Anticorrosion cement profile and anticorrosion method of cement profile

An anti-corrosion material and cement technology, which is applied in the anti-corrosion field of anti-corrosion cement profiles and cement profiles, can solve problems such as affecting the anti-corrosion effect and the cement surface is easy to fall off, and achieve the effect of preventing cement penetration, good anti-corrosion effect and long anti-corrosion time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

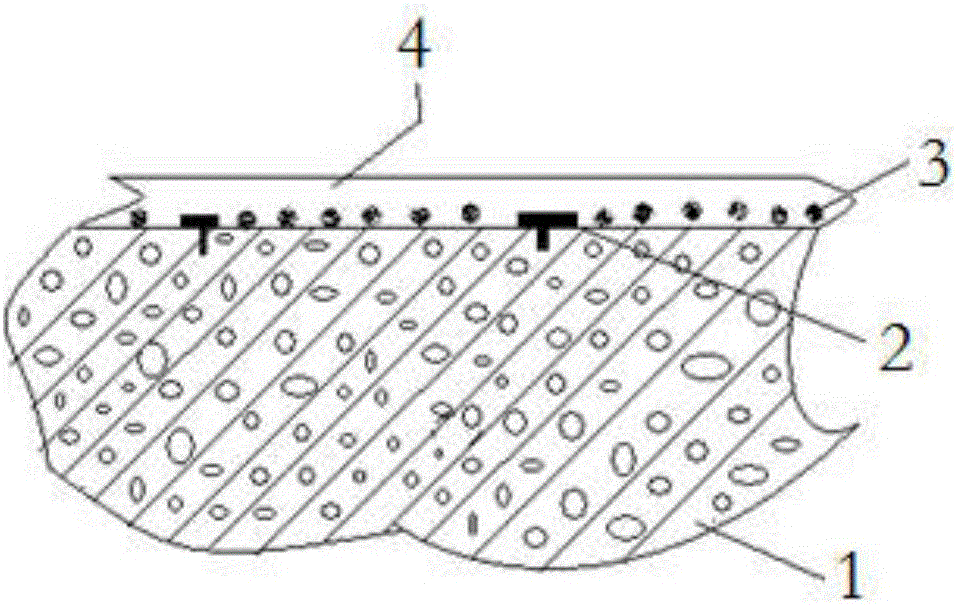

[0055] Such as figure 1 As shown, a kind of anti-corrosion cement profile comprises a cement part 1, a support part 2 is fixed on the surface of the cement part 1, and a support layer 3 is fixed on the support part 2, and then coated on the support layer 3 Anti-corrosion materials4.

Embodiment 2

[0057] This embodiment is based on Embodiment 1: the anti-corrosion material wraps the support member and the supporting layer.

Embodiment 3

[0059] This embodiment is based on Embodiment 2: the anti-corrosion material completely covers the surface of the cement part.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com