Patents

Literature

32results about How to "Easy to preservative treatment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

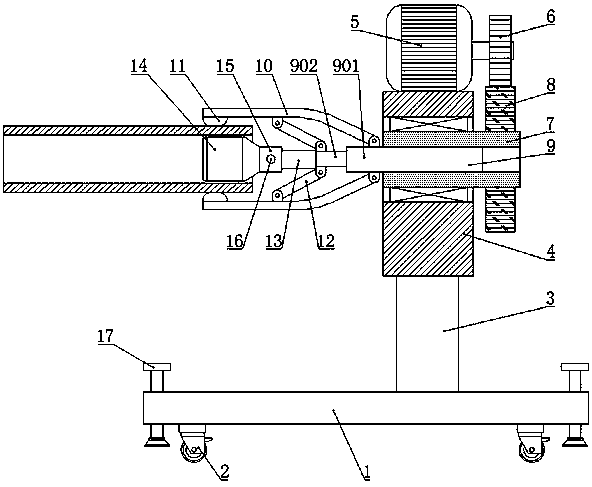

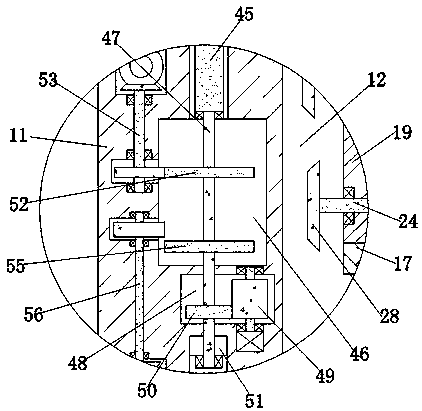

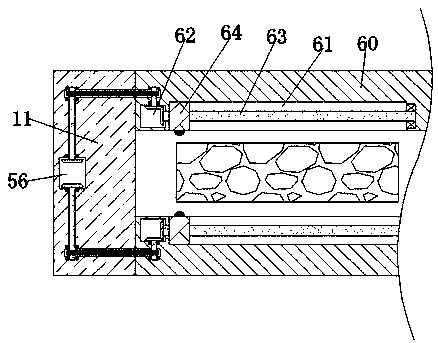

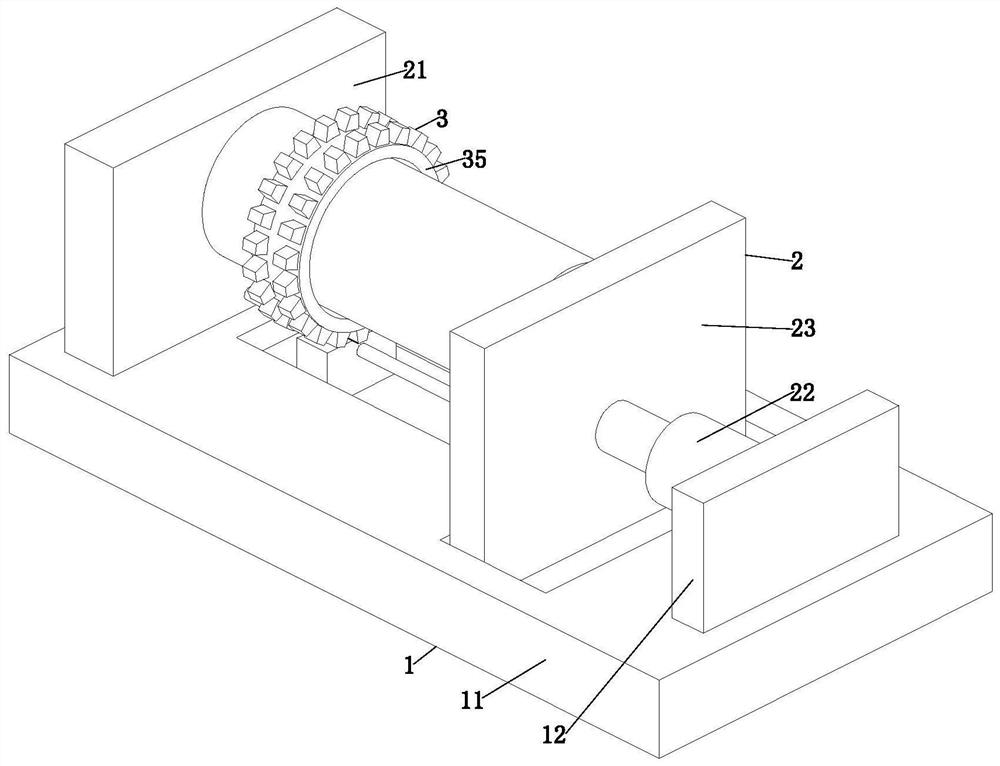

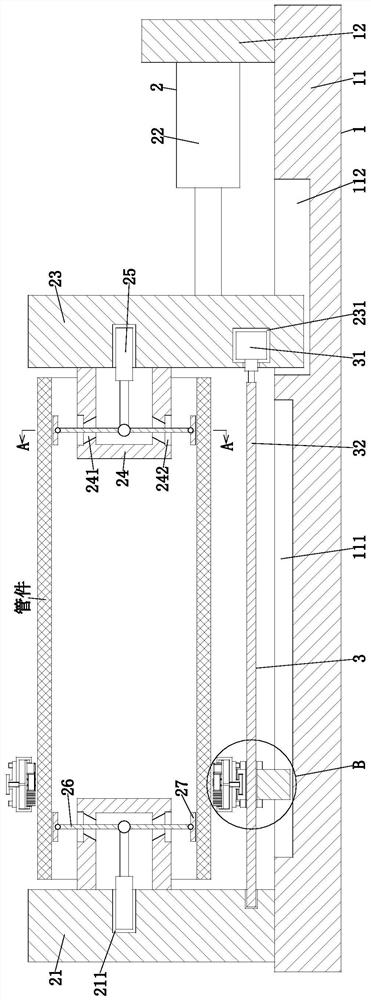

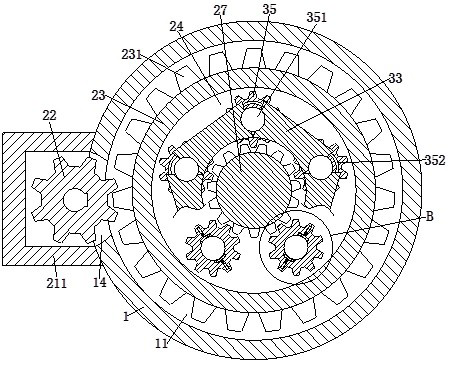

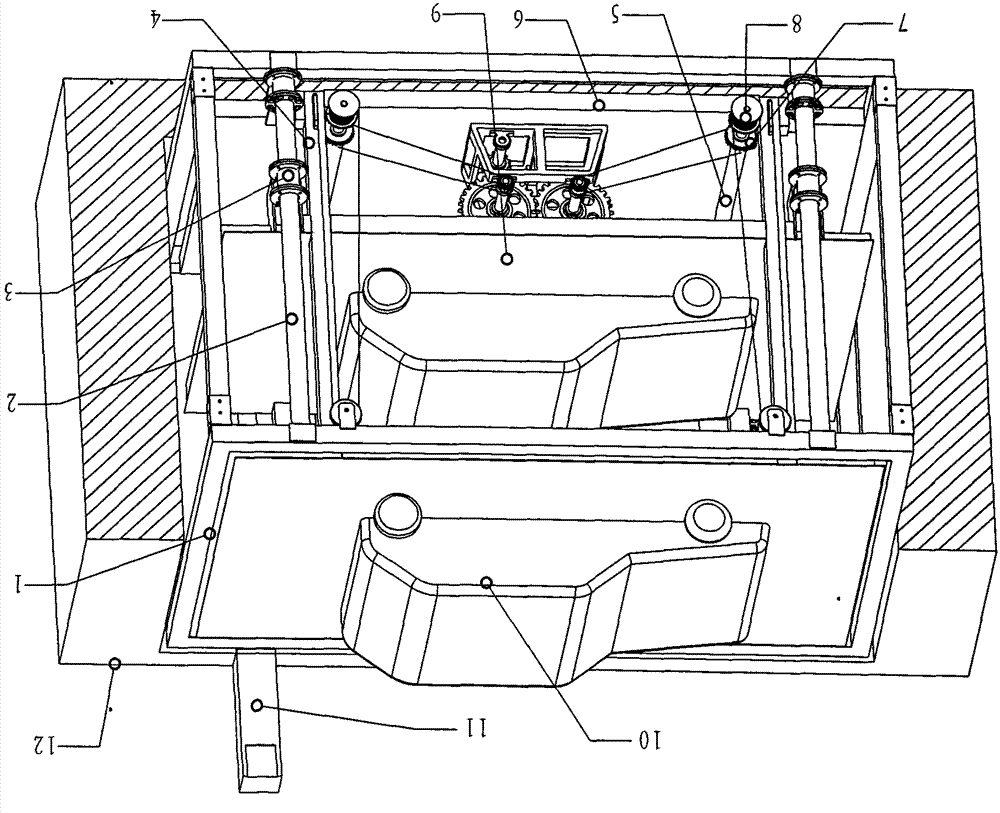

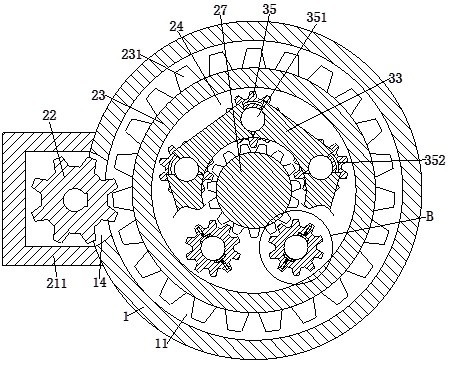

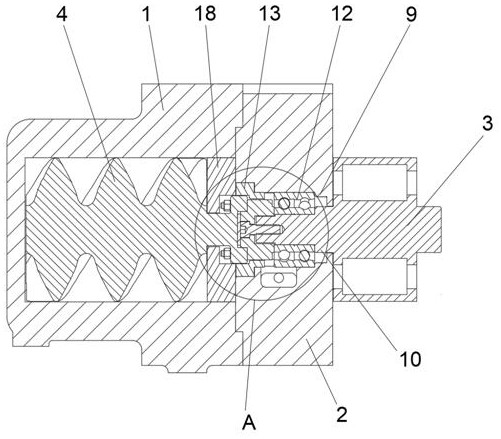

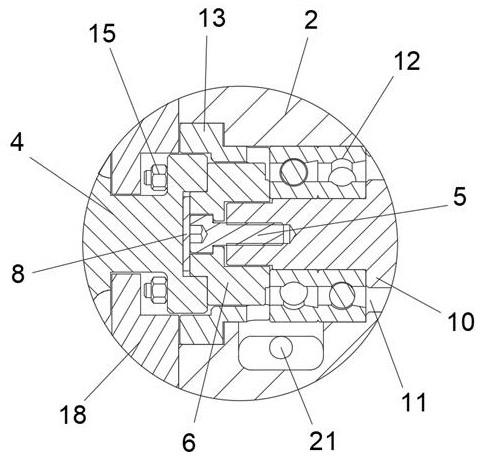

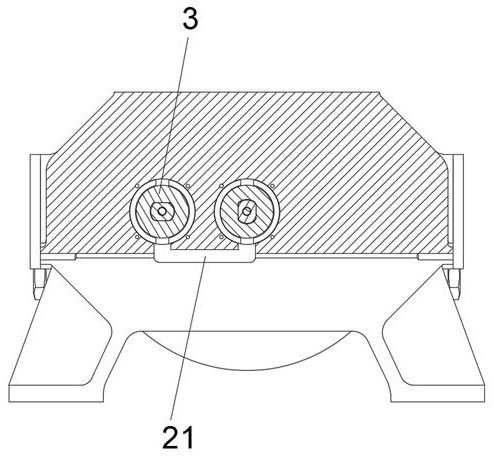

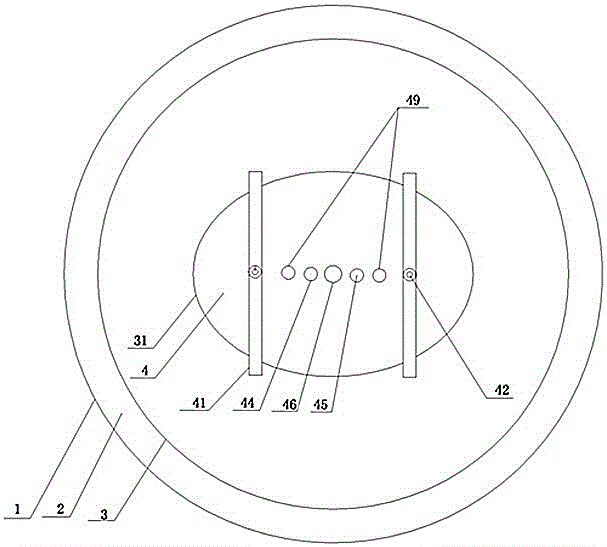

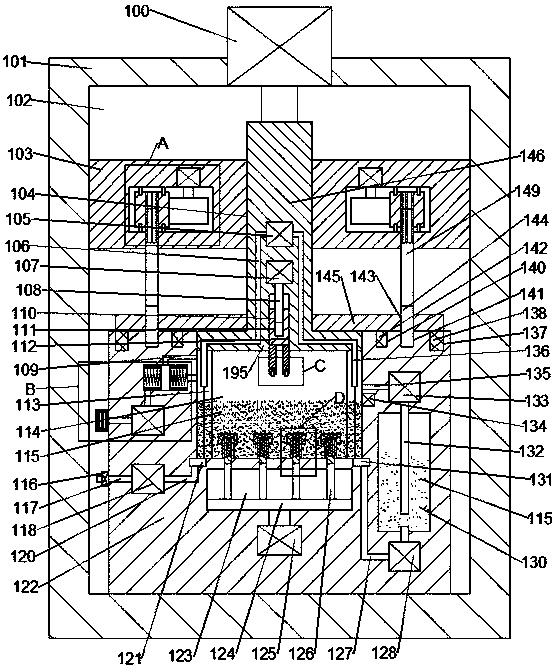

Pipeline anti-corrosion rotary clamping device

InactiveCN109333416AAvoid shakingEasy to moveWork holdersWork benchesMechanical engineeringAnti-corrosion

The invention discloses a pipeline anti-corrosion rotary clamping device. The pipeline anti-corrosion rotary clamping device solves the problems in the prior art that pipe coaxial clamping cannot be achieved and movement is inconvenient. The pipeline anti-corrosion rotary clamping device is characterized in that universal wheels are arranged at the four corners of a base so that movement can be facilitated; a support base is arranged on the base through a support frame, a rotary sleeve is rotatably supported in an inner cavity of the support base, and a motor drives the rotary sleeve to rotatethrough a transmission gear; and an electric push rod is coaxially fixed in an inner cavity of the rotary sleeve, clamping arms are symmetrically hinged to a fixed sleeve of the electric push rod, clamping blocks are symmetrically arranged on the clamping ends of the clamping arms, and support rods are hinged between the middle portions of the inner sides of the clamping arms and a telescopic rodof the electric push rod; and a centering fixed rod coaxially fixed together with the telescopic rod is coaxially connected with a centering shaft through a connecting sleeve. The centering shaft cooperates with the clamping arms and the clamping blocks to conduct centering clamping, the pipeline is stable, and the pipeline anti-corrosion rotary clamping device is suitable for clamping when the pipeline is subjected to anti-corrosion treatment.

Owner:荣成市天健管道防腐保温器材有限公司

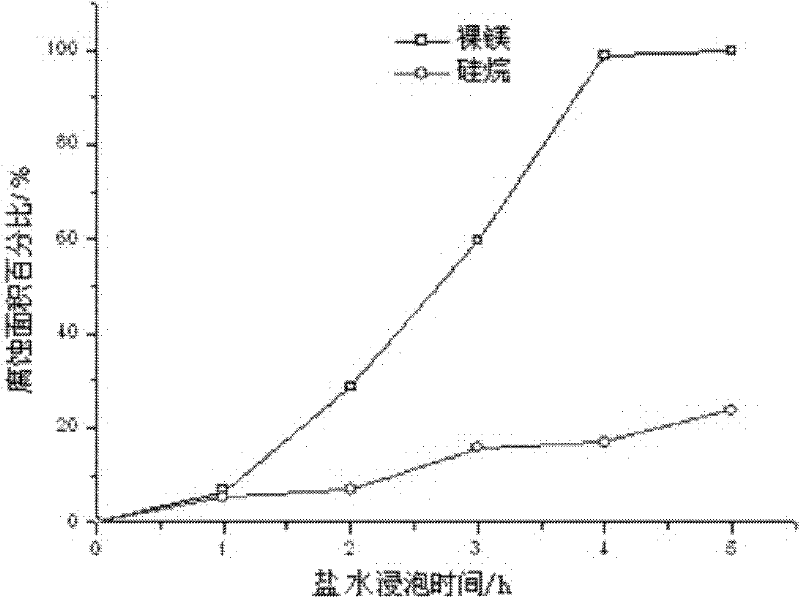

A treatment liquid, preparation method and process for improving magnesium alloy surface anticorrosion

InactiveCN102260424AImprove bindingSolving Corrosion ProblemsAnti-corrosive paintsMg alloysHigh humidity

A treatment solution, preparation method and process for improving surface corrosion resistance of magnesium alloys, used for surface protection of various magnesium alloys during short machining intervals, the treatment solution contains silane coupling agent, rare earth salt, corrosion inhibitor, ethanol , Combination of two or more components in deionized water, the main ratio is: silane 2%-15%, deionized water or ethanol 85%-98%; or silane 4%-12%, ethanol 4%-10% %, 80%-90% of deionized water; the total amount of other additives <1%. The treatment solution is simple and easy to operate. The thickness of the treated film is less than 2 microns, and it can resist the environment with a temperature higher than 50°C and a humidity higher than 80% for no less than 15 days, that is, the treated magnesium alloy has no corrosion marks on the surface for 15 days in a high-heat and high-humidity environment. The anti-corrosion film layer of the present invention has the following characteristics: 1) excellent bonding force with the alloy substrate; 2) good resistance to high temperature and high humidity; 3) does not affect the subsequent processing and surface coating of the workpiece.

