Patents

Literature

60results about How to "Long anticorrosion time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-temperature-resistant, anti-corrosion and thermal-insulation coating and preparation technology thereof

ActiveCN104673063AReduce internal stressImprove high temperature resistanceAnti-corrosive paintsEpoxy resin coatingsFirming agentCross linker

The invention discloses a high-temperature-resistant, anti-corrosion and thermal-insulation coating which comprises components in parts by weight as follows: 45-60 parts of film-forming resin, 20-30 parts of a pigment and filler, 15-30 parts of an aid and 25-30 parts of a solvent. The invention further designs a preparation technology of the high-temperature-resistant, anti-corrosion and thermal-insulation coating. The technology comprises steps as follows: firstly, mixing the film-forming resin with the pigment and the filler, sequentially adding an antifoaming agent, a leveling agent, a coupling agent, a crosslinking agent and a curing agent, and evenly stirring the mixture at the normal temperature to obtain the high-temperature-resistant, anti-corrosion and thermal-insulation coating. The coating has the advantages of environment-friendliness, low cost, high hardness, long service life, good heat resistance, good flexibility, good high-temperature resistance and the like.

Owner:JIANGSU XIN AN NEW MATERIALS TECH

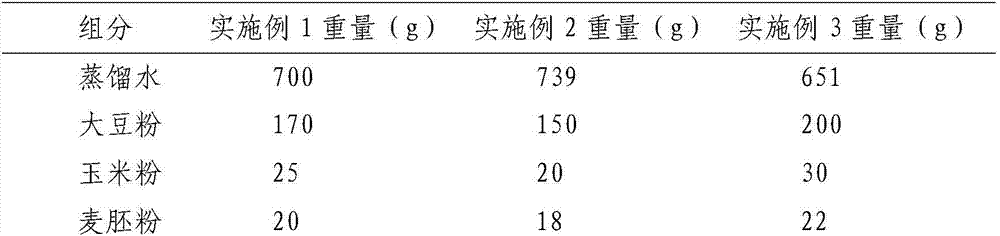

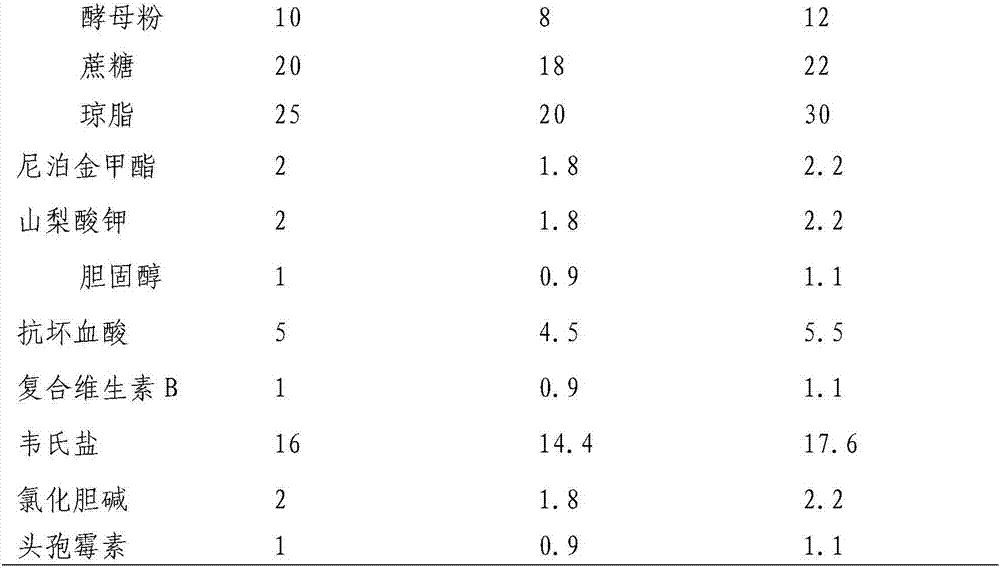

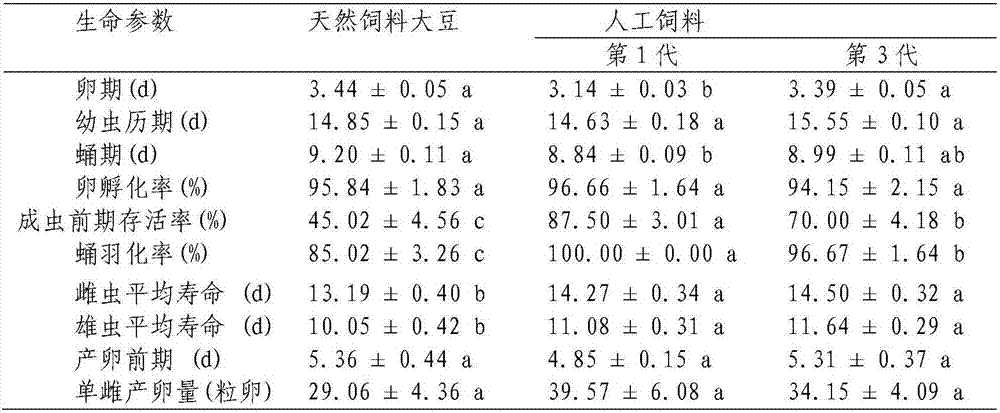

Artificial feed for etiella zinckenella and preparation method of artificial feed

InactiveCN107019126ALong anticorrosion timeImprove antibacterial propertiesAnimal feeding stuffAccessory food factorsBiotechnologyAnimal science

The invention relates to the field of insect feeding, and particularly provides artificial feed for etiella zinckenella and a preparation method of the artificial feed. The feed adopts soybean powder, corn powder and wheat germ flour as main nutritional substances, the main nutritional substances are matched with various auxiliary materials to prepare the artificial feed, the obtained feed is suitable for etiella zinckenella larva to eat, the feeding effect is better than that of a natural host, and the nutritional substances needed by the development of the etiella zinckenella larva can be satisfied in the feeding process; and moreover, the feed is long in anticorrosion time, and good in antibacterial effect, and the feed does not need to be replaced during the entire generation.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

Anti-corrosion asphalt paint

An anticorrosion asphalt paint for metal is prepared from petroleum asphalt (20-40 wt.%), solvent oil (30-50%), xylene (5-10%), rosin oil (5-10%) and green oil (5-15%). Its advantages include high adhesion, high effect on resisting water, moisture, corrosion, high temp and cracking, and easily erasing it by gasoline.

Owner:李铁君

Method for litchi anticorrosion and the application of grape fermentation health care products thereof

InactiveCN101204174AStay rosySimple methodFruit and vegetables preservationFood preparationPreservativeFermentation

The invention relates to an antisepsis method for litchi and an application of healthy products fermented by the grapes in litchi antisepsis, belonging to a field of fruit antisepsis. The invention solves the problems that storage time of the litchi is short, or a preservative has an adverse impact on taste or appearance of the litchi or contains chemical medicines which are not beneficial for human body; besides, the invention provides an antisepsis method for the litchi and the method can be read in an instruction in detail; the method disclosed in the invention is simple and no complex device and expensive medicines are needed; the used preservative is natural beneficial components fermented by the grape without any substances harmful to human body; the litchi only needs to be soaked and does not become damaged and turns black in a long time and the coat of the litchi can keep rose color for a long time.

