Connecting rod type vacuum adsorption horizontal movement machine

A vacuum adsorption and connecting rod technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of large height space, broken or bent guide rail, etc., and achieve the effect of stable operation, reduced impact, and not easy to shake

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

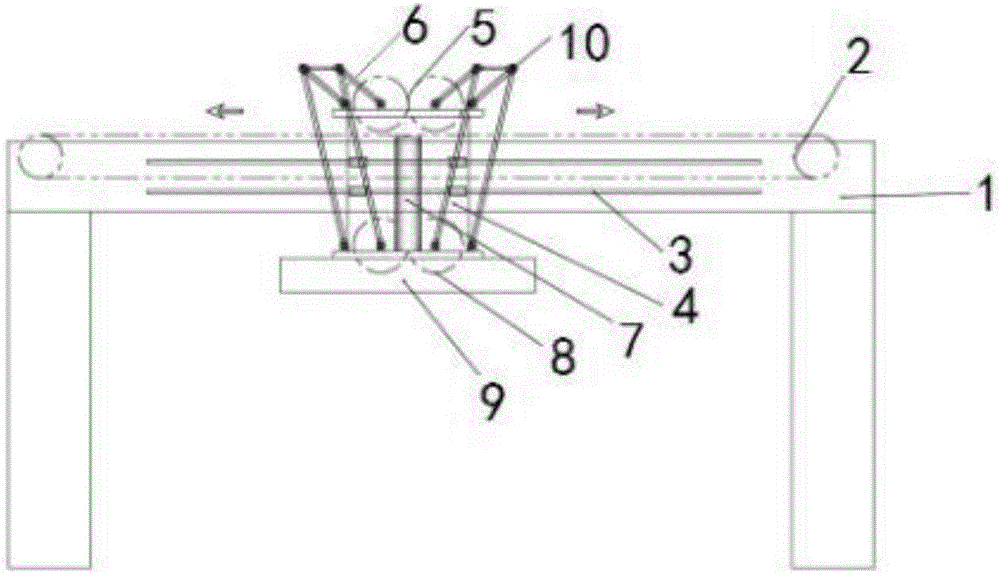

[0012] like figure 1 As shown, a link-type vacuum adsorption translation machine includes a main frame 1, a translation drive system 2, a translation guide rail 3, a translation trolley 4, an upper synchronous gear 5, a main linkage mechanism 6, a lifting drive system 7, and a lower synchronous gear 8. Lifting trolley 9, auxiliary link mechanism 10, the translating drive system 2 and translation guide rail 3 are installed on the beam of the main frame 1, and the translation trolley 4 is installed on the translation guide rail 3 through a slider and connected with the translation drive system 2 connection; the lifting drive system 7 is installed on the translation trolley 4, the lift trolley 9 is connected to the bottom of the lift drive system 7, and the bottom of the lift trolley 9 is provided with a vacuum adsorption mechanism; the top of the translation trolley 4 and the top of the lift trolley 9 are equipped with four positioning shafts. A pair of upper synchronizing gears...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com