Motor and electrical equipment comprising same

A motor and circuit board technology, applied in the field of motors, can solve the problems of inaccurate magnet sensing, inability to arrange other sensing elements, and less available space for circuits, so as to reduce height space, ensure thinning, and reduce Effects of Axial Dimensions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

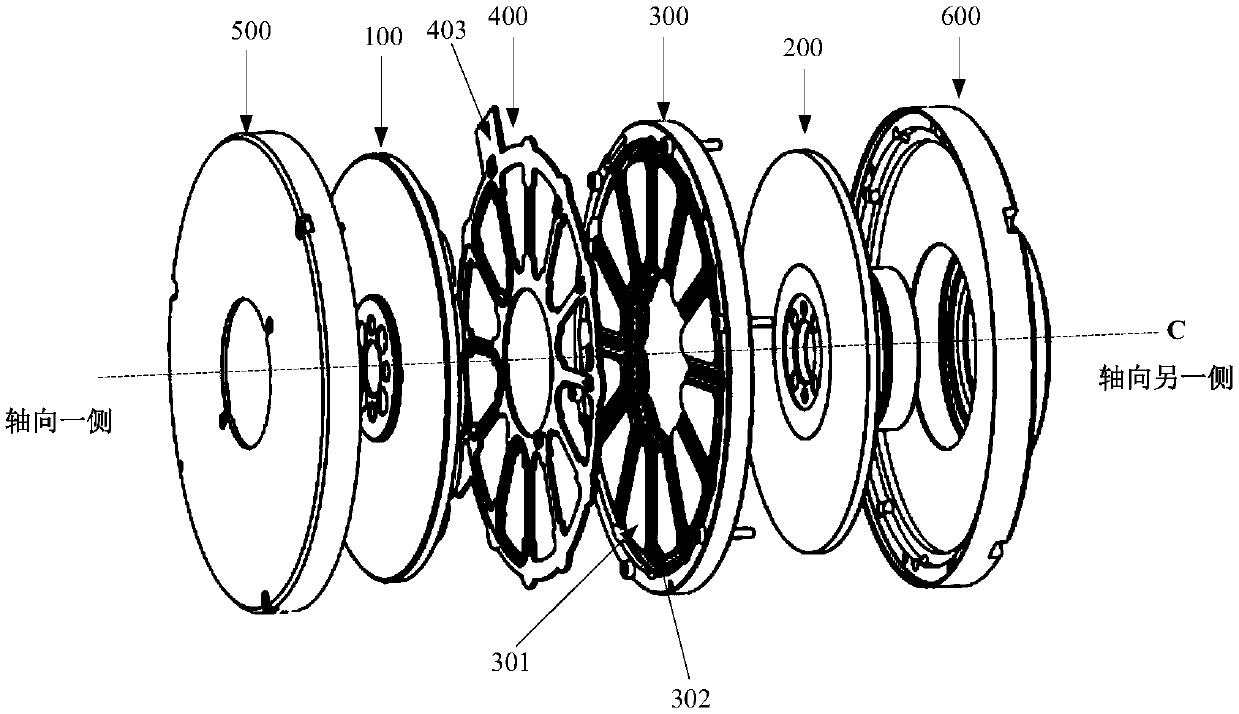

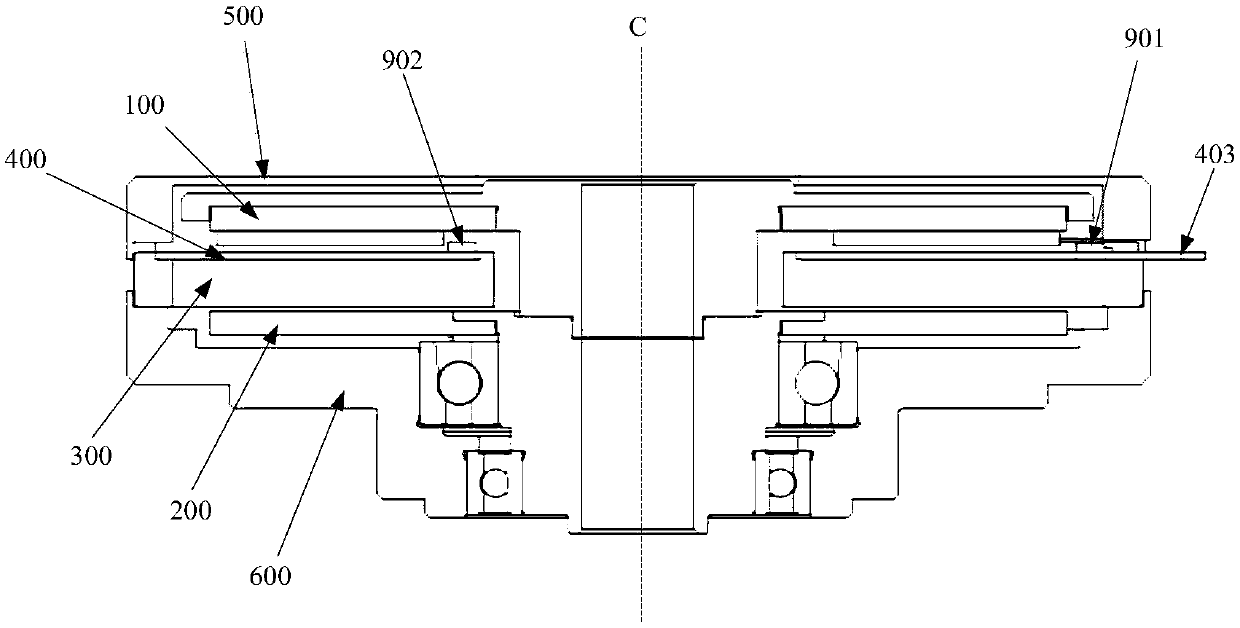

[0053] This embodiment provides a motor.figure 1 is an exploded schematic diagram of the motor, figure 2 is a sectional view of the motor.