Owner:刘杰龙 +6

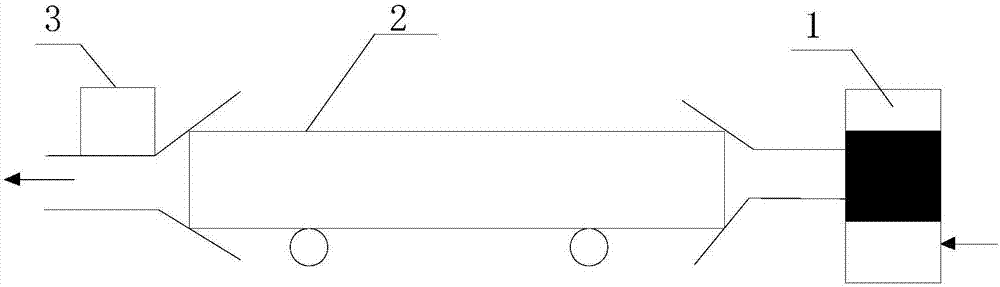

Coating method for internally coating pipe with clinkering epoxy graphene powder

InactiveCN107377340AGood chemical resistanceStrong solvent resistancePretreated surfacesCoatingsEpoxyImpurity

The invention discloses a coating method for internally coating a pipe with clinkering epoxy graphene powder. The coating method comprises the following specific steps that (1), the steel pipe is preheated, surface impurities are removed, and oxide skin is loosened; (2), an inner sandblasting process is adopted, the steel pipe reaches the metal white, the anchor pattern control depth is controlled to be within the range of 45-95 micrometers, and then surface dust is removed; (3), the steel pipe obtained after surface treatment is completed is uniformly heated with a pollution-free heat source; (4), the epoxy graphene powder is fully fluidized in a fluidization bed firstly; (5), the leveled coating is further gelled and cured; (6), after the overall temperature drops, watering cooling is performed; and (7), when the temperature drops below 150 DEG C, coating film performance detection is performed. According to the coating method for integrally coating the pipe with the clinkering epoxy graphene powder, pipe inner wall coating is more thorough, the anticorrosion coating covering is more uniform, the formed anticorrosion coating can effectively resist the chemical corrosion of organic matter and has the good insulativity, and the anticorrosion time is long.

Owner:武汉中电节能有限公司

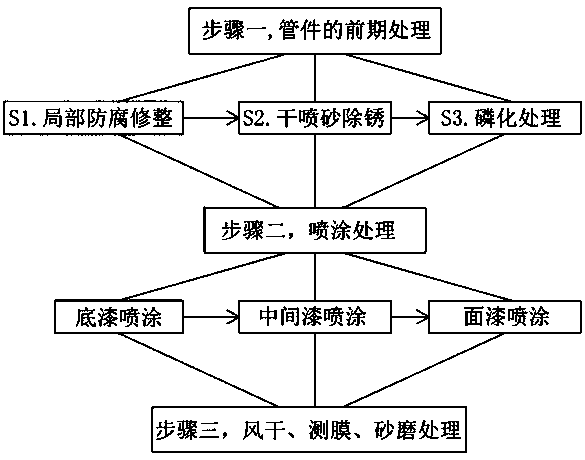

Technology of anti-corrosion spraying on surface of tower cylinder

InactiveCN110000073AAvoid localized corrosionAvoid corrosionPretreated surfacesCoatingsAbrasive blastingEngineering

The invention discloses a technology of anti-corrosion spraying on the surface of a tower cylinder. The technology of the anti-corrosion spraying on the surface of the tower cylinder comprises the following steps that 1, tower cylinder spraying pretreatment is carried out, specifically, S1, partial anti-corrosion finishing is carried out, S2, dry sandblasting for rust removal is carried out, and S3, parkerizing is carried out; 2, spraying treatment is carried out, specifically, under certain conditions, priming paint spraying, intermediate paint spraying and finishing paint spraying are carried out in sequence; and 3, air drying, film measuring and sanding treatment are carried out, specifically, after spray painting on the surface of a workpiece is subjected to air drying and is judged tobe qualified after being subjected to the film measuring, and the sanding treatment is carried out on the surface of a paint film to remove paint film particles and pollutants. According to the technology of the anti-corrosion spraying on the surface of the tower cylinder, through the three-step systematic spraying pretreatment steps including the partial anti-corrosion finishing, the dry sandblasting for rust removal and the parkerizing for the tower cylinder, the tower cylinder is effectively prevented from being partly corroded, meanwhile, the adhesive force between the priming paint and the surface of the tower cylinder can be enhanced, then through spraying three layers of interactive paint layers including priming paint, intermediate paint and finishing paint, the three-layer anticorrosion protection to the tower cylinder is formed , the spraying quality is high, the paint layers are not prone to falling off after being sprayed, the tower cylinder corrosion can be effectively prevented, and the anticorrosion time is long.

Owner:QINGDAO TIANNENG HEAVY INDUSTRIES CO LTD

High-strength titanium alloy steam turbine blade

InactiveCN108624783ALow costDoes not affect the chemical compositionAntifouling/underwater paintsBlade accessoriesEpoxyTitanium alloy

The invention discloses a high-strength titanium alloy steam turbine blade. The surface of the steam turbine blade is further provided with a protection layer, and the protection layer is prepared from, by mass, 10-15 parts of modified ethylene-propylene-diene monomer rubber, 15-20 parts of methyl phenyl silicone resin, 8-11 parts of organosilicon-modified epoxy resin, 5-7 parts of nanometer SiC powder, 13-15 parts of filler and pigment, 3-5 parts of dispersing agent, 10-15 parts of coupling agent, 13-15 parts of curing agent, 7-9 parts of defoaming agent and 1-3 parts of anti-mildew bactericide. The high-strength titanium alloy steam turbine blade has good strength, and is good in corrosion resistance, simple in preparation process, low in cost and long in service life.

Owner:南京赛达科技有限公司

Environment-friendly rust-proof water-based cutting fluid

InactiveCN104277904AImprove anti-corrosion functionImprove performanceAdditivesEnvironmental resistanceWater based

The invention discloses an environment-friendly rust-proof water-based cutting fluid, comprising the following components in parts by weight: 10-25 parts of alkylol amine or alkylol amine salt, 5-10 parts of silicate, 15-30 parts of sodium borate, 8-20 parts of sodium tungstate, 25-50 parts of boracic acid, 5-15 parts of sodium gluconate, 30-60 parts of a lubricating agent, 3-10 parts of a defoaming agent, 3-8 parts of a sterilizing agent, 3-6 parts of a pH modifier and 50-85 parts of water. The environment-friendly rust-proof water-based cutting fluid disclosed by the invention has cooling, cleaning and lubricating functions, and is environmentally friendly, long in service life, excellent in anti-corrosion performance and strong in stability.