Owner:UNIV OF SCI & TECH BEIJING

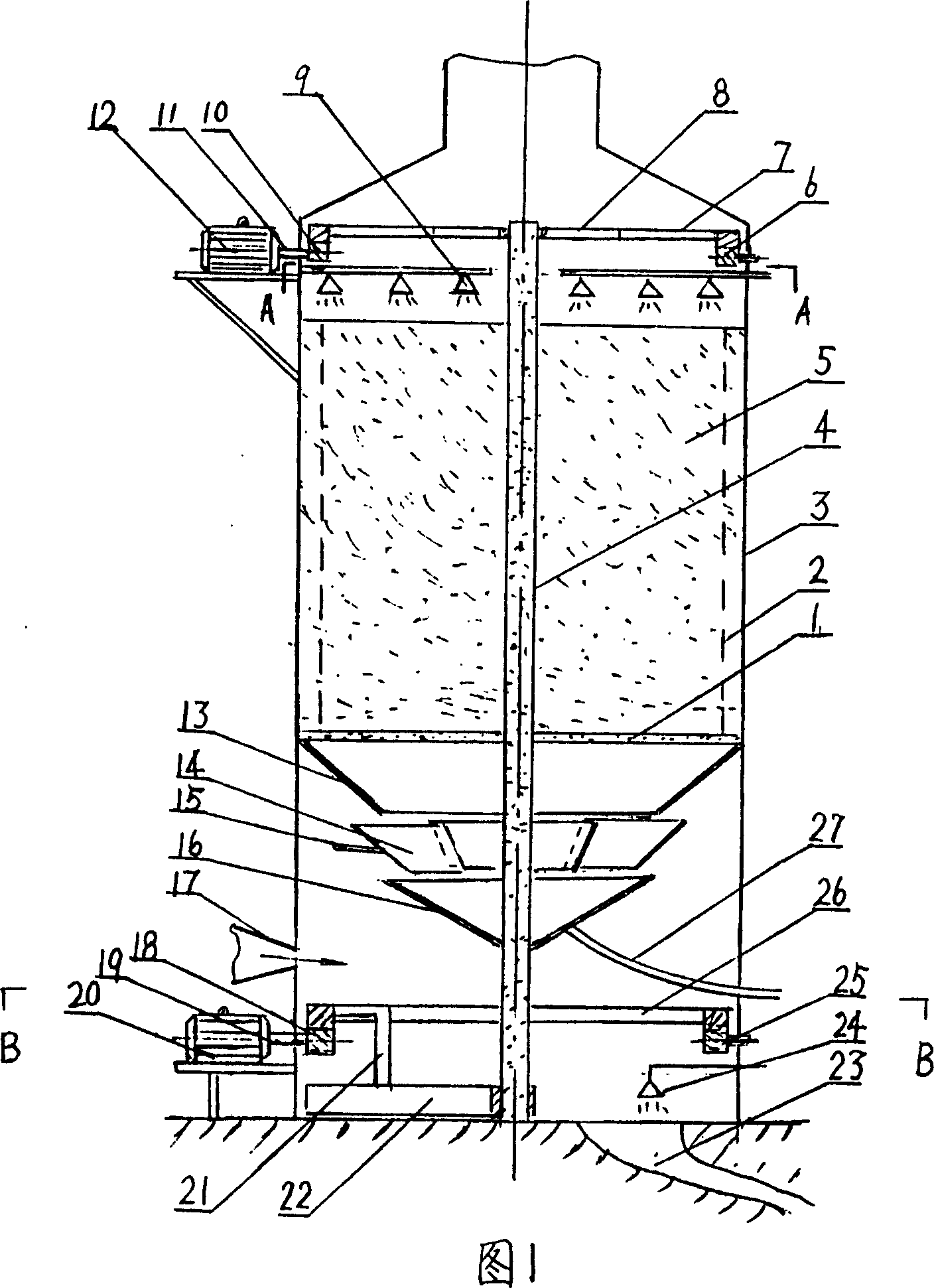

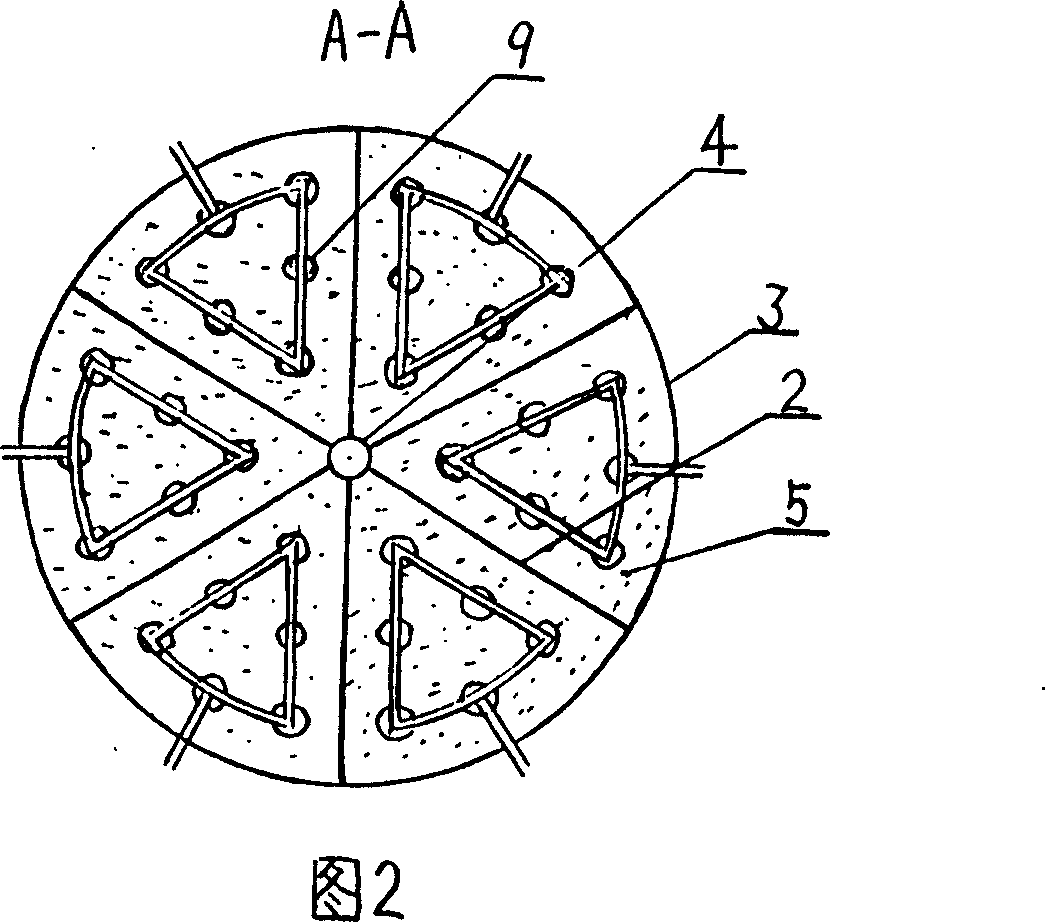

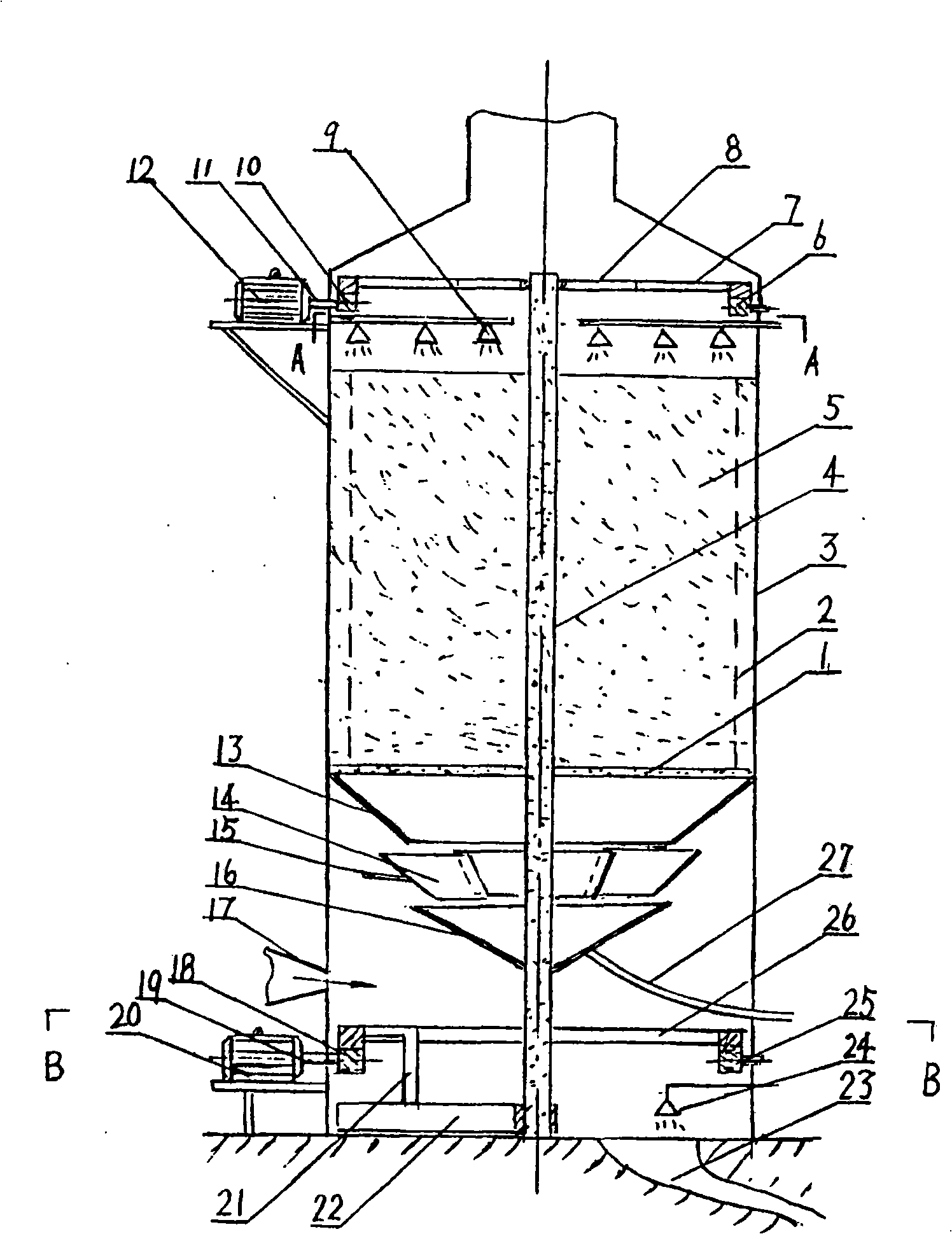

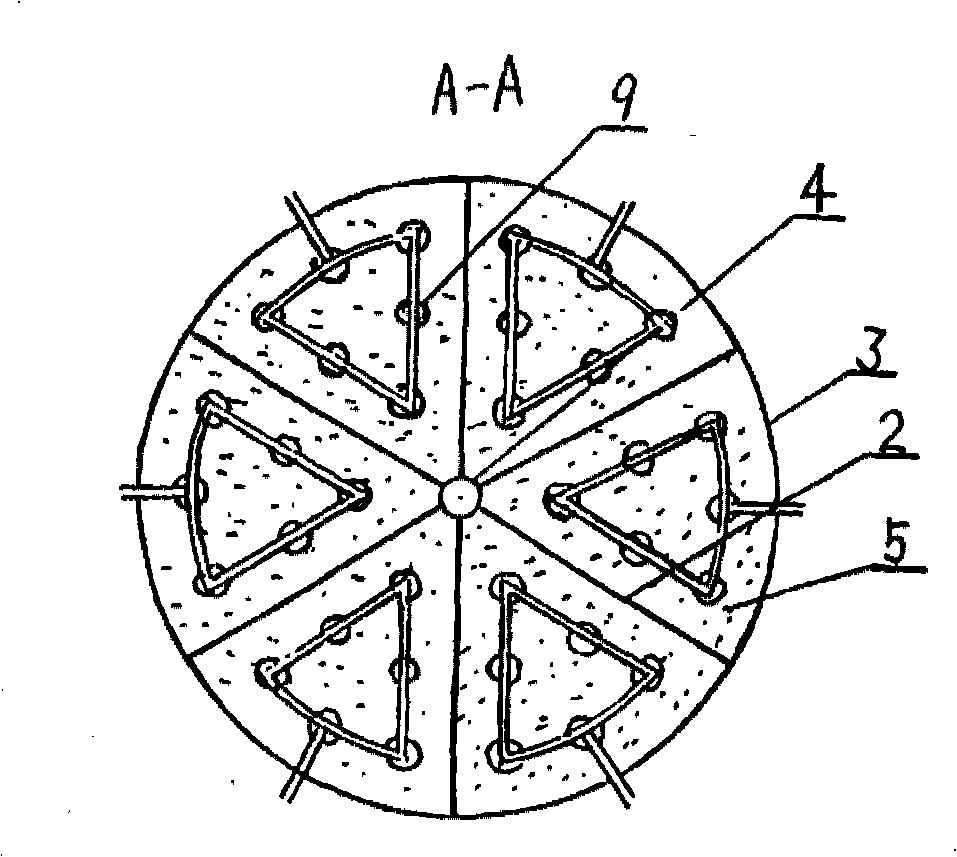

Active carbon flue gas desulfurizing reverse synchronous work tower

InactiveCN101058051AMeet the requirements of desulfurization workSmall footprintDispersed particle separationActivated carbonFlue gas

The invention provides an active carbon gas sulfur free reverse synchronic working tower, with several vertical separation barricade between the shell and the central post and active carbon layer within, each layer having spray device whose top having gear ring with fan shape wind resistance cover, tapering dilute acid introduction plate, gas and liquid introduction plate, dilute acid collection plate under the active carbon supporting plate, gear of the other gear ring teething with the other gear and fixed with scraping plate, dust exhaust under the tower, whose bottom has Venturi air inlet. This kind of synchronic tower can be adhesive of active carbon and dropping it off at the same time, realizing continuous working of the tower, meeting the requirement for desulfuration, with less land and equipment investment, low running cost and reduced corrosion area.