[0054] Such as figure 1 and figure 2 As shown, the motor has:

[0055] a shaft (not shown), which is configured to be able to rotate around the central axis C;

[0056] Two rotors 100, 200 are arranged in the axial direction with a predetermined interval, and at least one of the rotors 100 or 200 has a magnet (not shown in the figure). In this embodiment, the rotor 100 has a magnet as an example. , the configuration of the magnet can refer to the prior art;

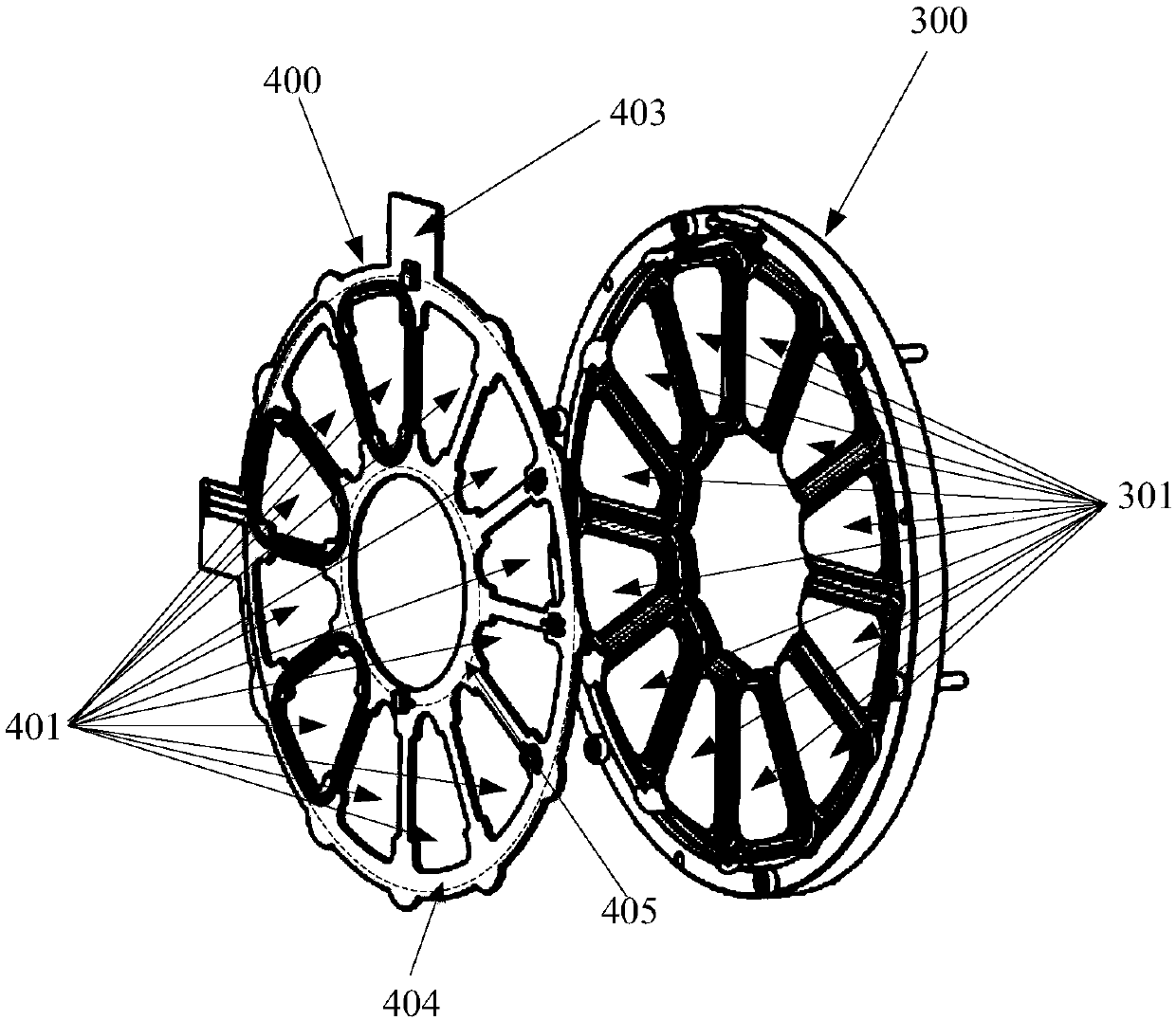

[0057] The stator 300 is disposed between the two rotors 100, 200, and has a plurality of stator cores 301 arranged in the circumferential direction and coils 302 wound on the plurality of stator cores 301;

[0058] The circuit board 400 is arranged between the stator 300 and the rotor 100 with magnets. In this embodiment, the circuit board 400 is facing the rotor 100, that i...

Embodiment 2

[0083] This embodiment provides an electric device, which has the motor described in Embodiment 1 and other conventional components. This embodiment does not limit the structure, arrangement and function of the conventional components, and reference may be made to the prior art.

[0084] In this embodiment, based on the structure of the motor in Embodiment 1, a circuit board is placed in the inner stator of the motor (such as a thin axial flux motor) to connect the motor coil lines and configure various required sensing elements , does not increase the air gap or the axial height of the motor, which reduces the space occupied by the stator height, thereby reducing the axial size of the motor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com