A treatment liquid, preparation method and process for improving magnesium alloy surface anticorrosion

A technology of anti-corrosion treatment and treatment liquid, which is applied in anti-corrosion coatings, coatings, etc., can solve problems such as corrosion between magnesium alloy processing procedures, and achieve strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Select a deformed AZ31 magnesium alloy with a size of 70 mm×35mm×1mm.

[0034] The specific steps are:

[0035] (1) Anticorrosive solution configuration: KH550: Deionized water: Ce(NO3) 3 10: 89.9: 0.1, change

[0036] The above-mentioned three-component substances are configured and stirred in proportions, and then stand still and prevent them from being hydrolyzed.

[0037] (2) Sample pretreatment: alkaline washing and degreasing → deionized water washing.

[0038] (3) Anti-corrosion treatment: Put the cleaned test piece into the anti-corrosion solution for 1 minute, take it out and bake it in an oven at 120°C for 30 minutes, and then leave it at room temperature.

[0039] The sample after the above treatment and the untreated sample are tested by electrode polarization, and the self-corrosion current density of the former is 1.28e -6 A / cm 2 , The latter is 6.772e -5 A / cm 2 , The polarization resistance of the anti-corrosion treatment and untreated parts are: 8.83e 4 Ω·cm 2 , 9....

Embodiment example 2

[0041] Select a deformed AZ31 magnesium alloy with a size of 70 mm×35mm×1mm

[0042] The specific steps are:

[0043] (1) Anti-corrosion solution configuration: KH460: deionized water volume ratio is 8:92. Put KH460 silane into deionized water in proportion to stir evenly and place to hydrolyze.

[0044] (2) Anti-corrosion treatment: polish the processed test piece with sandpaper to remove the oil, wipe it clean and put it in an anti-corrosion solution for 30 seconds, take it out, and bake it in an oven at 100°C for 30 minutes, and leave it at room temperature after taking it out.

[0045] (3) The samples after the above treatment and the untreated samples have undergone accelerated damp heat experiment, at a temperature of 60℃, humidity> After 17 days of continuous experiments in 80% of the constant temperature water bath, it was found that the surface of the treated sample did not have any corrosion spots, while the untreated sample had many corrosion spots on the surface after the s...

Embodiment example 3

[0047] Select a deformed AZ31 magnesium alloy with a size of 70 mm×35mm×1mm

[0048] The specific steps are:

[0049] (1) Anticorrosive liquid configuration: KH69:H 2 O:CH 3 CH 2 OH=2:2:96, put KH69 silane into deionized water and ethanol solution according to the proportion, stir evenly, and place to hydrolyze.

[0050] (2) Anti-corrosion treatment: polish the processed test piece with sandpaper to remove oil, wipe it clean, soak it in anti-corrosion solution for 1 minute, take it out and dry it.

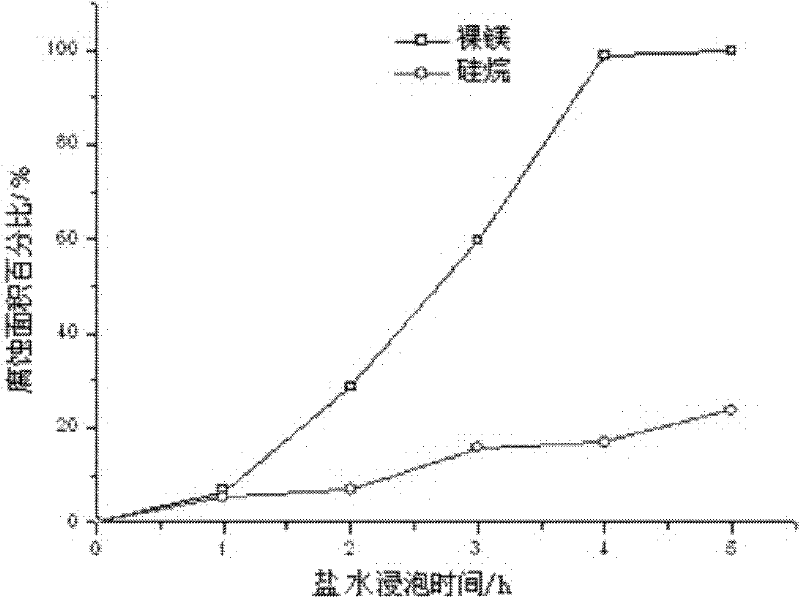

[0051] Put the bare magnesium alloy and the anticorrosive magnesium alloy sample into a 5% NaCl solution to accelerate the immersion for 5 hours. It can be found that the bare magnesium sample has a large area of corrosion, while the treated sample has only a small amount of corrosion (see image 3 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com