Tungsten-containing and sulfur-corrosion-resistant electroplating solution as well as electroplating method and application thereof

An electroplating solution and sulfur corrosion technology, applied in the sulfur-resistant electroplating solution and the tungsten-containing field, it can solve the problems of coating peeling off and short corrosion resistance time, and achieve the effect of increasing the thickness of the coating, improving the compactness and improving the overall anti-corrosion performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

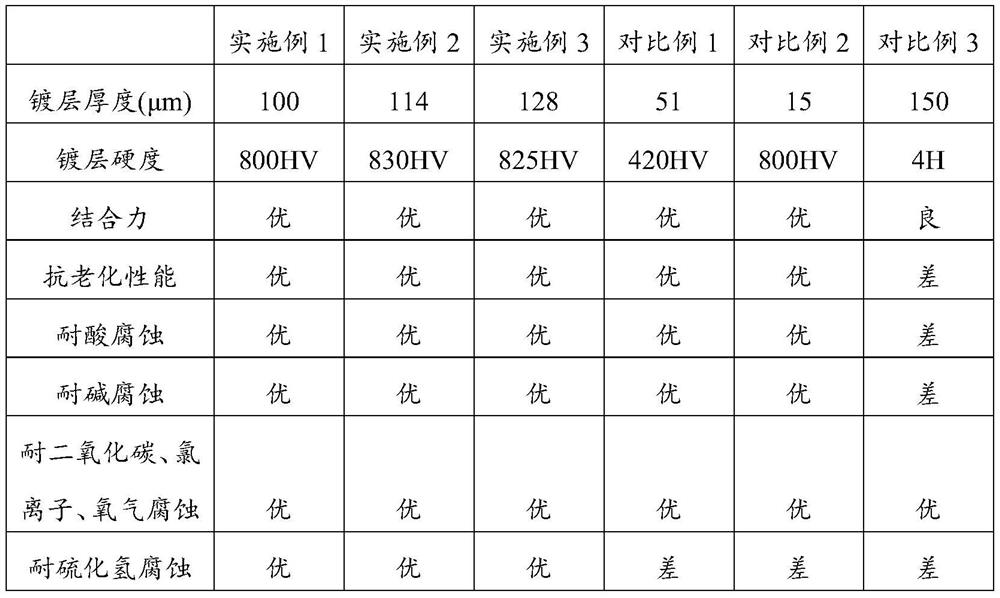

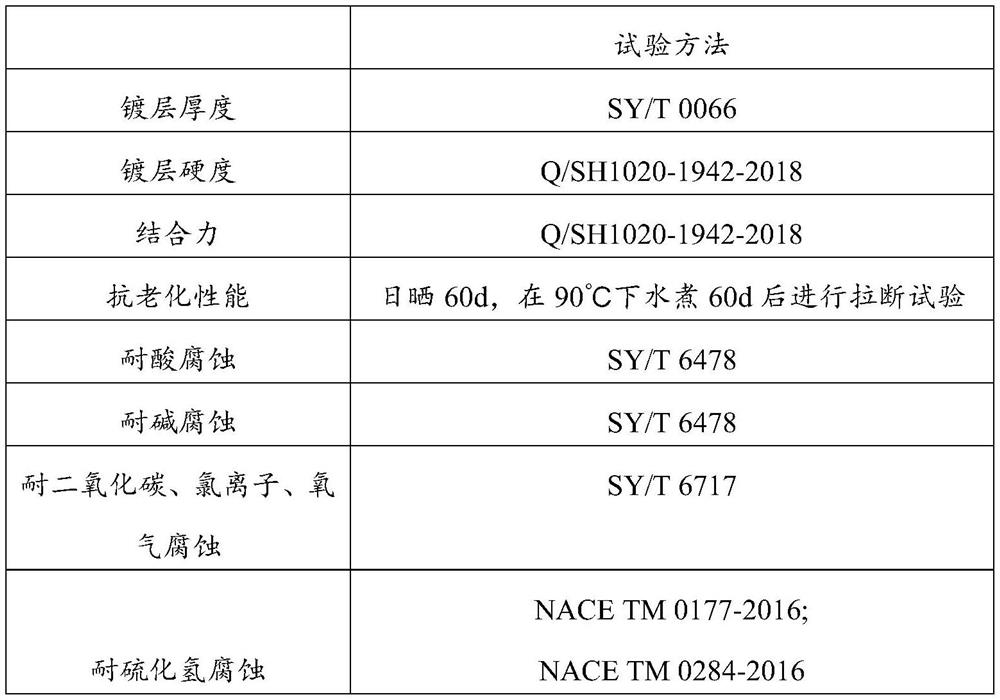

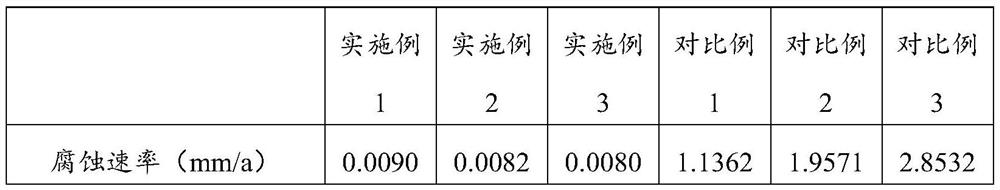

Examples

Embodiment 1

[0070] The pipe to be electroplated (material: J55N, model: ) for cleaning. After cleaning, degrease at a high temperature of 450°C for 3 hours, and then use quartz sand to derust the inner and outer walls of the pipe to obtain a pretreated pipe.

[0071] The pretreated pipe is subjected to inner layer electroplating, (inner layer main materials: 1000 parts of water, 270 parts of nickel sulfate and 50 parts of boric acid; 1000 parts of inner layer additive water, 0.3 parts of 4-hydroxybenzenesulfonamide, 0.6 parts of sodium benzoate, o 4 parts of methyl salicylaldehyde and 2.5 parts of sodium lauryl sulfate, the addition amount of the inner layer additive is 80ml / A·h; the addition amount of iron remover is 30ml / A·h).

[0072]The treatment conditions for inner layer electroplating are: temperature 60°C, pH 3.5, current 6.0A / dm 2 , the treatment time is 50min, and the inner plating solution is continuously filtered. After the electroplating was completed, the thickness of the...

Embodiment 2

[0077] The pipe to be electroplated (material: J55N, model: ) for cleaning, after cleaning, degrease at a high temperature of 350°C for 5 hours, and then use quartz sand to derust the inner and outer walls of the pipe to obtain a pretreated pipe.