Owner:CHAOHU GUANGFENG METAL PROD

Antiseptic for food packing paper

InactiveCN103993506AGrowth inhibitionMaintain nutrientsPaper/cardboardCorrosion-inhibiting/anti-oxidant agent additionMonoglycerideNon toxicity

The invention relates to the technical field of food packaging materials, and discloses an antiseptic for food packing paper. The antiseptic comprises 15-25wt% of succinic acid, 20-30wt of sodium hyaluronate, 10-15 parts of monoglyceride, 0.04-0.07wt% of sorbic acid, 0.05-0.1wt% of ascorbic acid, and the balance ethanol. The selection of succinic acid and sodium hyaluronate as raw materials and the matching with monoglyceride and ascorbic acid prolong the anticorrosion time, effectively inhibit the growth of bacteria, maintain the nutritional components and water of a food, and effectively prevent the corruption and the mildewing of the food; and the antiseptic has the advantages of reasonable formula, simple preparation, low cost, non-toxicity, innocuousness, and no influences on human bodies and environment.

Owner:ANHUI NINGGUO MINGHAO PACKAGING MATERIALS

Wood preservative treatment method

InactiveCN104441133ASolve problems that destroy the internal structure of woodReduce pollutionPressure impregnationMedicineCell membrane

The invention belongs to the field of wood preservative treatment, and particularly relates to a wood preservative treatment method. The wood preservative treatment method comprises the following steps of injecting purified water into wood cells by utilizing a pressure treatment tank, then permeating a preservative into the wood cells via the permeation effect of cell membranes, so that the wood has a long-time preservative effect. According to the invention, the wood cells are subjected to pressurization and water injection, and the preservative is injected via the permeation effect of the cell membranes, so that on one hand, the problem that the internal structure of the wood is damaged due to direct pressurization and injection of the preservative to the wood cells is solved, and on the other hand, the preservative is injected into the cells, so that the preservative time is prolonged, and good permeation property and high loss resistance are achieved. By adopting the method, even if the chemical preservative is used, the pollution to the environment by the preservative is greatly reduced.

Owner:ANHUI MENGFUJIA ARTS & CRAFTS

Water-based brass antioxidant with benzimidazole added and good weldability and preparation method thereof

InactiveCN106756964AReduce corrosionPrevent infiltrationMetallic material coating processesEpoxyWater based

The invention discloses a water-based brass antioxidant with benzimidazole added and good weldability. Each liter of antioxidant is prepared from the following raw materials including, by weight, 11-13 parts of 50wt.% phytic acid, 26-28 parts of 30wt.% hydrogen peroxide, 12-13 parts of polyethylene glycol, 2-4 parts of nano calcium carbonate, 3-4 parts of magnesium dihydrogen phosphate, 1-2 parts of sodium citrate, 2-3 parts of sodium carboxymethylcellulose, 8-10 parts of water-borne epoxy resin emulsion, 1.7-1.9 parts of tea polyphenol, 0.6-0.8 part of benzimidazole, 2.2-2.4 parts of gamma-chloropropyl trimethoxysilane and an appropriate amount of deionized water. The phytic acid and the hydrogen peroxide serve as main components, the phytic acid is subjected to silane coupling agent modification, then nano calcium carbonate modified through the benzimidazole and the other components are added for compatible application, the obtained antioxidant can be directly dissolved in water, the product is coated to the surface of brass and is not prone to falling off even after being subjected to repeated high temperature impact, the weldability is good, the corrosion resistant time is long, and the antioxidant and anti-discoloration capacity is high.

Owner:TIANCHANG RUNDA METAL ANTIRUST AUX

Seasoning for beef steak curried

The invention discloses a seasoning for beef steak curried. The seasoning comprises the following raw materials in parts by weight: 3-5 parts of starch, 1-2 parts of a dark soy sauce, 1-3 parts of curry powder, 1-2 parts of white granulated sugar, 0.3-0.9 part of table salt and 0.3-0.9 part of sodium glutamate. The beef steak curried made by using the seasoning for the beef steak curried, disclosed by the invention, is good in mouth feel, easy to cook, and long in antiseptic time; besides, a preservative used in the seasoning is natural extracts, healthy and safe and has a definite seasoning function.

Owner:上海珍馨化工科技有限公司

Anticorrosive metal primer

InactiveCN105440876APrevent surface discolorationHigh peel strengthAnti-corrosive paintsPolyester coatingsDiacetone alcoholCis-Butenedioic Acid

The invention discloses an anticorrosive metal primer. The anticorrosive metal primer is prepared from, by weight, 10-23 parts of amino resin, 14-42 parts of polyester resin, 10-18 parts of 1,2-propylene glycol-1-monobutyl ether, 11-28 parts of diethyl carbonate, 35-52 parts of 2,2-di(4-hydroxyphenyl)propane, 9-21 parts of cethyl trimethyl ammonium bromide, 13-27 parts of isoprene, 2-13 parts of ammonium stearate, 8-20 parts of triethyl acetocitrate, 5-10 parts of tetraethylenepentamine, 5-15 parts of maleic anhydride, 14-22 parts of diacetone alcohol, and 8-27 parts of ethyl alcohol. The paint prepared from the metal primer is environmentally friendly, free of toxicity, harmless to people, capable of being well combined with the metal primer and a finishing coat, high in water resistance, capable of preventing color change of a metal surface, improving the peel strength of a paintcoat and guaranteeing the anticorrosive effect, and long in anticorrosive time.

Owner:TONGLING MINGCHENG FOUNDRY

Steel bridge corrosion prevention technology

InactiveCN105332013AImprove the degree of industrialization of anti-corrosionImprove anti-corrosion performanceMolten spray coatingChromium freeZinc

The invention relates to the technical field of steel corrosion prevention and discloses a steel bridge corrosion prevention technology. Steel bridge components, chromium-free passivating fluid and antirust paint are included. The corrosion prevention technology comprises two steps, namely the overall corrosion prevention treatment and connection position corrosion prevention treatment; component overall corrosion prevention treatment is conducted before the components are connected, and after a steel bridge is connected, connection position corrosion prevention treatment is conducted; the component overall corrosion prevention treatment adopts the chromium-free passivating fluid electrogalvanizing method, and two times of electrogalvanizing treatment are conducted after dirt on the surface is cleaned up; the connection position corrosion prevention treatment adopts the thermal zinc spraying method, molten zinc is blown and adsorbed to the surface of the connection position after the dirt on the surface of the connection position is cleaned up, and pores are closed through the antirust paint. The steel bridge corrosion prevention technology is good in corrosion prevention effect, long in corrosion prevention time and high in industrial degree.

