Micro-nozzle and manufacture method thereof

A manufacturing method and technology for micro-nozzles, which are applied in separation methods, chemical instruments and methods, spraying devices, etc., can solve the problems of high manufacturing cost of micro-channel devices, complex micro-channel device processes, and high process environment requirements, and are easy to learn and master. , The effect of low production cost and low process environment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

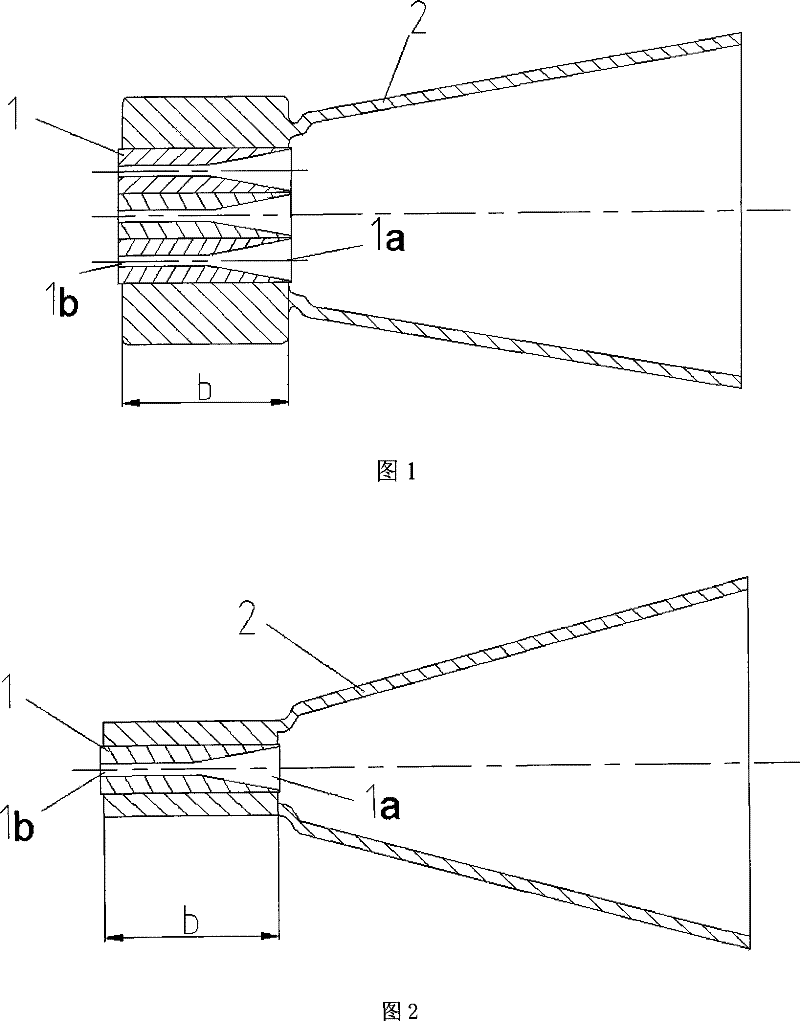

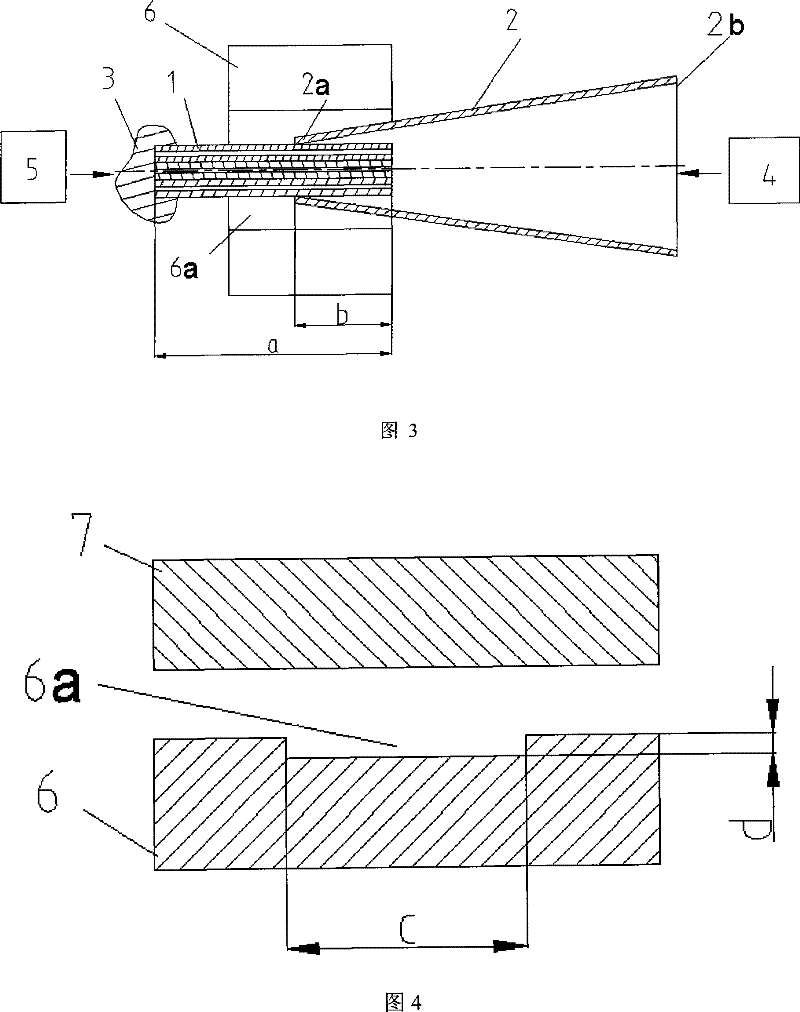

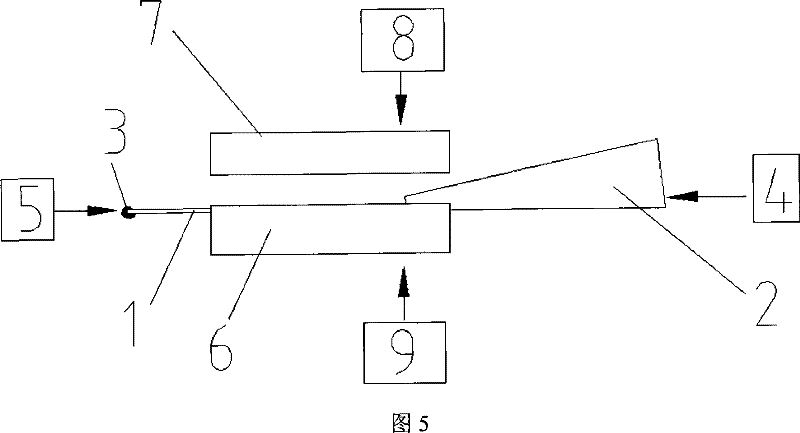

[0020] combine figure 1 And Fig. 2, the capillary 1 of micronozzle of the present invention is made up of micropipe 1b and transition duct 1a, and this capillary 1 is embedded in an end of plastic pipe 2, and this micropipe 1b communicates with nozzle external environment, and this transition duct 1a is connected with plastic pipe 2 The inner cavity of the transition duct 1a is communicated with each other, and the inner diameter of the transition duct 1a gradually decreases. Wherein, there is one or more than one capillary tube 1 , and the axes of the more than one capillary tube 1 with the same outer diameter are arranged in parallel in a row in the same plane. The plastic pipe 2 is a thermoplastic pipe, and the cross-sectional shape of the inner cavity perpendicular to the axis of the plastic pipe 2 is circular or gradually transitions from circular to oblate. The cross-sectional shape of the capillary lumen perpendicular to the axis of the capillary 1 is circular. The in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com