[0078] The pretreated pipe is subjected to inner layer electroplating, (inner layer main materials: 1000 parts of water, 330 parts of nickel sulfate and 30 parts of boric acid; 1000 parts of inner layer additive water, 0.5 parts of m-aminobenzenesulfonamide, 0.4 parts of sodium benzoate, 6 parts of salicylaldehyde and 1.5 parts of sodium lauryl sulfate, the addition amount of the inner layer additive is 40ml / A·h; the addition amount of iron remover is 80ml / A·h).

[0079] The treatment conditions for inner layer electroplating are: temperature 50°C, pH 5, current 2.0A / dm 2 , the treatment time is 70min, and the inner plating solution is continuously filtered. After the electroplating was completed, the thickness of the inner layer...

Embodiment 3

[0083] The pipe to be electroplated (material: J55N, model: ) for cleaning, after cleaning, degrease at 400°C for 4 hours at high temperature, and then use quartz sand to derust the inner and outer walls of the pipe to obtain a pretreated pipe.

[0084] The pretreated pipe is subjected to inner layer electroplating, (inner layer main materials: 1000 parts of water, 300 parts of nickel sulfate and 40 parts of boric acid; inner layer additives: 1000 parts of water, 0.4 parts of m-aminobenzenesulfonamide, 0.5 parts of sodium benzoate, ortho 5 parts of methyl salicylaldehyde and 2 parts of sodium lauryl sulfate, the addition amount of inner layer additive is 60ml / A·h; the addition amount of iron remover is 50ml / A·h).

[0085] The treatment conditions for inner layer electroplating are: temperature 55°C, pH 4, current 4.0A / dm 2 , the treatment time is 60min, and the inner plating solution is continuously filtered. After the electroplating was completed, the thickness of the inne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com