Owner:RENQIU YONGJI CONSTR & INSTALLATION ENG

Anti-rust undercoat of mine production machine

InactiveCN109161305AImprove adhesionDry fastAnti-corrosive paintsEpoxy resin coatingsDiacetone alcoholALUMINUM STEARATES

Owner:TONGLING MINGCHENG FOUNDRY

Treating technology for improving wood anti-corrosion property through cinnamyl aldehyde derivatives

ActiveCN107498667AImprove anti-corrosion performanceLong anticorrosion timePressure impregnationOpen tank impregnationSurface cleaningZinc

The invention discloses a treating technology for improving the wood anti-corrosion property through cinnamyl aldehyde derivatives and relates to the technical field of wood treatment. The cinnamyl aldehyde derivatives and deionized water are mixed to prepare a cinnamyl aldehyde derivative solution, then nanometer zinc oxide particles are added into the cinnamyl aldehyde derivative solution, and then through ultrasonic treatment, a pre-mixed solution is obtained; wood is soaked in the pre-mixed solution, under the normal temperature, soaking is conducted, then a binaphthol solution is added into the pre-mixed solution drop by drop, after drop-by-drop adding is completed, the pre-mixed solution and the wood are transferred into a vacuum reaction kettle, and vacuum soaking treatment is conducted; and then the wood is taken out, deionized water is adopted to conduct surface cleaning, and then natural draining is conducted. After the wood is treated through the treating technology, the remarkable inhibiting effect is achieved on fungi and mould.

Owner:阜南县中泰工艺品有限公司

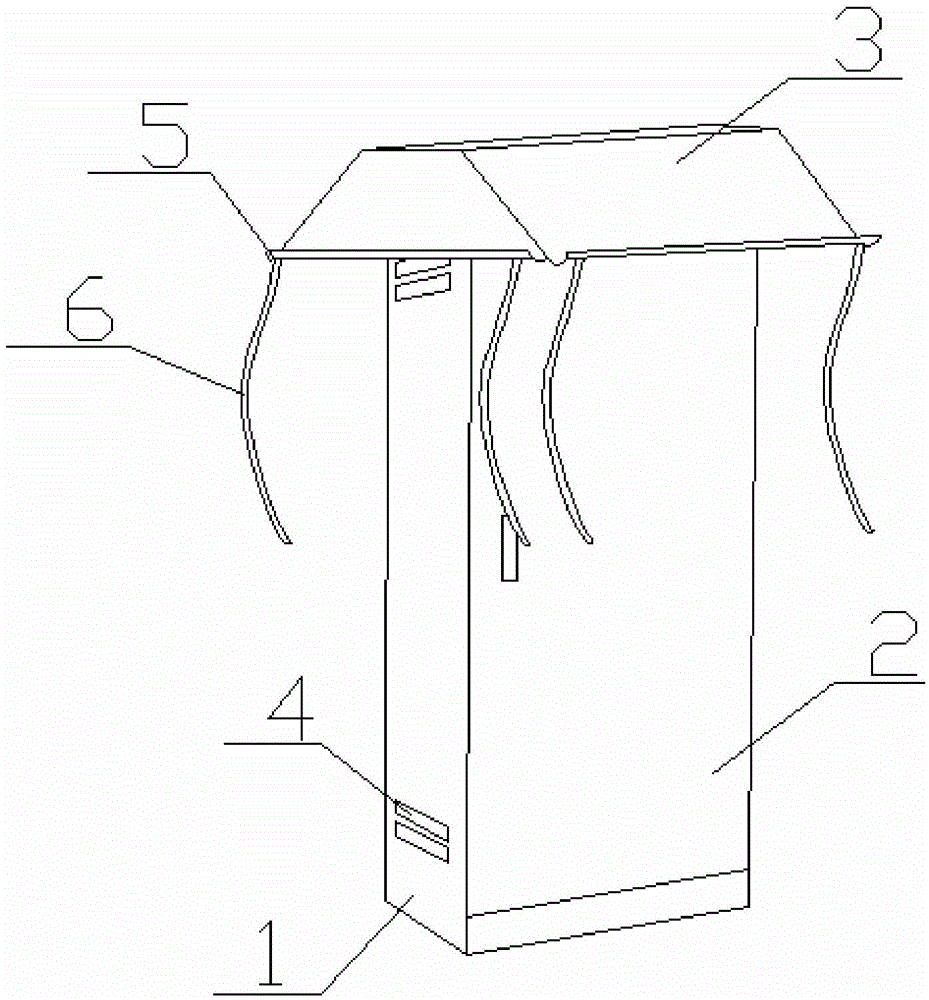

Outdoor high temperature-resisting power distribution box

InactiveCN104868377AAvoid enteringImprove applicabilitySubstation/switching arrangement cooling/ventilationSubstation/switching arrangement casingsStructural engineeringProtection layer

The invention discloses an outdoor high temperature-resisting power distribution box, which comprises a box body, and a box door connected onto the box body. The upper end of the box body is also provided with a rainproof cover; two sides of the box body are provided with vent holes; a protection layer is arranged outside the box body; a heat insulation board is arranged inside the box body; the rainproof cover comprises a rainproof cover body and a water guide groove arranged at the edge of the rainproof cover body, the rainproof cover body has a hollow ladder-shaped structure, the rainproof cover body is fixed above the box body, the water guide groove is arranged at the edge of the rainproof cover body, round holes are arranged at four corners of the rainproof cover body on the water guide groove, and hoses are arranged in the round holes; and the protection layer is a layer of high temperature-resisting coating material coating the surface of the box body. The outdoor high temperature-resisting power distribution box has the advantages that the structure is simple, high temperature can be resisted, waterproof performance and dustproof performance are good, the service life of the power distribution box is prolonged, normal operation of the power distribution box can be ensured, and the working efficiency is improved.

Owner:KINGSHORE NEW RESOURCES ELECTRIC JIANGSU

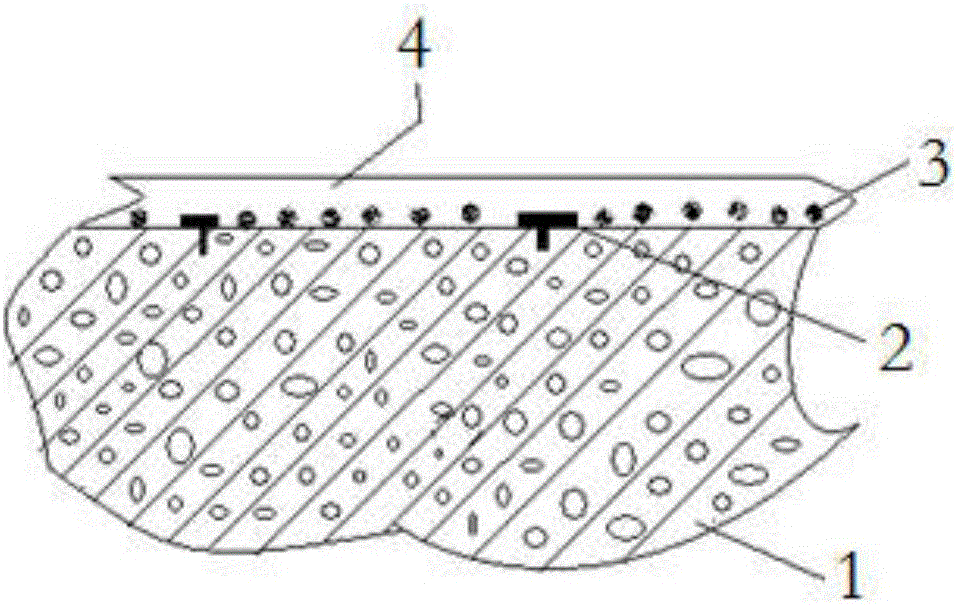

Anticorrosion cement profile and anticorrosion method of cement profile

InactiveCN105672500AUnique anti-corrosion structureFirmly attachedBuilding insulationsSeawaterMaterials science

