Rare earth-mixing high strength lithium bisilicate sitall material and preparation method thereof

A lithium disilicate and glass-ceramic technology, which is applied in the field of glass-ceramic materials and their preparation, can solve the problems of complex preparation process, difficult to obtain, and high requirements for equipment conditions, and achieves simple preparation method, low production cost, and excellent mechanical properties. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

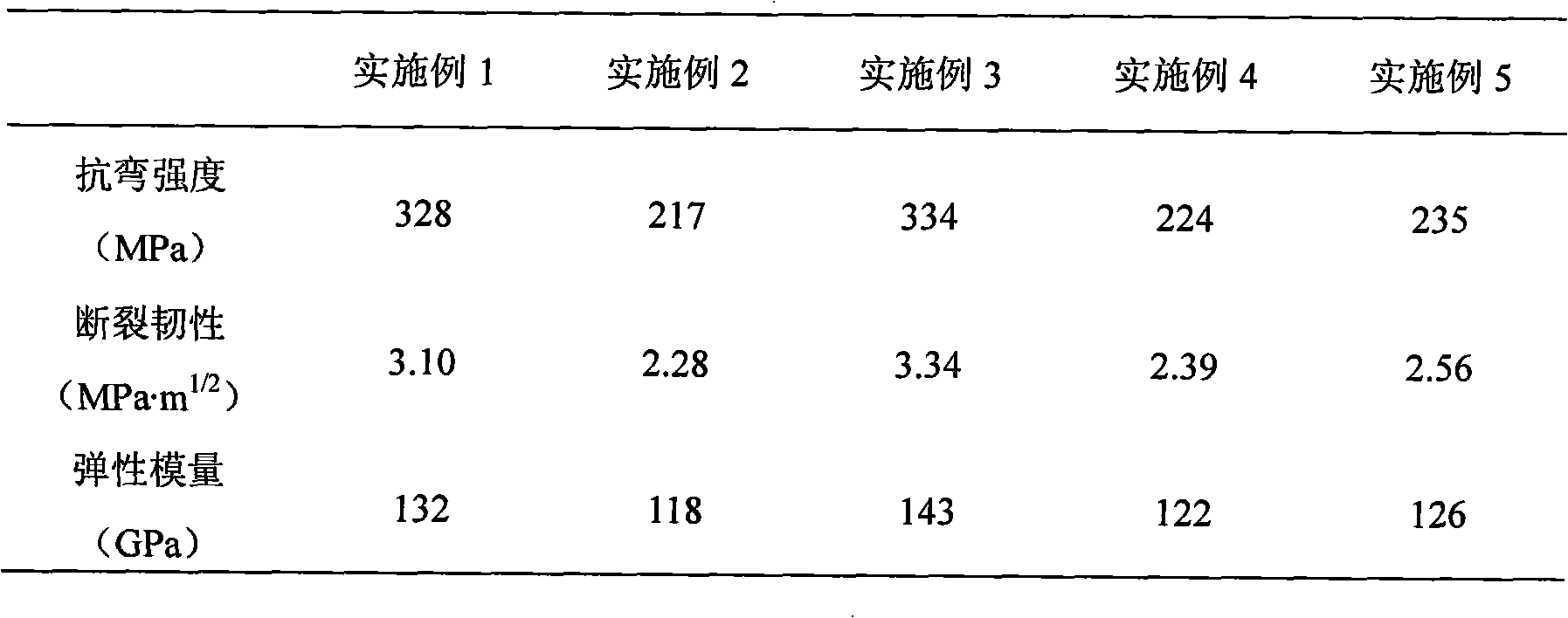

Embodiment 1

[0013] Embodiment 1: the glass-ceramic that the present invention relates to, its basic glass is by B 2 o 3 , SiO 2 ,P 2 o 5 、K 2 O. Li 2 O, ZrO 2 , La 2 o 3 Composition, the content of each composition is B 2 o 3 : 2.3mol%, SiO 2 : 65.0mol%, P 2 o 5 : 1.2mol%, K 2 O: 1.8mol%, Li 2 O: 27.1mol%, ZrO 2 : 1.8mol%, La 2 o 3 : 0.8 mol%.

Embodiment 2

[0014] Embodiment 2: the crystallized glass that the present invention relates to, its base glass is made of B 2 o 3 , SiO 2 ,P 2 o 5 、K 2 O. Li 2 O, Al 2 o 3 , ZrO 2 , Y 2 o 3 Composition, the content of each composition is B 2 o 3 : 2.1mol%, SiO 2 : 64.2mol%, P 2 o 5 : 1.0mol%, K 2 O: 1.6mol%, Li 2 O: 26.8mol%, Al 2 o 3 : 1.4mol%, ZrO 2 : 1.7mol%, Y 2 o 3 : 1.3 mol%.

Embodiment 3

[0015] Embodiment 3: the crystallized glass that the present invention relates to, its base glass is made of B 2 o 3 , SiO 2 ,P 2 o 5 、K 2 O. Li 2 O, Al 2 o 3 , ZrO 2 , Y 2 o 3 , La 2 o 3 Composition, B of each composition 2 o 3 : 1.1mol%, SiO 2 : 61.6mol%, P 2 o 5 : 2.5mol%, K 2 O: 1.2mol%, Li 2 O: 30.8mol%, Al 2 o 3 : 1.5mol%, ZrO 2 : 1.3mol%, Y 2 o 3 : 1.5mol%, La 2 o 3 : 1.0 mol% composition.

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com