FPSO large flare tower building technology

A flare tower, large-scale technology, applied in the overall construction process field of FPSO large flare tower, can solve problems such as unsafe high-altitude operations, improper handling of steel structures, easy deformation or fracture, etc., to achieve high construction efficiency, short construction period, avoid The effect of structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

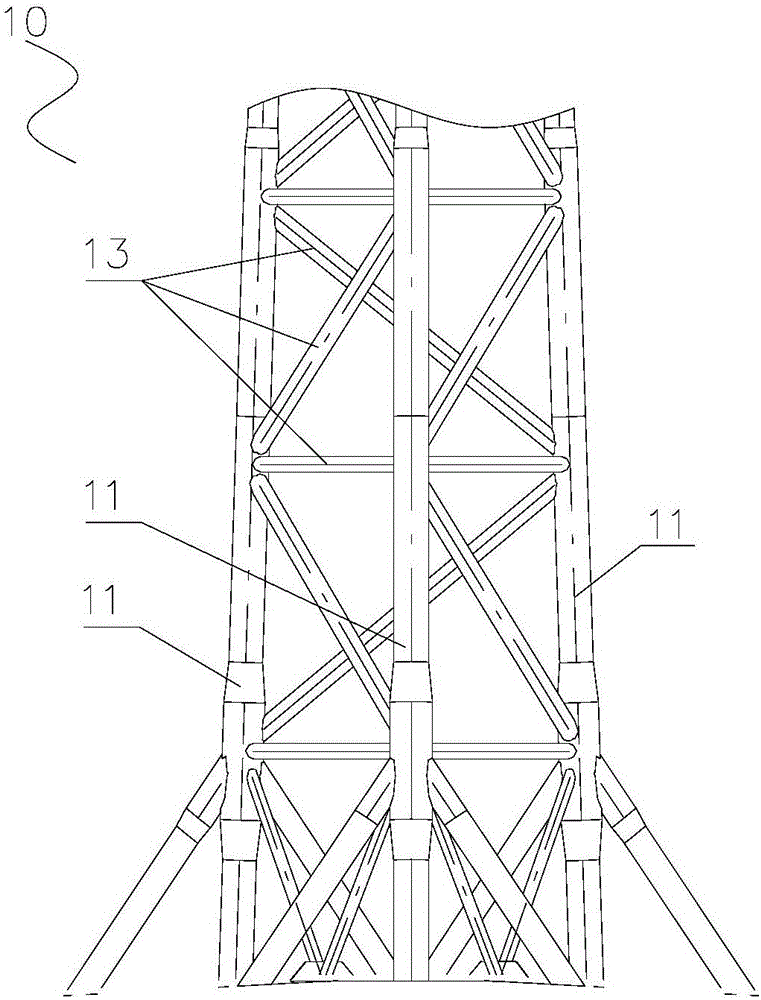

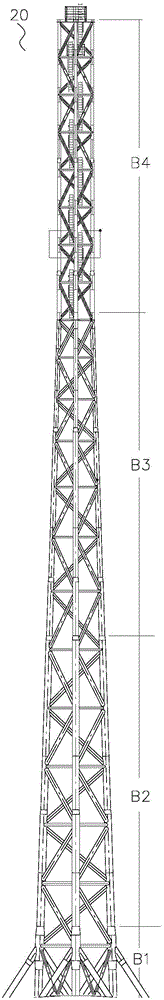

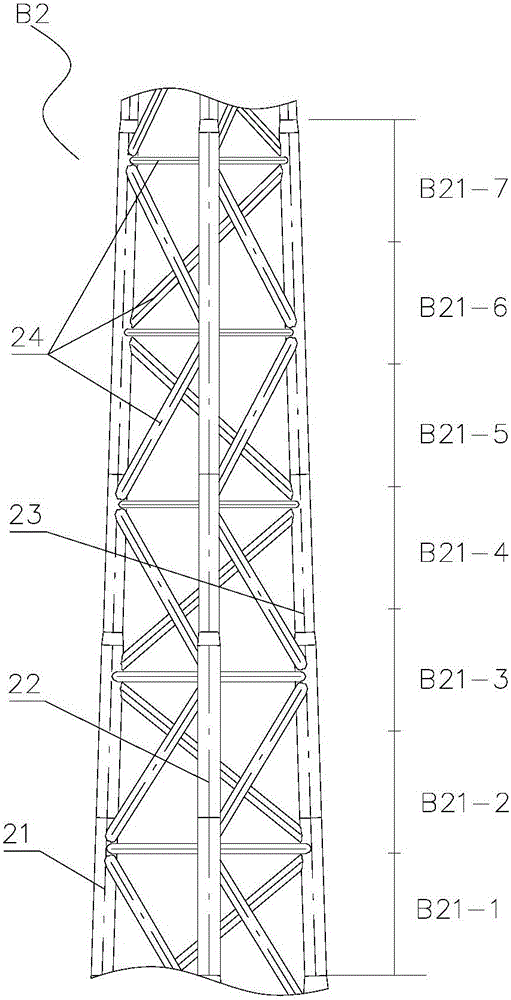

[0042] Please also see Figure 2 to Figure 7 , figure 2 It is a segmental schematic diagram of the flare tower in the FPSO large flare tower construction process of the present invention, image 3 yes figure 2 Schematic diagram of the structure of the B2 main segment in Figure 4 yes image 3 Schematic diagram of the construction process of the middle splicing section B21-1, Figure 5 It is a three-dimensional schematic diagram of the splicing process of each splicing section, Figure 6 It is a schematic diagram of the top view of the splicing process of each splicing section, Figure 7 yes figure 2 Schematic diagram of the main subsection assembly.

[0043] See figure 2 , the FPSO large-scale flare tower construction process in this case will build the flare tower 20 with a height of 117 meters and a total weight of about 380 tons. The construction plan divides the flare tower 20 into four main sections B1, B2, B3, and B4 from bottom to top, of which B1 is 8525mm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com