Mine gob filling and entry retaining device system and filling method

A technology of goaf and roadway retention, which is applied to fillings, safety devices, mining equipment, etc., can solve the problems of affecting the mining speed, no isolation means, and heavy labor, so as to achieve no impact on the mining speed, significant economic benefits, Fast filling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

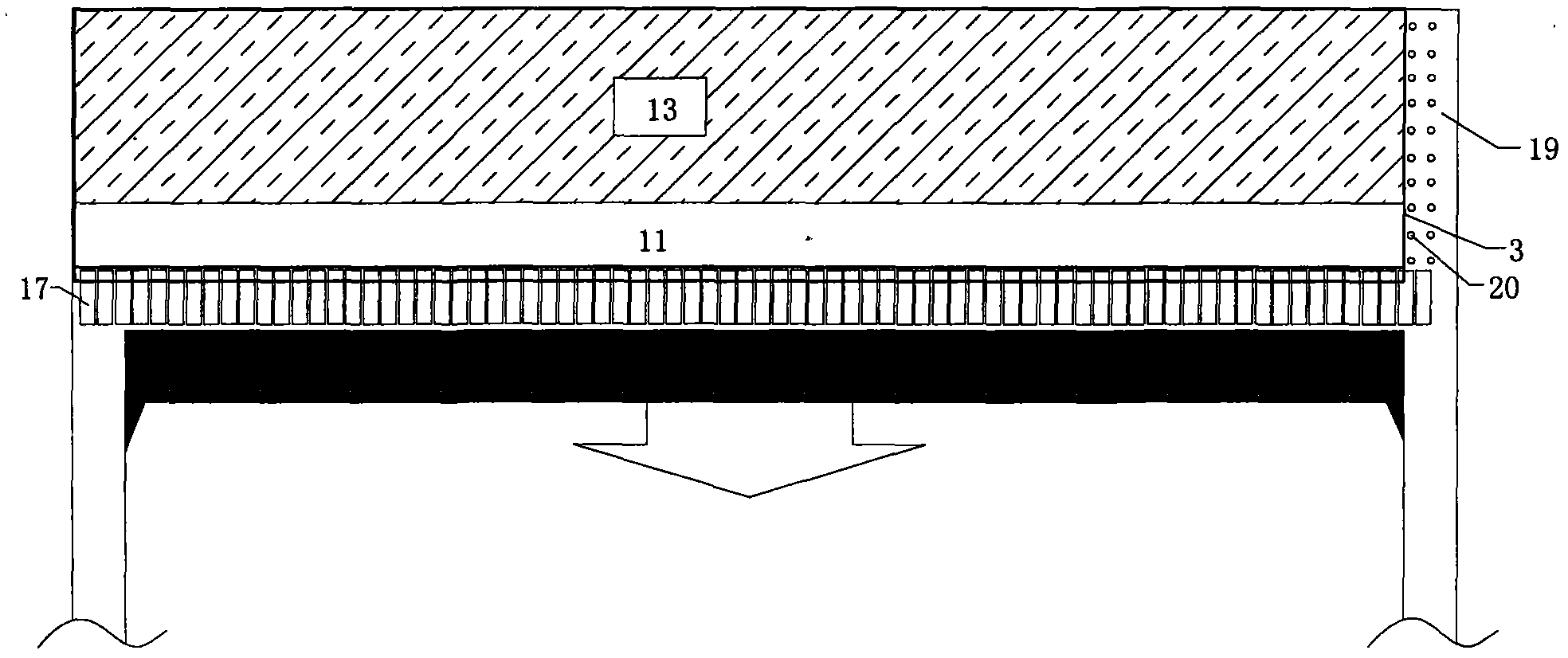

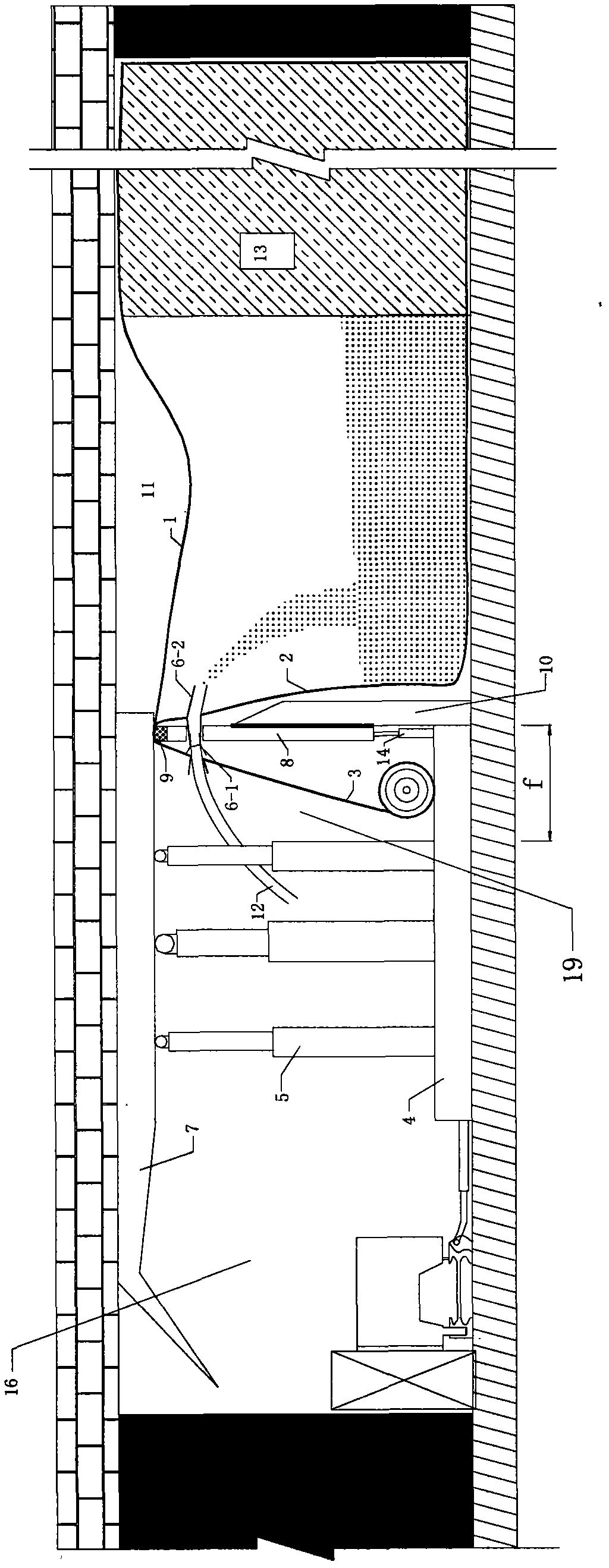

[0033] refer to Figure 1 to Figure 6Shown: a device system for mine goaf filling and roadway retention, including a coal mining face 16, a hydraulic support 17, and a goaf 11, the coal mining face 16 is provided with multiple hydraulic supports 17, the One end of the pillar 5 of the hydraulic support is connected with the base 4 of the hydraulic support, and the other end is connected with the top beam 7 of the hydraulic support. 7. The base 4 with a hydraulic support at the bottom is provided with a lifting side guard 8 and a fixed side guard 10 on the side of the gob 11. The lifting side guard 8 and the fixed side guard 10 are slidingly connected, and the fixed side guard is 10 is fixedly connected with the base 4 of the hydraulic support, one end of the lifting side guard 8 is connected with the hydraulic cylinder 14, the hydraulic cylinder 14 is fixedly connected with the base 4 of the hydraulic support, the other end of the lifting side guard 8 is inlaid with a rubber pa...