Owner:王惠生

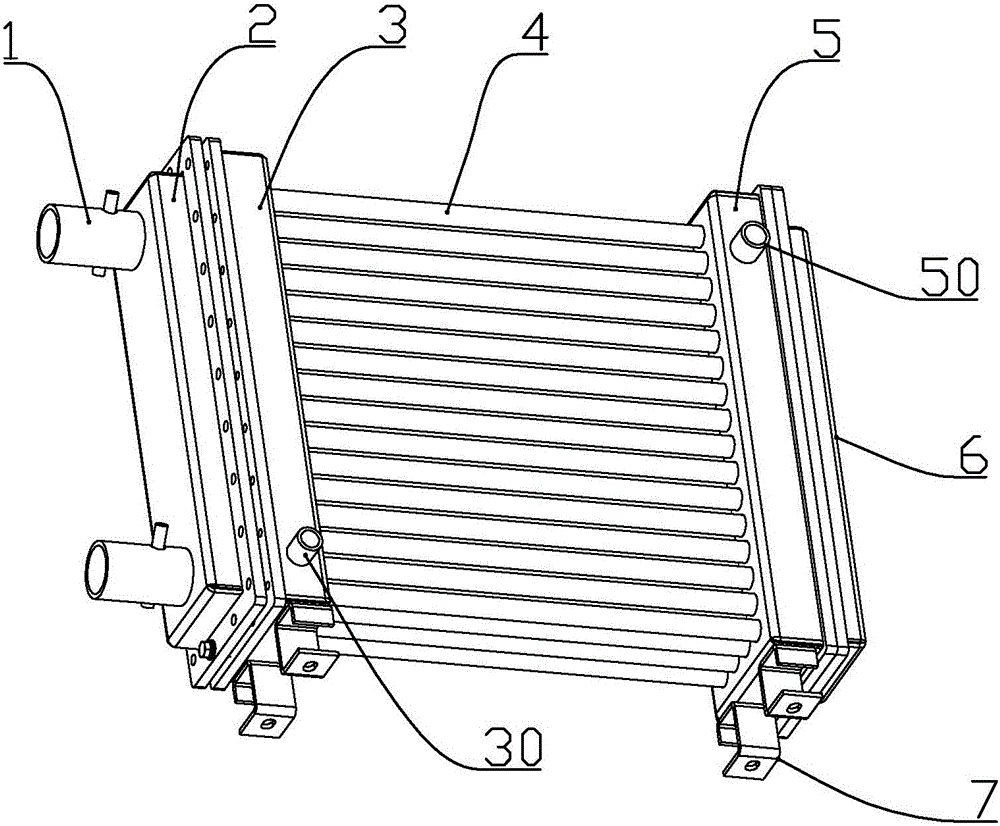

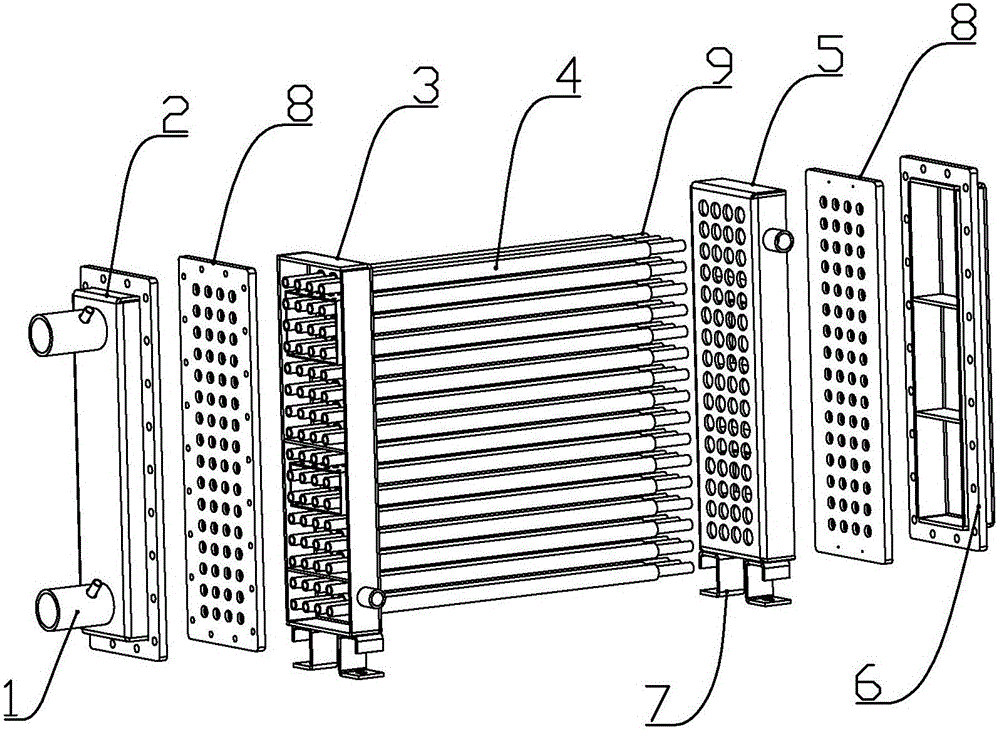

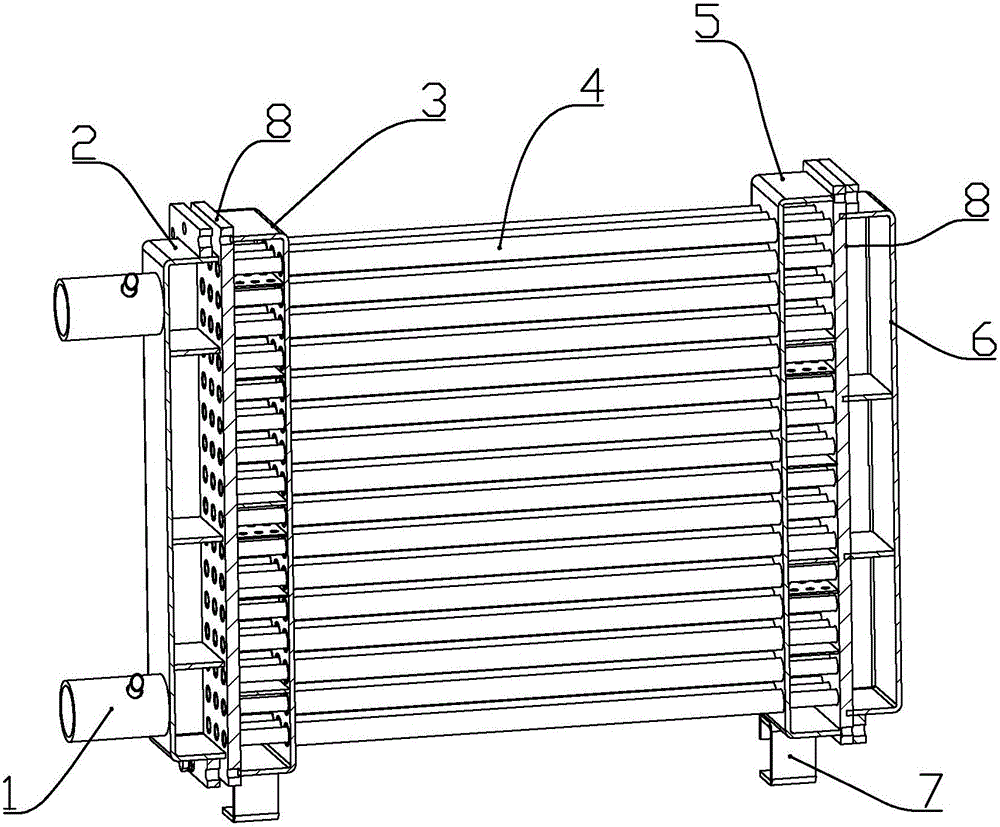

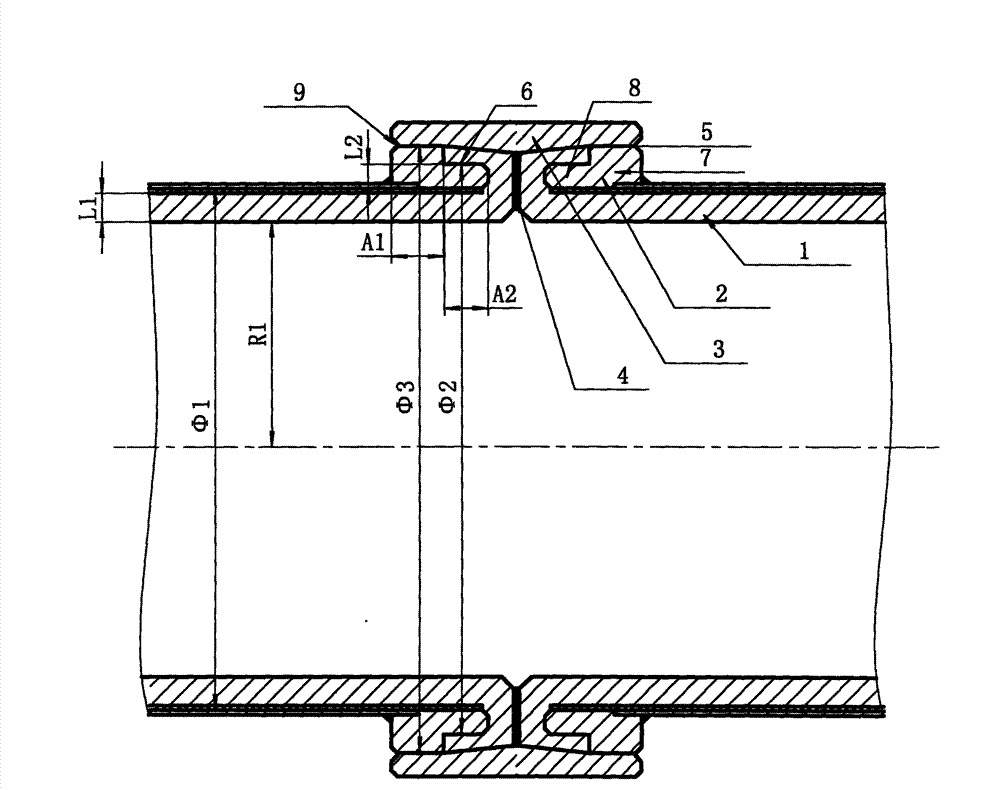

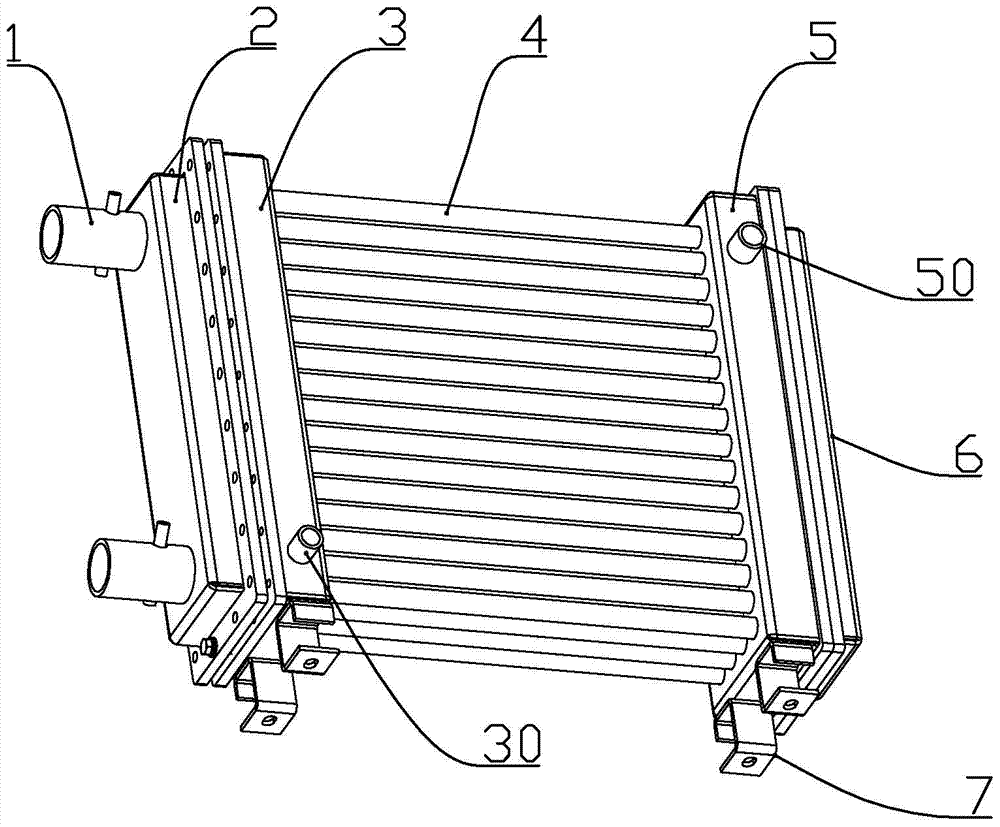

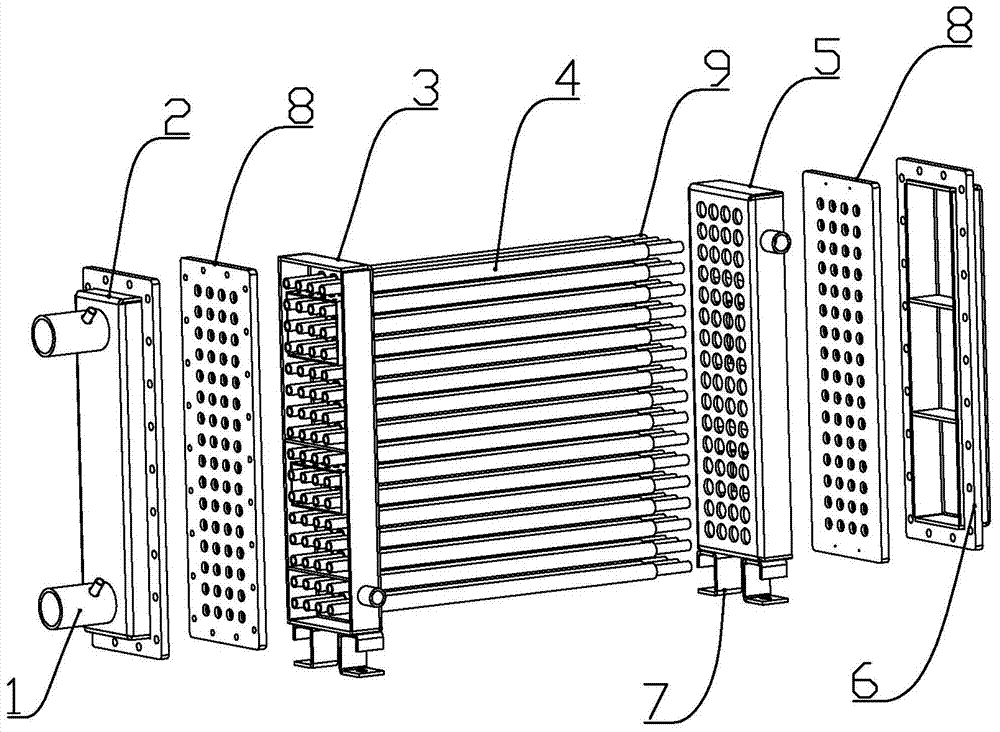

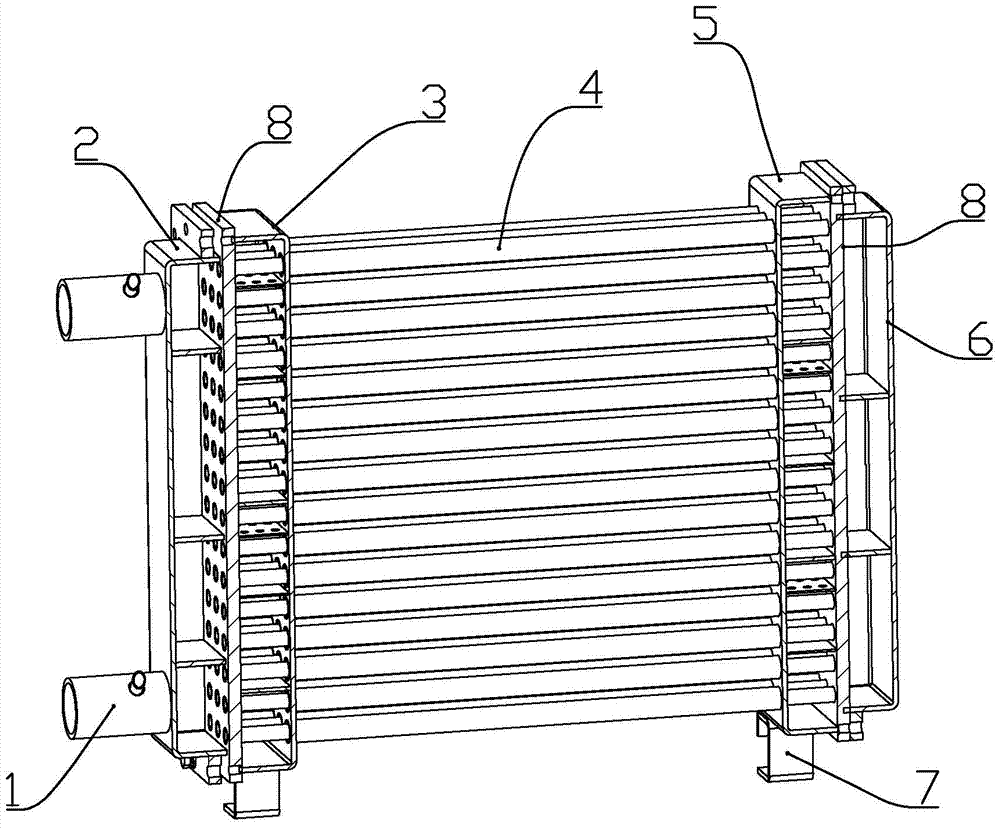

Multi-pass shell-and-tube flooded heat exchanger

ActiveCN105020942ASimple structureEasy to assemble and disassembleEvaporators/condensersStationary tubular conduit assembliesEngineeringRefrigerant

The invention discloses a multi-pass shell-and-tube flooded heat exchanger. The multi-pass shell-and-tube flooded heat exchanger comprises a plurality of outer shell tubes in array distribution, a plurality of heat exchange tubes penetrating the outer shell tubes, a first outer tube box, a second outer tube box, two tube plates, a first inner tube box and a second inner tube box, wherein the first outer tube box and the second outer tube box are respectively connected with the two ends of each outer shell tubes and are mutually communicated; the two tube plates are respectively connected with the two ends of each heat exchange tube, as well as the outer sides of the first outer tube box and the second outer tube box; the first inner tube box and the second inner tube box are respectively connected to the outer sides of the two tube plates; and the lower part of the first outer tube box is connected with a refrigerant inlet adapter, and the upper part of the second outer tube box is connected with a refrigerant outlet adapter. The multi-pass shell-and-tube flooded heat exchanger realizes passing of a refrigerant on both the shell side and the tube side, and adopts the structure that the outer shell tubes sleeve the heat exchange tubes, so that the refrigerant filling amount is much less than that of a common flooded evaporator, and the oil return performance is good.

Owner:ZHEJIANG QINGFENG REFRIGERATION EQUIP MFG

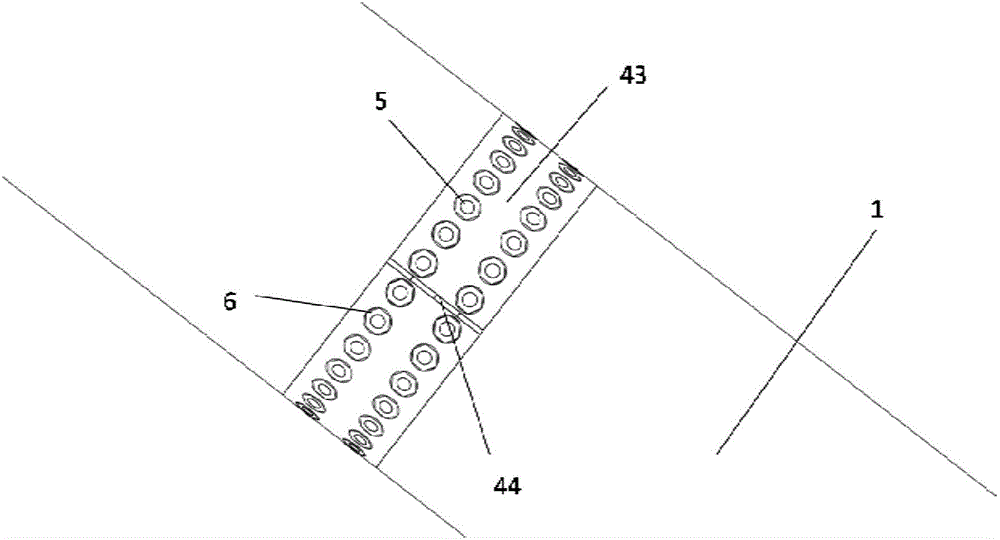

Novel rapid connecting device and method for following pipe piles while drilling

The invention discloses a novel rapid connecting device and method for following pipe piles while drilling. The connecting device comprises an upper connecting part, a lower connecting part, a steel sleeve, screws, nuts and anchoring reinforcing steel bars; the upper connecting part and the lower connecting part are arranged at two ends of the pipe pile; the screws are arranged on the circumference of the upper connecting part and the circumference of the lower connecting part; one end of each screw is connected with a prestressed reinforcing steel bar of the pipe pile; the outer circumference of the upper connecting part and the outer circumference of the lower connecting part of the adjacent pipe pile are sleeved with the steel sleeve; the nuts and the screws are matched to fix the steel sleeve; one end of each anchoring reinforcing steel bar is connected with the prestressed reinforcing steel bar, and the other end is perpendicular to the end surface of the pipe pile to extend out; anchoring holes are formed in the lower connecting part of the pipe pile; and filler is arranged in the anchoring holes. With the device and the method, the mounting mechanization degree is high, welding is avoided, the construction difficulty of workers is reduced, the working efficiency is improved, the pull-out capacity, the sealing performance and the pressure of pile side grouting of the following pipe piles while drilling are guaranteed, grouting bodies are prevented from entering pipe pile inner holes, and the project quality of the pipe piles is guaranteed.

Owner:GUANGZHOU ARCHITECTURE SCI RES INSTNEW TECH DEV CENT +1

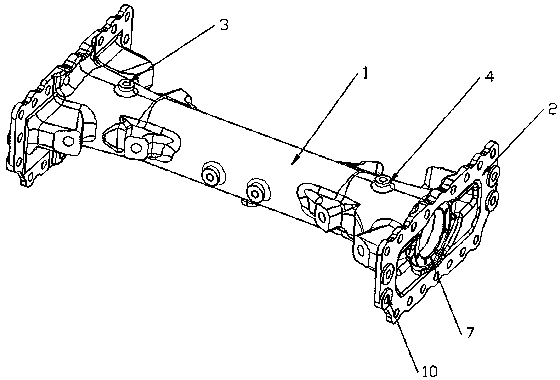

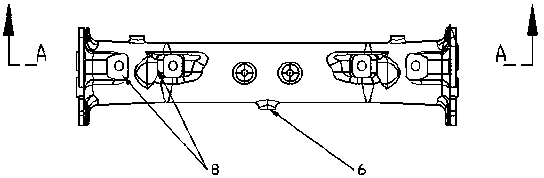

Integrally-cast crossbeam with air storage function of air suspension frame

PendingCN107757710AReduce connection processingReduce assemblyUnderstructuresStructural engineeringGas supply

The invention relates to an integrally-cast crossbeam with an air storage function of an air suspension frame. The crossbeam comprises a crossbeam main body and a pair of sealing end covers arranged at the two ends of the direction of the long axis of a crossbeam pipe body, wherein the crossbeam main body is formed by integrally casting the crossbeam pipe body and a pair of crossbeam connectors which are symmetrically arranged at the two ends of the crossbeam pipe body; meanwhile, a V-shaped seat pushing group is further integrally cast and formed on the outer wall of the crossbeam pipe body,and an air inlet and an air outlet are formed in the crossbeam pipe body; a reinforced convex rib group is further arranged on the inner wall of the crossbeam pipe body; and a seal ring set attached to the inner wall of the crossbeam pipe body is further mounted to the outer walls of one sections of the sealing end covers, wherein one sections of the sealing end covers extend into a cavity of thecrossbeam pipe body. The integrally-cast crossbeam has the advantages that the crossbeam is formed by integrally cast, on the basis of air supply storage, the sealing performance of the crossbeam canbe improved, the structural strength of the crossbeam is ensured, and meanwhile, manufacturing is more convenient.

