Inbound cooling system and method for vacuum pipeline maglev train

A technology of maglev trains and vacuum pipelines, which is applied in tunnel systems, sliding/floating railway systems, cooling fluid circulation devices, etc., can solve the problem of high temperature of train bodies and achieve the effect of reducing body temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

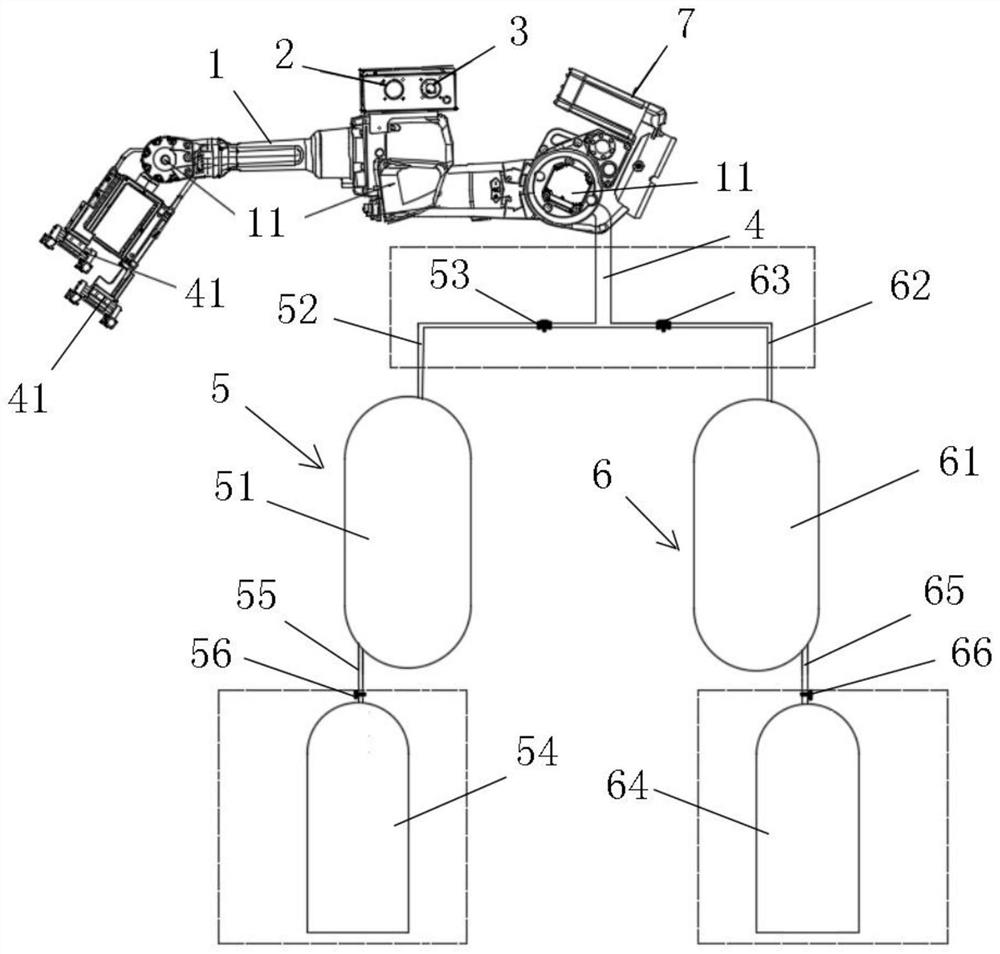

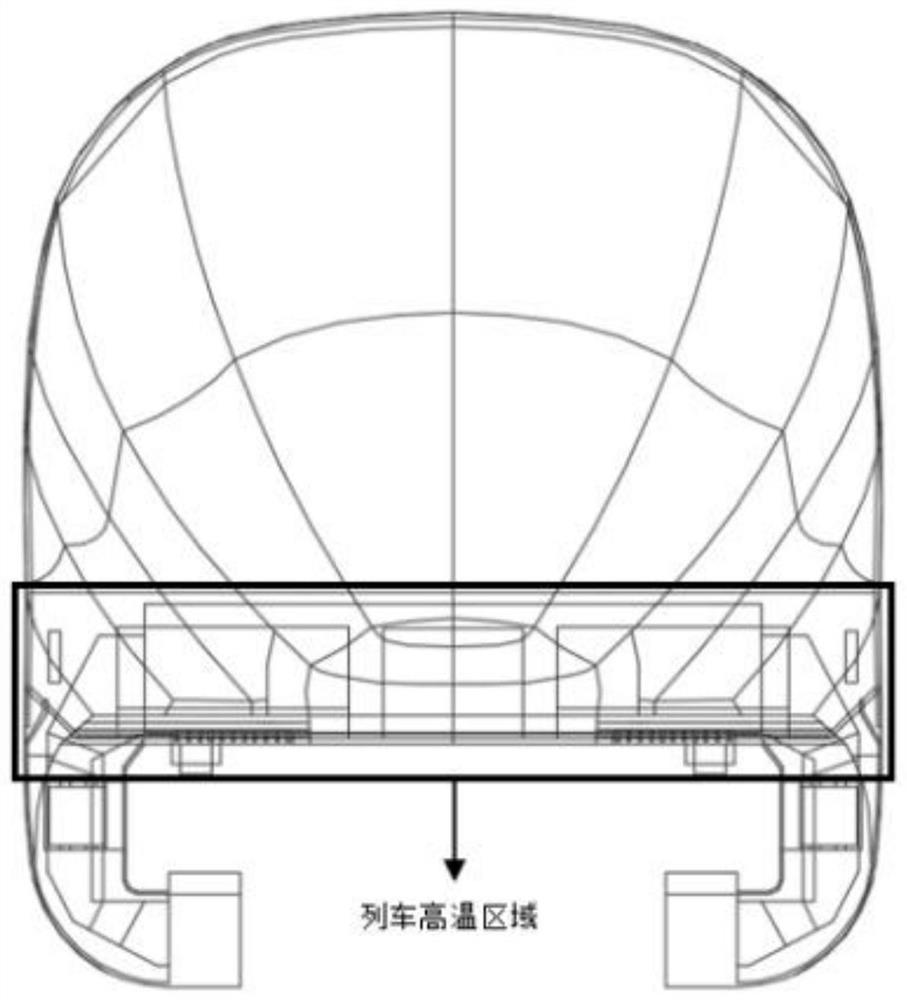

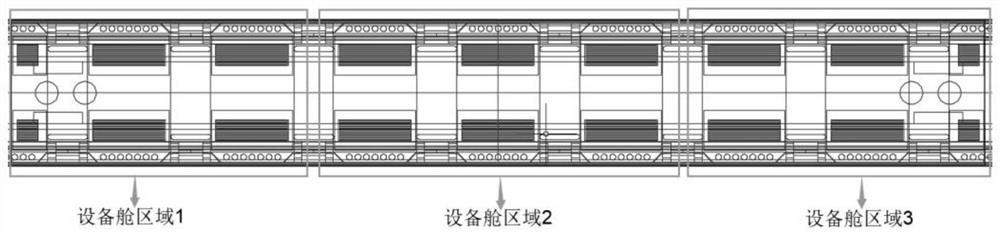

[0050] see Figure 1 to Figure 7 , an inbound cooling system for a vacuum tube maglev train according to an embodiment of the present invention, the inbound cooling system mainly includes a mechanical arm 1, a body temperature measuring device 2, a body material detection device 3, a cooling gas pipeline 4, and a high-pressure cold air supply System 5, high pressure constant temperature gas supply system 6 and controller 7. Wherein, the mechanical arm 1 is installed under the platform of the vacuum tube maglev train; the body temperature measuring device 2 is installed on the mechanical arm 1, and the body temperature measuring device 2 is used to detect the body temperature of the vacuum tube maglev train and send the body temperature signal To the controller 7; the body material detection device 3 is installed on the mechanical arm 1, and the body material detection device 3 is used to detect the body material of the vacuum pipeline magnetic levitation train, and sends the b...

Embodiment 2

[0060] A cooling method for entering a station of a vacuum tube maglev train according to an embodiment of the present invention. The vehicle body of the vacuum tube maglev train is cooled by using the cooling system for entering the station according to the above-mentioned embodiment 1 of the present invention. The cooling method for entering the station mainly includes the following steps:

[0061] Stop the vacuum tube maglev train to be cooled on the train platform, and control the mechanical arm 1 to move to a predetermined position close to the body of the vacuum tube maglev train through the controller 7;

[0062] Detect the body temperature of the vacuum pipeline maglev train at the predetermined position through the body temperature measuring device 2, and send the body temperature signal to the controller 7;

[0063] Detect the body material of the vacuum pipeline maglev train at the predetermined position through the body material detection device 3, and send the body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com