Sediment removal system and method for preventing sediment accumulation at canal bed of canal and

A sedimentation and drainage technology, which is applied in water conservancy projects, river regulation, sea area engineering, etc., can solve problems such as increased project costs, hidden safety hazards, hydraulic machinery wear, etc., and achieves improved sand discharge efficiency, safety and sand discharge, The effect of low-cost sand removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] For ease of understanding, the present invention will be further described below in conjunction with the accompanying drawings.

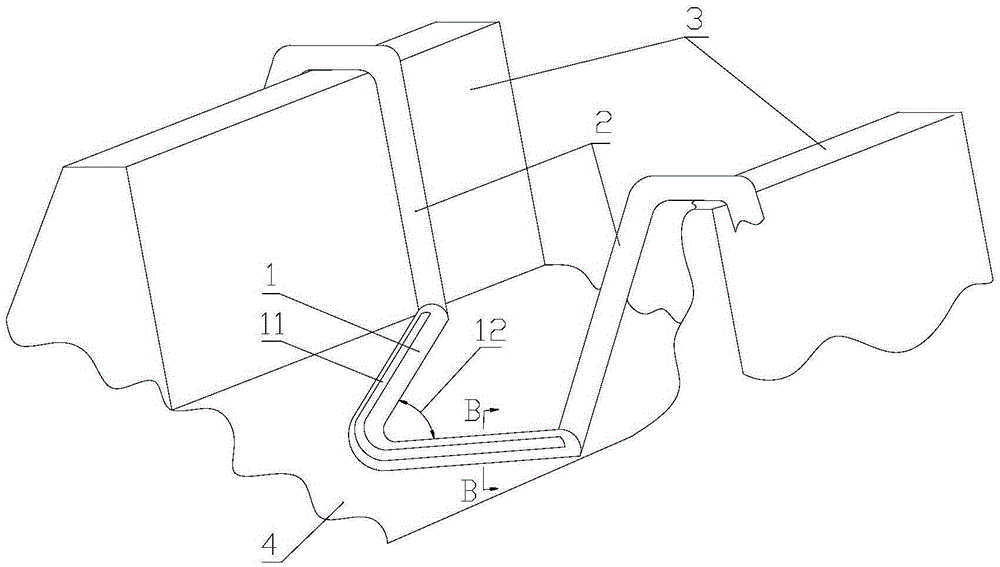

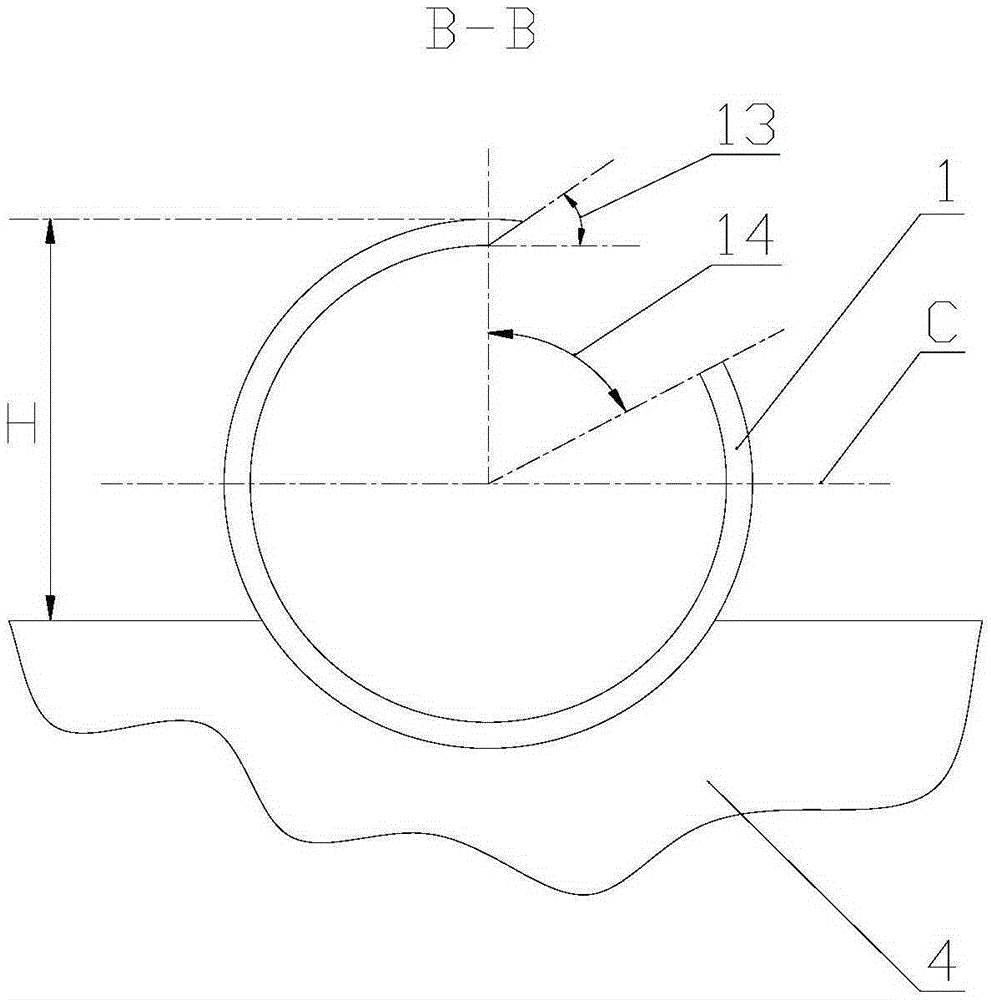

[0026] see figure 1 and figure 2 , figure 1 is a schematic diagram of a sand discharge system provided by the present invention, figure 2 yes figure 1 Middle B-B sectional view.

[0027] The sand discharge system provided by the present invention includes a vortex tube 1 and a siphon tube 2, wherein the vortex tube 1 is located at the bottom 4 of the water channel, and is used to form a spiral flow. The vortex tube 1 is V-shaped, and the V-shaped sharp corner points to the opposite direction of the water flow. The upstream side of the tube 1 is provided with an opening 11 extending along the axis of the tube, and the end of the vortex tube 1 is close to the bottom of the dike 3; Outside the canal.

[0028] The V-shaped included angle 12 of the vortex tube 1 may be 60°-120°. The diameter of the vortex tube 1 is generally 80 mm to 100 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com