Owner:JIANGSU TANGCHEN AUTOMOBILE PARTS

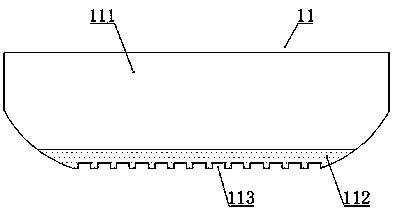

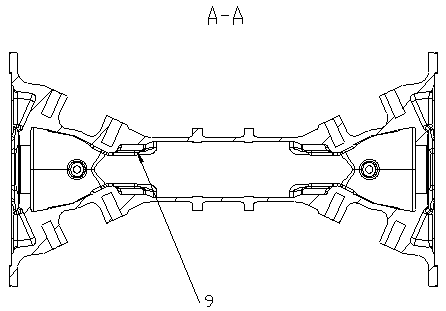

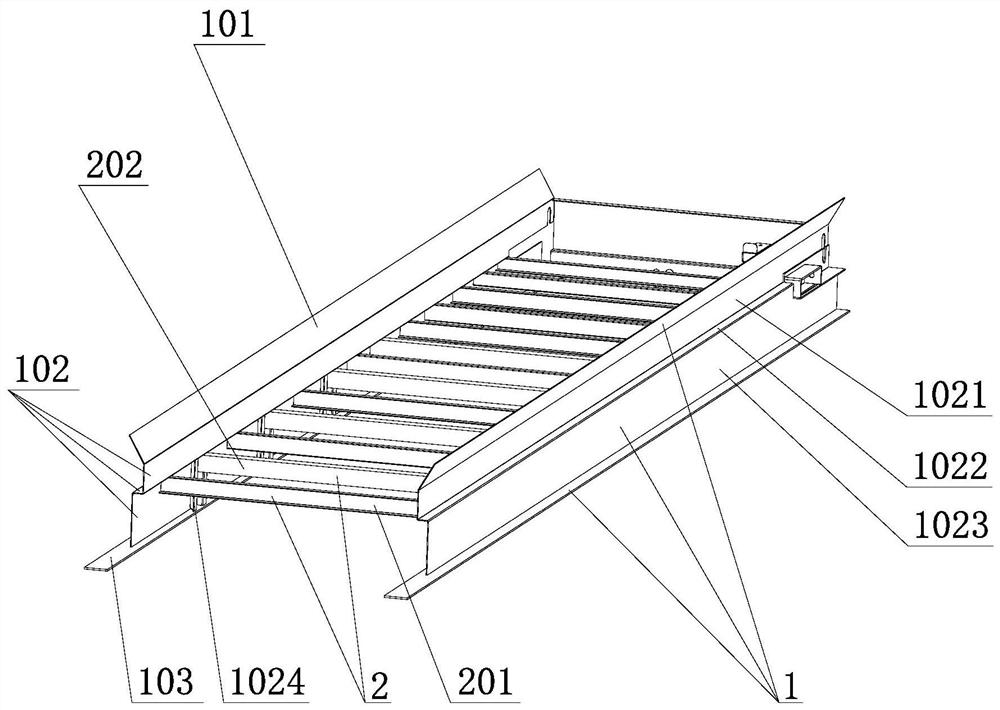

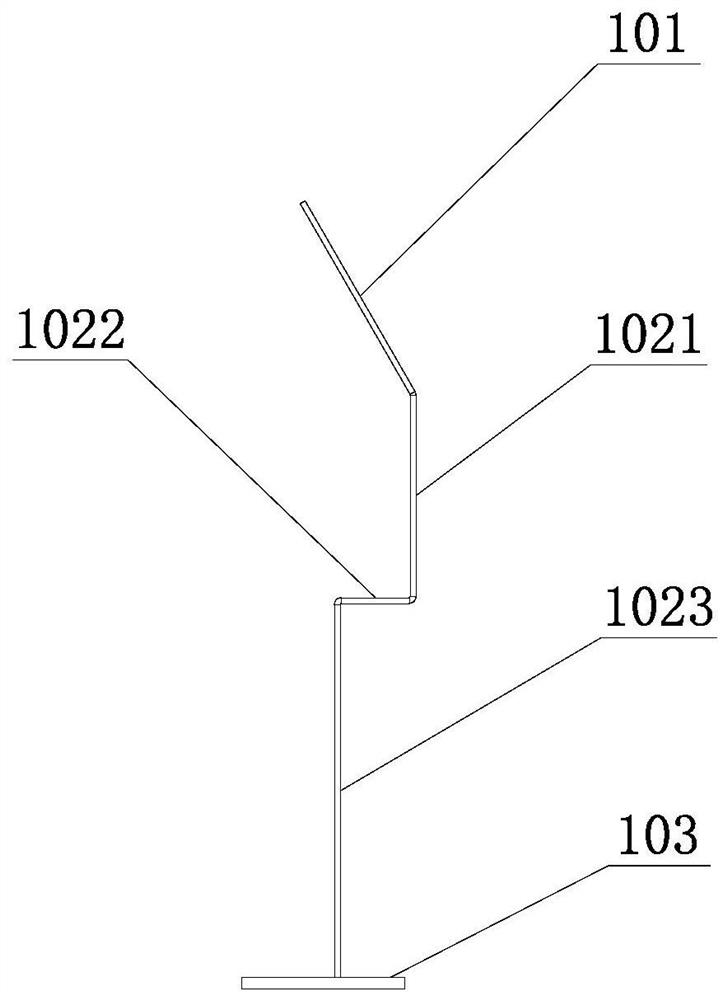

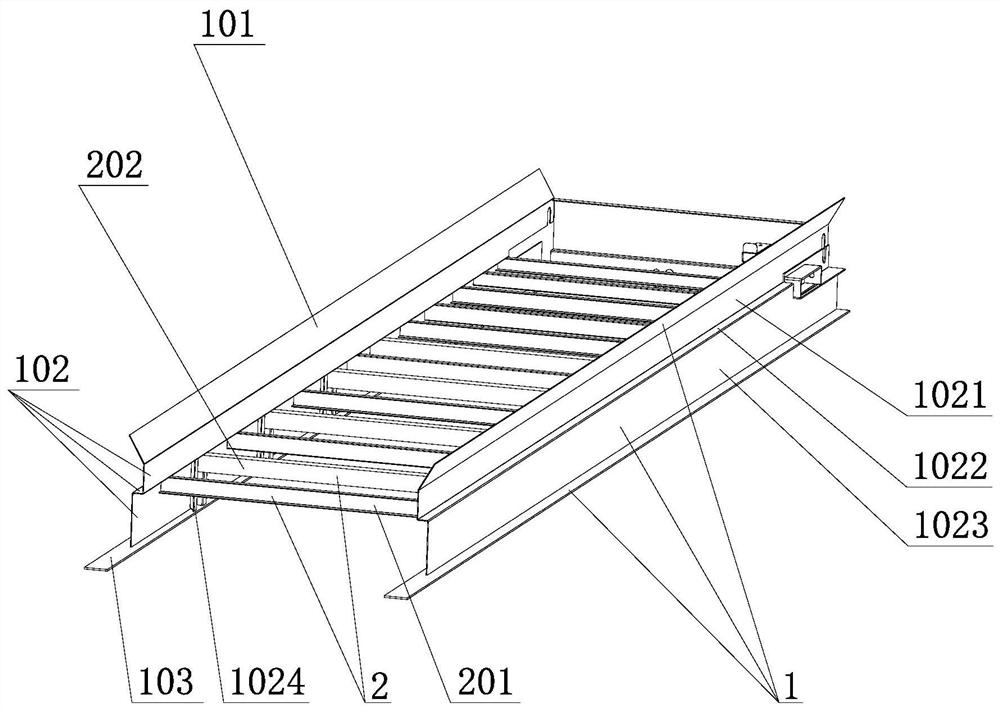

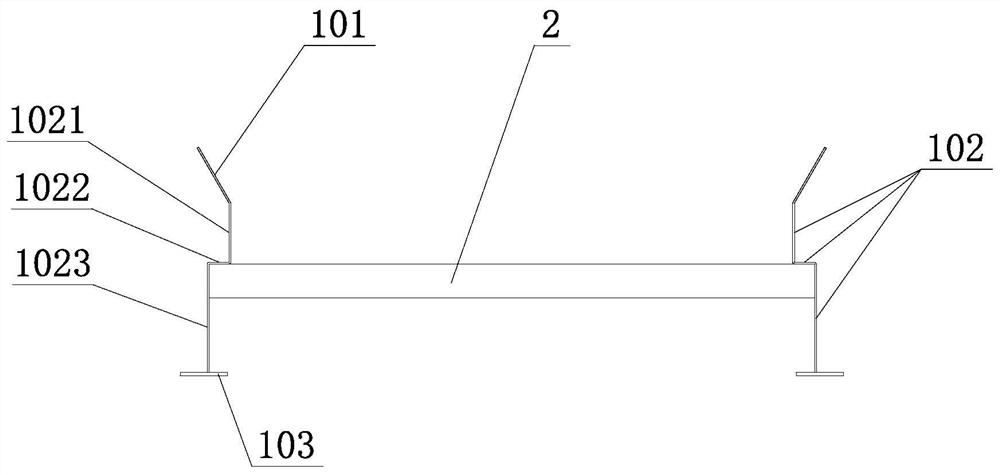

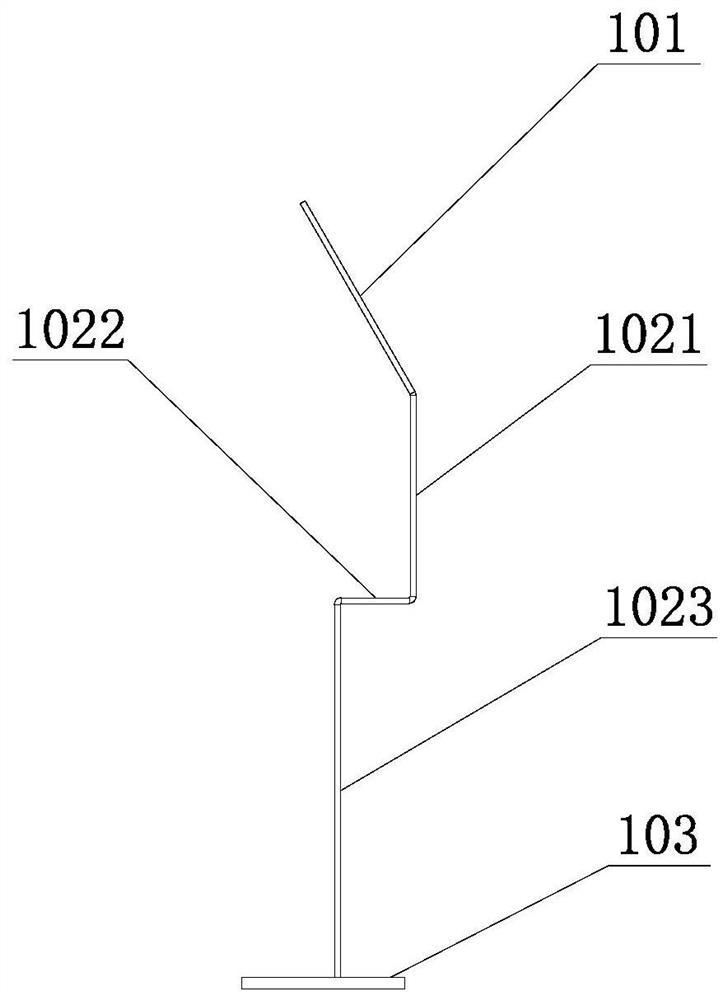

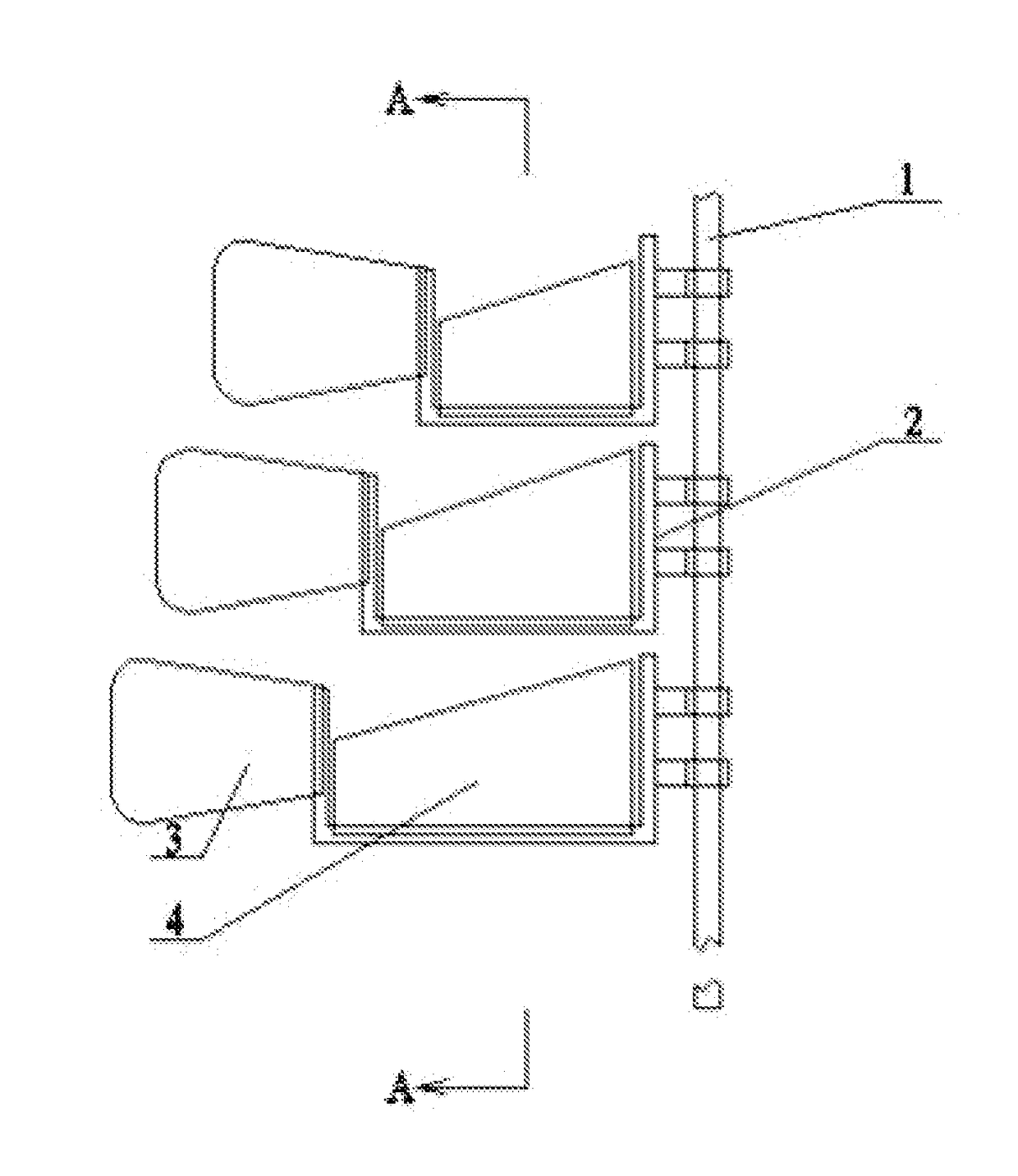

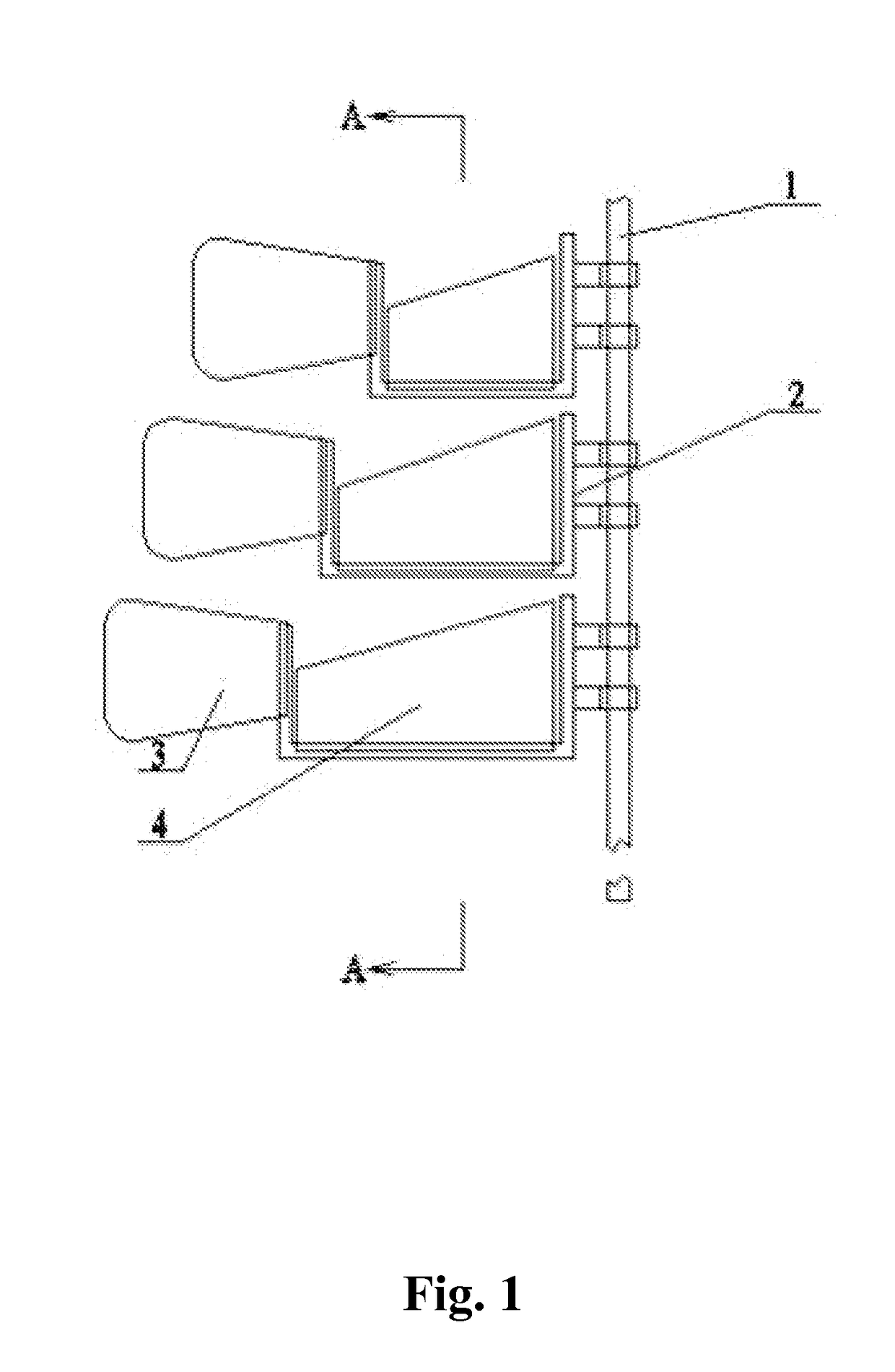

Self-dumping semitrailer frame

ActiveCN112519889AImprove structural strengthEasy to preservative treatmentUnderstructuresSuperstructure connectionsVehicle frameStringer

The invention relates to a self-dumping semitrailer frame which comprises two longitudinal beams and a plurality of cross beams arranged between the two longitudinal beams, and each longitudinal beamcomprises an upper wing plate, a web plate and a lower wing plate which are connected in sequence; the web plate comprises a plate A, a plate B and a plate C which are connected in sequence, the plateB is perpendicularly connected with the plate A and the plate C, the plate A is connected with the upper wing plate, the plate C is perpendicularly connected with the middle of the lower wing plate,and the plate B and the plate C are connected with the cross beam in a welded mode. The self-dumping semitrailer frame has the advantages of reasonable structural design, high structural strength, fewwelding processes, good matching with a chain conveying mechanism, stable and reliable structure and the like.

Owner:WEIHAI SHUNFENG SPECIAL VEHICLE MFG CO LTD

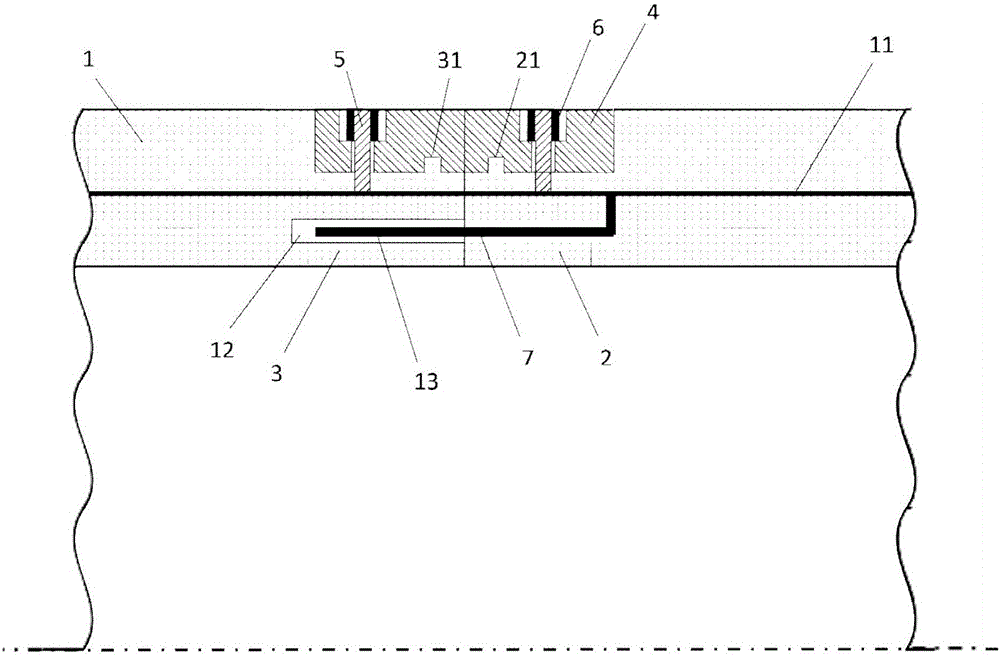

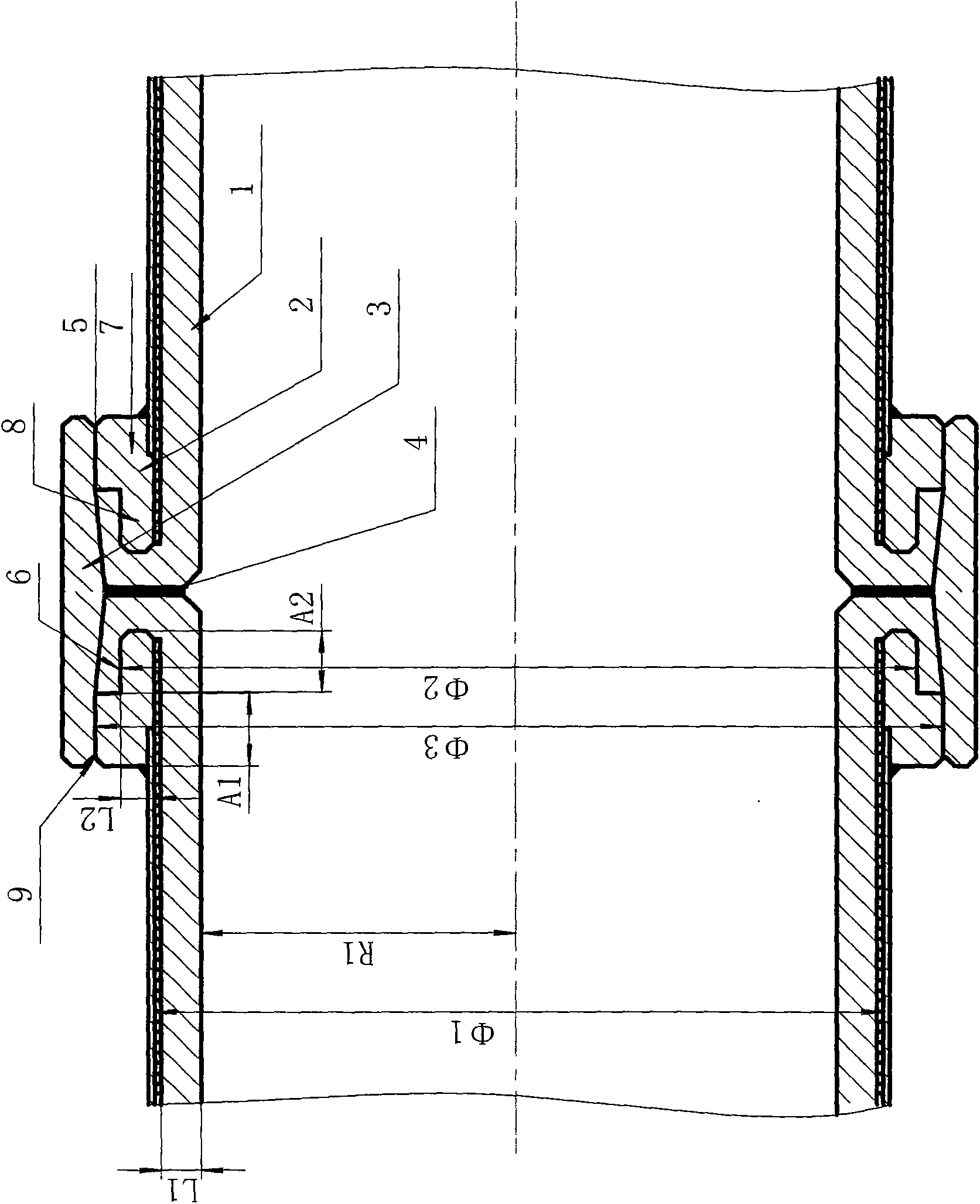

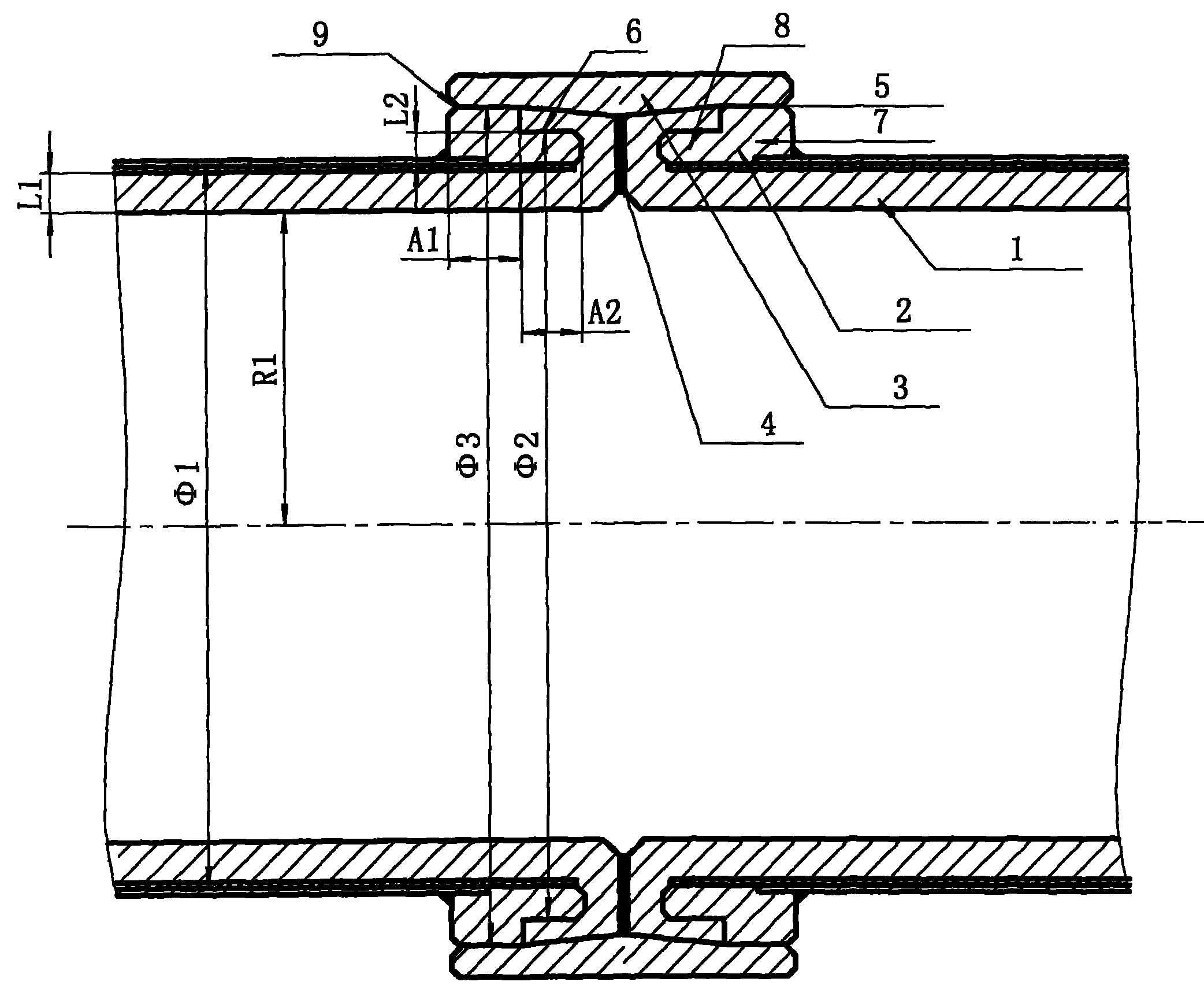

Connection method of ultrahigh molecular weight polyethylene pipelines

InactiveCN101988611BReduce consumptionLower the altitudePipe connection arrangementsRubber ringSteel jacket

