Cooling wall structure of blast furnace

A stave and blast furnace technology, applied in the direction of cooling devices, etc., can solve the problems of cooling pipes and connecting pipes hindering the flow of cooling water, difficult installation of connecting pipes and valves, and damage to the structural strength of the furnace shell, etc., so as to facilitate pipe penetration maintenance and easy The effect of sealing and preventing high-temperature gas leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

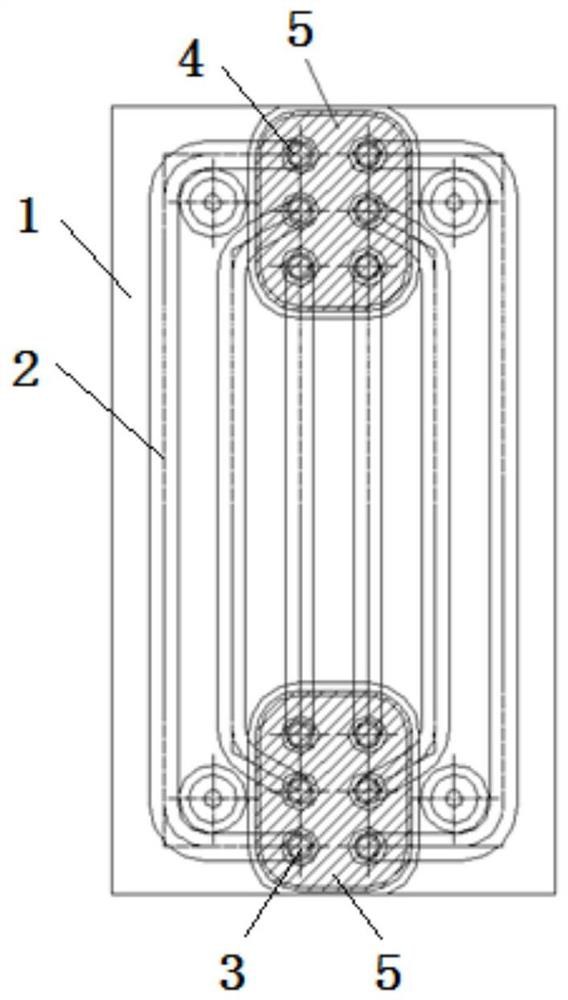

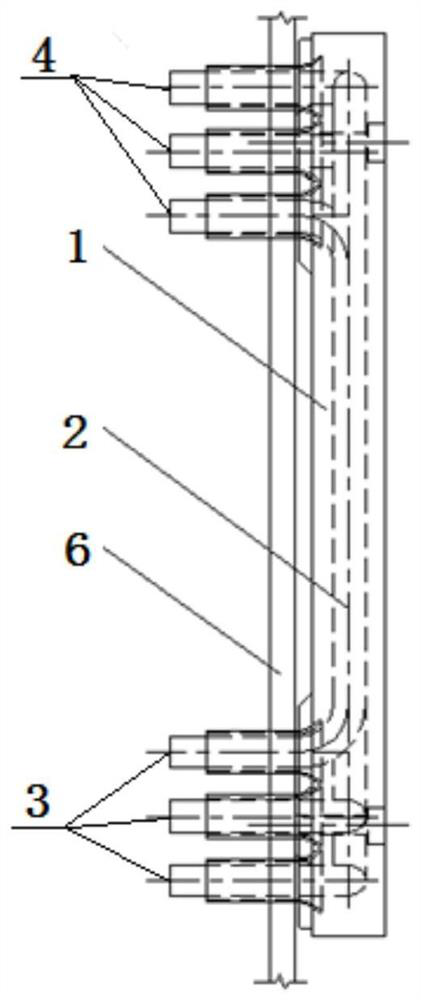

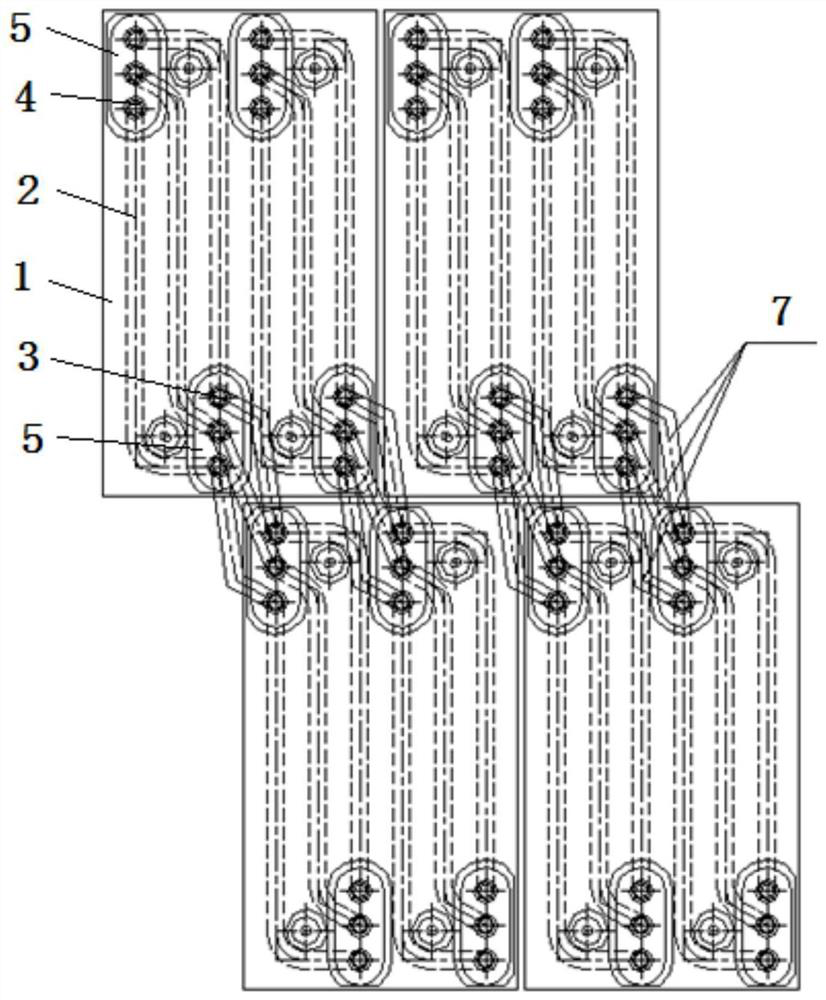

[0029] Such as Figure 5 and Figure 6 As shown, a blast furnace stave structure includes a multi-section stave 1, and six cooling pipes 2 are arranged in the wall body of each section of the stave 1, and the lower end of each section cooling pipe 2 is a water inlet 3, and the upper end is a water outlet 4, The water inlet 3 and the water outlet 4 pass through the furnace shell 6 of the blast furnace located on the outside of the stave 1, and the cooling pipes 2 of the adjacent upper and lower staves 1 are sequentially connected by connecting pipes 7 to form six cooling passages from bottom to top. The six cooling pipes 2 in the wall of each stave 1 are vertically parallel and arranged at equal intervals, the water inlet 3 and the water outlet 4 of the adjacent cooling pipes 2 are respectively arranged at random heights, and the height of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com