Production technology of compound sodium gualenate gargle

A technology of sodium azulene sulfonate and production technology, applied in the field of production technology of compound sodium azulene sulfonate gargle, can solve problems such as taste influence, and achieve the effects of promoting release, good therapeutic effect and reducing the generation of dental plaque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

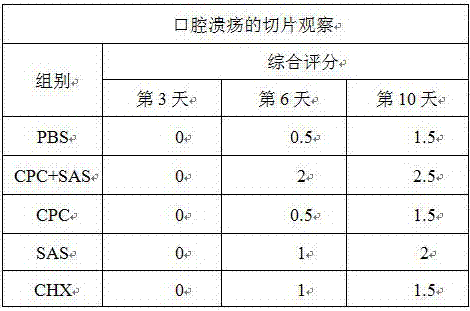

Image

Examples

Embodiment 1

[0012] A kind of compound azulene sulfonate sodium gargle production process of the present invention comprises the following steps:

[0013] (a) Configuration solution I: Heat 84.978% by mass purified water to 34°C, add 12% by mass of amorphous sorbitol, 0.45% by mass of sodium benzoate, and 0.045% cetylpyridinium chloride was stirred for 20 minutes to obtain solution Ⅰ, non-crystalline sorbitol: it is both a humectant and a sweetener, the moisturizing effect is relatively mild, and the taste is also good. Sodium benzoate: It is a good food preservative; Cetylpyridinium chloride: It belongs to cationic surfactant, which increases the permeability of cell wall by reducing surface tension, thereby inhibiting and killing bacteria. It can be used in oral mucosa Adsorption, but no irritation to the oral mucosa, no coloring to the tooth surface, antibacterial effect on bacteria, and can reduce the formation of plaque;

[0014] (b) Prepare solution II: according to the formula rati...

Embodiment 2

[0018] A kind of compound azulene sulfonate sodium gargle production process of the present invention comprises the following steps:

[0019] (a) Configuration solution I: Heat 70.002% by mass purified water to 36°C, add 28% by mass of amorphous sorbitol, 0.55% by mass of sodium benzoate, and 0.055% cetylpyridinium chloride was stirred for 25 minutes to obtain solution Ⅰ, non-crystalline sorbitol: it is both a humectant and a sweetener, the moisturizing effect is relatively mild, and the taste is also good. Sodium benzoate: It is a good food preservative; Cetylpyridinium chloride: It belongs to cationic surfactant, which increases the permeability of cell wall by reducing surface tension, thereby inhibiting and killing bacteria. It can be used in oral mucosa Adsorption, but no irritation to the oral mucosa, no coloring to the tooth surface, antibacterial effect on bacteria, and can reduce the formation of plaque;

[0020] (b) Prepare solution II: Dissolve sodium azulene sulfo...

Embodiment 3

[0024] A kind of compound azulene sulfonate sodium gargle production process of the present invention comprises the following steps:

[0025] (a) Configuration solution I: Heat 76.77% by mass purified water to 35°C, add 20% by mass of amorphous sorbitol, 0.5% by mass of sodium benzoate, and 0.05% cetylpyridinium chloride was stirred for 23 minutes to obtain solution Ⅰ, non-crystalline sorbitol: it is both a humectant and a sweetener, the moisturizing effect is relatively mild, and the taste is also good. Sodium benzoate: It is a good food preservative; Cetylpyridinium chloride: It belongs to cationic surfactant, which increases the permeability of cell wall by reducing surface tension, thereby inhibiting and killing bacteria. It can be used in oral mucosa Adsorption, but no irritation to the oral mucosa, no coloring to the tooth surface, antibacterial effect on bacteria, and can reduce the formation of plaque;

[0026] (b) Prepare solution II: according to the formula ratio, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com