The invention relates to a connection method of ultrahigh molecular weight polyethylene pipelines, comprising the following steps: carrying out the U-shape turning on the ends of the pipelines, adding a sealing rubber ring at the joint part of two U-shape turnups, lining a steel ring at the interior of the U-shape turnup and sleeving a steel jacket which has a tapered inside at the outside; pressing two U-shape joints into the steel jacket from two sides of the external steel jacket by squeezing the steel rings of the two pipelines from the both sides, and performing the compulsively squeezing based on the slope principle; and sealing by a high strength anaerobic adhesive, galvanizing the steel pieces at the joint part, and then performing the packaging and sealing by the radiation cross-linked polyethylene heat-shrinkable tape. The connection method of the invention can bear the pressure of 30 MPa without the leakage, and can reduce the consumption of the joint material and enhance the construction speed significantly.

Owner:JIANGSU SHENSHI NEW MATERIAL TECH

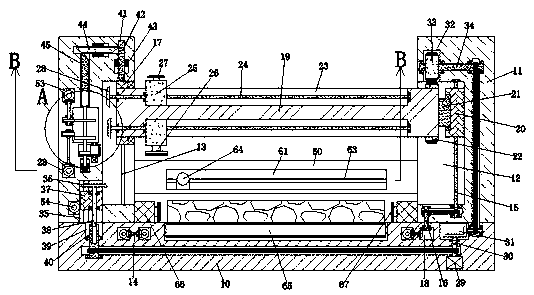

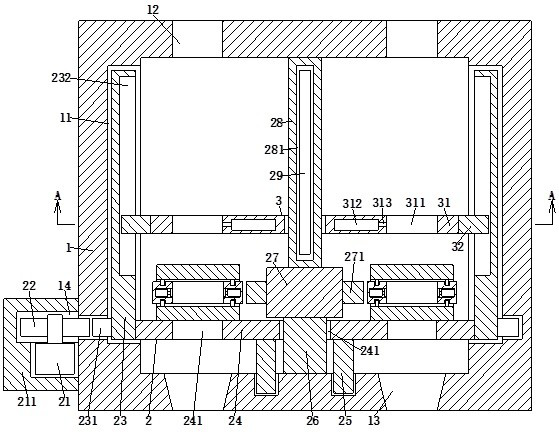

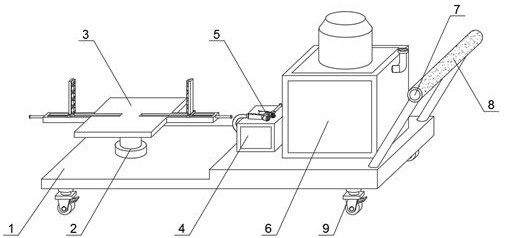

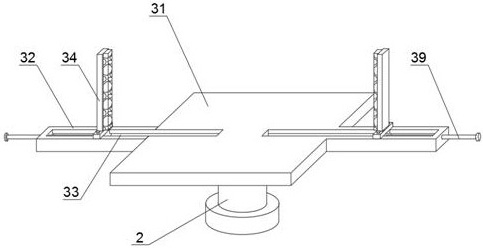

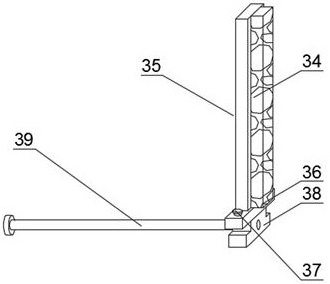

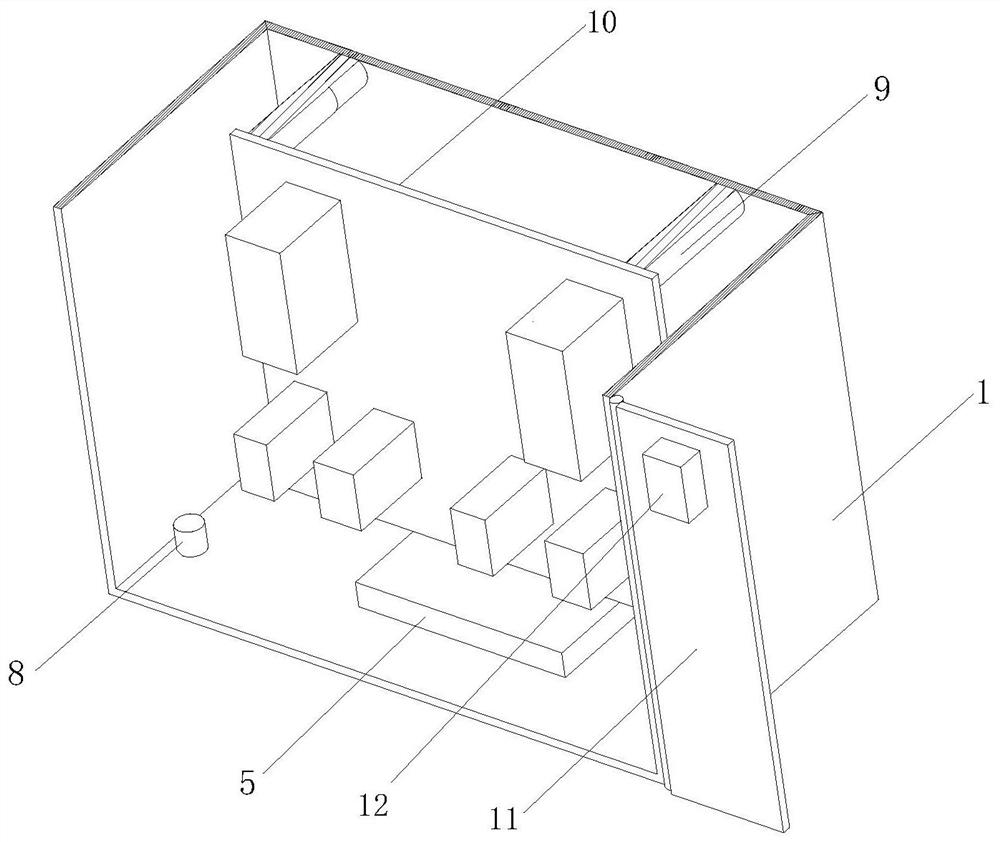

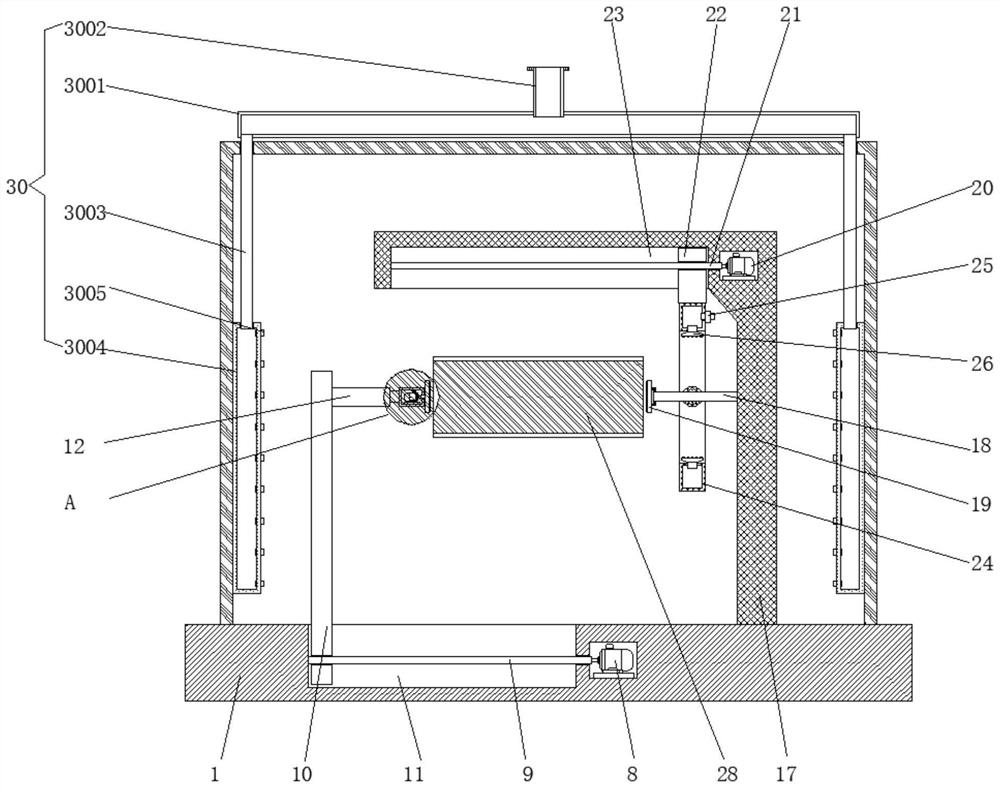

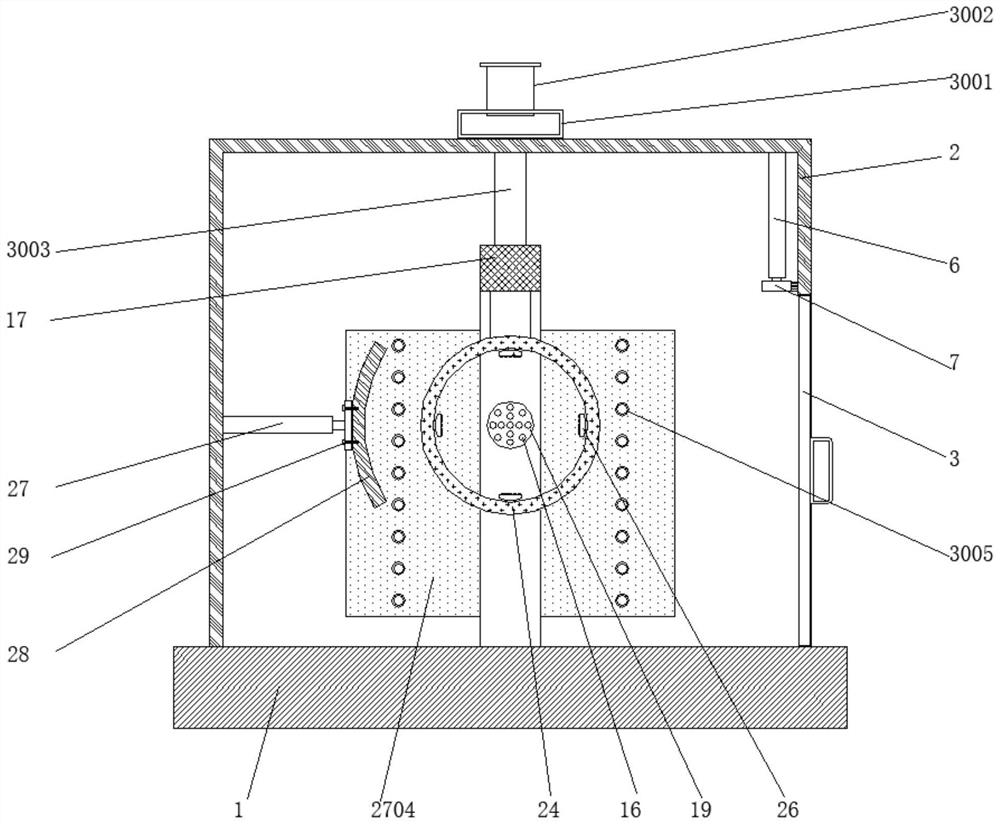

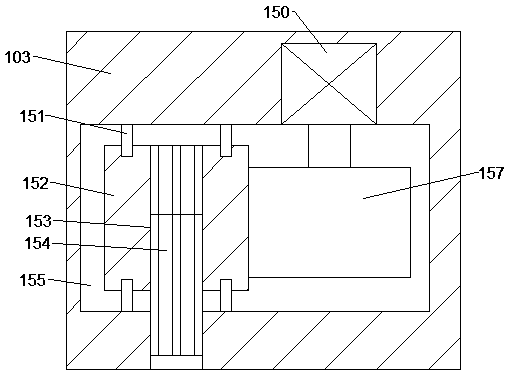

Modern wood preservation improving device

InactiveCN109203151AEasy to useReduce operationImpregnation spraying apparatusWood treatment detailsEngineeringMechanical engineering

The invention discloses a modern wood preservation improving device which comprises a base, a polishing device, a control device and a paint spraying device, wherein the polishing device is arranged on the base, the control device is arranged on the base, and the paint spraying device is arranged on the base; the polishing device comprises supporting blocks, the supporting blocks are arranged at the upper end of the base in a left-right symmetry mode and are fixedly connected, first grooves with opposite openings are arranged at the opposite ends of the supporting blocks, a first lead screw isarranged in the first groove on the left side in a front-back symmetry mode, first connection devices which are in power and matching connection with the first lead screw are fixedly arranged in inner walls of the lower sides of the first grooves, and a second lead screw is arranged in the first groove on the right side. The device can automatically perform wood surface preservation treatment, sothat wood use performance is certainly improved; the device is simple and convenient to operate, can reduce operation time of staff and has low cost; furthermore, the processing efficiency and effects are all certainly improved, and wood preservation treatment is certainly improved.

Owner:何慧敏

Connection method of ultrahigh molecular weight polyethylene pipelines

InactiveCN101988611AAvoid hidden dangersHigh sealing pressurePipe connection arrangementsRubber ringSteel jacket

The invention relates to a connection method of ultrahigh molecular weight polyethylene pipelines, comprising the following steps: carrying out the U-shape turning on the ends of the pipelines, adding a sealing rubber ring at the joint part of two U-shape turnups, lining a steel ring at the interior of the U-shape turnup and sleeving a steel jacket which has a tapered inside at the outside; pressing two U-shape joints into the steel jacket from two sides of the external steel jacket by squeezing the steel rings of the two pipelines from the both sides, and performing the compulsively squeezing based on the slope principle; and sealing by a high strength anaerobic adhesive, galvanizing the steel pieces at the joint part, and then performing the packaging and sealing by the radiation cross-linked polyethylene heat-shrinkable tape. The connection method of the invention can bear the pressure of 30 MPa without the leakage, and can reduce the consumption of the joint material and enhance the construction speed significantly.

Owner:JIANGSU SHENSHI NEW MATERIAL TECH

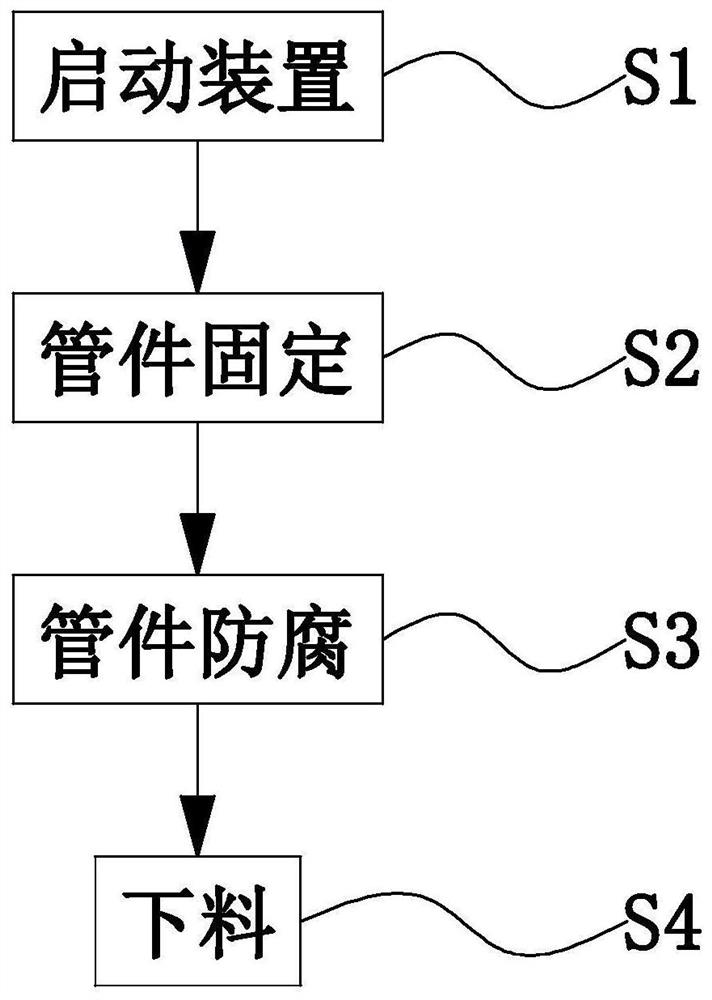

Chemical pipeline anti-corrosion treatment method

InactiveCN112403830AEasy to preservative treatmentAffect performanceLiquid surface applicatorsHollow article cleaningPreservativeProcess engineering

The invention discloses a chemical pipeline anti-corrosion treatment method. A following chemical pipeline anti-corrosion treatment device is adopted in the chemical pipeline anti-corrosion treatmentmethod, and the chemical pipeline anti-corrosion treatment device comprises a machining rack, a fixing unit and a coating unit. The fixing unit is arranged at the upper end of the machining rack in asliding manner, and the coating unit is installed at the inner side of the fixing unit. The device can solve the problems that most of traditional chemical pipeline anti-corrosion treatment adopts manual paint spraying to conduct anti-corrosion treatment on a chemical pipeline, due to the fact that paint spraying components are complex, certain harm can be caused to the human body, even coating cannot be guaranteed, and the use performance of the chemical pipeline is affected; and an existing chemical pipeline anti-corrosion treatment device basically and directly conducts anti-corrosion treatment on the machined chemical pipeline, dust and scraps on the surface of the chemical pipeline cannot be removed in time, and therefore the problems that a preservative falls off easily, cost is wasted, and the anti-corrosion effect cannot be achieved are solved.

