Cantilever connecting structure for roots pump or screw pump

A connection structure, screw pump technology, applied in the direction of pumps, pump components, rotary piston pumps, etc., can solve the problems of runout, the inability of the rotor to mesh, and meet the stiffness, etc., to reduce the requirements of machining, reduce the risk of deviation, increase The effect of locking force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

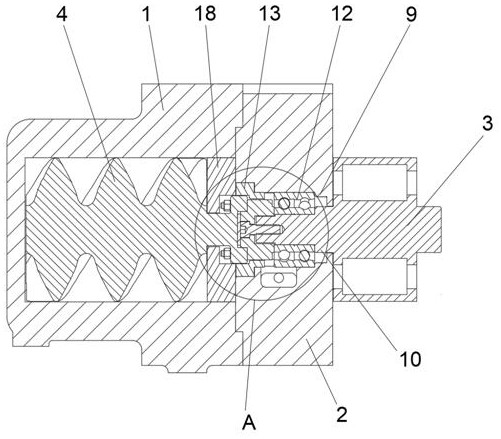

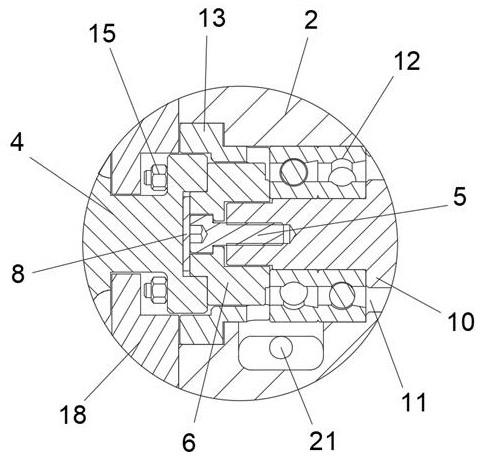

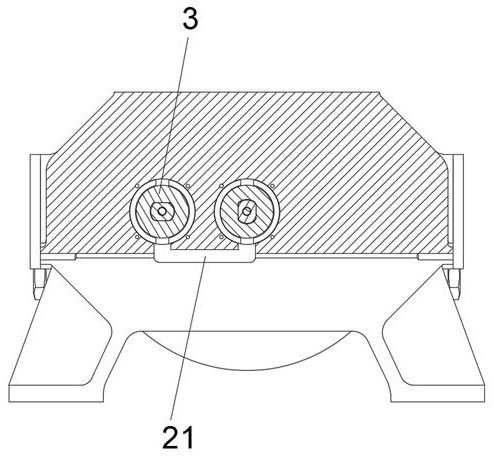

[0035] Embodiment one, such as Figure 1-10 As shown, a cantilever connection structure for a Roots pump or a screw pump includes an outer casing 1, a bearing cover 2, a drive shaft rotor 3 and a cantilever rotor 4, and one end of the drive shaft rotor 3 is connected to the drive shaft through a locking bolt 5. One side of the positioning sleeve 6 is fixedly connected, and the inner circle of the other side of the driving positioning sleeve 6 is provided with a circular boss 7, and the outer circle of the other side of the driving positioning sleeve 6 is respectively provided with bolt holes 14; the cantilever rotor 4 and The drive shaft rotor 3 is set coaxially. The cantilever rotor 4 includes a linear rotor 41, a transition cylinder 42 and a cantilever rotor positioning ring 43. One side of the linear rotor 41 is connected with the cantilever rotor positioning ring 43 through the transition cylinder 42. The cantilever The outer surface of the rotor positioning ring 43 is pro...

Embodiment 2

[0041] Embodiment 2, as a further preferred solution of Embodiment 1, a wave spring 8 is fixedly installed between the outer surface of the circular boss 7 and the inner surface of the groove 44 . Through the wave spring 8, the driving shaft rotor 3 and the driving positioning sleeve 6 can play a reverse driving force when locking, so that the locking bolt 5 of the driving positioning sleeve 6 and the thread in the bolt hole on the end face of the driving shaft rotor 3 Locking increases the locking strength and eliminates the gap, so that it will not loosen due to high-speed rotation and vibration, similar to traditional lock nuts and thrust washers. In this embodiment, the locking bolt 5 adopts an inner hexagonal bolt structure, and preferably uses a fine thread bolt, so that the effect is more obvious.

Embodiment 3

[0042] Embodiment three, such as Figure 6 As shown, as a further preferred solution of Embodiment 1, the side of the drive shaft rotor 3 close to the cantilever rotor 4 is provided with a flat key structure, and the side surface of the driving positioning sleeve 6 is provided with a flat key hole 61, and the driving positioning sleeve 6 passes through the flat key hole 61 cooperate with the flat key structure. Using the flat keyway formed by the flat key structure on one side of the drive shaft rotor 3, the drive shaft rotor 3 is inserted into the drive positioning sleeve 6, and during the rotation of the drive shaft rotor 3, the drive positioning sleeve 6 can be better driven to rotate together .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com