Coating method for internally coating pipe with clinkering epoxy graphene powder

A technology of graphene powder and sintered epoxy, which is applied to the device, coating, pretreatment surface and other directions of coating liquid on the surface. Demand, the inner wall of buried metal pipelines are not very good in corrosion resistance, etc., to achieve the effects of easy control of coating quality, good chemical resistance, and excellent impact resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

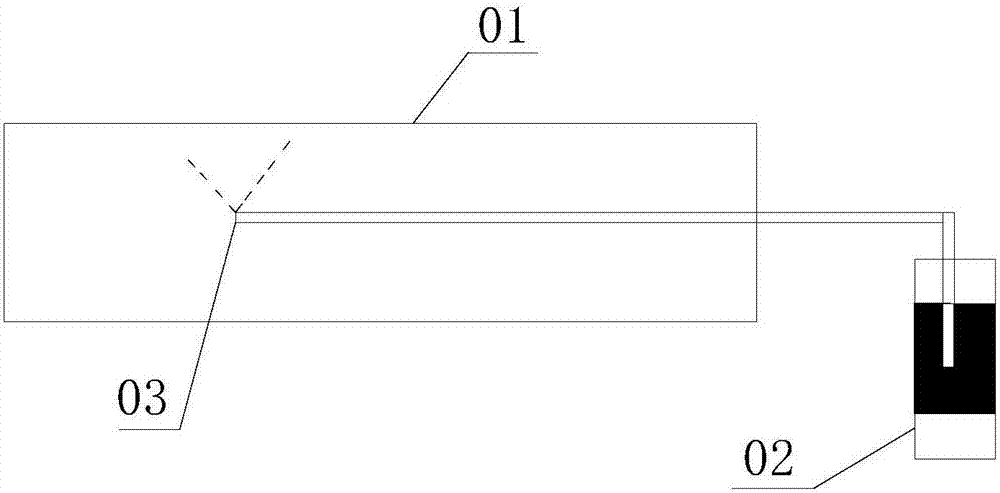

[0032] refer to figure 1 , a method for coating the inside of a pipeline with fused-bonded graphene epoxy powder, using an internal spraying method, is suitable for coating the inner wall of a pipeline with a relatively large aperture, and specifically includes the following steps:

[0033] (1) Preheat the steel pipe 01 to remove surface impurities and loosen scale.

[0034] (2) The internal sand blasting treatment process is adopted to make the steel pipe reach a metallic white color, and the anchor pattern controls the depth

[0035] Control it at 45-95um, and then remove the dust on the surface.

[0036] (3) The surface-treated steel pipe 01 is uniformly heated by a non-polluting heat source, preferably using an intermediate frequency coil to heat the steel pipe 01. The heating temperature can be adjusted according to the production speed, the thickness of the pipe wall, and the desired gelling and curing time of the coating. Control it between 280-470°C, preferably 350°C...

Embodiment 2

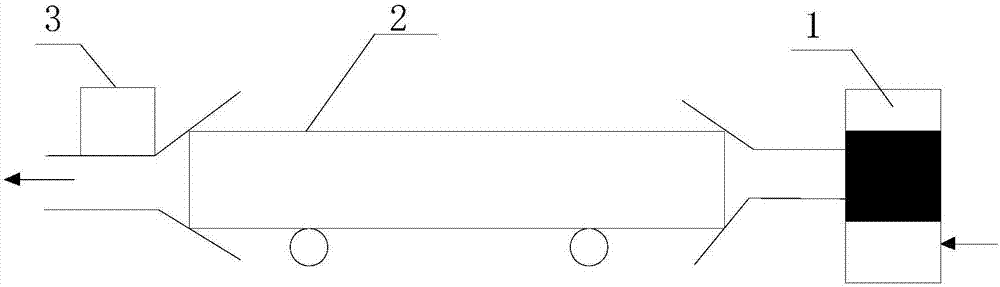

[0042] see figure 2 , a method for coating the interior of a pipeline with fused-bonded graphene epoxy powder, adopts a vacuum suction coating method, and is used for coating the inner walls of smaller-diameter pipelines and elbows, specifically comprising the following steps:

[0043] (1) preheating pipeline 2, remove surface debris, loose scale;

[0044](2) Adopt the internal sand blasting treatment process to make the steel pipe reach the metallic white color, control the depth of the anchor pattern at 45-95um, and then remove the dust on the surface;

[0045] (3) The surface-treated steel pipe is uniformly heated by a non-polluting heat source and controlled between 280-470°C;

[0046] (4) Vacuum suction coating method is adopted to make compressed air enter the pipe 2 from one side through the fluidized bed 1. After the powder is mixed with the air, it melts and adheres to the surface of the pipe wall when it contacts with the high-temperature pipe wall, and the pipe 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| curing time | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com