Anticorrosive paint as well as preparation method and application thereof

A technology of anti-corrosion coatings and anti-rust pigments, applied in the field of coatings, can solve problems such as short service life, poor salt spray resistance, and poor environmental adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A kind of anticorrosion coating, comprises following component A and component B,

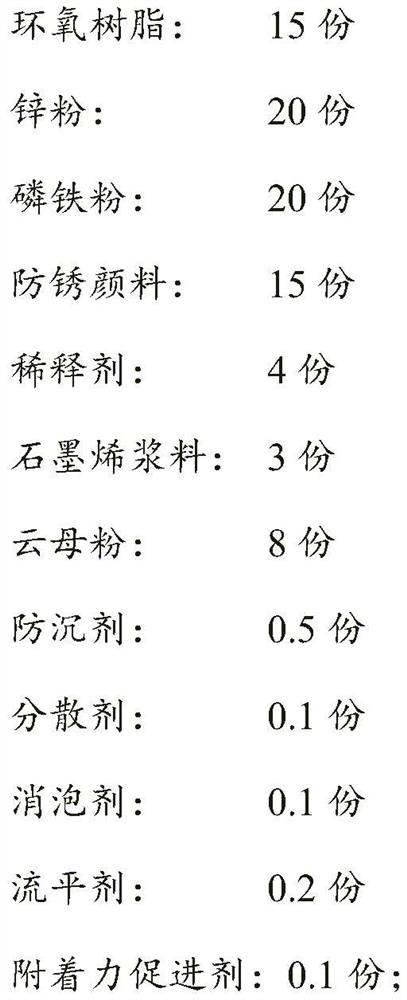

[0041] Wherein, component A raw material weight composition is as follows:

[0042]

[0043] Wherein, the graphene slurry is prepared according to the following process: first, 15 g of pyrrole and 120 g of ferric chloride are dissolved in 800 ml of water, and then the solution is reacted at 90° C. for 24 h to generate a carbon-containing polymer (polypyrrole), and then The reacted solution was cooled with liquid nitrogen and dried in a lyophilizer; then the dried powder was placed in a tube furnace and heated to 900°C for 1 hour in a nitrogen atmosphere at a heating rate of 5°C / min. After natural cooling, take out the solid powder; then disperse the powder in dilute sulfuric acid at 60°C and stir to remove iron particles, then filter and freeze-dry to obtain graphene. Finally, add xylene and n-butanol in sequence in the container and stir evenly, then add graphene while stirring, the...

Embodiment 2

[0054] A kind of anticorrosion coating, comprises following component A and component B,

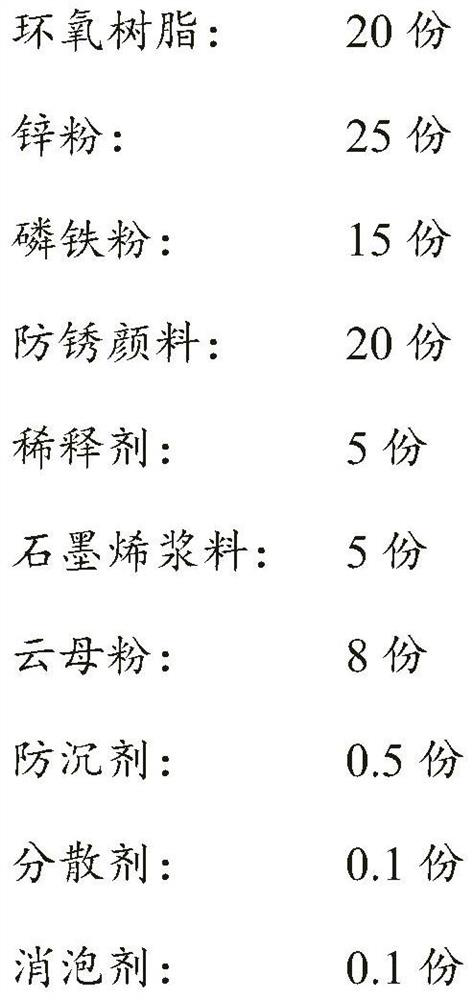

[0055] Wherein, component A raw material weight composition is as follows:

[0056]

[0057]

[0058] Wherein, the graphene slurry is prepared according to the following process: first, 15 g of pyrrole and 120 g of ferric chloride are dissolved in 800 ml of water, and then the solution is reacted at 90° C. for 24 h to generate a carbon-containing polymer (polypyrrole), and then The reacted solution was cooled with liquid nitrogen and dried in a lyophilizer; then the dried powder was placed in a tube furnace and heated to 900°C for 1 hour in a nitrogen atmosphere at a heating rate of 5°C / min. After natural cooling, take out the solid powder; then disperse the powder in dilute sulfuric acid at 60°C and stir to remove iron particles, then filter and freeze-dry to obtain graphene. Finally, add xylene and n-butanol in sequence in the container and stir evenly, then add graphene while s...

Embodiment 3

[0069] A kind of anticorrosion coating, comprises following component A and component B,

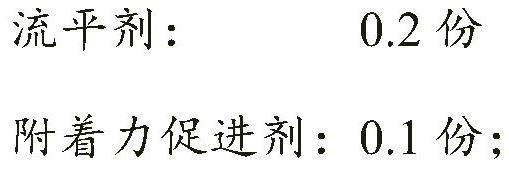

[0070] Wherein, component A raw material weight composition is as follows:

[0071]

[0072]

[0073] Wherein, the graphene slurry is prepared according to the following process: first, 15 g of pyrrole and 120 g of ferric chloride are dissolved in 800 ml of water, and then the solution is reacted at 90° C. for 24 h to generate a carbon-containing polymer (polypyrrole), and then The reacted solution was cooled with liquid nitrogen and dried in a lyophilizer; then the dried powder was placed in a tube furnace and heated to 900°C for 1 hour in a nitrogen atmosphere at a heating rate of 5°C / min. After natural cooling, take out the solid powder; then disperse the powder in dilute sulfuric acid at 60°C and stir to remove iron particles, then filter and freeze-dry to obtain graphene. Finally, add xylene and n-butanol in sequence in the container and stir evenly, then add graphene while s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com