The invention relates to an anticorrosion cement profile and an anticorrosion method of the cement profile. The anticorrosion cement profile comprises a cement piece; a supporting piece is fixed to the surface of the cement piece; a supporting layer is fixed to the supporting piece; then the supporting layer is coated with an anticorrosion material. According to the cement profile, an anticorrosion layer of the cement profile is not prone to falling off, the anticorrosion effect is better, the anticorrosion time is longer, and the cement penetration phenomenon and the situation that calcium and magnetism ions ooze out are prevented. The cement profile better facilitates anticorrosion of cement profiles located in seawater, and the problem that the salt content of seawater is high, and accordingly the cement profiles can be easily corroded is solved. According to the anticorrosion cement profile and the anticorrosion method of the cement profile, at normal temperature, in seawater, the anticorrosion life of the cement profile can be 25 years or above. The anticorrosion method is used in the production process of the cement profile and can also be used in the using process of the cement profile. The anticorrosion material can be used after being stirred, no hard blocks exist after stirring and mixing, and a uniform state is achieved.

Owner:叶元龙 +2

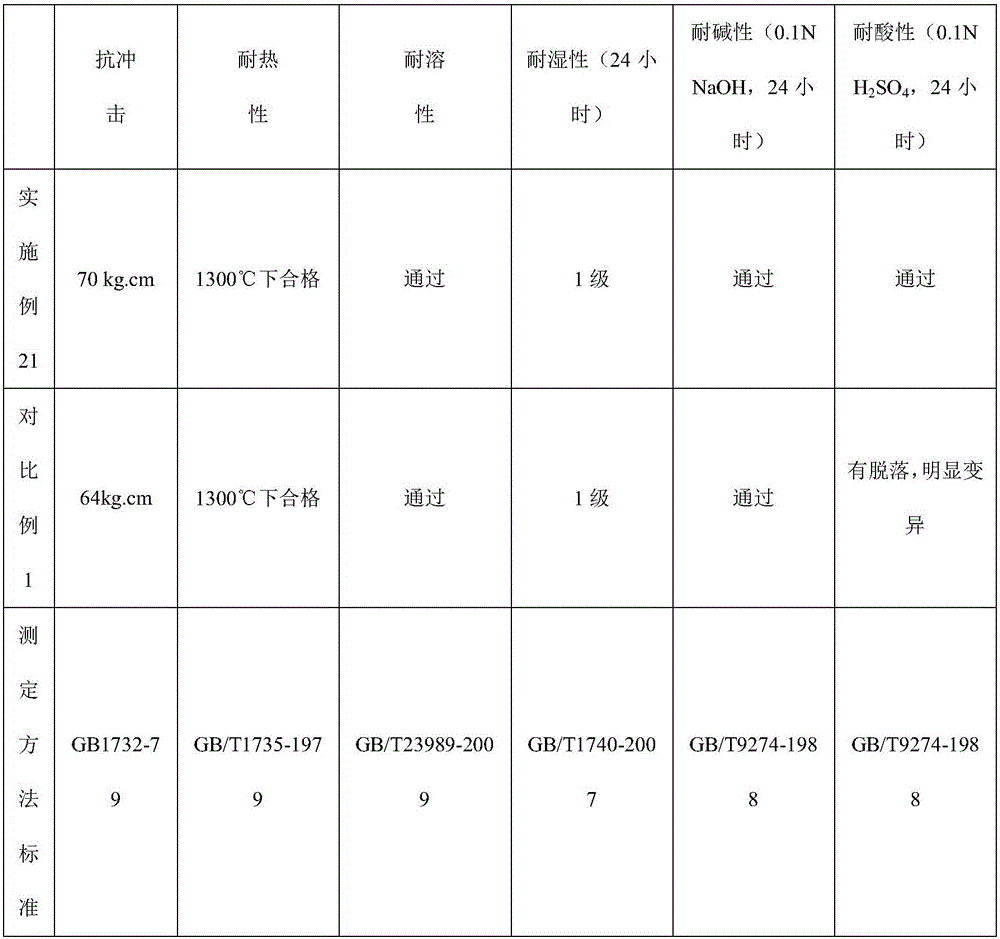

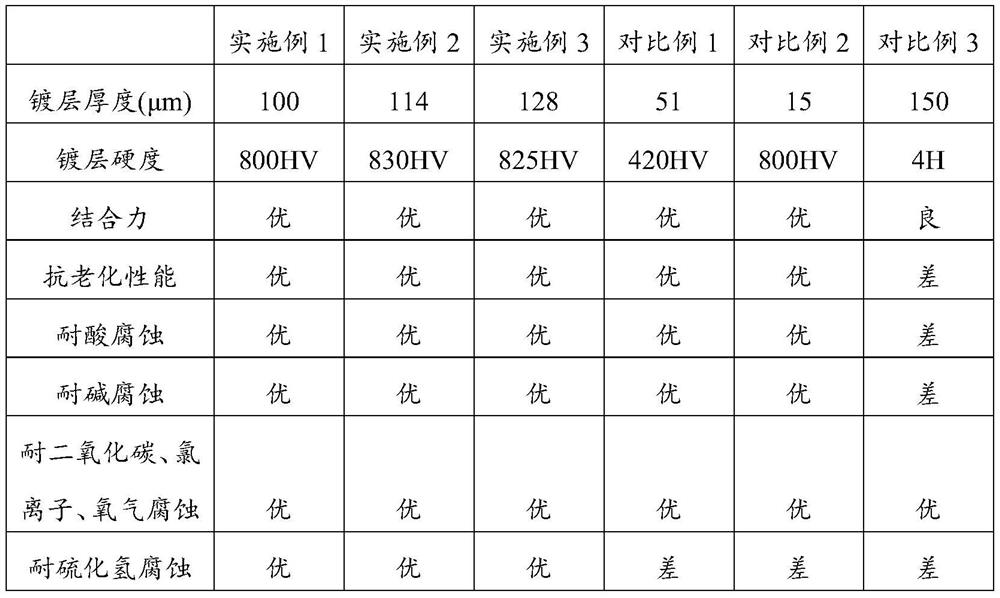

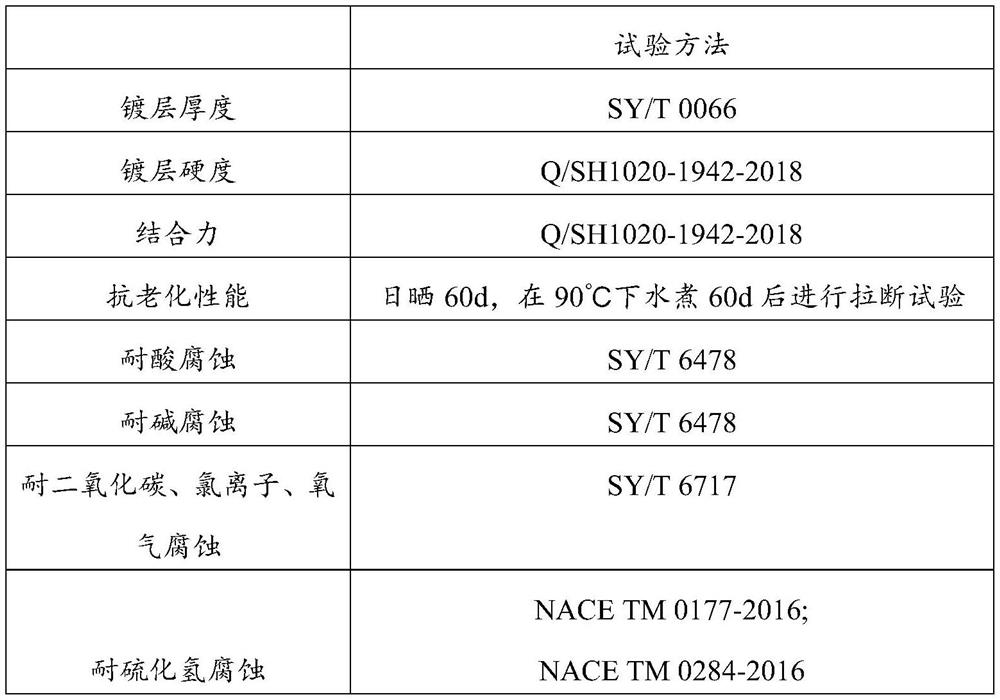

Tungsten-containing and sulfur-corrosion-resistant electroplating solution as well as electroplating method and application thereof