Owner:章耀尹

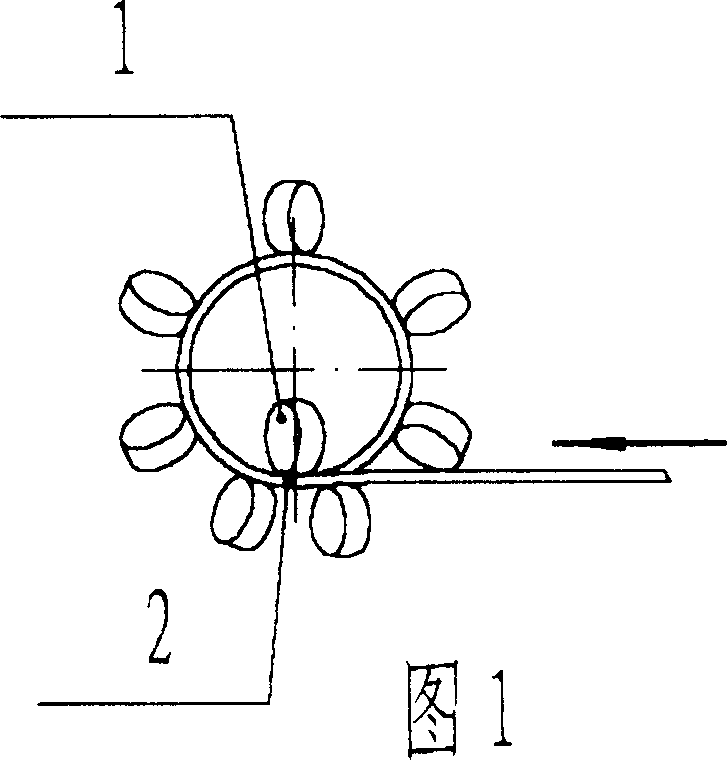

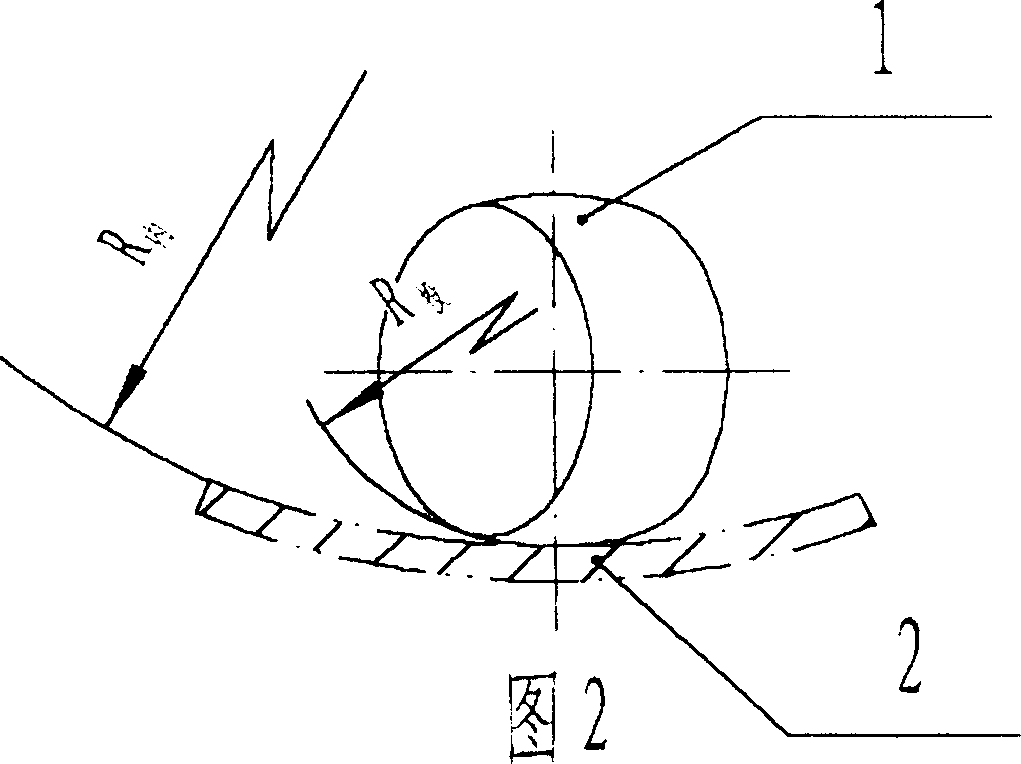

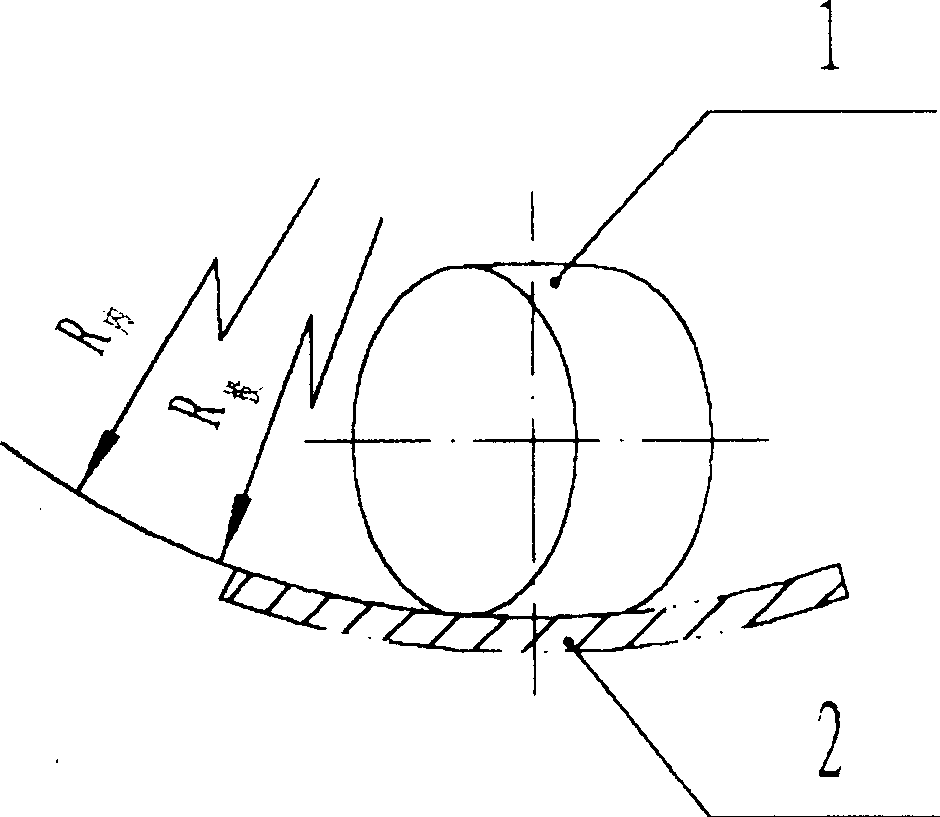

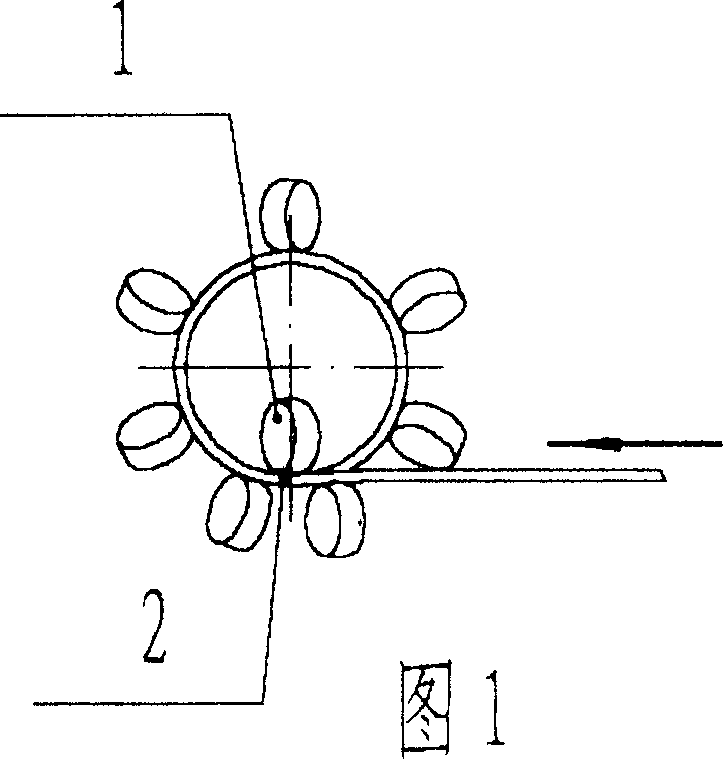

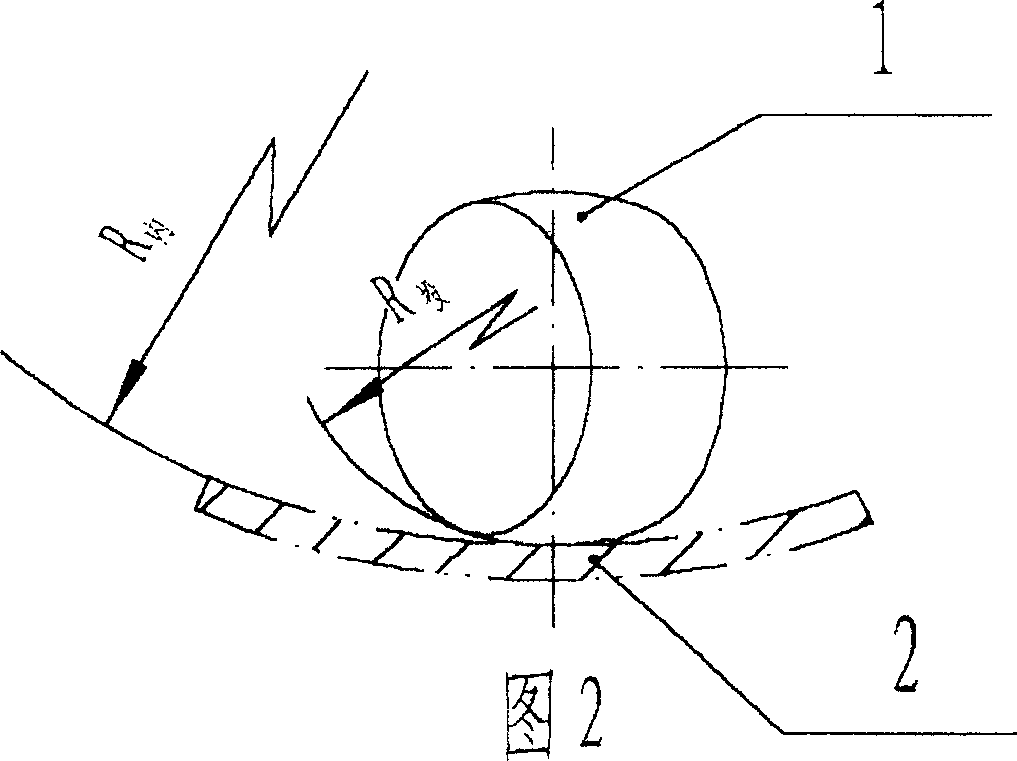

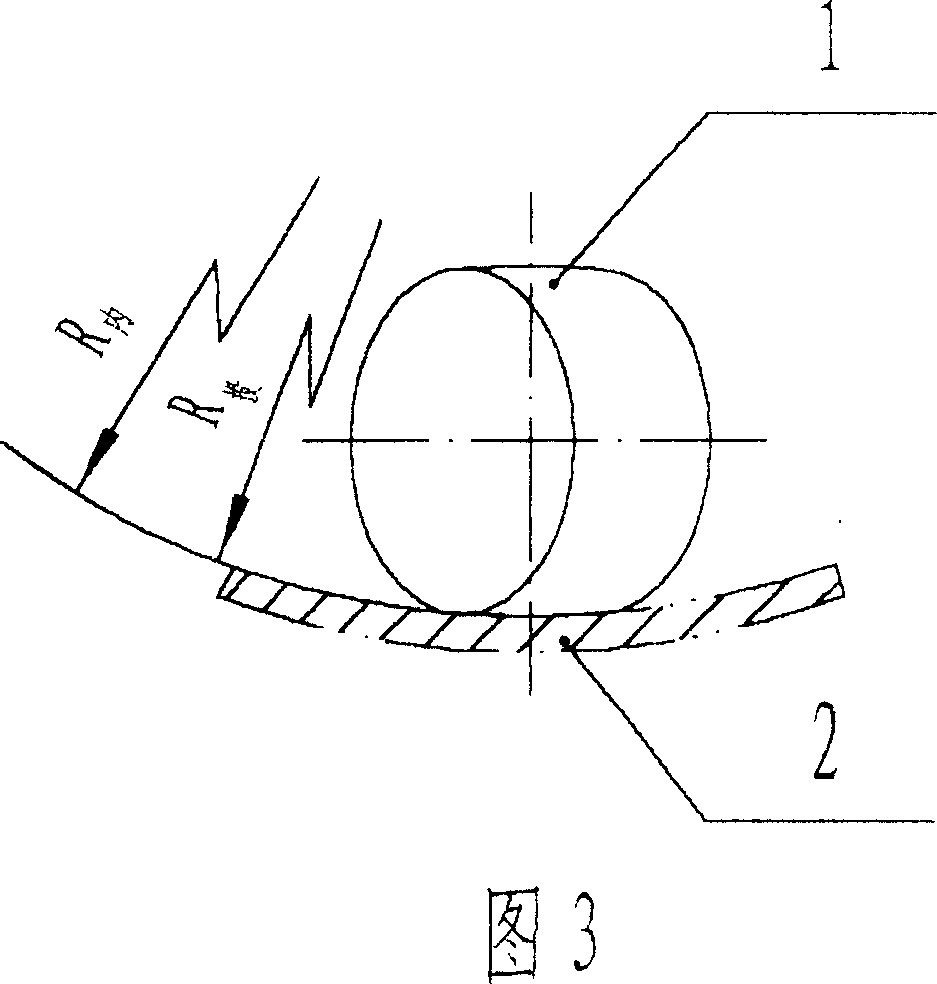

Inner press roller roll type outline matching screw tube blank

The inner press roller with rolling outline matching screw pipe blank features its rolling curve equation. Owing to the linear contact, the present invention can avoid wavy rolling impression and raise the rolling quality. The decrease of wavy rolling impressing is favorable to the anticorrosion treatment of the pipe, low conveying resistance, homogeneous deformation of the pipe and inherent quality of pipe.

Owner:白忠泉

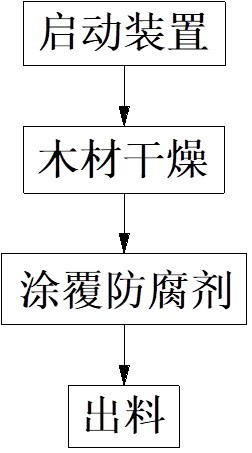

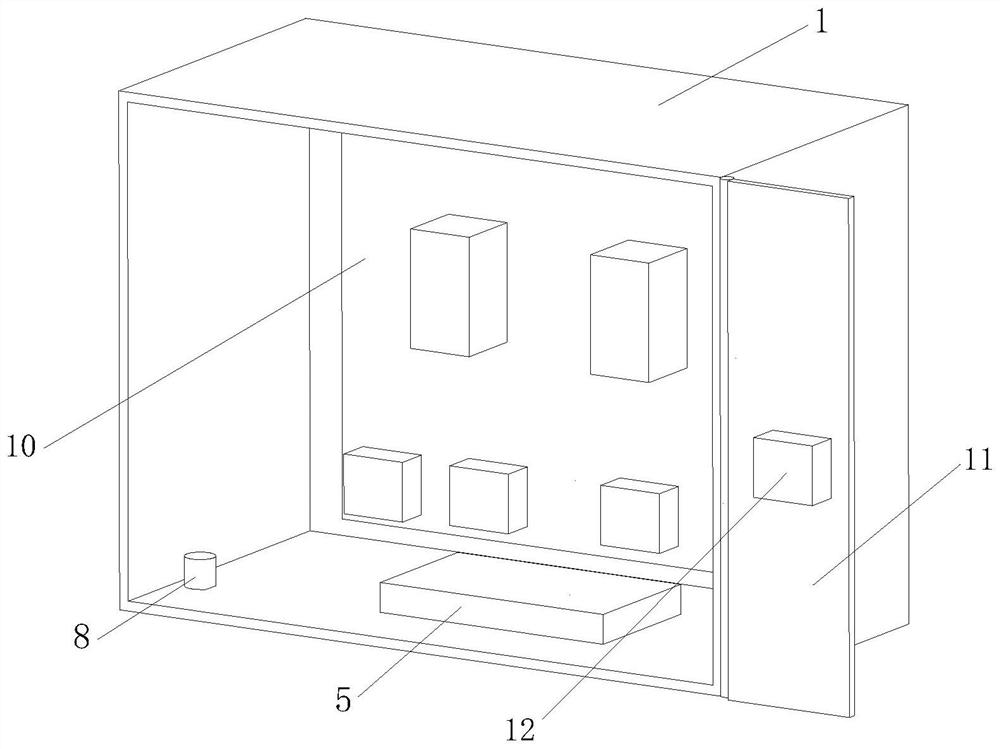

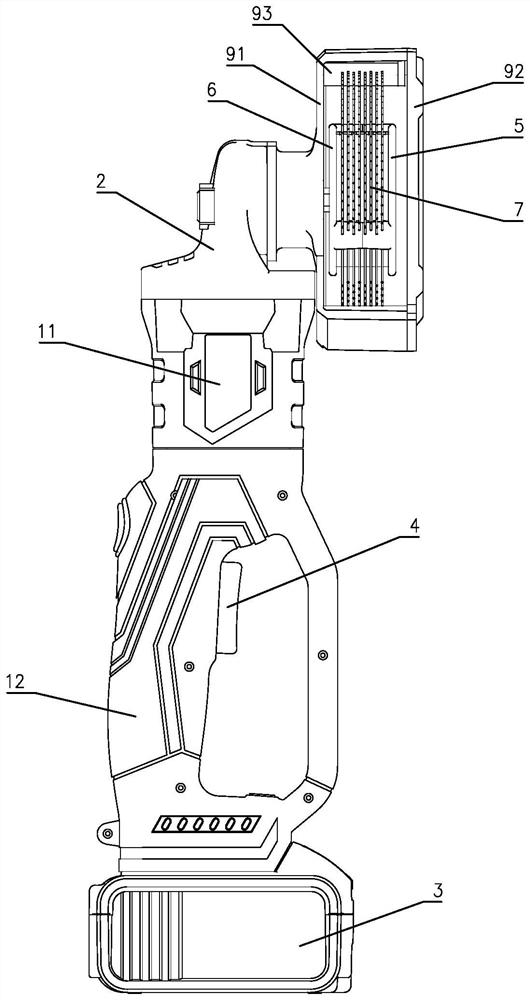

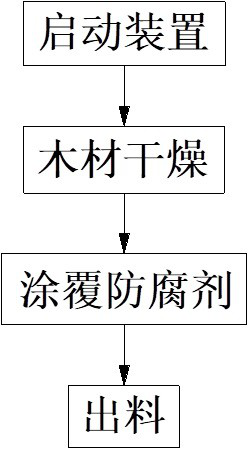

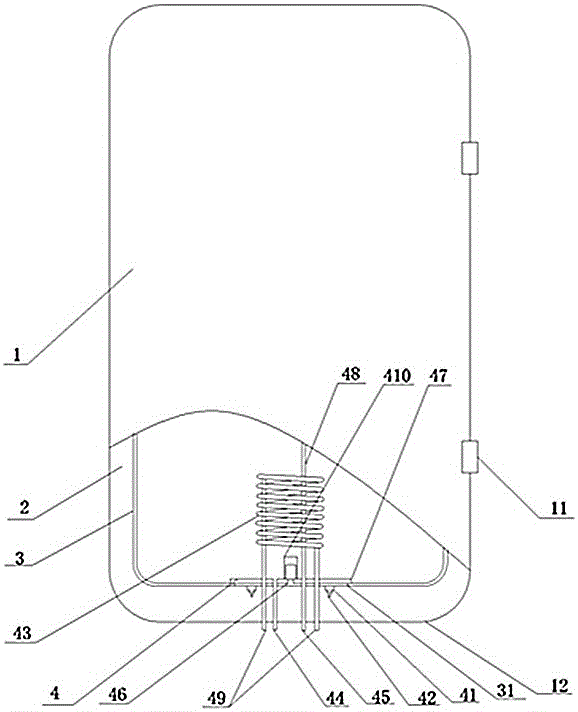

A kind of wood preservative treatment method

ActiveCN112372779BEasy to preservative treatmentTimely dryingWood treatment detailsPretreatment apparatusPreservativePulp and paper industry

A wood antiseptic treatment method provided by the present invention, the wood antiseptic treatment method adopts the following wood antiseptic treatment device, the wood antiseptic treatment device includes a processing shell, a transmission unit and an execution unit, the inner wall of the processing shell is provided with an annular chute, the transmission unit The sliding is set in the annular chute, and the execution unit is installed on the transmission unit; the present invention can solve the problem of "1. Most of the traditional wood antiseptic treatment is to manually apply preservatives on the wood surface, but the preservatives have complex components and are easy to damage the human body It causes great harm, and the coated wood needs to be air-dried naturally, so it is easy to adhere to dust and affect the anti-corrosion effect; 2. The current wood anti-corrosion device basically performs anti-corrosion treatment on the wood one by one, and cannot be processed in batches, so it affects the anti-corrosion effect. Work efficiency, and increase working hours" and other issues.

