Columnar hollow fiber membrane module manufacturing method and columnar hollow fiber membrane module manufacturing device

A production method and fiber membrane technology, applied in the field of separation membranes, can solve problems such as high labor intensity, high cost, and performance degradation of membrane modules, and achieve the effects of reducing work intensity, improving utilization rate, and reducing hole plugging rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

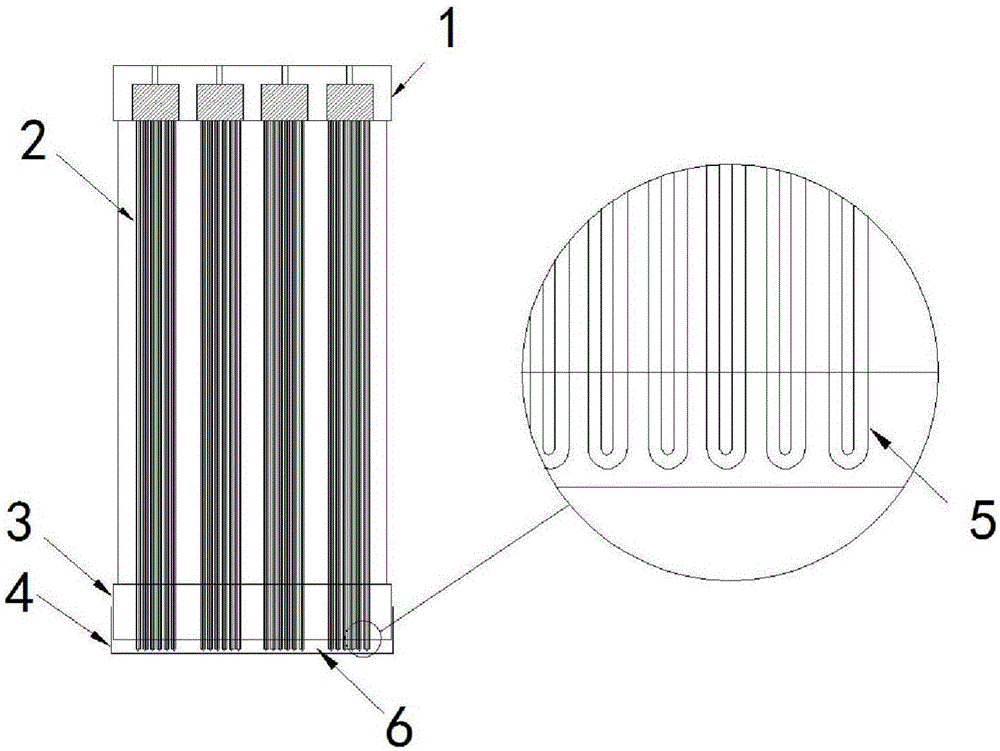

[0035] Embodiment 1: as figure 1 As shown, a columnar hollow fiber membrane module, the U-shaped membrane filament unit bundle 2 is distributed in the glue injection cavity 6, the upper part of the U-shaped membrane filament unit bundle 2 is connected to the upper end cover 1 of the membrane module, and the U-shaped membrane filament unit bundle 2 The lower part of the membrane module is collected and loaded into the lower end cover 3 of the membrane module, the lower part of the lower end cover 3 of the membrane module is connected to the injection end cover 4, and the U-shaped membrane filament unit bundle 2 has a U-shaped membrane filament end 5.

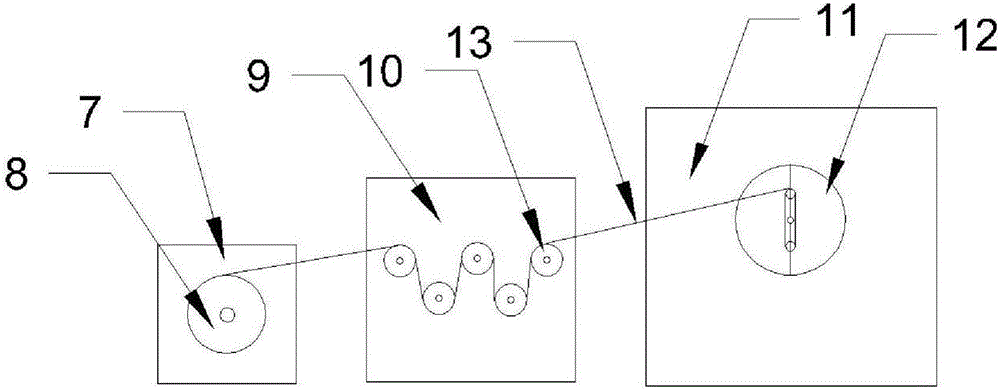

[0036] A device for making U-shaped membrane tow, a hollow fiber membrane wire feeder 7, a wire feeder 8 on the wire feeder 7, and a hollow fiber membrane 13 connected to the traction roller 10 on the traction machine 9 through the wire feeder 8 , the hollow fiber membrane filament 13 is connected to the filament collection devic...

