exhaust system

A technology of exhaust system and exhaust pipe, which is applied in the direction of exhaust devices, gas chambers, gas channels, etc., and can solve the problems of expensive energy consumption and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

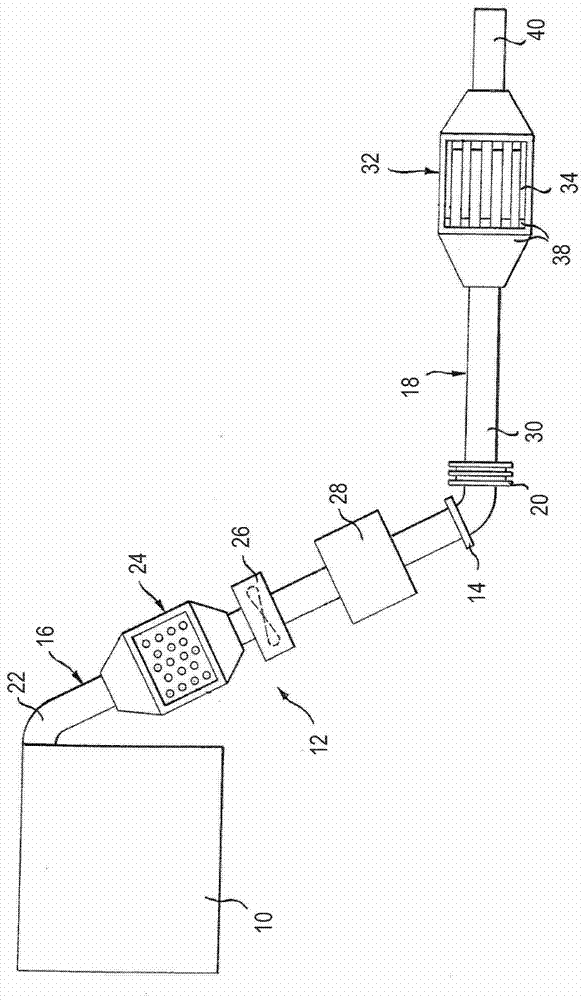

[0038] As an example, figure 1 An internal combustion engine 10 of a motor vehicle and a downstream exhaust system 12 are shown. The exhaust system 12 has a manifold section 16 extending as far as the flange 14 and a bottom section 18 adjoining the manifold section 16 downstream, the manifold section 16 and the bottom section 18 being connected to each other by a vibration decoupling device 20 .

[0039] The internal combustion engine 10 is adjoined by an exhaust pipe having a first pipe section 22 which leads to a particle receiving accumulator 24 having an oxidation catalytic converter.

[0040] Immediately downstream of the particulate receiving accumulator 24 , a turbocharger 26 is disposed in the manifold section 16 . Alternatively, the location of the particle receiving accumulator 24 and the location of the turbocharger 26 may also be interchanged. Also disposed in manifold section 16 , and more particularly downstream of particulate receiving accumulator 24 and turboch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com