Preservative treatment method for furniture wood

A technology for preservative treatment and wood, applied in wood treatment, wood heat treatment, wood treatment details, etc., can solve the problems of wood perishability, wood corrosion, inability to completely eliminate harmful microorganisms, etc., to extend service life and prolong anticorrosion time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

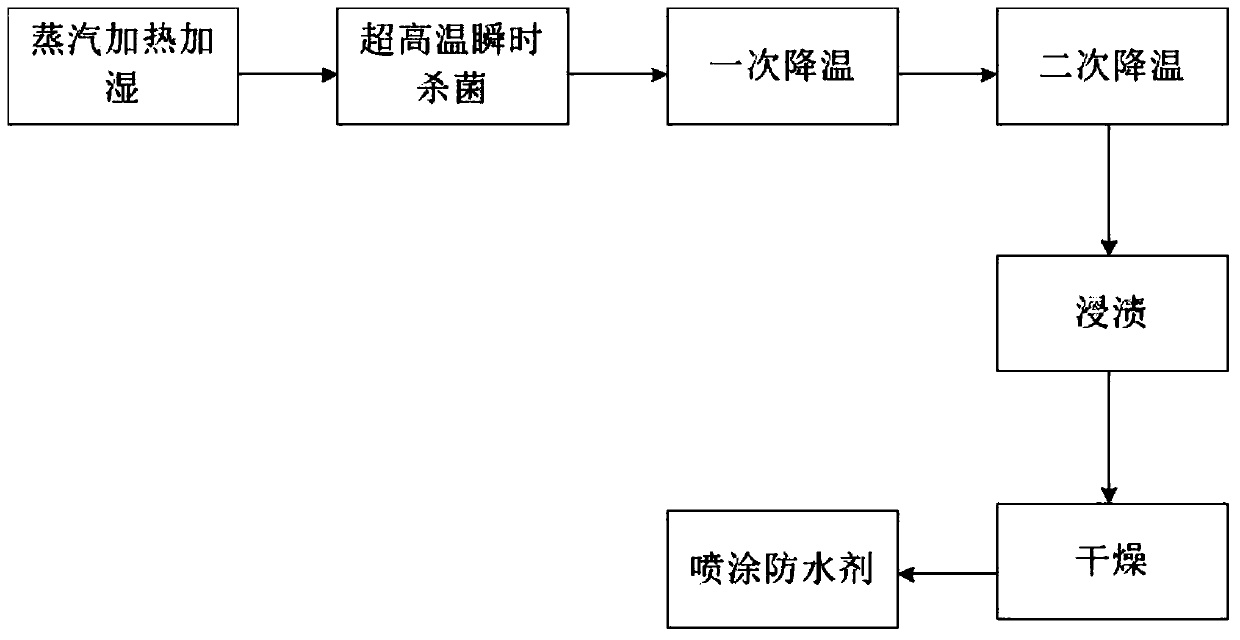

[0044] Please refer to figure 1 , a kind of anticorrosion treatment method of furniture wood, comprises the following steps:

[0045] a1: Steam heating and humidification: Use steam at a temperature of 30°C to heat and humidify the wood in a closed container for 45 minutes;

[0046] a2: Ultra-high temperature instant sterilization: put the wood in a sealed tank, heat the inside of the sealed tank, seal the sealed tank after heating, and use ultra-high temperature steam to sterilize, the temperature is 130 ° C, the time is 7s, and the pressure is 0.14 MPa;

[0047] a3: One-time cooling: use humid air with a temperature of 60°C and a humidity of 13% to cool the wood once for 15 minutes;

[0048] a4: Secondary cooling: use humid air with a temperature of 20°C and a humidity of 11% to flow on the surface of the wood, and perform secondary cooling on the wood for 15 minutes;

[0049] a5: Impregnation: put the wood into the treatment tank, keep a negative pressure of 0.11Mpa under...

Embodiment 2

[0066] Please refer to figure 1 , a kind of anticorrosion treatment method of furniture wood, comprises the following steps:

[0067] a1: Steam heating and humidification: Use steam at a temperature of 50°C to heat and humidify the wood in an airtight container for 30 minutes;

[0068] a2: Ultra-high temperature instant sterilization: put the wood in a sealed tank, heat the inside of the sealed tank, seal the sealed tank after heating, and use ultra-high temperature steam to sterilize, the temperature is 150 ° C, the time is 4s, and the pressure is 0.13 MPa;

[0069] a3: One-time cooling: use humid air with a temperature of 70°C and a humidity of 14% to cool the wood once for 10 minutes;

[0070] a4: Secondary cooling: Use humid air with a temperature of 25°C and a humidity of 12% to flow on the surface of the wood, and perform secondary cooling on the wood for 10 minutes;

[0071] a5: Impregnation: put the wood into the treatment tank, keep a negative pressure of 0.11Mpa un...

Embodiment 3

[0090] Please refer to figure 1 , a kind of anticorrosion treatment method of furniture wood, comprises the following steps:

[0091] a1: Steam heating and humidification: Use steam at a temperature of 35°C to heat and humidify the wood in a closed container for 40 minutes;

[0092] a2: Ultra-high temperature instant sterilization: put the wood in a sealed tank, heat the inside of the sealed tank, seal the sealed tank after heating, and use ultra-high temperature steam to sterilize, the temperature is 140 ° C, the time is 5s, and the pressure is 0.135 MPa;

[0093] a3: One-time cooling: use humid air with a temperature of 65°C and a humidity of 13.5% to cool the wood once for 13 minutes;

[0094] a4: Secondary cooling: Use humid air with a temperature of 22.5°C and a humidity of 11.5% to flow on the surface of the wood, and perform secondary cooling on the wood for 13 minutes;

[0095] a5: Impregnation: put the wood into the treatment tank, keep a negative pressure of 0.11Mp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com