The invention discloses a tungsten-containing and sulfur-corrosion-resistant electroplating solution as well as an electroplating method and application of the tungsten-containing and sulfur-corrosion-resistant electroplating solution, and belongs to the technical field of corrosion prevention of oil field pipes. The tungsten-containing and sulfur-corrosion-resistant electroplating solution comprises an inner-layer electroplating solution, a middle-layer electroplating solution and an outer-layer electroplating solution, wherein the main materials of the inner layer and the middle layer comprise nickel sulfate, and main materials of the outer layer comprise nickel sulfate and sodium tungstate. Meanwhile, each layer of electroplating solution further comprises an additive. The tungsten-containing and sulfur-corrosion-resistant electroplating solution provided by the invention is used for carrying out three-layer electroplating on a pipe, all the components in each layer of electroplating solution are reasonably proportioned, so that when the prepared electroplating solution is used for electroplating, the thickness of a plating layer can be increased, meanwhile, the bonding force among all the layers is good, no leakage point exists, thus the corrosion resistance time is long, and the corrosion resistance to hydrogen sulfide is good.

Owner:山东音速石油产业技术研究院有限公司

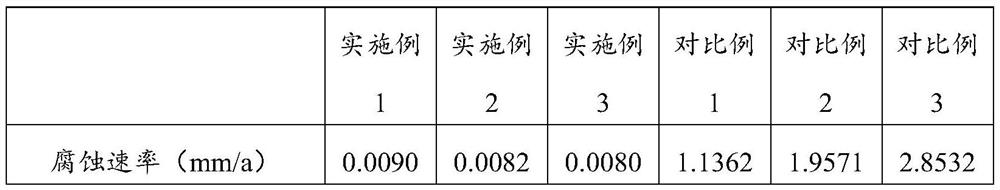

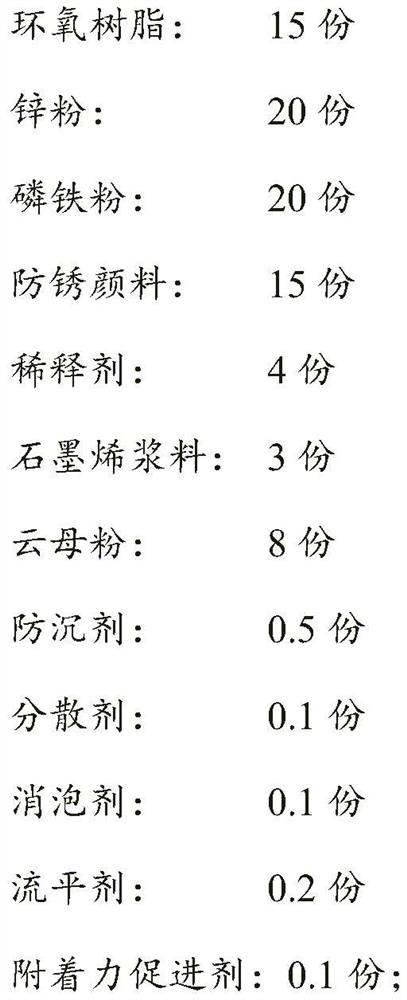

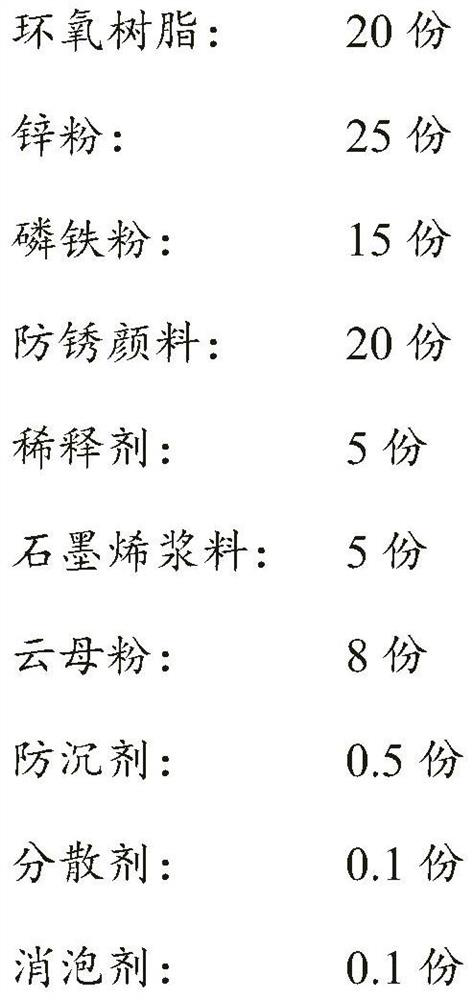

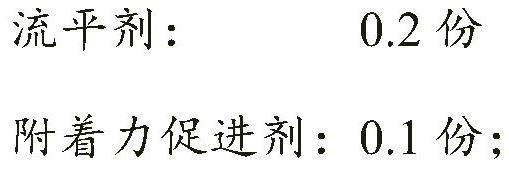

Anticorrosive paint as well as preparation method and application thereof

InactiveCN112680056AImprove anti-corrosion performanceIncrease profitGrapheneAnti-corrosive paintsEpoxyPolyamide

