Method for manufacturing closed flanged metal plate

A manufacturing method and metal plate technology, which is applied in the field of bending and forming of metal plates, can solve problems such as inconvenient operation, difficult to bend and seal, and laborious folding, so as to achieve the effects of convenient processing and manufacturing, guaranteed product quality, and guaranteed shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

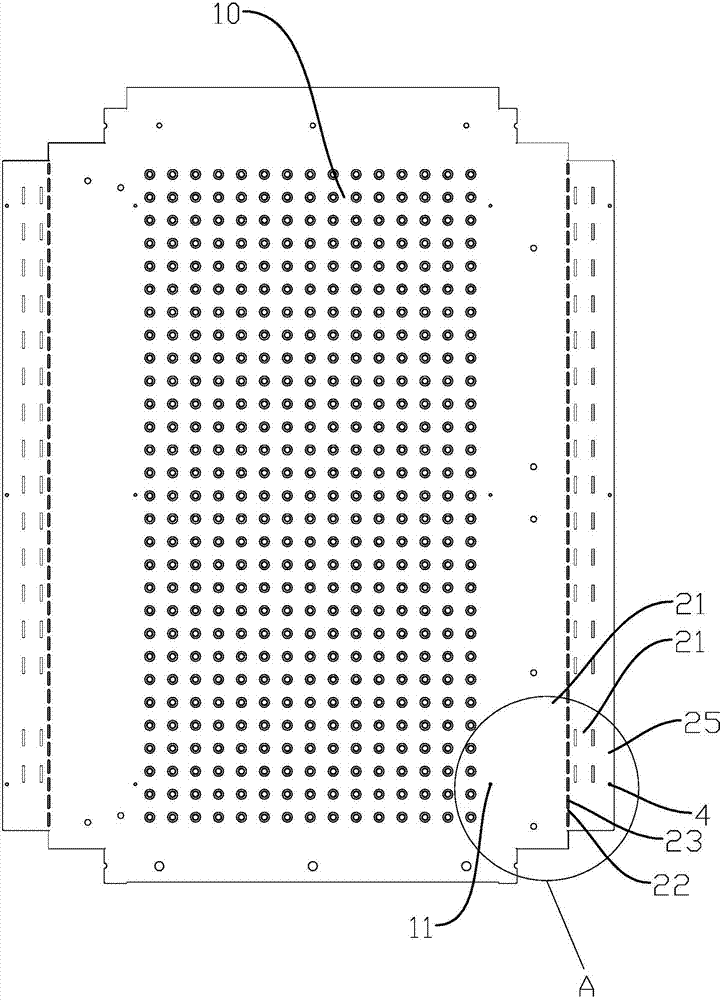

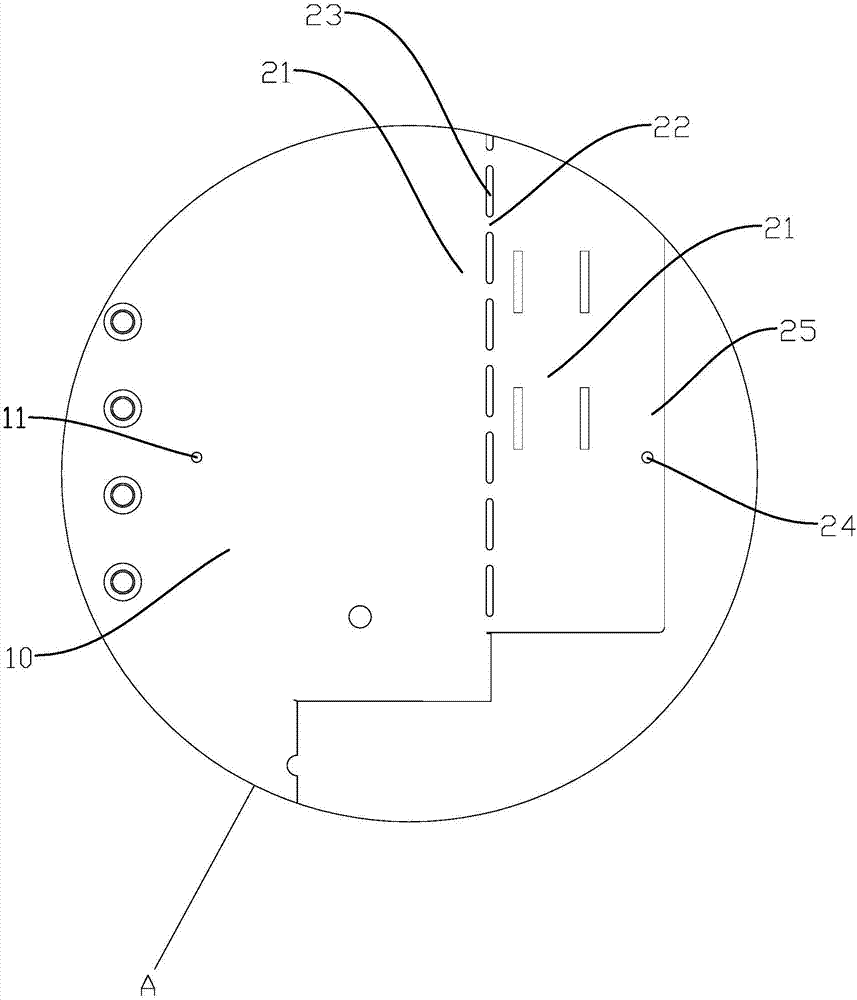

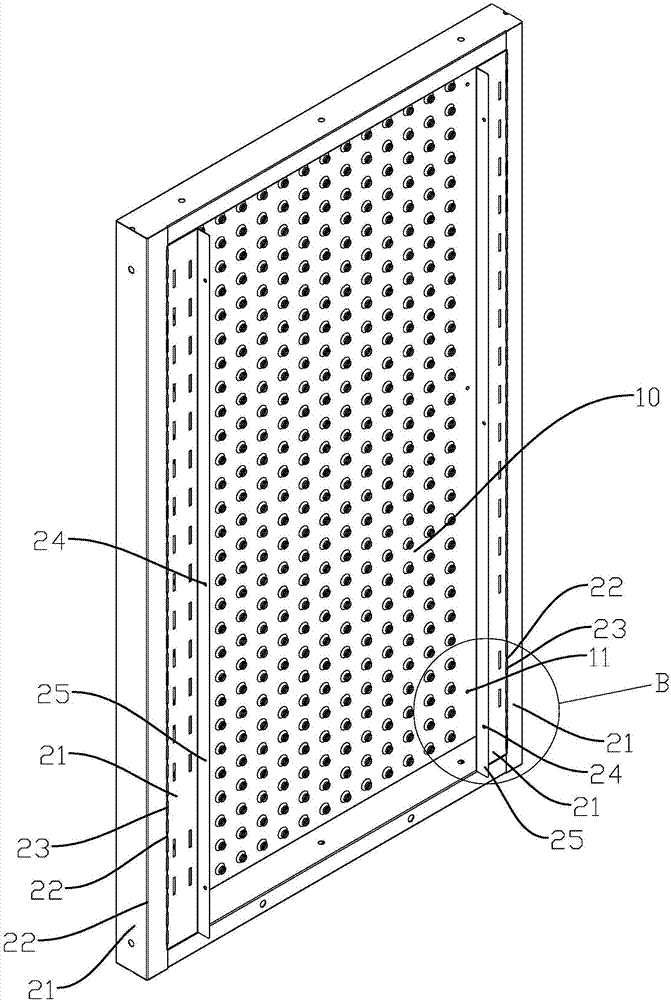

[0023] refer to Figure 1 to Figure 6 , a method of manufacturing a closed folded edge metal plate, which is used to bend the part to be bent on the metal plate into a closed tubular folded part, the folded part includes turning the part to be bent along a number of fold lines A number of flanged plates 21 formed, and the section of the folded portion is polygonal, comprising the following steps:

[0024] Step 1: A plurality of through holes 23 distributed along at least one fold line 22 on the part to be bent is opened on the metal plate, which can weaken the structural strength of the corresponding fold line 22 and facilitate manual bending operations by workers.

[0025] Step 2, using bending equipment to bend the part to be bent, so that the edge plate 21 on both sides of the folding line 22 without a through hole 23 is bent to a predetermined angle along the folding line 22 between them, and no through hole 23 is opened The strength of the bending line 22 is relatively s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com