Coal mine gob filling system and method

A technology for goafs and coal mines, which is applied in fillings, mining equipment, earth-moving drilling, etc. It can solve problems such as damage to ground buildings, volatilization of harmful gases, and inability to carry out farming, and achieve fast filling speed, reduced consumption, and safety. The effect of efficient production requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

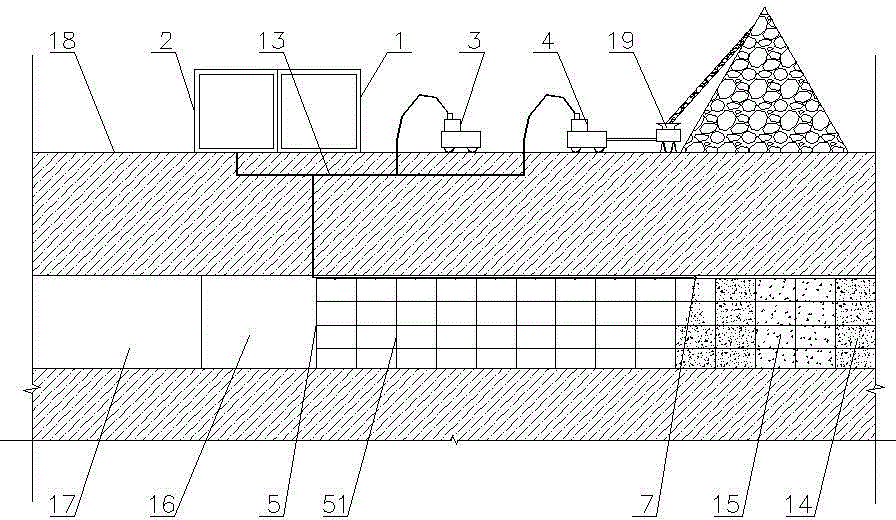

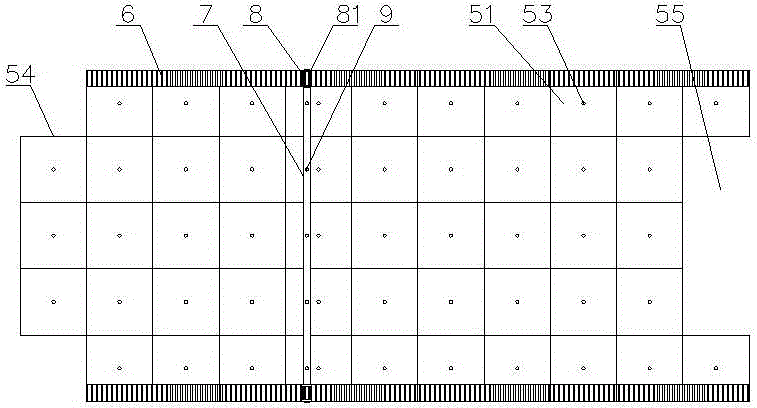

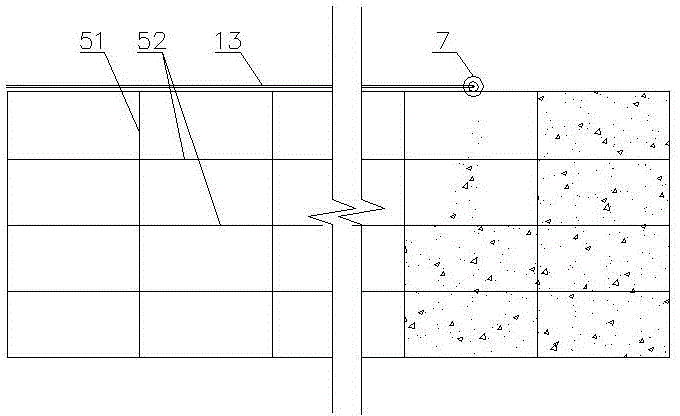

[0026] Such as Figure 1-Figure 6 The coal mine goaf filling system shown includes a control room 1, an air chamber 2, a cement pumping machine 3, a coal gangue pumping machine 4, and a coal gangue pumping machine 4 and a coal gangue stockpile arranged on the ground 18. Coal gangue pulverizing conveyor 19 is arranged between. In the goaf 16, an airbag group 5 is laid. The airbag group 5 is composed of five rows and five rows of airbag monomers 51. The head and tail of the airbag group 5 are respectively provided with a raised portion 54 and a concave portion 55. The raised portion 54 is engaged with the recessed portion 55 . Three layers of pre-drawn nets 52 are arranged at intervals up and down in the airbag unit 51, and the pre-drawn nets 52 are parallel to each other; a one-way valve 53 is arranged on the top surface of the airbag unit 51, and a one-way air inlet is arranged on the one-way valve 53 531 , a one-way air outlet 532 and a pressure sensor 533 extending into th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com