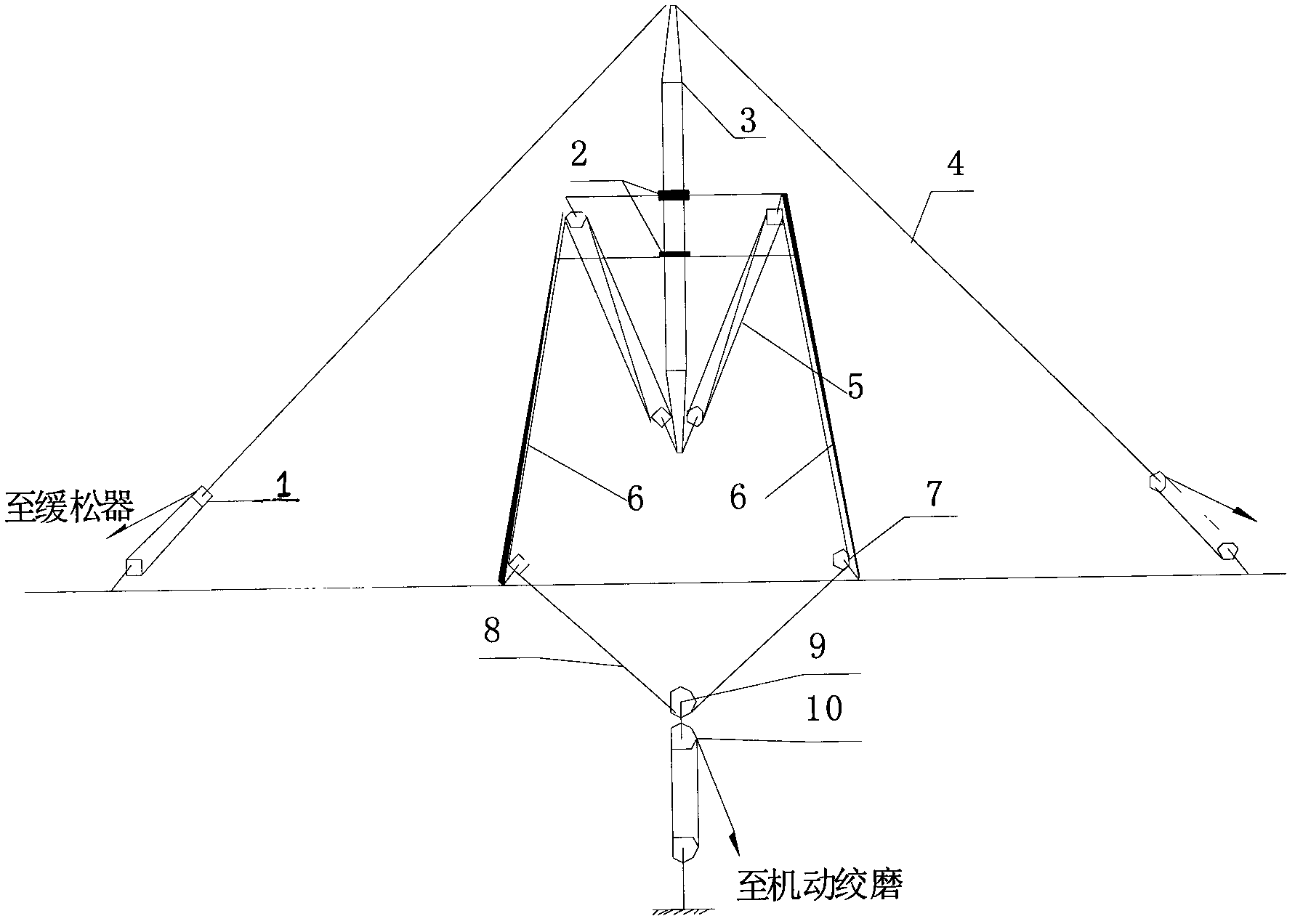

[0032] 1. Construction preparation: According to the ready-made parameters of the construction, it is determined to use the central suspension and external floor-to-ceiling poles for iron tower assembly. The poles adopt a combined type and are assembled from standard joints, pole heads and pole tails. Among them, the material of the poles is Q235. . It is assembled by 11 standard sections, 1 section head, 1 section tail, top cap, base and other accessories. The standard section, pole head and pole tail are welded lattice structures, and the standard section and standard section, standard section and pole head, pole tail, pole head and top cap, pole tail and base are connected by bolts; standard combination of pole holding The length is 40 meters, and the section is 800*800; the lifting lug of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com