Automatic carrying clamp hand assembly

A gripper and assembly technology, applied in the field of manipulators, can solve problems such as large stroke and swing space, complex gas path control structure, and large assembly rotation radius, and achieve short rotation switching time, save action stroke time, and lighten the structure. The effect of intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The structure of the gripper assembly applying the technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

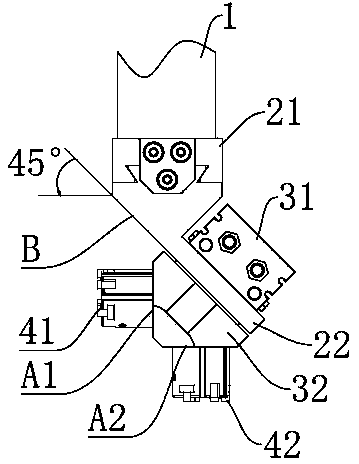

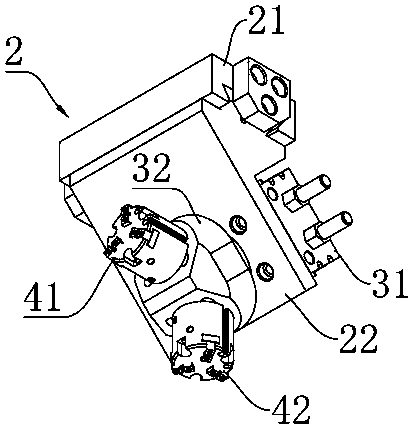

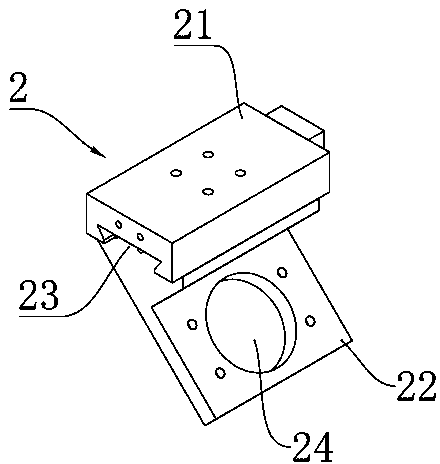

[0035] Such as figure 1 , figure 2 with image 3 As shown, an automatic handling gripper assembly that can be used in conjunction with a machining center includes a support frame 2 that can be installed on a transport arm 1 and a rotary driver installed on the support frame 2 . The machining center is a device capable of processing mechanical parts, such as a machine tool, and the automatic handling gripper assembly mainly provides the machining center with workpieces to be processed and removes processed workpieces. The machining centers each have a gripper that can grip a workpiece, for which purpose the gripper itself also has a gripping axis.

[0036] Wherein the carrying arm 1 is a component capable of reciprocating movement and driving the gripper assembly to at least move up and down, l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com