The invention belongs to the technical field of coatings, and discloses an anticorrosive paint as well as a preparation method and an application thereof. The anticorrosive paint comprises a component A and a component B. The component A comprises epoxy resin, zinc powder, an antirust pigment, graphene slurry, a filler and an assistant. The component B comprises modified polyamide and a diluent. By means of a cathode protection mechanism of zinc powder, the surface of the steel is prevented from being corroded; meanwhile, graphene is added into the paint, so that the permeation rate of a corrosive medium is reduced, and the corrosion resistance of the coating is improved; the graphene and the zinc powder are in lap joint to form a conductive path, the utilization rate of the zinc powder is increased, the use amount of the zinc powder can be greatly reduced, the film-forming property of the coating, the flexibility and adhesive force of the coating are improved, the salt spray resistance effect of the coating is enhanced, the corrosion resistance time of marine equipment can be prolonged when the coating is applied to the marine equipment, and the maintenance period and cost are reduced.

Owner:ZHUHAI FUDAN INNOVATION INST

Preparation method for PH-nano steel and iron corrosion inhibitor

The invention provides a preparation method for a PH-nano steel and iron corrosion inhibitor, which includes the following steps: (1) palm wax and sodium hydroxide are respectively prepared; the mixture of absolute ethyl alcohol and deionized water is prepared; first deionized water is then prepared; (2) the prepared palm wax is heated to melt until the palm wax is clear, and the liquid palm wax is poured into a first three-neck bottle; (3) the prepared sodium hydroxide is poured into the first deionized water until the sodium hydroxide is completely dissolved, and is then poured into the first three-neck bottle loaded with the liquid palm wax, and finally, the prepared mixture of absolute ethyl alcohol and deionized water is completely poured into the first three-neck bottle. The product prepared by the method has stable properties, good physicochemical properties and long anticorrosion time, and can resist high temperature, coating is thin, guns and cannons do not need to be cleaned before being used, and the product does not have adverse effects on the performance of the guns and the cannons after shooting.

Owner:长沙艾格防护新材料技术研发有限公司

Preparation method of chromium-free passivating agent for cold-rolled sheet surface passivation

InactiveCN111074256AImprove corrosion resistanceLow toxicityMetallic material coating processesChromium freeO-Phosphoric Acid

The invention relates to the technical field of cold-rolled sheet passivation, and particularly relates to a preparation method of a chromium-free passivating agent for cold-rolled sheet surface passivation. The preparation method can meet the environmental protection requirements, improve the corrosion resistance of a passivated cold-rolled sheet, prolong the corrosion resistance time of the passivated cold-rolled sheet and meet the gradually rising requirements of users. The preparation method comprises the steps of (1) dissolving, specifically, adding 100g / L of magnesium fluoride, 20g / L ofammonium tripolyphosphate, 20g / L of sodium fluosilicate, 20g / L of a coordination agent, 4-5g / L of a catalyst, 25g / L of nitric acid, 35g / L of phosphoric acid and 12g / L of calcium nitrate into water anduniformly mixing; (2) adjusting the pH value, specifically, adding hydrochloric acid to adjust the pH value of the solution to 2.0; (3) adding silicon dioxide, specifically, adding silicon dioxide accounting for 40-50% of the mass of the solution into the solution after pH adjustment, and uniformly stirring to obtain a mixed solution; and (4) adding a surfactant, specifically, adding 2g / L of a surfactant into the mixed solution, and uniformly mixing to obtain the chromium-free passivating agent.

Owner:CANGZHOU HUARUN CHEM

Environmentally-friendly preservative liquid for metals

InactiveCN104530969ALong anticorrosion timeLow costAnti-corrosive paintsAlginic acid coatingsAcetic acidEthylic acid

The invention relates to environmentally-friendly preservative liquid for metals. A raw material formula of the preservative liquid consists of the following components: a silane coupling agent, sodium alginate, rutin, tea saponin, water, isopropyl alcohol and an acetic acid buffer solution. The preservative liquid provided by the invention is long in corrosion protection time, wide in application range and low in cost and is green and environmentally friendly.

Owner:QINGDAO JIASHANG CREATIVE CULTURE

A kind of wood preservative treatment method

InactiveCN104441133BSolve problems that destroy the internal structure of woodReduce pollutionPressure impregnationMedicineCell membrane

The invention belongs to the field of wood preservative treatment, and particularly relates to a wood preservative treatment method. The wood preservative treatment method comprises the following steps of injecting purified water into wood cells by utilizing a pressure treatment tank, then permeating a preservative into the wood cells via the permeation effect of cell membranes, so that the wood has a long-time preservative effect. According to the invention, the wood cells are subjected to pressurization and water injection, and the preservative is injected via the permeation effect of the cell membranes, so that on one hand, the problem that the internal structure of the wood is damaged due to direct pressurization and injection of the preservative to the wood cells is solved, and on the other hand, the preservative is injected into the cells, so that the preservative time is prolonged, and good permeation property and high loss resistance are achieved. By adopting the method, even if the chemical preservative is used, the pollution to the environment by the preservative is greatly reduced.

Owner:ANHUI MENGFUJIA ARTS & CRAFTS

Preparation method for preparing preservative particles by tea dregs recycling

InactiveCN106071641ALong anticorrosion timeSimple preparation stepsFood preservationSolubilityWater soluble

The invention relates to a preparation method for preparing preservative particles by tea dregs recycling and belongs to the technical field of preservative particle preparation, in order to overcome the defect that preservatives prepared in the prior art are poor in water solubility, short in acting time and prone to air oxidation leading to inactivation. The method includes: dispersing waste tea dregs for extracting organics, concentrating and drying the organics prior to preparing active anticorrosive powder, subjecting the tea dregs to hydrolysis for preparing hydrogel, subjecting hydrogel and active anticorrosive powder to composite preparation, and then performing drying and grinding to prepare the slow-release preservative particles. The preservative particles have long-time effective preservative effect on food. Preservative time of the preservative particles is prolonged by 10-15%, acting temperature can reach 10-55 DEG C, preparation steps are simple, and the preservative particles are green, environment friendly, harmless to human beings and pollution free.

Owner:郭舒洋

Rice preservative

InactiveCN103535432ARaw materials are easy to getSimple methodEdible seed preservationBiotechnologySodium acetate

The invention discloses a rice preservative comprising the following components in parts by weight: 15-20 parts of calcium propionate, 5-10 parts of ethanol, 10-20 parts of hydrochloric acid lignin, 10-20 parts of lactic acid and 20-30 parts of sodium diacetate. The rice preservative disclosed by the invention has the advantages of easiness for obtaining raw materials, simple preparation method, low cost, convenience for use and operation, non toxicity, harmlessness to environment and people, good preservative effect, long preservative time and wide applicability.

