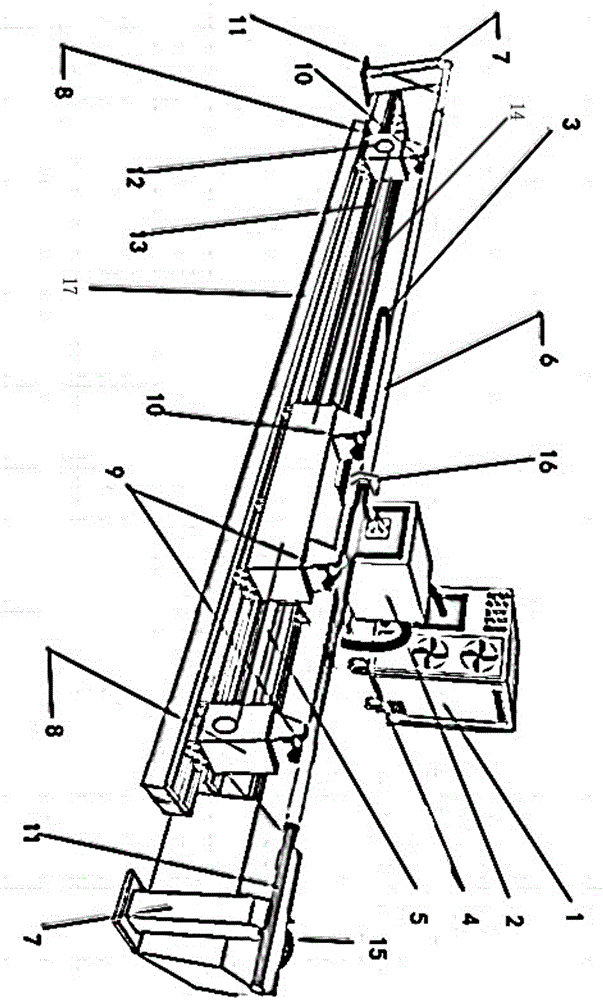

Equipment and technology for sintering enamel coating on surface of steel pipe

A steel pipe and enamel technology, which is applied in the field of enamel processing, can solve the problems of unqualified steel pipe enamel products, temperature difference problems, and horizontal hanging, etc., so as to improve the difficulty of operation, save the height space of the workshop, and save energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] There is a steel pipe that needs to be enamelled. Its diameter is 168MM, its thickness is 5MM, and its length is 12 meters. The enameling procedure is as follows:

[0039] 1. According to the outer diameter of the steel pipe, the induction coil is made, the inner diameter of the coil is 190MM, and the number of induction coils is 10;

[0040] 2. Connect the induction coil with the electromagnetic frequency induction heating equipment, the cooling circulating water pipe and the power cord;

[0041] 3. Pre-treat the steel pipe to be enamelled, remove oil and rust, and dry the water;

[0042] 4. Make enamel slurry for enamel spraying, and use organic binder to replace part of the clay as a suspending agent;

[0043] 5. Spray the enamel slurry obtained in step 4 on the pre-treated steel pipe, with a spray thickness of 160±20 microns;

[0044] 6. Put the steel pipe coated with enamel glaze in a moisture oven to dry the moisture of the enamel glaze layer;

[0045] 7. Place...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com