Special-shaped flange for pipeline hard seal connection

A special-shaped flange, hard sealing technology, used in flange connection, pipe/pipe joint/pipe fitting, through components, etc., can solve the problems of harsh working environment, long construction period, leakage, etc., and achieve good anti-corrosion effect and anti-corrosion time. The effect of long, high withstand voltage performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to better understand the present invention, the present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

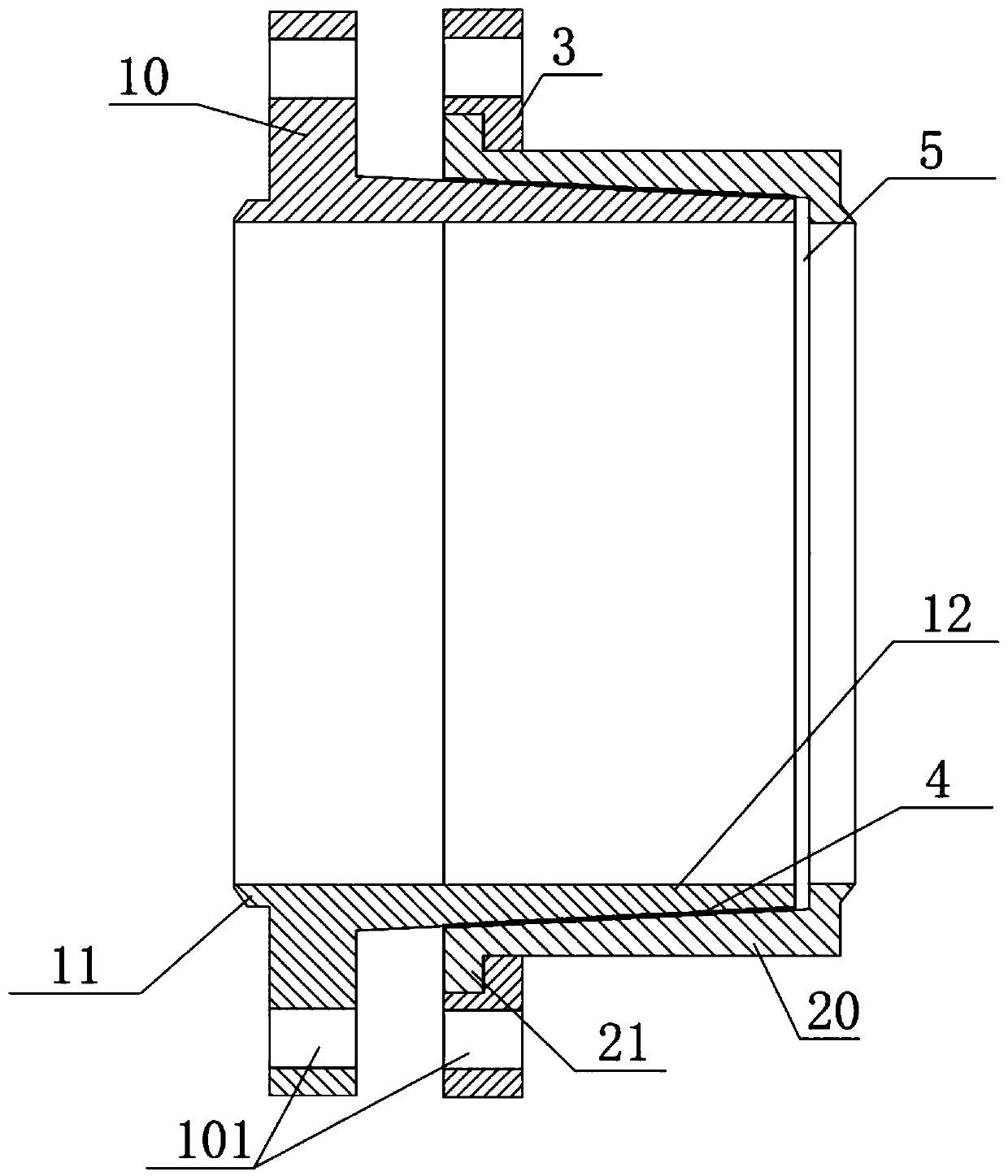

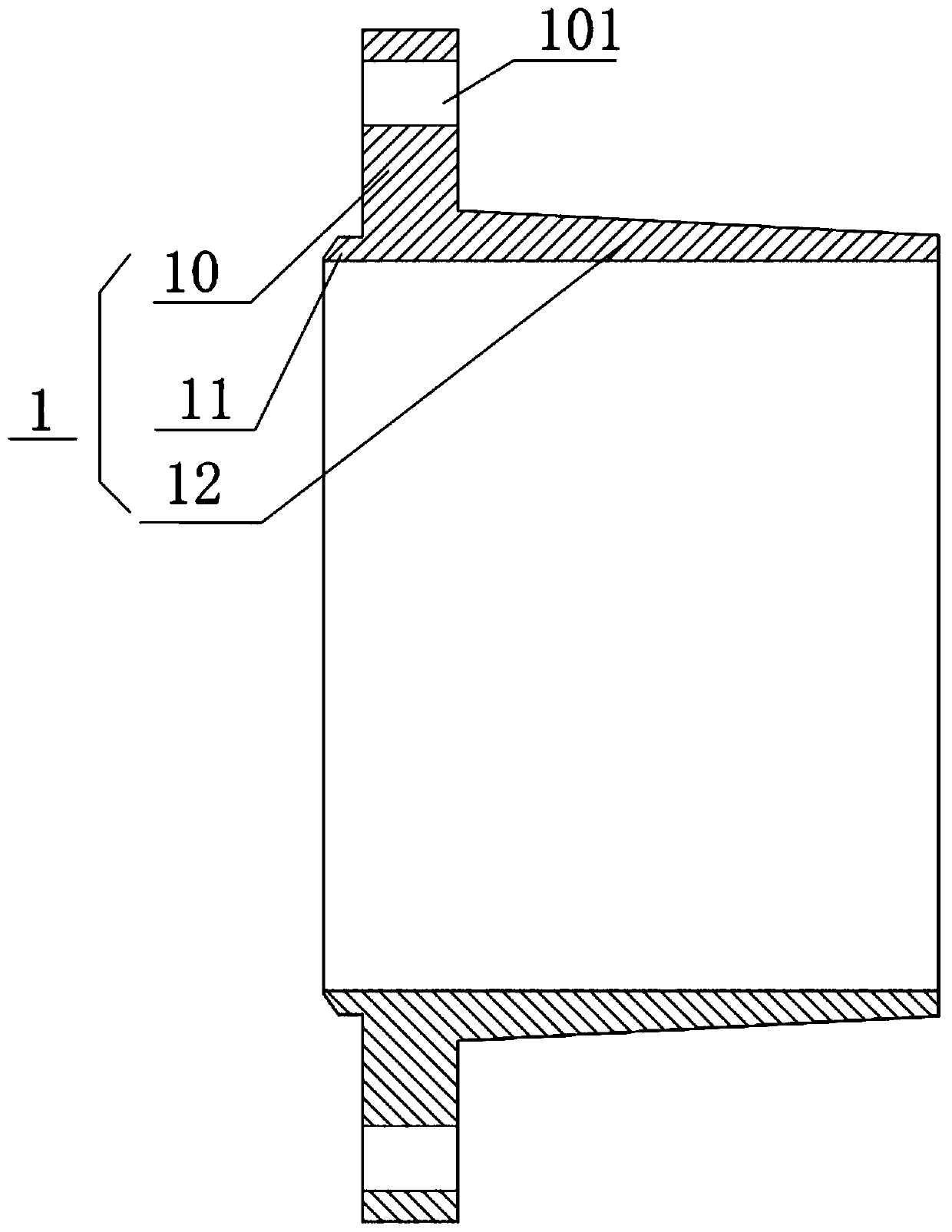

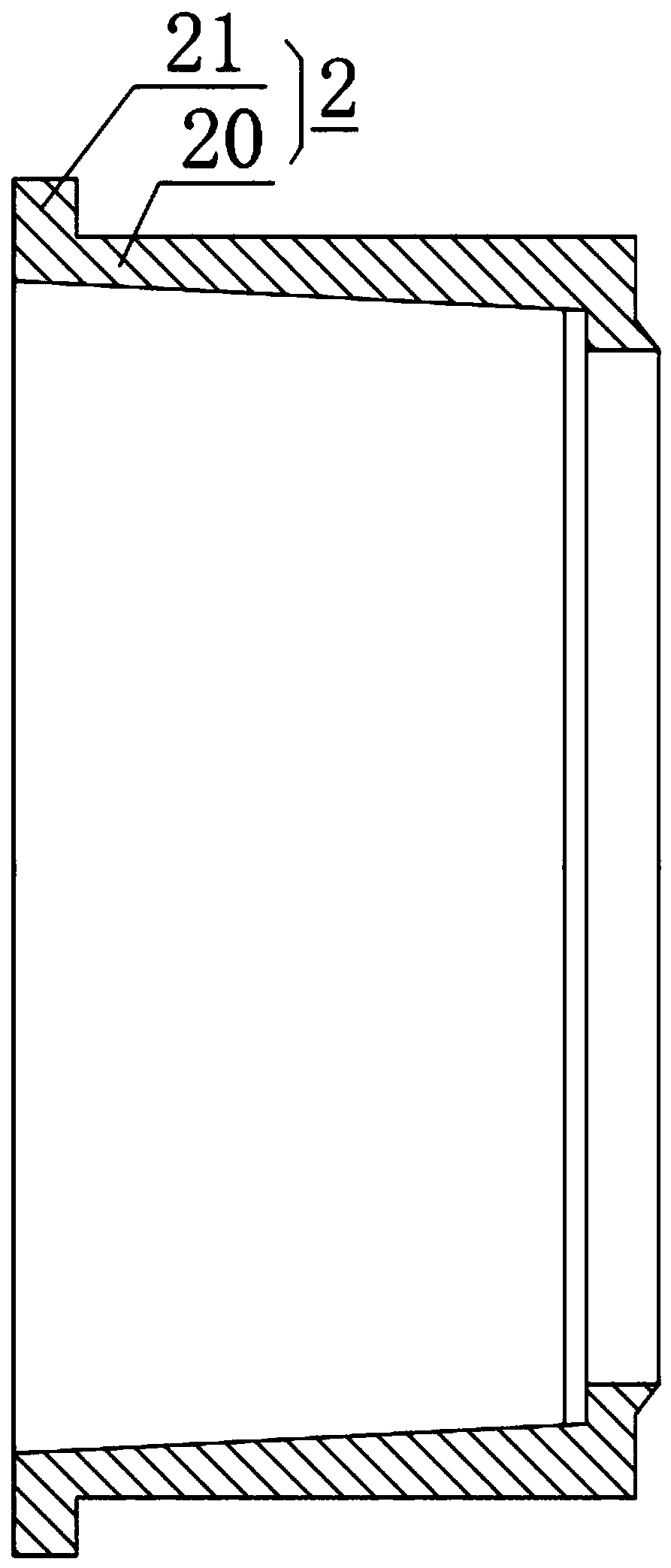

[0021] Such as Figure 1 to Figure 4 As shown, a special-shaped flange used for the hard-sealed connection of pipelines includes a connecting male end 1, a connecting female end 2, and an outer flange 3. The connecting male end 1 is matched and penetrated inside the connecting female end 2. A sealing layer 4 is provided between the female ends 2, and the outer casing flange 3 is sleeved on the outer side of the connecting male end 1, and the outer casing flange 3 and the connecting male end 1 are fixedly connected by fasteners. The fit between the connecting male end 1 and the connecting female end 2 is a transition fit, and the fit between the jacket flange 3 and the connecting female end 2 is a clearance fit. The connecting female end 2 is generally made of Q235 steel, and the connecting male e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com