Owner:占协琼

Anti-static water-based brass antioxidant with added conductive black and preparation method thereof

InactiveCN106756918AReduce corrosionPrevent infiltrationMetallic material coating processesWater basedAntioxidant

The invention discloses an anti-static water-based brass antioxidant with added conductive black. Each liter of the antioxidant is prepared from, by weight, 15-17 parts of 50wt.% phytic acid, 24-26 parts of 30wt.% hydrogen peroxide, 11-14 parts of polyethylene glycol, 3-5 parts of sodium hexametaphosphate, 4-5 parts of the conductive black, 6-8 parts of ethyl acetate, 1.4-1.8 parts of sorbitan monooleate, 0.3-0.5 part of lauryl sodium sulfate, 2-4 parts of diglycolamine, 4-6 parts of malic acid, 2.6-2.8 parts of vinyl trimethoxy silane, and a proper amount of deionized water. The phytic acid and the hydrogen peroxide are used as main components, after being modified by a silane coupling agent, the phytic acid is mixed with the modified conductive black and other components, and the obtained antioxidant is resistant to high temperature and static; and the attachment force is high and the anti-rust effect is good when the antioxidant is smeared on the surface of brass, the corrosion resistant time is long, and the color changing preventing performance is good.

Owner:TIANCHANG RUNDA METAL ANTIRUST AUX

Surface treatment technology of T-shaped component for ship

InactiveCN112024341AAchieving seawater corrosion resistance and other characteristicsAvoid affecting the quality of anti-corrosion treatmentPretreated surfacesSpecial surfacesPre treatmentSurface processing

The invention belongs to the field of surface treatment of T-shaped components of ships, and particularly discloses a surface treatment technology for a T-shaped component of a ship. The technology includes the following steps that pretreatment of the surface of the T-shaped component is performed, and pretreatment includes degreasing treatment, surface refining treatment and rusting treatment; protective film treatment is performed and includes spraying of a protective inner layer film and coating of the protective inner layer film; anti-corrosion liquid treatment is performed, specifically,the treated component is immersed in an anti-corrosion tank containing the anti-corrosion liquid, and the temperature of the anti-corrosion tank is kept at 20-20 DEG C for 5-20 min; and after the component treated by the anti-corrosion liquid is dried, anti-corrosion finish paint is sprayed to the surface of the component, and surface treatment is completed. According to the technology, the T-shaped component is subjected to surface pretreatment, protective film treatment and anti-corrosion liquid treatment, so that multiple layers of compact protective films are formed on the surface of the component, the corrosion prevention time is prolonged, the relatively good corrosion prevention purpose is achieved, and the characteristics of seawater corrosion resistance and the like of the T-shaped component are achieved.

Owner:ZHONGCHUAN NO 9 DESIGN & RES INST

Anticorrosion bridge stand

InactiveCN105281265AImprove corrosion resistanceStrong anti-salt spray performanceElectrical apparatusZinc borateFilling materials

The invention relates to an anticorrosion bridge stand. A layer of protection layer is coated outside the bridge stand. A layer of sheath wraps outside the protection layer. The composition of the protection layer includes 15-25 parts of zinc borate modified phenolic resin, 7-9 parts of diatomite, 4-6 parts of filling material, 2-3 parts of dispersants, 0.5-1.0 part of corrosion removers, 5-15 parts of silicon dioxide, 5-20 parts of hydroquinone, 40-80 parts of water and 3-4 parts of composite rare earth. The anticorrosion bridge stand has relatively high moisture resistance and corrosion resistance so that the service life of the bridge stand can be increased, and safety and utilization rate can be increased.

Owner:江苏宇恒电气有限公司

Preservative treatment method for furniture wood

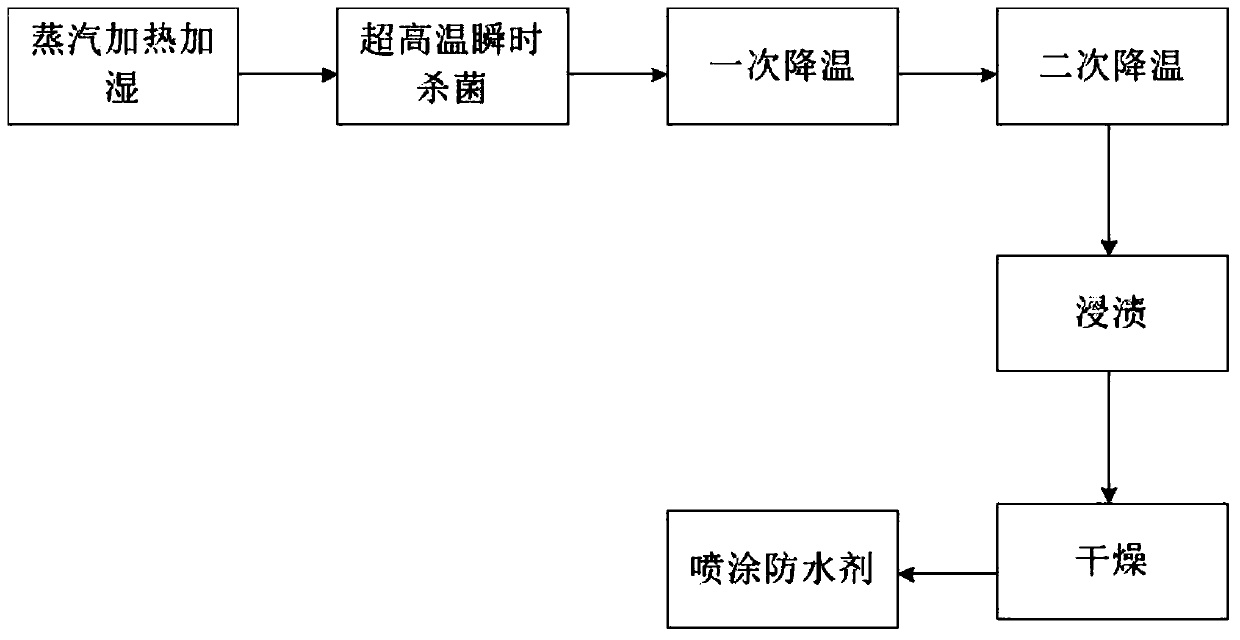

InactiveCN111002412ALong anticorrosion timeExtended service lifeWood treatment detailsThermal wood treatmentMicroorganismPreservative

The invention discloses a preservative treatment method for furniture wood. The preservative treatment method comprises the following steps of steam heating and humidifying, ultrahigh-temperature instantaneous sterilization, primary cooling, secondary cooling, dipping, drying and spraying of a waterproof agent. The wood is sterilized in an ultrahigh-temperature instantaneous sterilization mode, the inner layer and the outer surface of the wood can be rapidly sterilized, meanwhile, the fiber structure in the wood cannot be damaged, the wood is soaked in a preservative after sterilization is completed, microorganisms cannot grow and reproduce in the wood, the wood preservative effect is enhanced, and the service life of the wood is prolonged.

Owner:福州立雅家具有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com