Embodiment 2

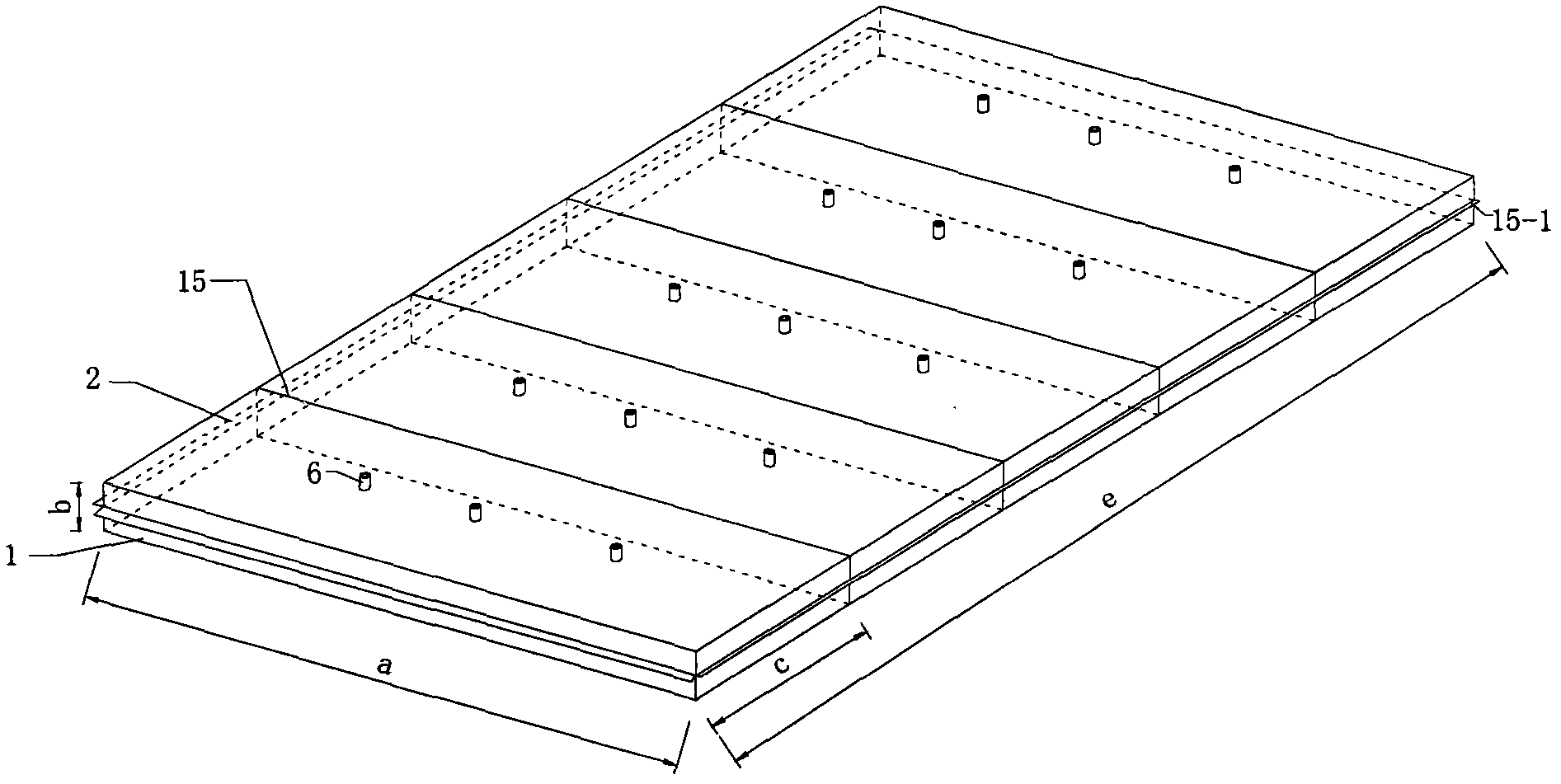

[0050] refer to figure 1 , figure 2 , Figure 3 ~ Figure 7 Shown: a device system for mine goaf filling and roadway retention, including a coal mining face 16, a hydraulic support 17, and a goaf 11. The coal mining face is provided with multiple hydraulic supports 17, hydraulic supports 17 A hole with a diameter of 0.2-0.5m is opened at the rear tail beam 18 of the rear tail beam. The one-time closed flexible isolation mold barrel 3 is sewn from the first layer of high-strength fiber cloth 1 and the second layer of high-strength fiber cloth. A layer of high-strength fiber cloth is provided with an injection cylinder 6, which is sewn from double-layer fiber cloth. The injection cylinder 6 is inserted into the filling delivery pipe 12 for binding connection, and the disposable closed flexible isolation mold cylinder 3 is wound around the hydraulic pressure The upper part of the front end of the support top beam 7 enters the rear of the hydraulic support 17, and the one-time c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com