Multi-head automatic metering and filling system

A technology of automatic metering and filling system, which is applied in the directions of packaging, transportation and packaging, and types of packaging items. It can solve the problems of low filling accuracy, high noise and large floor space, and achieve simple structure and fast filling speed. , The effect of easy cleaning and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

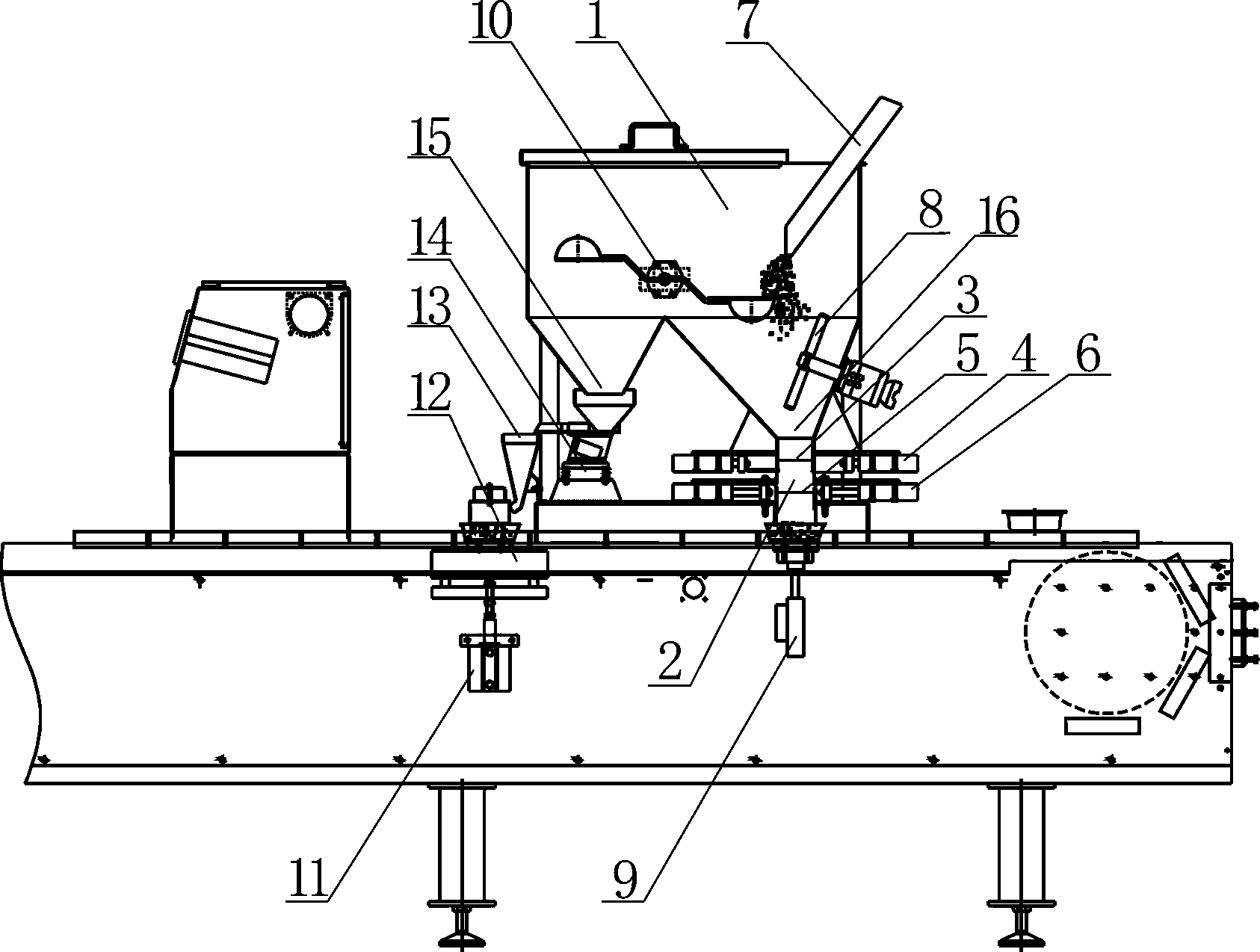

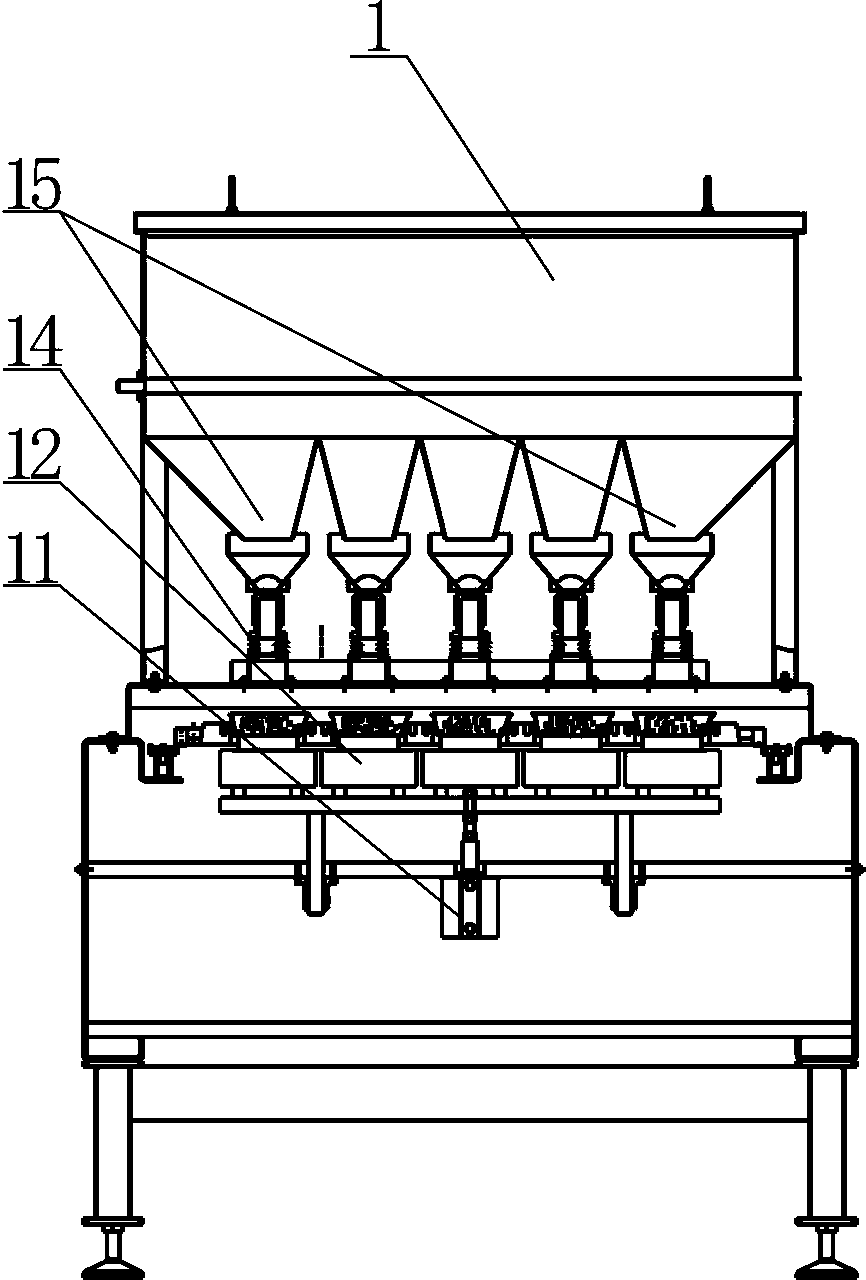

[0020] Such as figure 1 , 2 As shown, the multi-head automatic metering and filling system is mainly composed of a hopper 1, a quantitative container 2, two sets of upper plates 3, an upper cylinder 4, two sets of lower plates 5, and a lower cylinder 6. The lower end of the hopper 1 is arranged side by side. Five discharge ports 16, each discharge port 16 place is provided with described quantitative container 2, and each quantitative container 2 is provided with described two sets of upper boards 3 and two sets of lower boards 5, quantitative container 2. It is composed of an upper cylinder and a lower cylinder. The lower cylinder can move up and down relative to the upper cylinder to adjust the volume of the quantitative container. The upper port of the upper cylinder is set There is a material chute 7, two sets of upper boards are respectively located on both sides of the quantitative container 2, and the upper cylinder 4 respectively drives the two sets of upper boards 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com