Owner:漳平瑞景木业有限公司

Incinerator hopper metal structural part machining process

PendingCN113634988AEasy to preservative treatmentImprove anti-corrosion performanceIncinerator apparatusThick plateMachining process

The invention discloses an incinerator hopper metal structural part machining process. The process comprises the following steps that S1, plate cutting is conducted, a steel plate is selected as a machining raw material plate, the thickness of the steel plate is 12-16 mm, cutting treatment is conducted on the steel plate, and the plate is subjected to cutting through mechanical cutting and gas cutting; linear cutting adopts mechanical cutting; a part with the curve and the thick steel plate are cut through gas cutting; dirt and grease on the surface of steel are removed before cutting, and a certain space is reserved below the steel, so that slag can be blown out conveniently; and during gas cutting, a cutting torch moves at a constant speed, during thick plate gas cutting, a cutting nozzle is kept perpendicular to the surface of a workpiece, the cutting nozzle is moved to be switched into normal gas cutting after the whole section is cut through, and the speed is slightly slowed down when gas cutting is about to reach the end point of the part. According to the process, good anti-corrosion treatment can be carried out on the metal structural part, the anti-corrosion performance of the metal structural part can be improved, and the service life can be prolonged.

Owner:江苏中高电力装备科技有限公司

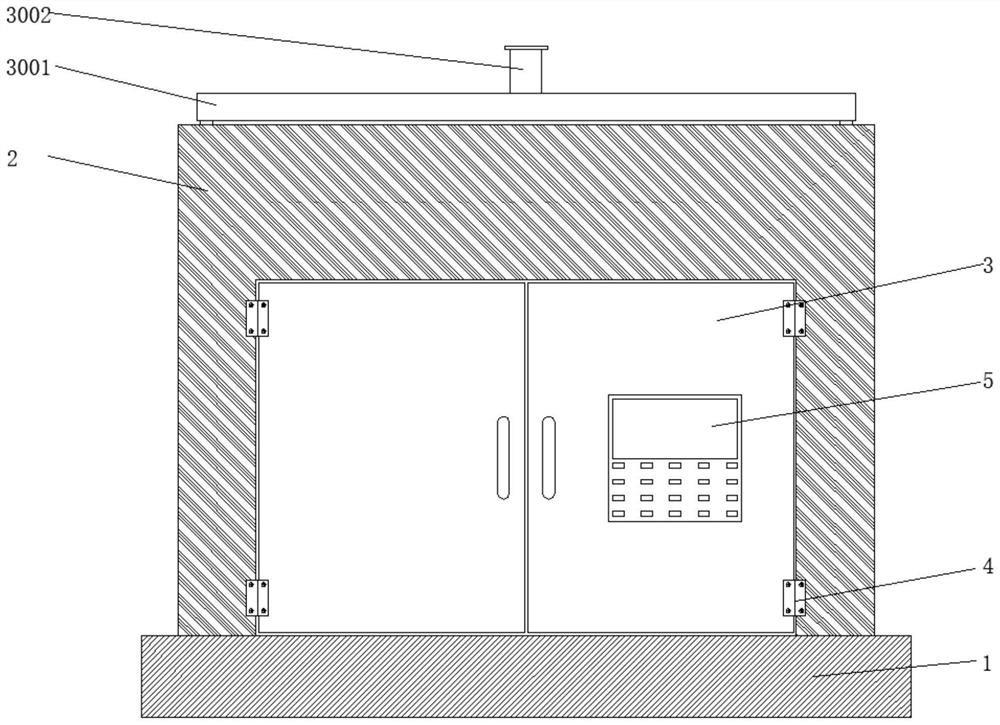

An electrical control cabinet and its anti-radiation and anti-static nano-coating

ActiveCN110913675BReduce electromagnetic radiation pollution levelsEasy to preservative treatmentShielding materialsElectrostatic discharge protectionFiberCarbon fibers

The invention belongs to the technical field of electrical control cabinets, in particular to an electrical control cabinet and its anti-radiation and anti-static nano-coating. The anti-radiation coating is evenly doped with nano-silver particles, the electrostatic shielding layer is sandwiched with a carbon fiber grid, the electrical control cabinet includes a cabinet body, and a static eliminator is installed at the bottom of the cabinet inner cavity. One corner of the inner cavity of the cabinet is provided with a ground wire port, the ground wire of the static eliminator is electrically connected to the ground wire port, the inner wall of the cabinet is sprayed with the radiation-proof coating, and the radiation-proof The top surface of the coating is adhesively bonded to the electrostatic shielding layer. The invention absorbs electromagnetic waves through the anti-radiation coating, protects the human body and electronic equipment from damage and interference by electromagnetic waves, greatly reduces their electromagnetic radiation pollution level, and provides an anti-corrosion layer to perform good anti-corrosion treatment on the outer wall of the cabinet.

Owner:无锡环宇电气有限责任公司

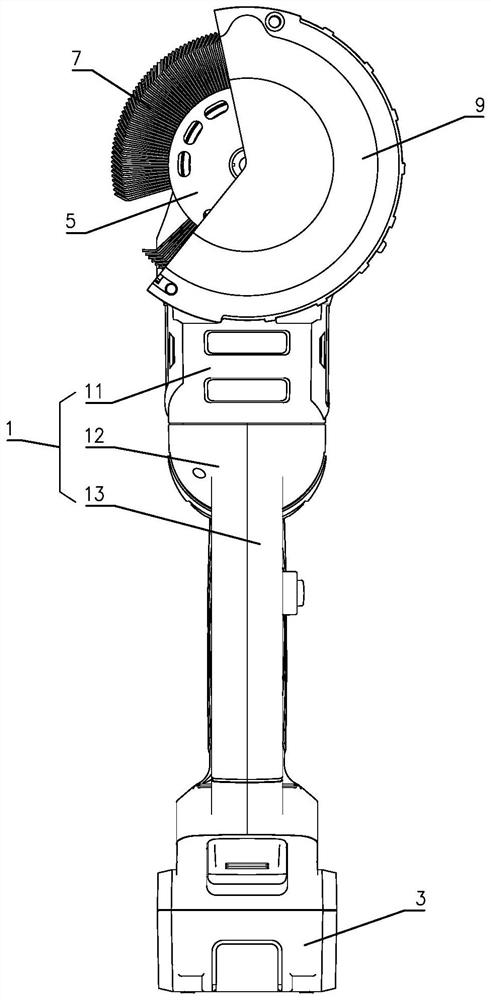

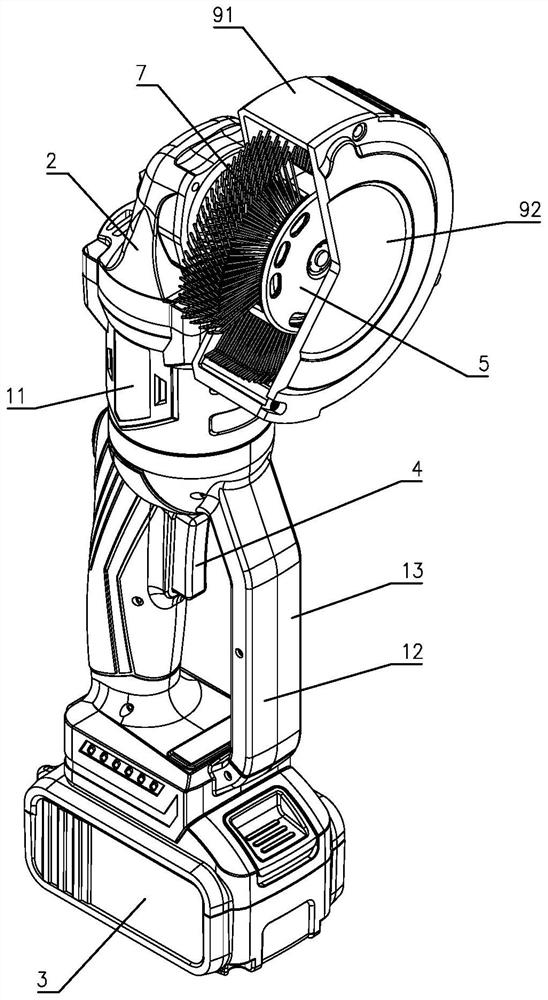

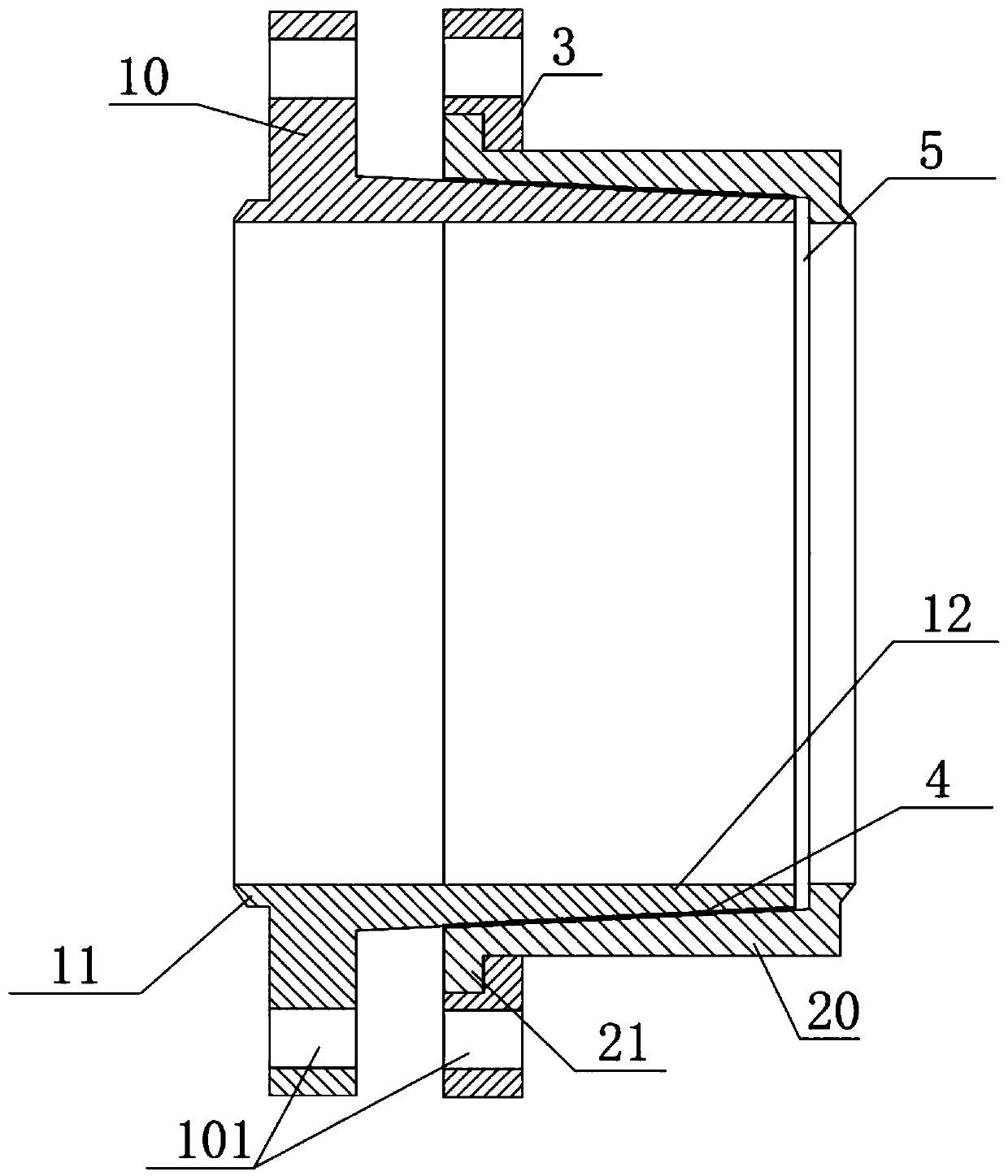

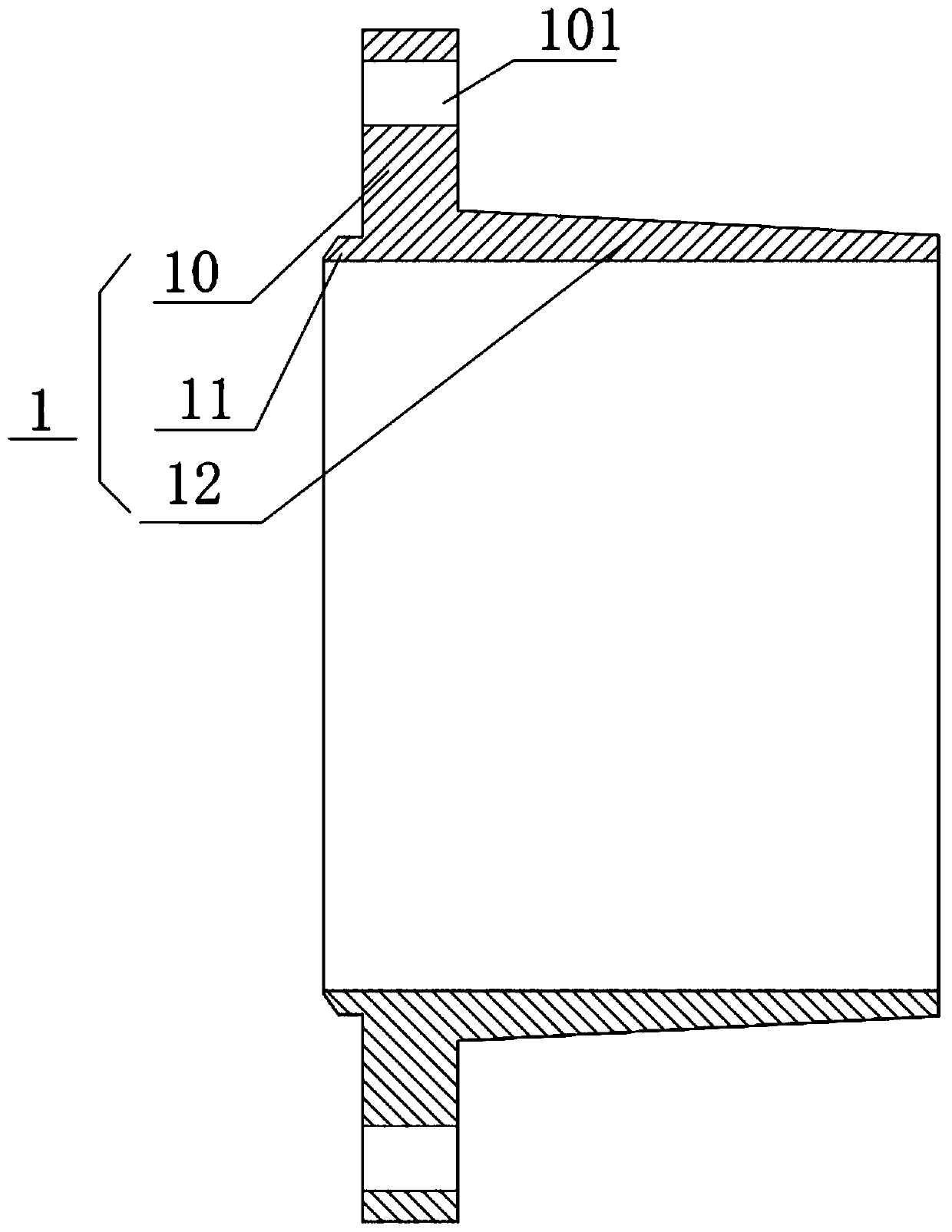

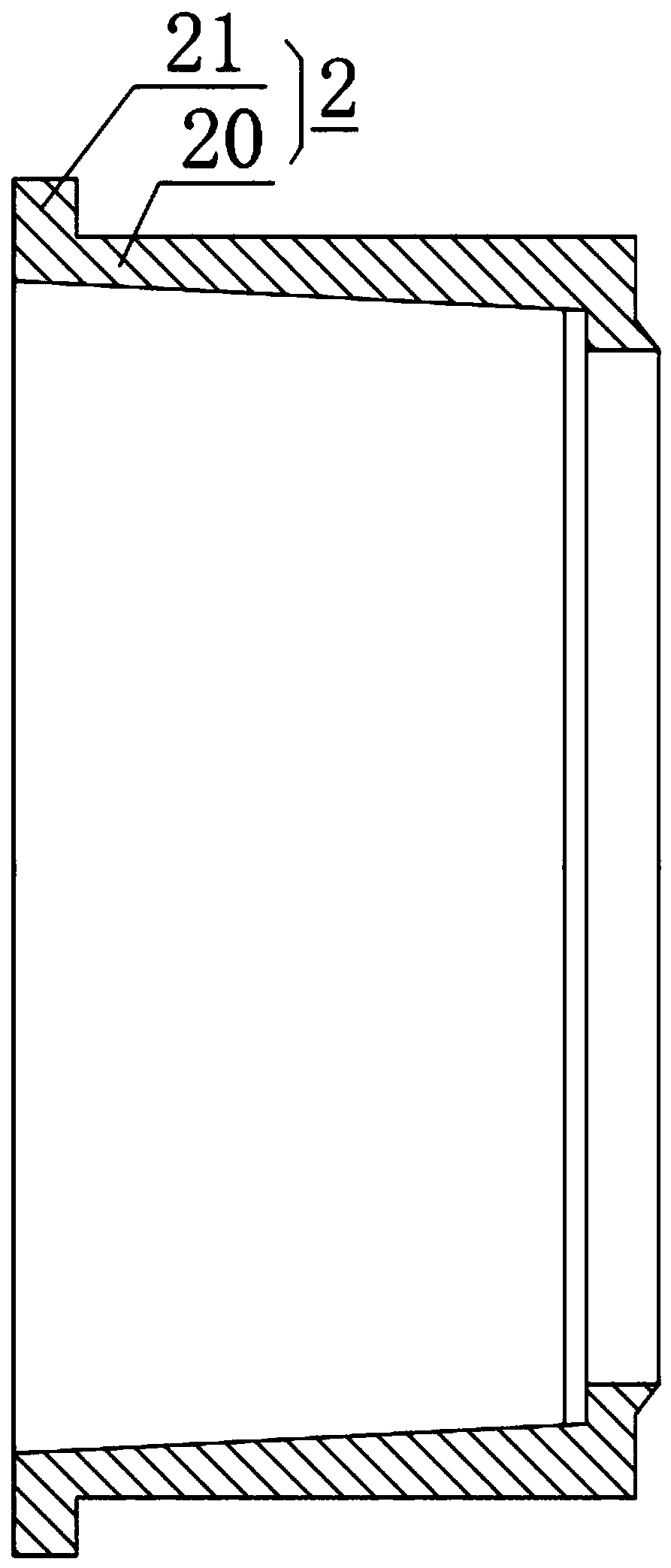

Multifunctional electric grinding machine

PendingCN113977420ASimple structureEasy to operateGrinding carriagesPortable grinding machinesElectric machineEngineering

The invention relates to a multifunctional electric grinding machine which comprises a main body, a motor and a battery are correspondingly arranged at the upper end and the lower end of the main body, a control device connected with the motor and the battery is arranged in the main body, and a grinding device is installed on an output shaft of the motor; the grinding device comprises a front buckling piece and a rear buckling piece which are buckled with each other, and a grinding wheel clamped between the front buckling piece and the rear buckling piece; the front buckling piece and the rear buckling piece are fixed to the output shaft of the motor through mounting holes formed along the axis; the grinding wheel comprises a supporting ring; densely-distributed steel wires are arranged on the supporting ring; each steel wire is arranged in the radial direction of the supporting ring; the end, away from the supporting ring, of the steel wire is provided with a polishing contact formed through bending, and the bending direction of the polishing contact is consistent with the rotating direction of the grinding wheel. The multifunctional electric grinding machine has the advantages of being simple in structure, convenient to operate and control, high in functionality, good in adaptability and high in grinding efficiency.

