Integrally-cast crossbeam with air storage function of air suspension frame

A technology of integral casting and air suspension, applied in the substructure, transportation and packaging, vehicle parts, etc., can solve the high problems affecting the connection, difficult layout, and relatively high precision requirements of components, reducing connection processing and reducing processing accuracy. , The effect of improving the sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following examples can enable those skilled in the art to understand the present invention more comprehensively, but the present invention is not limited to the scope of the described examples.

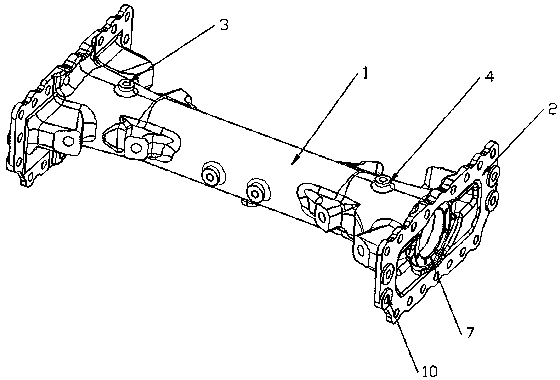

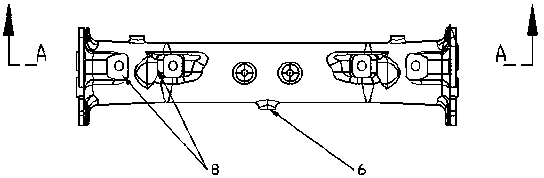

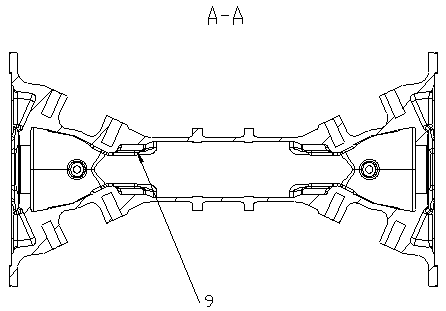

[0028] Such as Figure 1-Figure 4 Shown is an integrally cast air suspension beam with air storage function, which is used to connect the left and right longitudinal beams of the vehicle frame.

[0029] beams include

[0030] A beam main body, the beam body is integrally cast from a beam tube body 1 and a pair of longitudinal beam connecting flanges 2 symmetrically arranged at both ends of the beam tube body 1, and the outer wall of the beam tube body 1 is integrally cast V-shaped push seat group, the beam tube body 1 is a tubular structure with two ends open, and at the two ends of the beam tube body 1 in the long axis direction, there are an air inlet 3 and an air inlet 3 communicating with the inner cavity of the beam tube body 1. The air outlet 4 is also provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com