Improved type air suspension

An air suspension, an improved technology, applied in the direction of suspension, elastic suspension, interconnection system, etc., can solve the problems of increasing the weight and cost of the braking system, increasing the number of air storage tanks, and narrow air storage tank layout space, etc. Achieve the effect of reducing machining accuracy, reducing installation height and reducing assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The following examples can enable those skilled in the art to understand the present invention more comprehensively, but the present invention is not limited to the scope of the described examples.

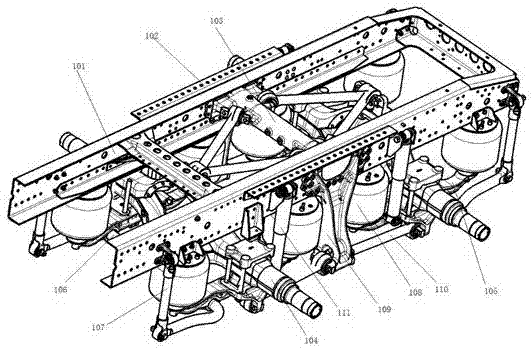

[0060] Such as Figure 1-Figure 14 A modified air suspension is shown, including

[0061] A pair of symmetrically arranged longitudinal beams 101 have several connection holes on the longitudinal beams 101 .

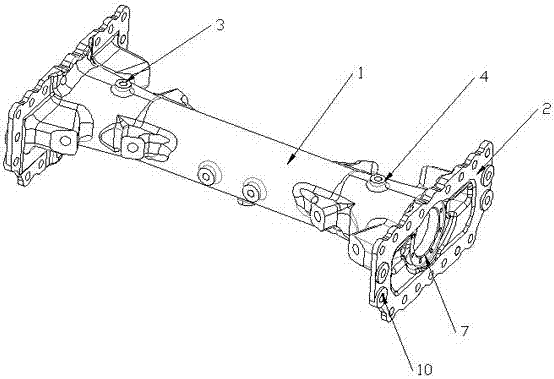

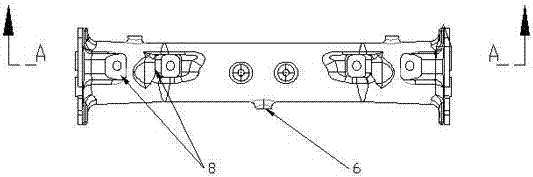

[0062] A beam 103 installed between two longitudinal beams, such as Figure 2-Figure 5 As can be seen from the schematic diagram shown, the beam 103 includes

[0063] A beam main body, the beam body is integrally cast from a beam tube body 1 and a pair of longitudinal beam connecting flanges 2 symmetrically arranged at both ends of the beam tube body 1, and the outer wall of the beam tube body 1 is integrally cast V-shaped push seat group, the beam tube body 1 is a tubular structure with two ends open, and at the two ends of the beam tube body 1 in the long axis di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com