Embodiment 2

[0038] Embodiment 2: A method for manufacturing a columnar hollow fiber membrane module, comprising the following steps;

[0039] U-shaped membrane tow manufacturing steps: winding the hollow fiber membrane 13 to form a U-shaped membrane tow with a required length and bending at one end;

[0040] Glue injection step: the U-shaped film tows are respectively injected at one end (the other end of the bent head) to form mutually independent casting unit bundles;

[0041] Assembly steps: install the casting unit bundle into the membrane shell (pressure membrane module) or membrane frame (submerged module) and fix it;

[0042] Glue pouring step: directly install the glue injection end cover at the U-shaped end of the bending unit beam head, and carry out glue pouring;

[0043] Curing and cutting step: After the glue is cured, cut the glue surface so that the membrane thread passes through the hole to complete the production of the membrane module.

Embodiment 3

[0044] Embodiment 3: A device for realizing the bending of one end of the membrane filament to form a U-shaped membrane filament bundle, including a wire feeder 7, a tractor 9, and a wire collector 11 arranged in sequence to transport the hollow fiber membrane filament, and the wire feeder Wire feeder 8 is arranged on machine 7, and wire feeder 8 is used for conveying the hollow fiber membrane filament of winding; There is five-roller traction device on tractor 9; Five-roller traction device is prior art product,

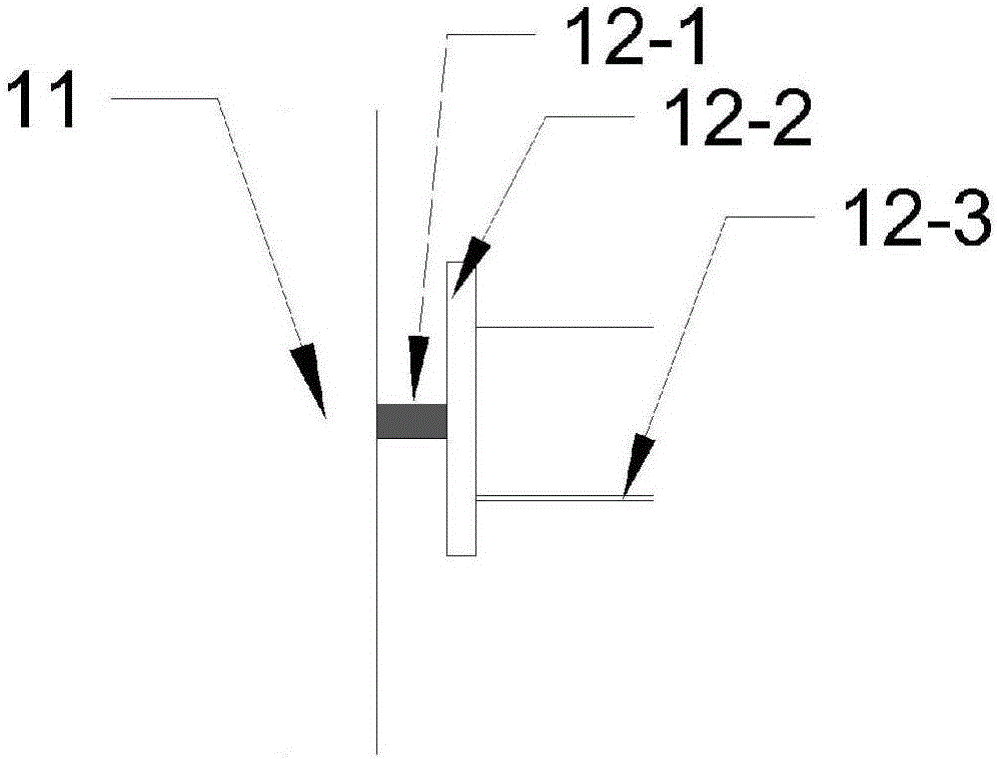

[0045] The wire receiving machine 11 has a rectangular wire receiving device 12 with adjustable diameter, and the rectangular wire receiving device 12 consists of image 3 The rotating shaft 12-1 shown in the figure, the rotating disk 12-2 and two radially movable threading rods 12-3 are composed, and the threading mechanism formed by the two threading rods 12-3 forms a rectangle, so It can be expressed as a rectangular wire collecting device.

[0046] A method for m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com