Owner:北京永逸舒克防腐蚀技术有限公司 +1

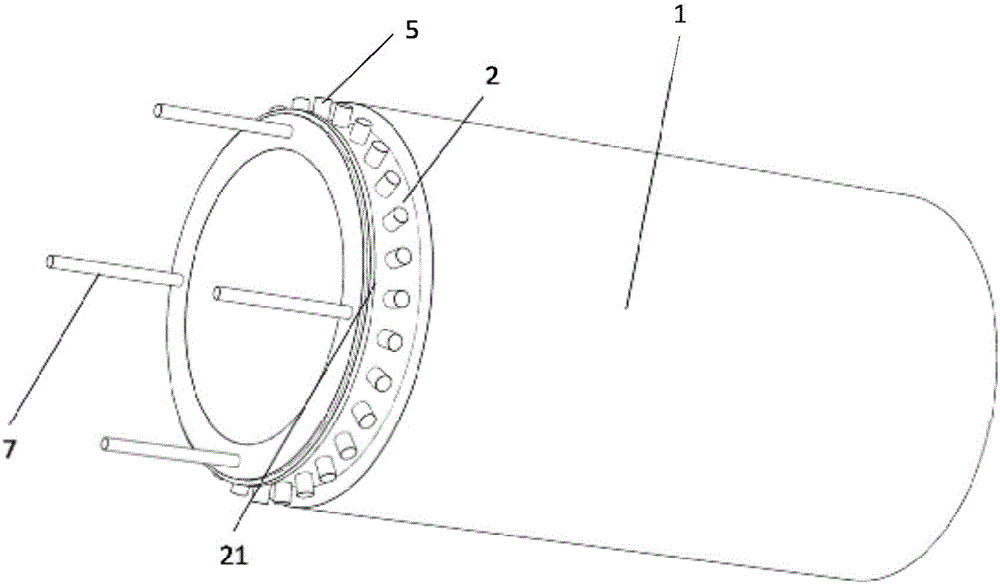

Special-shaped flange for pipeline hard seal connection

InactiveCN109764200AEasy to seal the connectionFast constructionFlanged jointsEngineeringMaterial Perforation

The invention provides a special-shaped flange for pipeline hard seal connection. The special-shaped flange for pipeline hard seal connection comprises a connecting male end, a connecting female end and an outer sleeve flange, wherein the connecting male end is arranged in the connecting female end in a penetrating way; a sealing layer is arranged between the connecting male end and the connectingfemale end; the outer sleeve flange sleeves the outer side of the connecting male end and is fixedly connected with the connecting male end. According to the special-shaped flange for pipeline hard seal connection provided by the invention, a sealed connection manner with the cooperation of the connecting male end, the connecting female end and the outer sleeve flange replaces an original weldingmanner so as to connect two groups of pipelines in a sealing way; through the special-shaped flange provided by the invention, sealed connection can be conveniently carried out on the spot, and the construction speed can be accelerated; the connecting male end and the connecting female end can be conveniently subjected to relevant preservative treatment, so that the problems of cracking and perforation of an original pipeline welding joint can be solved, and the giant loss caused by cracking and perforation of the welding joint is directly reduced; and in addition, the wall thickness of the part on which the connecting male end and the connecting female end crossing and sleeving mutually is larger, so that the overall preservative time is longer, and the pressure-resistant performance isbetter.

Owner:天津海科瑞德科技有限公司 +1

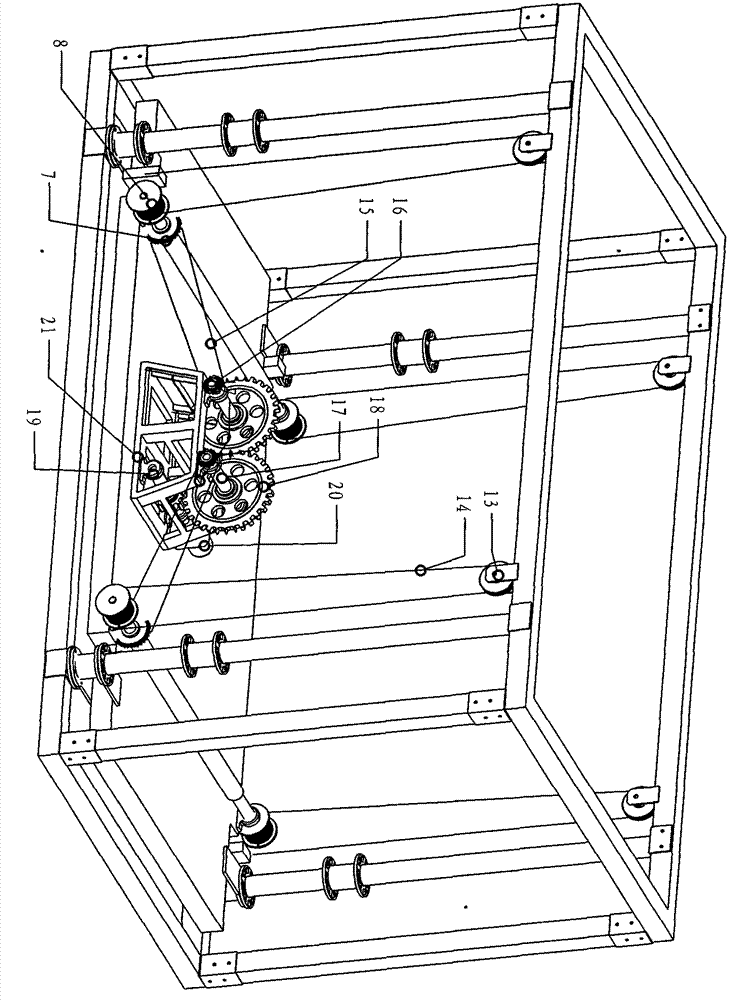

Whole lifting-type underground garage

Owner:HUBEI SAIER AUTOMATION EQUIP

Active carbon flue gas desulfurizing reverse synchronous work tower

InactiveCN100534578CMeet the requirements of desulfurization workSmall footprintDispersed particle separationDesorptionOperating cost

The invention provides an activated carbon flue gas desulfurization reverse synchronous working tower, which belongs to a flue gas desulfurization device. A plurality of longitudinal partition partitions are fixed between the tower shell and the central column, and the partition partitions are activated carbon layers. There are nozzle devices above each activated carbon layer. There is a ring gear above the nozzle device. There is a fan-shaped wind-blocking cover on the ring gear. There is another ring gear at the lower part of the tower body, the teeth on the other ring gear mesh with the teeth on the other gear on the shaft of the other motor, and a scraper is fixed under the other ring gear, and the bottom of the tower body There is a dust outlet, and there is a Venturi inlet at the lower part of the tower body. This synchronous working tower can simultaneously perform adsorption and desorption of activated carbon in the same tower, so that one tower can work continuously and meet the requirements of desulfurization work. Thereby reducing the floor area, saving equipment investment, reducing operating costs, and greatly reducing the corrosion area.

Owner:王惠生

A multi-shell tube flooded heat exchanger

ActiveCN105020942BSimple structureEasy to assemble and disassembleEvaporators/condensersStationary tubular conduit assembliesShell and tube heat exchangerEngineering

The invention discloses a multi-shell tube flooded heat exchanger, which comprises a plurality of shell tubes distributed in an array, a plurality of heat exchange tubes passing through each shell tube, and a tube respectively connected and communicated with two ends of each shell tube. The first outer tube box and a second outer tube box are respectively connected to the two ends of each heat exchange tube and are respectively connected to the first outer tube box and the two tube sheets connected to the outside of the second outer tube box, and are respectively connected to two A first inner tube box and a second inner tube box outside the tube sheet; the lower part of the first outer tube box is connected with a refrigerant inlet connection pipe, and the upper part of the second outer tube box is connected with a refrigerant outlet connection pipe. The heat exchanger is a flooded heat exchanger in which the refrigerant goes through the shell side and the refrigerant goes through the tube side. Through the structure of the heat exchange tube in the shell and tube, the refrigerant charge is much less than that of the ordinary flooded evaporator. And the oil return performance is good.

Owner:ZHEJIANG QINGFENG REFRIGERATION EQUIP MFG

Dump semi-trailer frame

ActiveCN112519889BImprove structural strengthEasy to preservative treatmentUnderstructuresSuperstructure connectionsVehicle frameClassical mechanics

The invention relates to a self-unloading semi-trailer frame, which includes two longitudinal beams and a plurality of cross beams arranged between the two longitudinal beams, and the longitudinal beams include an upper flange, a web and a lower flange connected in sequence; the web It includes plate A, plate B and plate C connected in sequence, the plate B is vertically connected with the plate A and the plate C respectively, the plate A is connected with the upper wing plate, and the plate C is connected with the lower wing plate The middle part of the board is vertically connected, and the board B and the board C are respectively connected to the beam by welding. It has the advantages of reasonable structural design, high structural strength, less welding process, good cooperation with chain conveying mechanism, stable and reliable structure, etc.

Owner:WEIHAI SHUNFENG SPECIAL VEHICLE MFG CO LTD

Wood preservative treatment method

ActiveCN112372779AReduce harmSave time at workWood treatment detailsPretreatment apparatusAir dryingMechanical engineering

The invention provides a wood preservative treatment method. The method adopts the following wood preservative treatment device, the wood preservative treatment device comprises a processing shell, atransmission unit and an execution unit, an annular sliding groove is formed in the inner wall of the processing shell, the transmission unit is arranged in the annular sliding groove in a sliding mode, and an execution unit is mounted on the transmission unit. The wood preservative treatment method can solve the problems that firstly, most of traditional wood preservative treatment adopts manpower to coat the surface of wood with a preservative, but the preservative is complex in component and prone to causing great harm to a human body, and the coated wood needs to be naturally air-dried, sothat dust is prone to adhering to the wood, and the preservative effect is affected; and secondly, an existing wood preservative device basically performs preservative treatment on wood one by one and cannot perform batch processing, so that the working efficiency is influenced, the working time is prolonged, and the like.

Owner:漳平瑞景木业有限公司

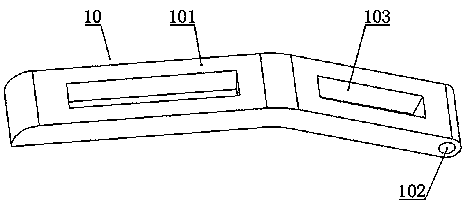

Blade device for a mixing propeller and the application thereof

ActiveUS9776148B2Easy to preservative treatmentGuaranteed uptimeShaking/oscillating/vibrating mixersTransportation and packagingPropellerEngineering

A blade device for a mixing propeller has a rocking shaft and a plurality of blade units. The blade unit is made of a flexible material and is installed on the rocking shaft via a fixing groove. The blade unit includes a horizontal propelling flexible blade and a vertical uplifting flexible blade. The fixing groove has a horizontal section and a vertical section. One end of the horizontal propelling flexible blade is inserted in the vertical section of the fixing groove while the other end of which is kept free so that it can swing back and forth. One end of the vertical uplifting flexible blade is inserted in the horizontal section of the fixing groove while the other end of which is kept free so that it can swing back and forth.

Owner:JIANGSU PROVINCIAL ACAD OF ENVIRONMENTAL SCI

A surface-treated pre-embedded plate processing technology for anti-fall beams

ActiveCN106012805BImprove the efficiency of co-infiltration anticorrosion treatmentEasy to preservative treatmentSolid state diffusion coatingBridge structural detailsAlloyRebar

The invention discloses a machining process for efficient surface treatment of a beam-falling prevention embedded plate. The machining process comprises the following steps that a mounting outer thread is machined on the outer side of one end of an embedded cylinder; the other end of the embedded cylinder is welded to an embedded bar to form an embedded bar cylinder; a cylinder mounting hole used for mounting the embedded bar cylinder is machined in a fixing plate; a mounting inner thread matched with the mounting outer thread is machined on the inner wall of the cylinder mounting hole; the fixing plate and the embedded bar cylinder are subjected to chemical degreasing, water washing and drying, and rust spots and oxide scales on the surface of the fixing plate and the surface of the embedded bar cylinder are removed in a shot blasting mode; and the fixing plate and the embedded bar cylinder are subjected to surface anticorrosion treatment and then assembled together in a threaded connection mode. The machining process for efficient surface treatment of the beam-falling prevention embedded plate can be used for conveniently conducting composite anticorrosion treatment combining multicomponent alloy permeability, Dacromet and a closed layer on the beam-falling prevention embedded plate.

Owner:JIANGSU TIEBAO FORGING

Inner press roller roll type outline matching screw tube blank

The inner press roller with rolling outline matching screw pipe blank features its rolling curve equation. Owing to the linear contact, the present invention can avoid wavy rolling impression and raise the rolling quality. The decrease of wavy rolling impressing is favorable to the anticorrosion treatment of the pipe, low conveying resistance, homogeneous deformation of the pipe and inherent quality of pipe.

Owner:白忠泉

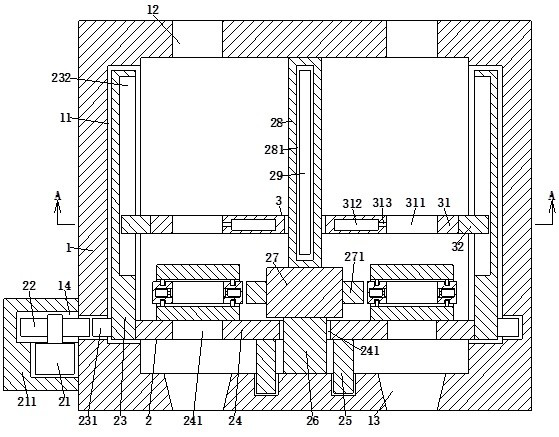

Cantilever connecting structure for roots pump or screw pump

ActiveCN113606131AEnsure rigidityEnsure overall performance is maintainedChemical industryRotary piston pumpsDrive shaftClassical mechanics

The invention discloses a cantilever connecting structure for a roots pump or a screw pump. The cantilever connecting structure comprises an outer shell, a bearing end cover, a driving shaft rotor and a cantilever rotor, wherein the driving shaft rotor is connected with a driving positioning sleeve, and a circular boss is arranged on the driving positioning sleeve; the cantilever rotor comprises a linear rotor, a transition cylinder and a cantilever rotor positioning ring; the cantilever rotor positioning ring is fixedly connected with the driving positioning sleeve; and the cantilever rotor is sleeved with the outer shell, the bearing end cover is arranged at the outer side of the driving shaft rotor, a first step is arranged in the bearing end cover, a second step is arranged on the outer surface of the driving shaft rotor, a bearing cavity is formed between the first step and the second step, and a bearing is installed in the bearing cavity. The cantilever connecting structure overcomes the defects in the prior art, the cantilever rotor positioning ring is matched with the driving positioning sleeve, the driving positioning sleeve is matched with the driving shaft rotor, the rigidity of the cantilever rotor can be ensured, the overall performance of the cantilever rotor can be kept, the machining requirement of the cantilever rotor is greatly lowered, and embedded matching of an extended shaft and the rotor is not needed any more.

Owner:兑通真空技术(上海)有限公司

Anti-corrosion treatment device for ball valve body

PendingCN112718354AEasy to clamp and fixClamp firmlyPretreated surfacesCoatingsCorrosion preventionPhysics

The invention discloses an anti-corrosion treatment device for a ball valve body. The anti-corrosion treatment device comprises a base, a first motor and an arc-shaped electric heating plate, wherein a fixing frame is fixed to the right side of the upper end face of the base, a support is fixed to the right inner wall of the fixing frame, an annular liquid passing channel is fixed to the bottom of a sliding block, the arc-shaped electric heating plate is connected with the rear inner wall of a cover frame through a second electric telescopic rod, and a demisting mechanism penetrates through the top of the cover frame. According to the anti-corrosion treatment device for the ball valve body, after the ball valve body is placed and fixed, the electric valve and external feeding equipment can be connected together through a connecting hose, then a worker can leave the cover frame and close a rotary door, after the electric valve is opened, an anti-corrosion agent is sprayed out through the annular liquid passing channel and a spray head in sequence, anti-corrosion treatment of the ball valve body is facilitated, at the moment, the annular liquid passing channel and the spray head can slide leftwards and rightwards along with the sliding block, and meanwhile, the ball valve body rotates, so that the ball valve body can be subjected to more comprehensive and uniform anti-corrosion treatment.

Owner:YANCHENG RUIDE PETROCHEM MACHINERY CO LTD

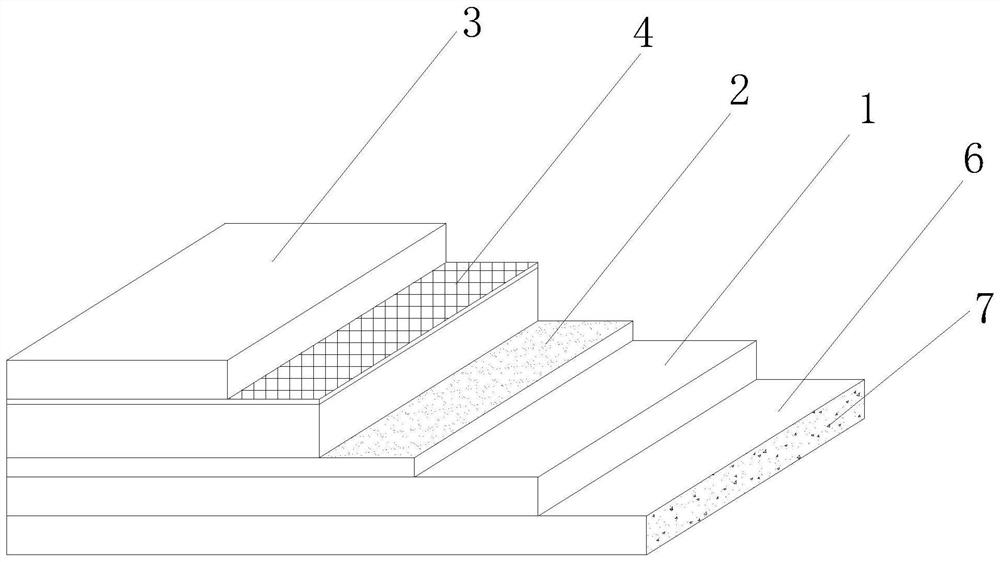

Spiral coil heat exchange pressure-bearing water tank

InactiveCN106595055AEasy to preservative treatmentEasy to replace and maintainFluid heatersMechanical apparatusWater source heat pumpNew energy

The invention discloses a spiral coil heat exchange pressure-bearing water tank and belongs to the field of pressure-bearing heat preservation water tank engineering systems. At present, along with active promotion of energy-saving environment-friendly policies, some new energy projects are greatly developed, for example, the cleanliness is greatly improved due to utilization of air energy heat pumps, ground source heat pumps and water source heat pumps, and the heat exchange type pressure-bearing heat preservation water tank belongs to necessary and conventional equipment when the new energy is used for obtaining living hot water; however, the heat exchange type pressure-bearing heat preservation water tank capable of being matched with the heat pumps and good in heat exchange effect does not exit all the time. In order to solve the problem, the spiral coil heat exchange pressure-bearing water tank is specially designed and composed of a shell, a heat preservation layer, an inner container and an end cover. Auxiliary accessories are integrated and assembled to the end cover for facilitating maintenance and replacement and meanwhile being beneficial to corrosion prevention treatment on the inner wall of the inner container; and the end cover is assembled to the inner side of a port, the structure is reasonable, and leakage is avoided.

Owner:BINZHOU ARMOR FORCE SOLAR TECH

Machining process for efficient surface treatment of beam-falling prevention embedded plate

ActiveCN106012805AEfficient use ofImprove the efficiency of co-infiltration anticorrosion treatmentSolid state diffusion coatingBridge structural detailsAlloyRebar

The invention discloses a machining process for efficient surface treatment of a beam-falling prevention embedded plate. The machining process comprises the following steps that a mounting outer thread is machined on the outer side of one end of an embedded cylinder; the other end of the embedded cylinder is welded to an embedded bar to form an embedded bar cylinder; a cylinder mounting hole used for mounting the embedded bar cylinder is machined in a fixing plate; a mounting inner thread matched with the mounting outer thread is machined on the inner wall of the cylinder mounting hole; the fixing plate and the embedded bar cylinder are subjected to chemical degreasing, water washing and drying, and rust spots and oxide scales on the surface of the fixing plate and the surface of the embedded bar cylinder are removed in a shot blasting mode; and the fixing plate and the embedded bar cylinder are subjected to surface anticorrosion treatment and then assembled together in a threaded connection mode. The machining process for efficient surface treatment of the beam-falling prevention embedded plate can be used for conveniently conducting composite anticorrosion treatment combining multicomponent alloy permeability, Dacromet and a closed layer on the beam-falling prevention embedded plate.

Owner:JIANGSU TIEBAO FORGING

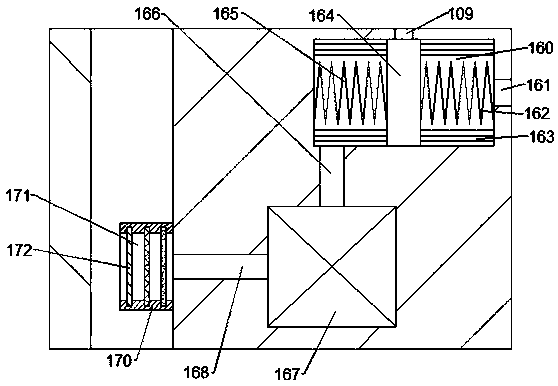

Supercharging device and use method thereof

InactiveCN109129778ASimple structureEasy to operateWood treatment detailsWood heatingEngineeringPiston

The invention discloses a supercharging device and a use method thereof. The supercharging device adopts a wood preservative treatment device; the wood preservative treatment device comprises a devicehousing; a working chamber is formed in the device housing; a treatment box body is fixedly mounted on the bottom wall of the working chamber; an electric cylinder is fixedly mounted in the end surface of the top of the device housing; the end surface of the bottom of a downward piston push rod of the electric cylinder is fixedly connected with a pressure block; a fastening block is fixedly mounted in the internal wall of the working chamber; a sliding square hole which runs through the upper end surface and the lower end surface of the fastening block is formed in the fastening block; the pressure block is in sliding fit with the sliding square hole; a compression block is arranged at the bottom of the pressure block; an preservative chamber with an upward opening is formed in the end surface of the top of the treatment box body; side slide grooves are symmetrically formed in the left wall and the right wall of the preservative chamber; the side slide groove is in sliding fit with the compression block; and a sealing plate is mounted on the external side of the pressure block in the form of sliding fit.

Owner:YIWU ZHIXIN TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com