Technology of anti-corrosion spraying on surface of tower cylinder

An anti-corrosion spraying and tower tube technology, which is applied to the surface coating liquid device, pre-treatment surface, coating and other directions, can solve the problems of short anti-corrosion time, coating failure, soaking, etc., to prevent local corrosion and anti-corrosion time Long, high-quality spray results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

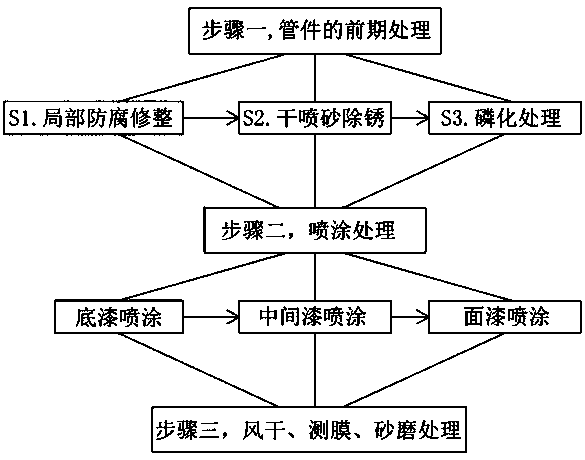

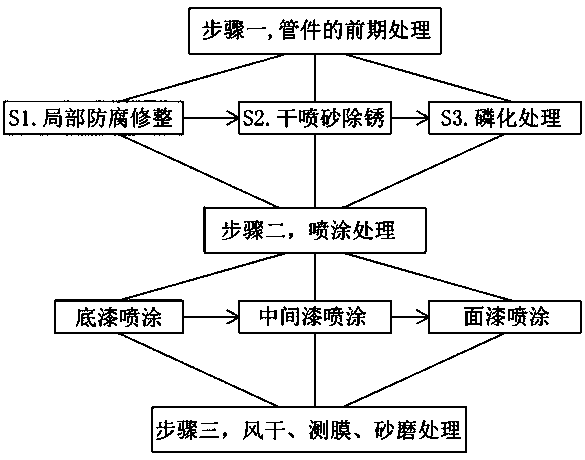

[0019] An anti-corrosion spraying process on the surface of a tower tube, comprising the following steps:

[0020] Step 1, pre-treatment of tower tube spraying: S1. Partial anti-corrosion repair: The assembled platform should be removed and anti-corrosion separately, and the remaining detachable accessories should be hot-dip galvanized for anti-corrosion, and flashes and burrs must be trimmed after hot-dip galvanizing; S2. Sand blasting and derusting: Use the high-pressure and powerful steel sand in the compressed air of the drying and impurity removal equipment to spray through the alloy nozzle, so that the tower can form a rough surface, and the basic surface roughness is 40um. The compressed air used for dry sandblasting It must be dry, and the sand material must be angular, clean, dry, and no oil stains are allowed. The average particle size of soluble salt free matter and feldspar is 0.5mm; ensure that the steel surface after sandblasting is free of visible grease, dirt, r...

Embodiment 2

[0029] An anti-corrosion spraying process on the surface of a tower tube, comprising the following steps:

[0030] Step 1, pre-treatment of tower tube spraying: S1. Partial anti-corrosion repair: The assembled platform should be removed and anti-corrosion separately, and the remaining detachable accessories should be hot-dip galvanized for anti-corrosion, and flashes and burrs must be trimmed after hot-dip galvanizing; S2. Sand blasting and derusting: Use the high-pressure and powerful steel grit in the compressed air of the drying and impurity removal equipment to spray through the alloy nozzle to make the tower form a rough surface. The basic surface roughness is 50um. The compressed air used for dry sandblasting It must be dry, and the sand material must be angular, clean, dry, and no oil stains are allowed. The average particle size of soluble salt free matter and feldspar is 0.6mm; ensure that the steel surface after sandblasting is free from visible grease, dirt, rust and...

Embodiment 3

[0039] An anti-corrosion spraying process on the surface of a tower tube, comprising the following steps:

[0040] Step 1, pre-treatment of tower tube spraying: S1. Partial anti-corrosion repair: The assembled platform should be removed and anti-corrosion separately, and the remaining detachable accessories should be hot-dip galvanized for anti-corrosion, and flashes and burrs must be trimmed after hot-dip galvanizing; S2. Sandblasting and derusting: Use the high-pressure and powerful steel grit in the compressed air of the drying and impurity removal equipment to spray through the alloy nozzle to make the tower tube form a rough surface, and the basic surface roughness is between 60um, which is used for dry sandblasting The compressed air must be dry, and the sand material must be angular, clean, dry, and no oil stains are allowed. The free matter of soluble salts and feldspar particle size are 0.8mm; ensure that the steel surface after sandblasting has no visible grease, dirt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com