Active carbon flue gas desulfurizing reverse synchronous work tower

A technology of synchronous work and activated carbon, which is applied to the separation of dispersed particles, chemical instruments and methods, and separation methods, and can solve the problems of high investment, large footprint of desulfurization equipment, and high operating costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

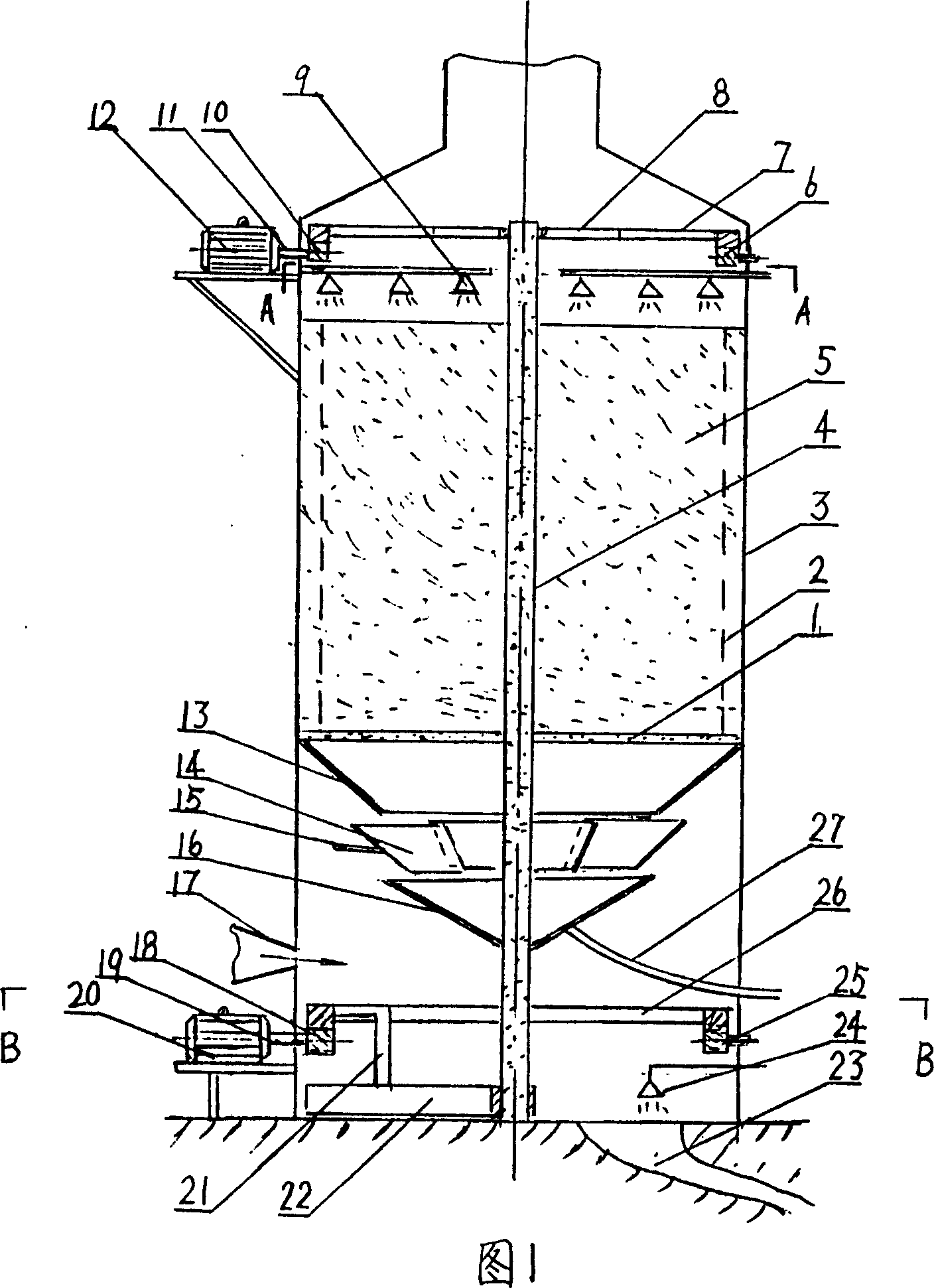

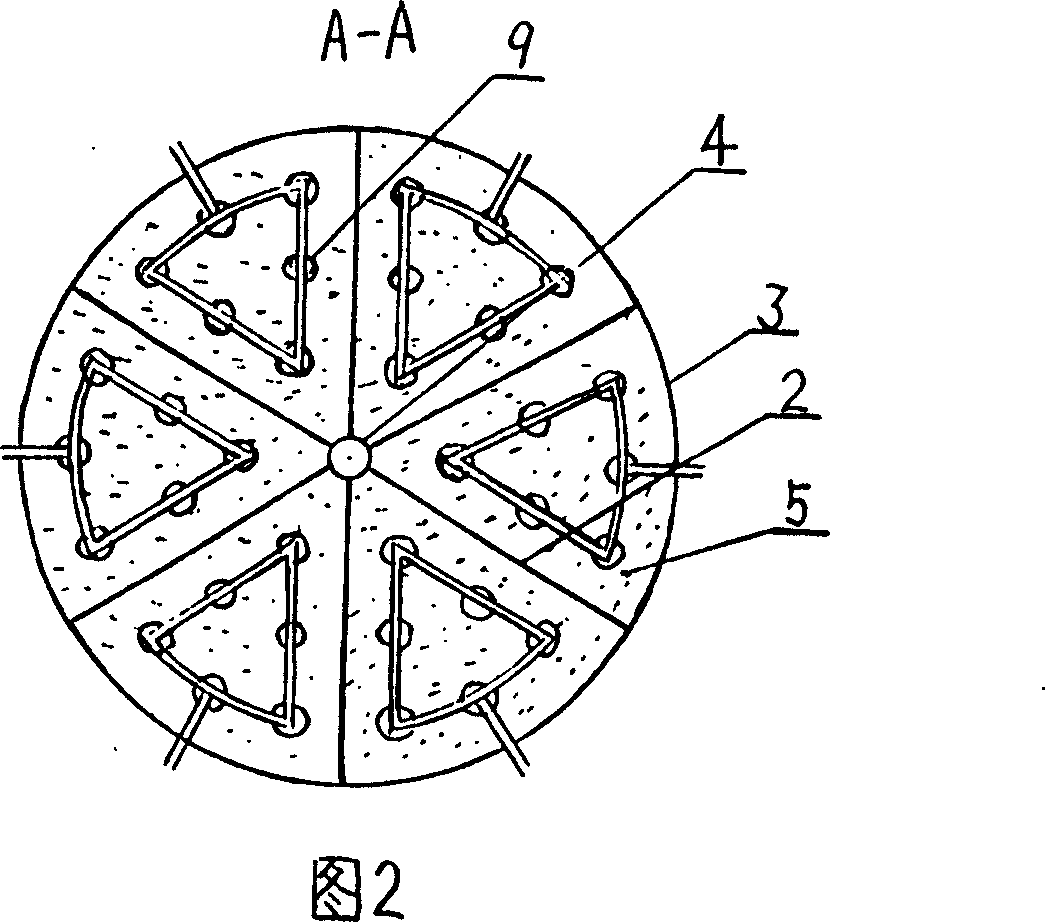

[0011] The specific structure of the present invention is illustrated below in conjunction with the embodiment given with accompanying drawing.

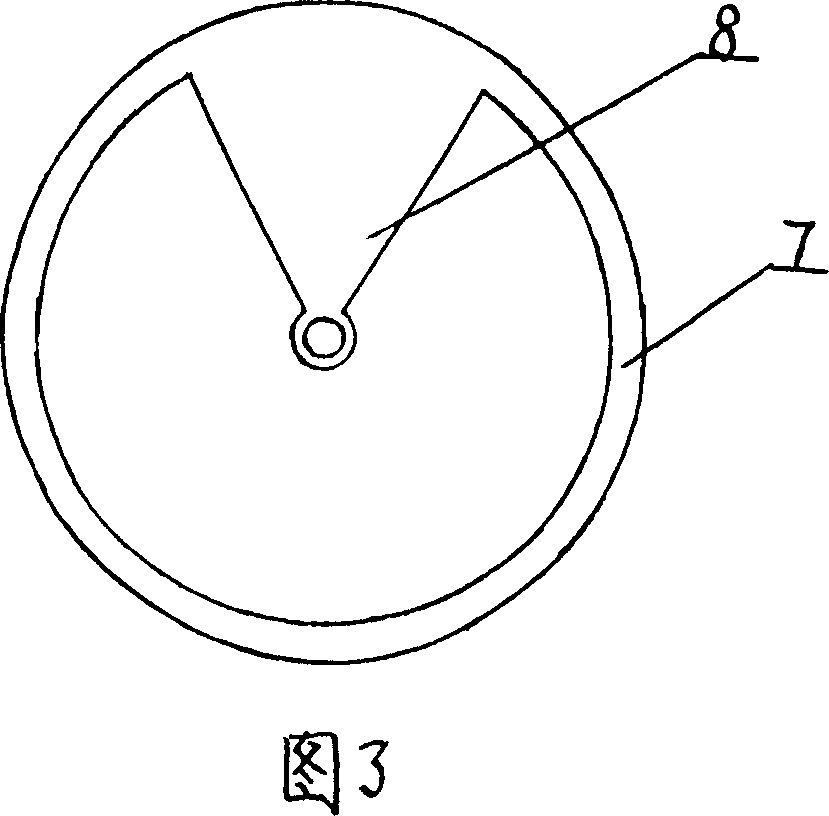

[0012] As shown in the accompanying drawings, the activated carbon flue gas desulfurization reverse synchronous working tower of the present invention has a tower shell (3), a central column (4) inside the tower shell, and a plurality of Longitudinal partition partitions (2), activated carbon layers (5) between the partition partitions, activated carbon support layer (1) under the partition partitions, sprinkler devices (9) above each activated carbon layer, and sprinkler devices above the sprinkler devices. The ring gear (7) has a fan-shaped choke cover (8) on the ring gear, and the teeth on the ring gear mesh with the teeth on the gear (10) on the shaft (11) of the motor (12). There is a tapered dilute acid drainage pan (13) under the supporting layer, and there are annular, overlappingly installed gas-liquid deflectors (14) under ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com